Hollow shaft rotary sealing concrete mixing truck

A mixing transport vehicle and rotary sealing technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as weak sealing effect of end faces, complicated maintenance work, and large wear and tear of parts, so as to ensure Sealing effect, reduced maintenance difficulty, fast discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

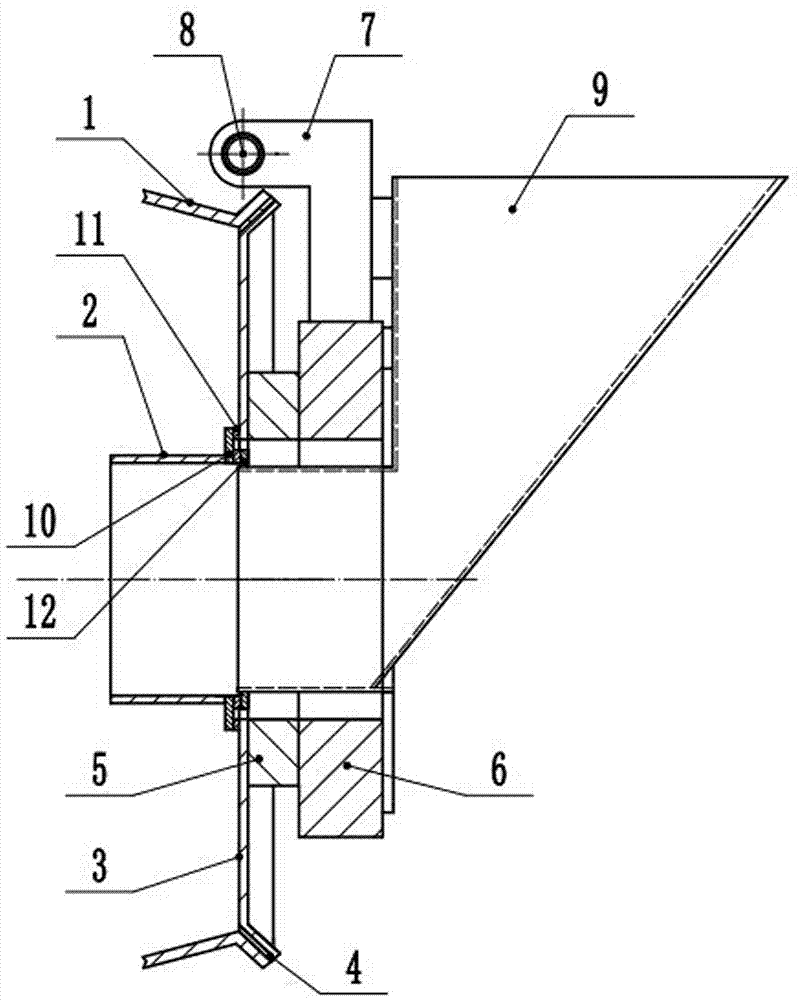

[0021] A concrete mixer truck with a hollow shaft rotary seal, such as figure 1 , including a mixing drum 1 installed on the car body and capable of rotating relative to the car body, a feeding drum 2 is arranged at the center of the outlet of the mixing drum 1;

[0022] The mixer truck also includes a moving part that is installed on the car body and can move relative to the car body. The moving part is a rotating bracket 7 that is mounted on the car body in a rotational connection through a hinged shaft 8, and is also provided with a drive cylinder. One end of the drive cylinder is hinged with the rotary bracket, and the other end is hinged with the car body, and the rotary bracket 7 can be rotated and opened under the action of the drive cylinder.

[0023] A sealing cover 3 is mounted on the moving part through a slewing support, and the slewing support includes a static ring 6 fixedly connected to the moving part by bolts and a moving ring 5 fixedly connected to the sealin...

specific Embodiment 2

[0029] The difference between this embodiment and the first embodiment is that the moving part is a sliding bracket installed on the vehicle body through a sliding fit, and can move back and forth relative to the vehicle body through a linear drive device to realize the opening and closing of the mixing drum 1 .

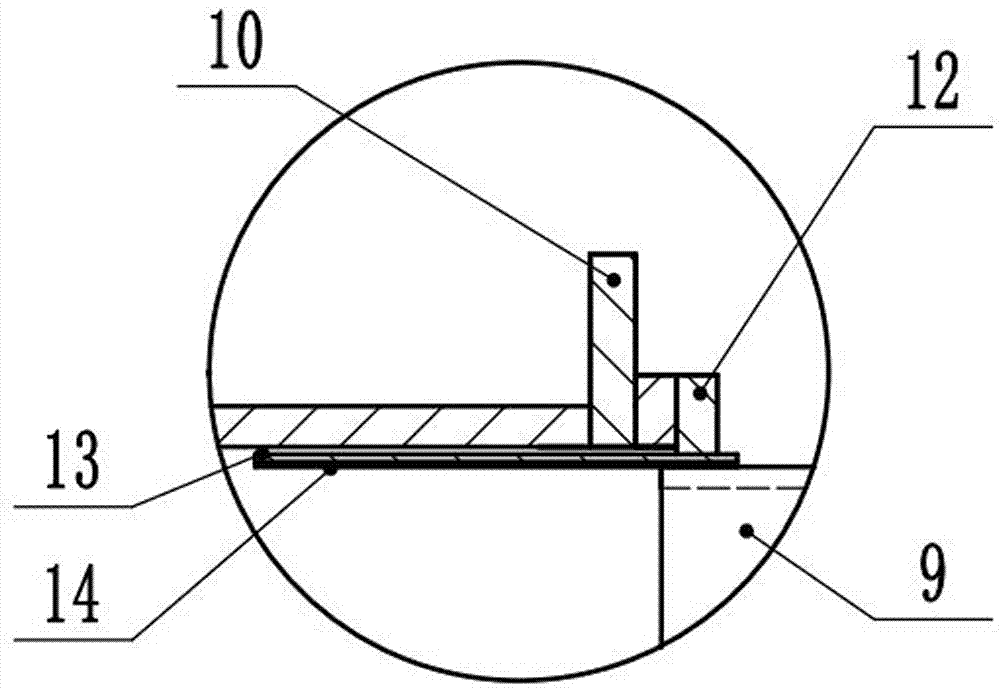

[0030] In order to ensure that the feeding hopper 9 can always be connected with the feeding cylinder 2 when moving back and forth, and avoid material leakage when the sliding bracket moves back and forth, the junction of the feeding hopper 9 and the feeding cylinder 2 is provided with a feeding cylinder. 2. The extension sleeve inside, the extension sleeve includes a soft tube 14 made of soft wear-resistant material on the inner layer, and an elastic support body 13 on the outer layer, and the elastic support body 13 is in contact with the rubber retaining ring 12 to realize dynamic seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com