High-efficiency heat radiating LED (light emitting diode) lamp and manufacture method thereof

A technology of LED lamps and LED lamps, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc. and other problems, to achieve the effect of simple structure, solving heat dissipation problems and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

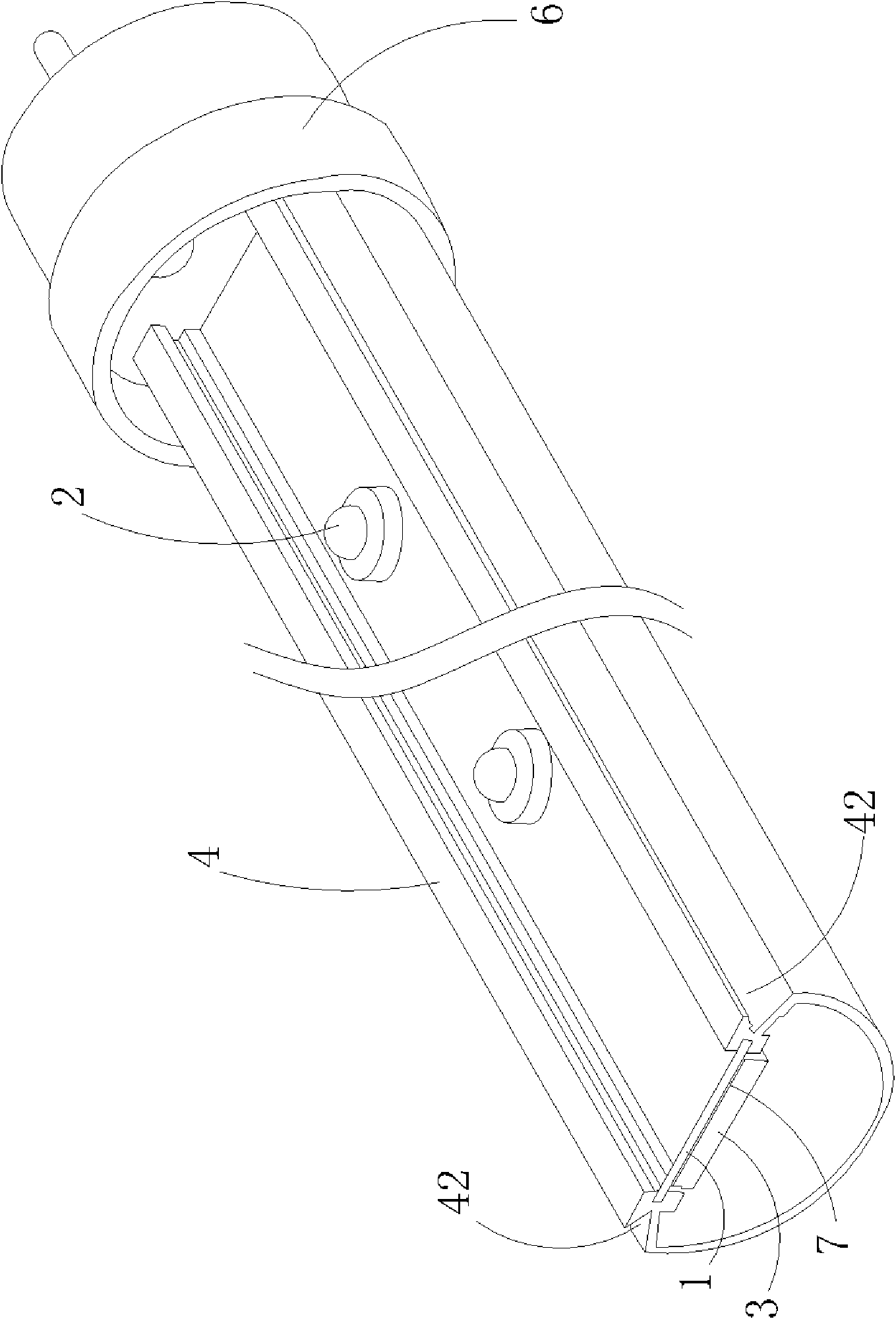

[0022] Example: see figure 1 and figure 2 , a method for preparing a high-efficiency heat dissipation LED lamp of the present invention, which comprises the following steps:

[0023] (1) Prepare a strip-shaped PCB soldering board 1, arrange a printed circuit connected to the LED lamp 2 on the PCB soldering board 1, and weld several LED lamps 2 evenly on the PCB soldering board 1, directly below the LED lamp 2 The PCB welding board 1 is provided with a through hole 11;

[0024] (2) Adopt graphite to prepare a strip-shaped graphite radiator 3, and evenly arrange some heat-conducting rivets 31 on the graphite radiator 3, the heads of the heat-conducting rivets 31 protrude from the graphite radiator 3, and two adjacent heat-conducting rivets 31 The spacing between them is equal to the spacing between two adjacent LED2 lamps on the PCB welding board 1;

[0025] (3) Apply heat-conducting paste on the top surface of the graphite radiator 3 and the top of the heat-conducting rivet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com