Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Uniform and firm attachment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanopore array film on stainless steel surface and preparation method thereof

InactiveCN102268713ALess investmentLow priceMaterial nanotechnologyAnodisationElectrochemical anodizationElectrochemistry

The invention particularly relates to a stainless steel surface nano-pore array film and a preparation method thereof. The technical scheme is that: stainless steel treated by surface pretreatment is used as an anode and is placed in a phosphate buffer solution to perform electrochemical anodic oxidation treatment; the time for the electrochemical anodic oxidation treatment is 0.1-4 h; a nano-pore array film is obtained on the treated stainless steel surface; the voltage for the electrochemical anodic oxidation is 10-80 V, and the temperature for the electrochemical anodic oxidation is -5 to 40 DEG C. The preparation method of the invention is simple, effective, environment-friendly, and low in cost; the stainless steel surface nano-pore array prepared by the method has a structured and ordered structure, a high density, a controllable pore diameter and pore depth, and no other impurity elements intervened, is firmly combined with the substrate, and has strong corrosion resistance andhigh hardness.

Owner:WUHAN UNIV OF SCI & TECH

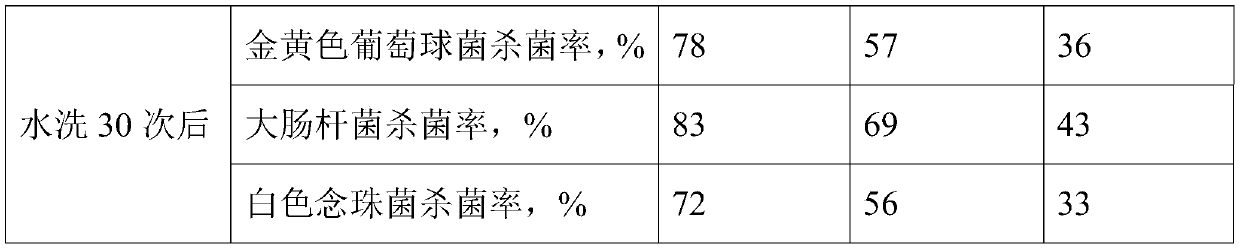

Preparation method of polyvinyl alcohol composite nano-filtration membrane

InactiveCN108159894AImprove wettabilityUniform and firm attachmentSemi-permeable membranesMembranesCross-linkFiltration membrane

The invention discloses a preparation method of a polyvinyl alcohol nano-filtration membrane. The preparation method comprises the following steps of: mixing ethanol and pure water according to a volume ratio of 1:1, adding a certain amount of 1,3,5-benzene tricarbonic acid and sodium dodecyl sulfate, and carrying out stirring for dissolution at a normal temperature to prepare a cross-linking agent solution; dissolving polyvinyl alcohol in pure water, carrying out heating and stirring at 95 DEG C for 1.5 hours to prepare an aqueous solution, and dropwise adding concentrated H2SO4 for later use; coating a predetermined amount of the cross-linking agent solution on a polysulfone base membrane by slit coating; and coating a predetermined amount of the polyvinyl alcohol aqueous solution on thesurface of the membrane by slit coating, and carrying out drying in an oven at a certain temperature to obtain a membrane, thereby forming an ultra-thin skin layer with a uniform thickness of 40-80 nanometers. According to the preparation method provided by the invention, the cross-linking agent with hydrophilic groups is selected to form a gradient cross-linked structure with gradually decreasing cross-linking degrees from bottom to top, so that the water flux can be greatly improved. Moreover, the wettability of the base membrane can be obviously improved, which is helpful for PVA to be uniformly and firmly attached to the base membrane.

Owner:ZHEJIANG UNIV OF TECH

Antibacterial stainless steel and preparing method thereof

The invention particularly relates to antibacterial stainless steel and a preparing method thereof. According to the technical scheme of the antibacterial stainless steel and the preparing method thereof, stainless steel obtained after surface pretreatment is put into a dopamine buffer solution to be deposited for 0.1 h to 72 h under the condition with the temperature ranging from -5 DEG C to 40 DEG C; then the obtained stainless steel is put into a solution containing titanium ions to be deposited for 0.1 h to 6 h; and finally the obtained stainless steel is put into a solution containing silver ions to be deposited for 0.1 h to 6 h, and therefore the antibacterial stainless steel is obtained. The concentration of the dopamine buffer solution ranges from 0.01 mol / L to 1 mol / L, the concentration of the solution containing the titanium ions ranges from 0.001 mol / L to 1 mol / L, and the concentration of the solution containing the silver ions ranges from 0.001 mol / L to 1 mol / L. By means of the antibacterial stainless steel and the preparing method thereof, the technology is simple, environment friendliness is achieved, and the cost is low; the surface antibacterial nanometer film layer structure of the antibacterial stainless steel prepared through the method is well-defined and orderly, is firmly combined with a base material, is high in corrosion resistance and hardness and has good antibacterial performance both under the illumination condition and the non-illumination condition.

