An anti-corrosion recyclable manhole cover

A manhole cover and cover body technology, applied to artificial islands, underwater structures, buildings, etc., can solve the problems of poor bearing capacity of composite material manhole covers, poor freeze-thaw resistance of cement manhole covers, high cost of cast iron manhole covers, etc., and achieve excellent corrosion resistance Anti-corrosion performance, easy to promote, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

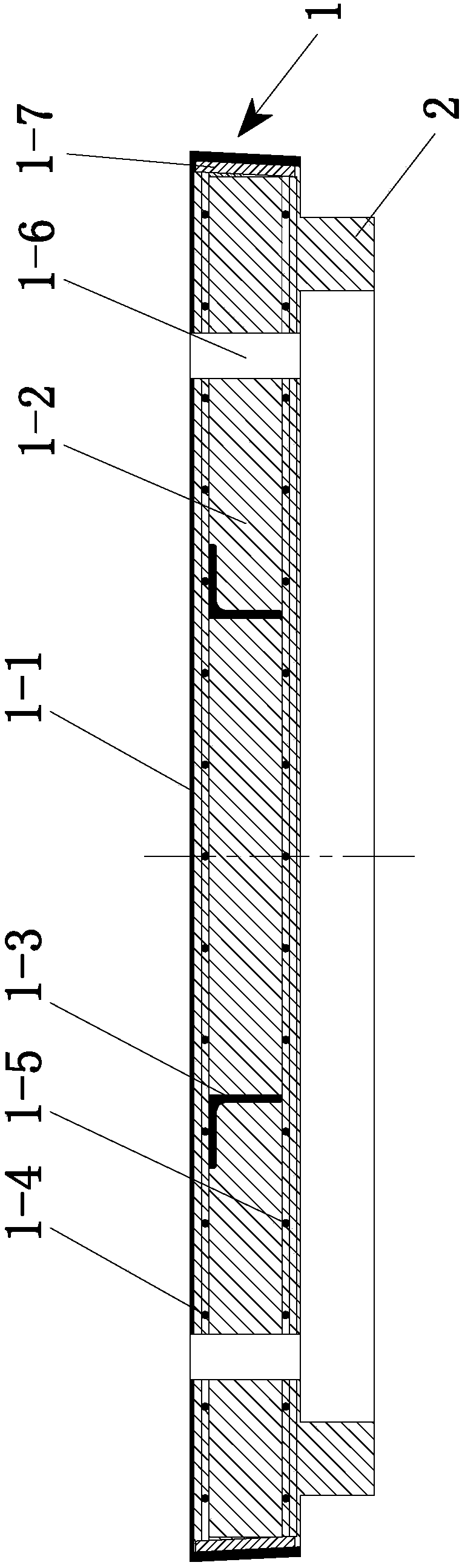

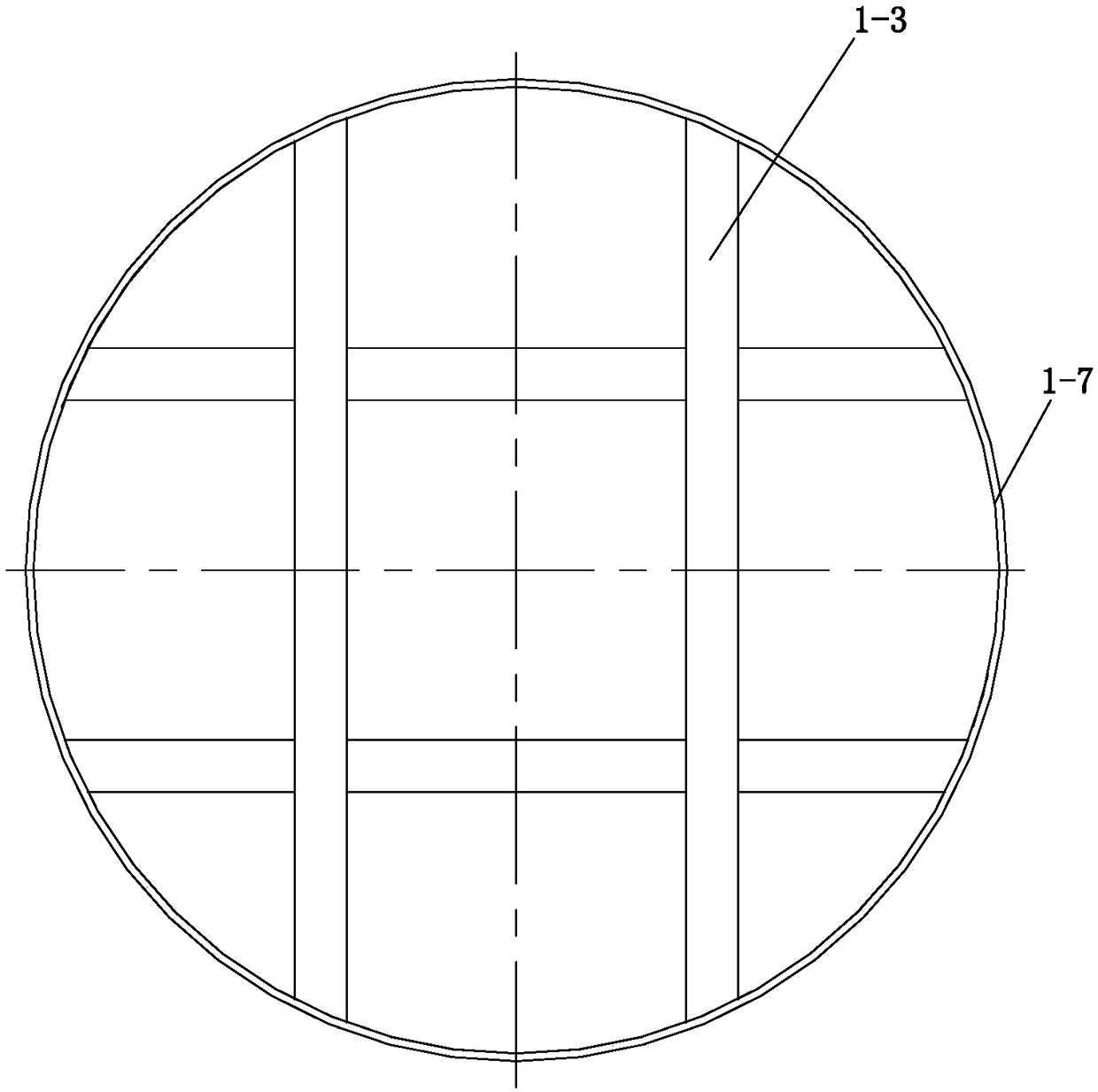

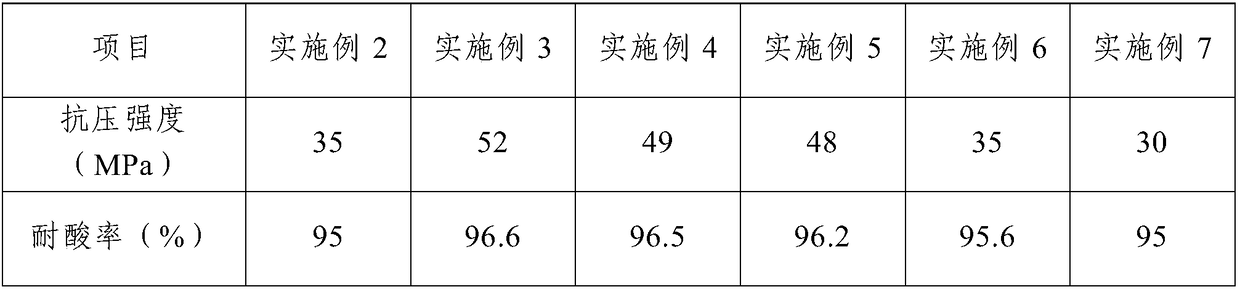

[0031] Such as figure 1 and figure 2 The shown anti-corrosion recyclable manhole cover includes a cover body 1 and a centering part 2, the shape of the cover body 1 is a round cake, the centering part 2 is located at the bottom of the cover body 1, and the centering part 2 is cylindrical in shape, the central axis of the cover body 1 and the centering part 2 coincide, the cover body 1 includes a surface layer 1-1 and an inner layer 1-2, and the inner layer 1-2 A steel skeleton is provided, and the steel skeleton includes a shaped steel 1-3 shaped like a well, an upper steel wire mesh 1-4 arranged on the upper part of the shaped steel 1-3, a lower steel mesh 1-5 arranged on the lower part of the shaped steel 1-3 and The steel hoop 1-7 arranged on the outer periphery of the section steel 1-3, the surface layer 1-1 is arranged on the upper surface of the inner layer 1-2 and the outer surface of the steel hoop 1-7, and the surface layer 1-1 It is made of fine mortar added with ...

Embodiment 2

[0039] to combine figure 1 and figure 2 , the manufacture method of anticorrosion recyclable manhole cover of the present invention is:

