Seal type plate filter with cleanable filter core cross section

A plate filter and sealed technology, which is applied in the direction of fixed filter element filter, filtration separation, separation method, etc., can solve the problems affecting the quality of sodium nitrate products, high settling resistance, high solution viscosity, etc., and achieve good transparency and fineness , no material consumption, high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

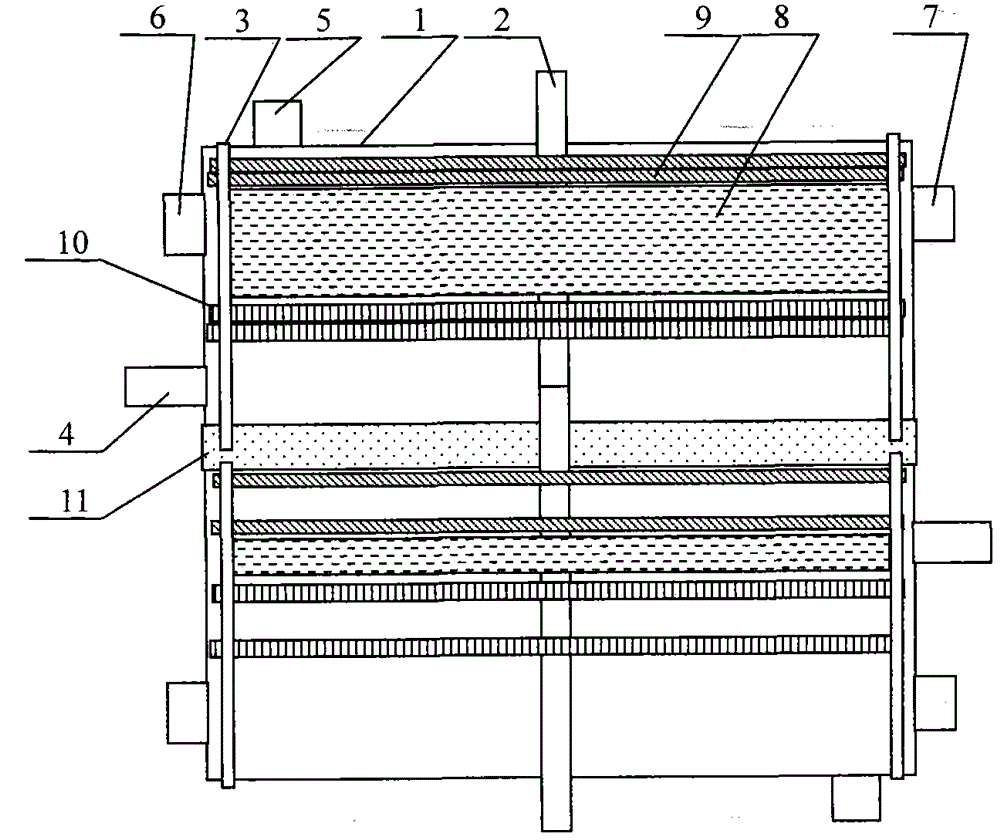

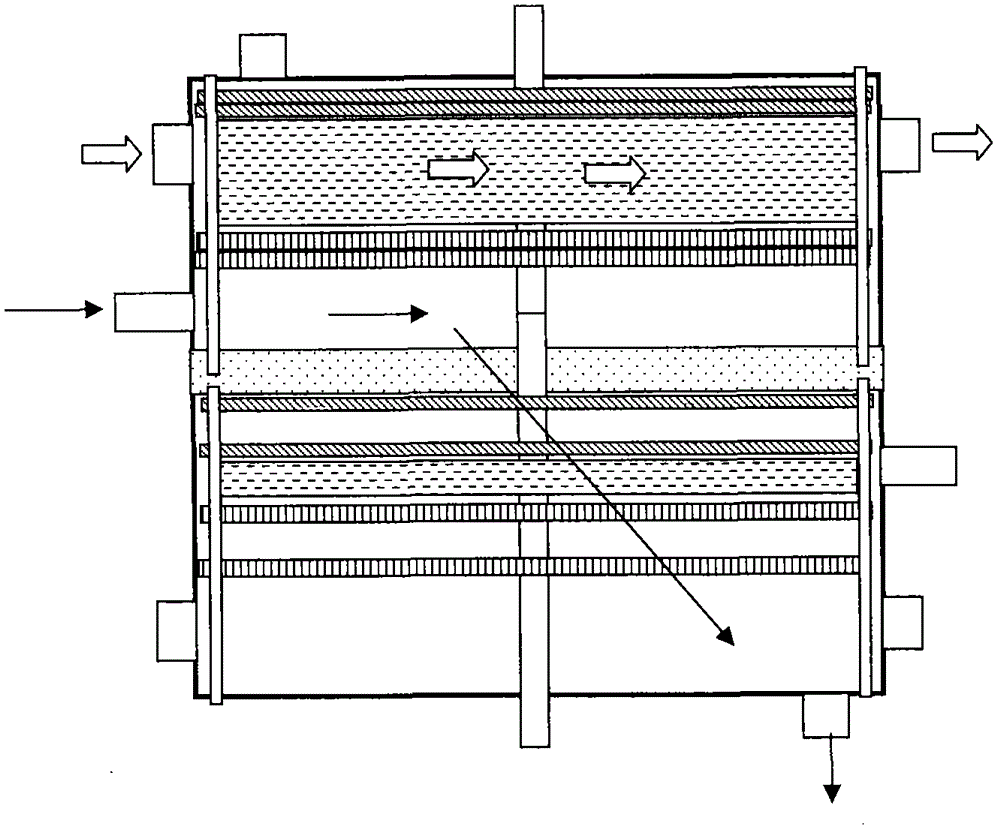

[0020] Embodiment 1: as attached figure 1 As shown, the guide column 3 and the clutch lever 2 are installed longitudinally in the box 1, and the outer closed orifice pair 9, the filter element 8 and the inner closed orifice are installed in parallel in the box 1 along the longitudinal direction of the guide column 3 and the clutch lever 2 from outside to inside. Auxiliary 10, wherein, after the filter element 8 is longitudinally compressed, the transverse channel is closed and has the smallest longitudinal penetration hole, and the filter element 8 is longitudinally pulled apart to have the largest transverse channel, and the outer closed orifice pair 9 and the inner closed orifice pair 10 have at least two layers respectively parallel orifice plates, each layer of orifice plate is evenly distributed with longitudinal through-holes, and the orthographic projections of the holes of adjacent two-layer orifice plates do not overlap each other in the longitudinal direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com