Owner:WUHAN UNIV OF SCI & TECH

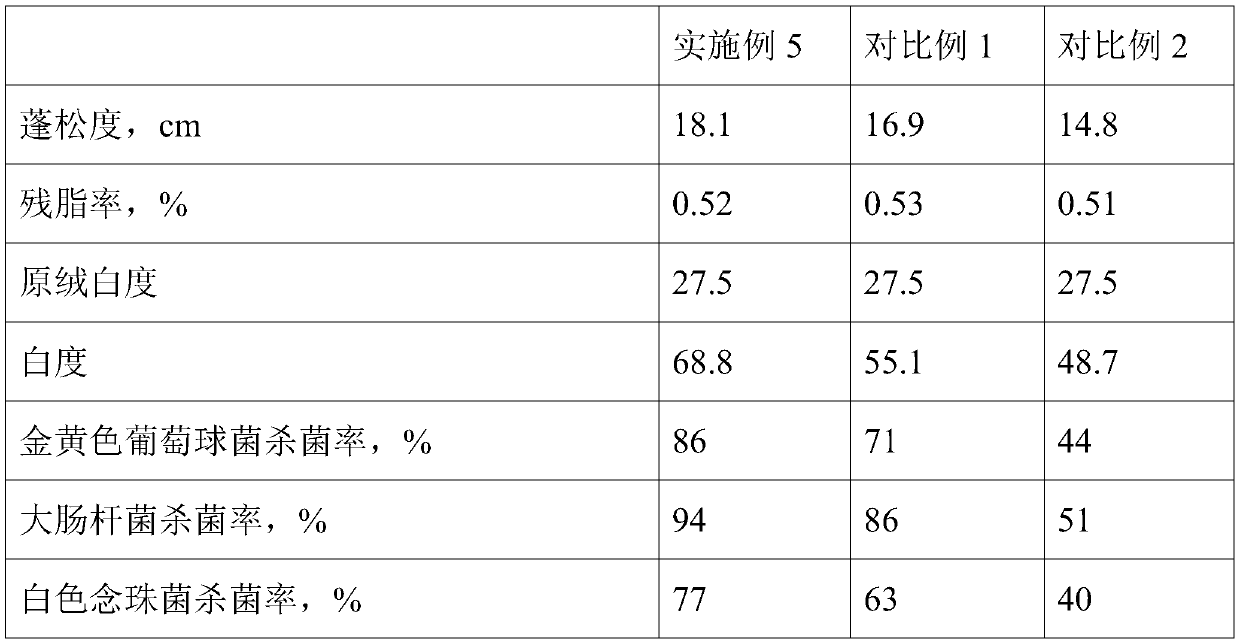

Preparation method for washable and antibacterial down feathers

InactiveCN110904690AGood antibacterial functionReduce dust contentBiochemical fibre treatmentFreeze-dryingAntibacterial property

The invention discloses a preparation method for washable and antibacterial down feathers. The method comprises the following steps of washing, dewatering and drying raw feathers, and removing residual dust and sand to obtain pretreated down feathers; adding a detergent into the pretreated down feathers for fine washing, then rinsing the pretreated down feathers with clear water, performing dewatering, adding a humic acid compound and chitosan to be uniformly mixed, and performing dipping, filtering, washing, drying and cooling to obtain the washable and antibacterial down feathers. The humicacid compound is prepared by adopting the following process of mixing humic acid and a sodium hydroxide solution, performing heating and stirring, adding disproportionated rosin and carbon nanotubes,performing shaking, adding soybean protein, adjusting the pH value of a system to be 8.8-9.4, adding monoepoxy-terminated polysiloxane to be continuously stirred, then carrying out microwave processing, performing distilling to remove the water, and performing freeze drying to obtain the humic acid compound. The obtained washable and antibacterial down feathers are good in fiber fluffiness and excellent in antibacterial function; and after the washable and antibacterial down feathers are washed with the water for multiple times, the antibacterial performance is not reduced, the original elasticity and compression performance can be restored, and the fluffiness of the down feathers is guaranteed.