[0040] The first step is to design the metal mold according to the structure of the manhole cover to be made, and then apply the release agent in the metal mold and preheat it to 130°C. Preheat the steel skeleton formed by connecting the lower steel wire mesh 1-5 and the steel hoop 1-7 until the temperature of the steel skeleton is constant at 150°C;

[0041] The second step is to pour thermoplastic concrete with modified sulfur at a temperature of 130°C into the preheated metal mold, and use a vibration platform located at the lower part of the metal mold to vibrate the thermoplastic concrete in the metal mold during the pouring process Tamping, smoothing, and then put the preheated steel skeleton into the metal mold, and then continue to pour thermoplastic concrete with modified sulfur at 130°C into the metal mold, and use the The vibr...

Embodiment 3

[0051] to combine figure 1 and figure 2 , the manufacture method of the anticorrosion recyclable manhole cover of the present embodiment is:

[0052] The first step is to design the metal mold according to the structure of the manhole cover to be made, and then apply the release agent in the metal mold and preheat it to 135°C. Preheat the steel skeleton formed by connecting the lower steel wire mesh 1-5 and the steel hoop 1-7 until the temperature of the steel skeleton is constant at 150°C;

[0053] The second step is to pour thermoplastic concrete with modified sulfur at a temperature of 135°C into the preheated metal mold, and use a vibration platform located at the lower part of the metal mold to vibrate the thermoplastic concrete in the metal mold during the pouring process Tamping, smoothing, and then put the preheated steel skeleton into the metal mold, and then continue to pour thermoplastic concrete with modified sulfur at a temperature of 135°C into the metal mold,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com