Submersible pump bearing

A technology for submersible pumps and bearings, applied to bearings, bearing components, shafts and bearings, etc., can solve problems affecting service life, bearings are easy to rust, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

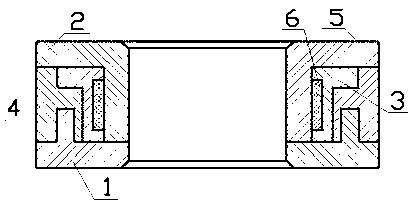

[0010] Such as figure 1 As shown, a submersible pump bearing of the present invention includes a bearing body and a bearing cover 1 installed on the shaft, the bearing body includes an inner shaft sleeve 2, an intermediate layer 3 and an outer shaft sleeve 4, and the inner shaft sleeve 2 One end is in contact with the shaft, the other end is perpendicular to the axis of the shaft, and the other end of the inner shaft sleeve 2 is an annular retaining ring 5, and the middle layer 3 is sleeved on the inner shaft sleeve 2, between the middle layer 3 and the inner shaft sleeve. Rolling elements 6 are installed on the contact surface of the shaft sleeve 2 , and the middle layer 3 and the inner shaft sleeve 2 are sealed and moved with each other, and the outer shaft sleeve 4 is sleeved on the middle layer 3 .

[0011] Wherein, when the bearing cover 1 is matched with the bearing body, the flange on the bearing cover 1 is embedded in the groove on the outer sleeve 4; the rolling eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com