Owner:六安市皖西羽绒有限公司

Novel polyvinyl alcohol nanofiltration membrane preparation method

ActiveCN106914156AImprove wettabilityUniform and firm attachmentSemi-permeable membranesCross-linkPolymer science

The invention discloses a novel polyvinyl alcohol nanofiltration membrane and a preparation method thereof. The method comprises the following steps: 1) mixing and dissolving ethylene glycol monomethyl ether and deionized water according to mass ratio of 1: 1 to prepare a solvent, respectively adding terephthalaldehyde and sodium dodecanesulphonate in the above solvent to prepare a mixing solution, heating the above mixing solution to the temperature of 60-65 DEG C, and stirring and dissolving the material to obtain a cross-linking agent solution; 2) dissolving the polyvinyl alcohol in deionized water to prepare an aqueous solution with mass fraction of 0.05-0.1%, heating the above aqueous solution to the temperature of 90-100 DEG C and stirring the material for 1.5 hours to prepare a polyvinyl alcohol aqueous solution; and 3) pouring the prepared cross-linking agent on a polysulfone base membrane, standing the material for 5 min and removing the superfluous solvent, placing the material in a baking oven at the temperature of 28 DEG C and drying the material; pouring the prepared polyvinyl alcohol aqueous solution on the surface of the membrane, and transferring the material into the baking oven and drying the material at the temperature of 60-90 DEG C for forming the membrane. The prepared polyvinyl alcohol nanofiltration membrane has high penetration selectivity and pollution-resistant performance, the method is easy to carry out, and a used modifier is easily available.

Owner:ZHEJIANG UNIV OF TECH

Low-cost waterless cleaning method for environmentally-friendly printing and dyeing textiles

InactiveCN107604710AImprove adsorption capacityEasy to embedDyeing processMicroballoon preparationTextile printerFiber

The invention provides a low-cost waterless cleaning method for environmentally-friendly printing and dyeing textiles, and relates to the technical field of textile printing and dyeing. The low-cost waterless cleaning method comprises the following steps: microcapsule dye preparation, textile pretreatment, electrostatic spraying and hot-pressing trimming. By adopting the printing and dyeing methodprovided by the invention, no waste water is generated, the purposes of saving water and energy and reducing environmentally pollution are achieved, the dye is firmly combined with the textiles, excellent color fastness is obtained, and the microcapsule dye is of protectiveness for the textiles by adopting original silk liquid pretreatment and electrostatic spraying, so that light fastness, washing fastness, rubbing fastness and ironing fastness of the dyed textiles are obviously promoted; the preparation process is simple and easily controlled in technology, and is applicable for continuousmass dyeing of the textiles of various raw materials.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

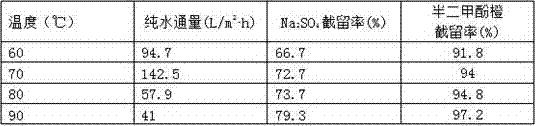

High-fill-power down preparation method

InactiveCN110699967AGuaranteed fluffinessLoft fiber loft performance guarantee of downFibre treatmentFreeze-dryingPotassium hydroxide

The invention discloses a high-fill-power down preparation method. The method includes steps: washing raw down, dewatering, drying, and removing residual dust to obtain premade down; mixing humic acidand potassium hydroxide solution, heating, stirring, adding epoxidized soybean oil and graphene, oscillating, adding sweet potato protein powder, adjusting a system pH value to 8.8-9.4, adding aminopropyl-terminated polycyanopropyl methyl siloxane, continuing stirring, performing microwave treatment, distilling for water removal, and performing freeze drying to obtain a premade material; adding adetergent into the premade down, performing fine washing, rinsing with clean water, dewatering, adding the premade material and chitosan, well mixing, impregnating, filtering, washing, drying and cooling to obtain high-fill-power down. The high-fill-power down prepared according to the method is high in fill power, low in damage, great in antibacterial function and low in dust content, the antibacterial performance of the high-fill-power down does not decline after repeated washing, and original elasticity and compression performance of the down can be recovered, so that fill power of the down is guaranteed.

