Dedusting system special for scrap steel crushing

A dust removal system and steel scrap technology, applied in the field of machinery, can solve the problems of dust removal system explosion, reduce maintenance times, and reduce intangible costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

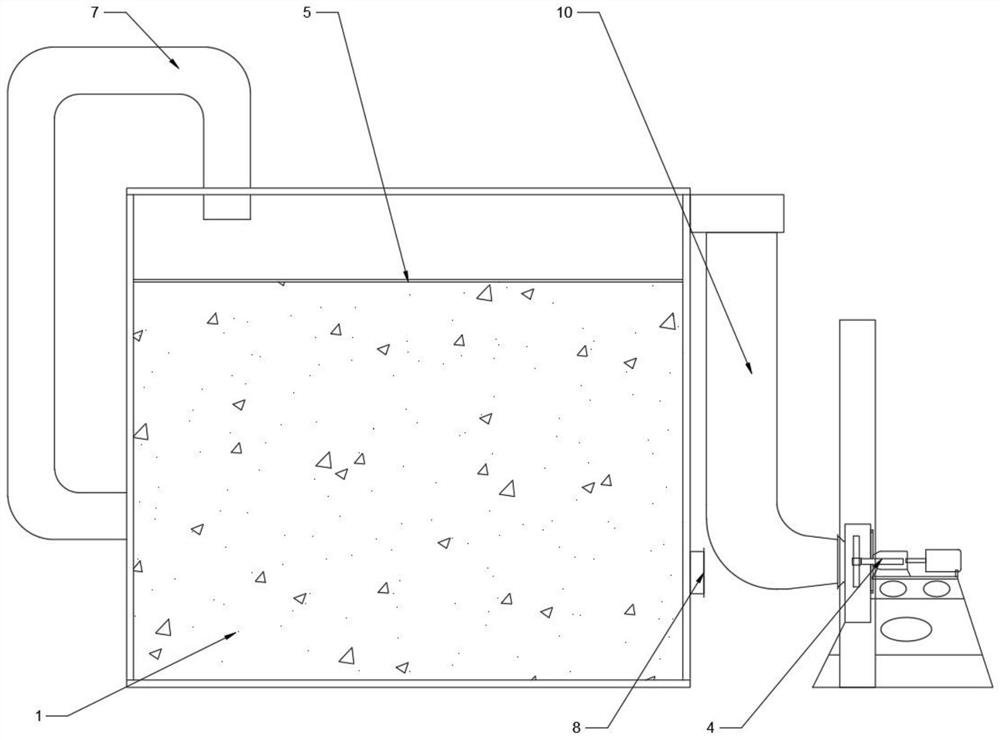

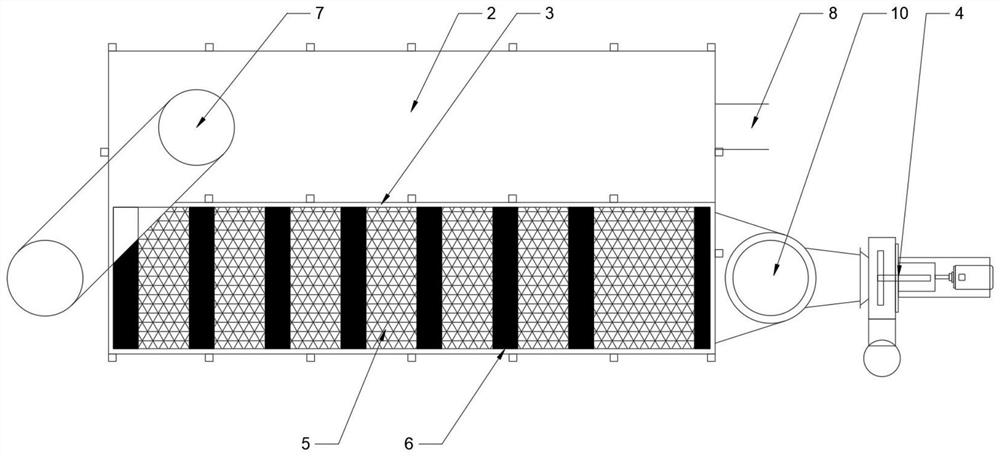

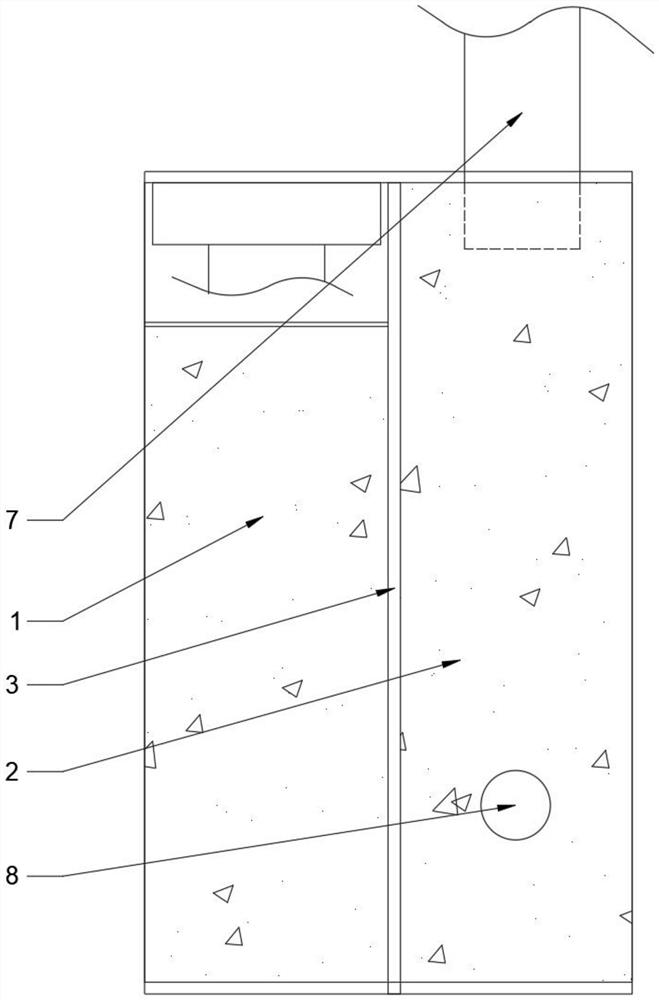

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] When the present invention is implemented in practice, a special dust removal system for scrap steel crushing includes a dust removal cabin 1 and a separation cabin 2, a partition wall 3 is provided between the dust removal cabin 1 and the separation cabin 2, and a dust removal fan is connected to one side of the dust removal cabin 1 4. There are dust filter cloths 5 inside the dust removal cabin 1, and the dust filter cloths 5 are arranged at equidistant intervals. There is a corridor 6 at the interval between the dust filter cloths 5. The dust removal cabin 1 and the separation cabin 2 are connected by a pipe 7. One side of the separation cabin 2 An air inlet 8 is provided, and an ash shoveling door 9 is provided at the bottom of the dust removal cabin 1 and the separation cabin 2 .

[0020] As an improvement, the dust filter cloth 5 is arranged near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com