Owner:六安市皖西羽绒有限公司

Colored stainless steel based on ion implantation and preparation method thereof

InactiveCN102021525BThe process steps are simpleProcess environment is cleanVacuum evaporation coatingSputtering coatingRoom temperatureHardness

The invention relates to a colored stainless steel based on ion implantation and a preparation method thereof. The technical scheme is as follows: placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel to obtain the colored stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 1*10<17>-1*10<19> ions / cm<2>; or placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 5*10<15>-5*10<19> ions / cm<2>; and taking out, carrying out heat treatment, and cooling to room temperature in the furnace to obtain the colored stainless steel. The invention has the advantages of simple process and clean environment, and the obtained colored stainless steel has the characteristics of multiple color varieties, high reproducibility, uniform color, beautiful appearance, high durability and no separation. Compared with the stainless steel prior to preparation, the surface hardness and the corrosion resistance are obviously improved.

Owner:WUHAN UNIV OF SCI & TECH

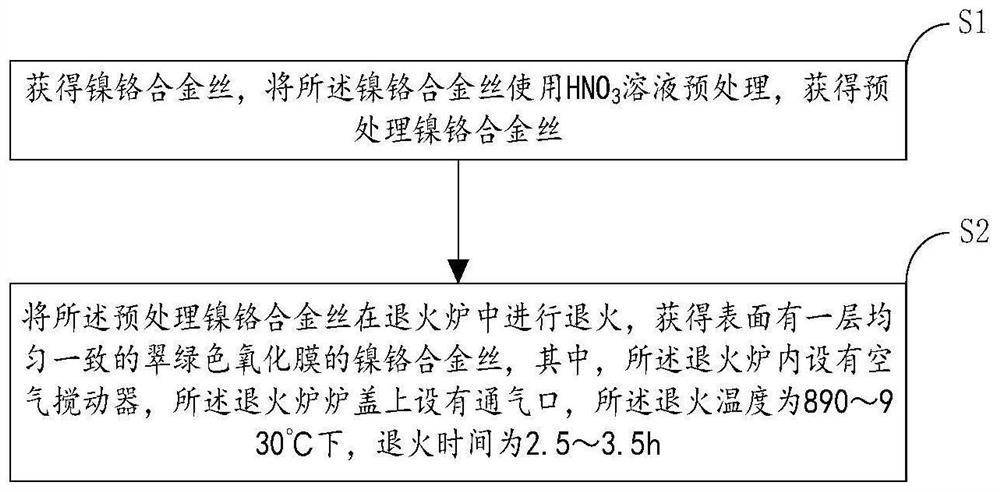

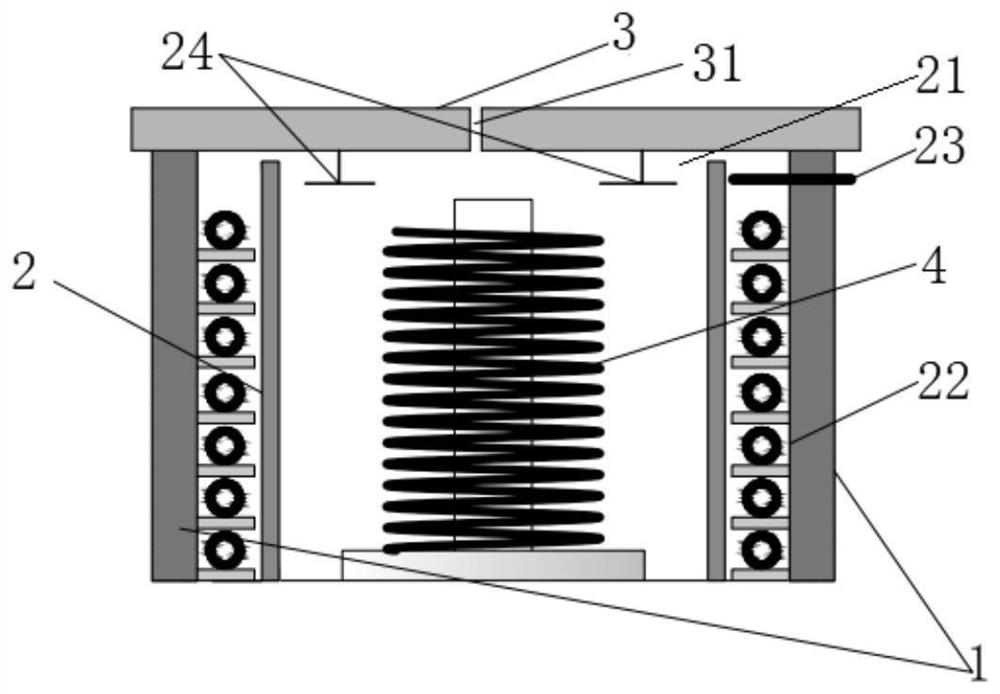

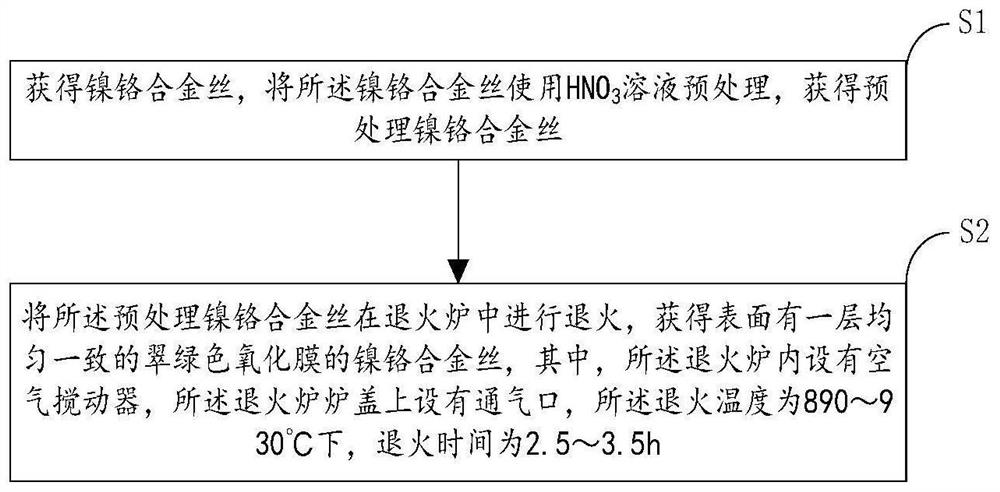

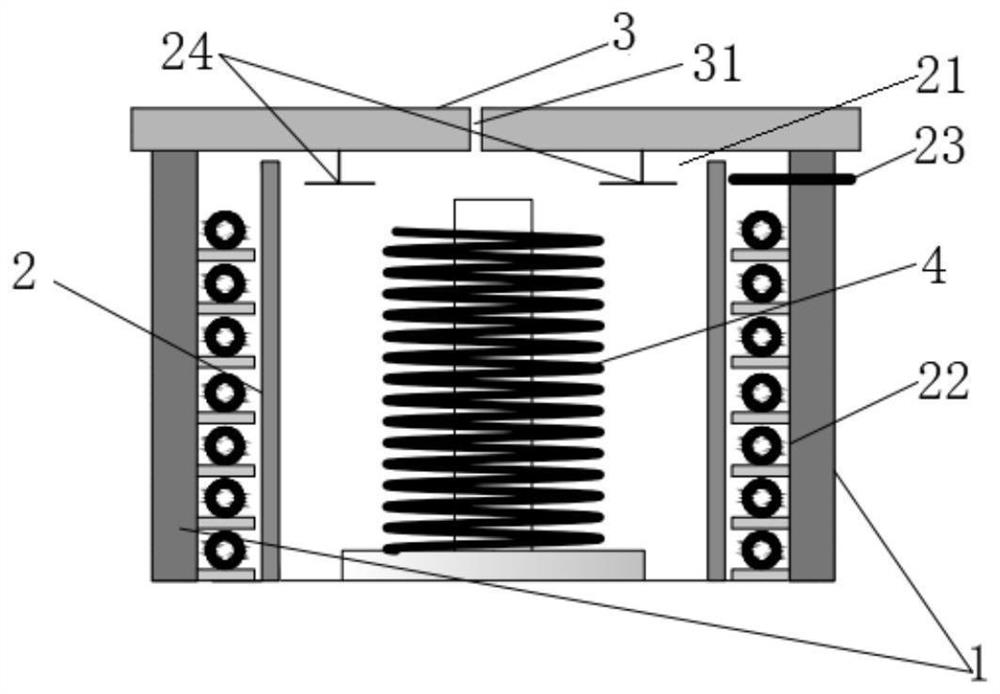

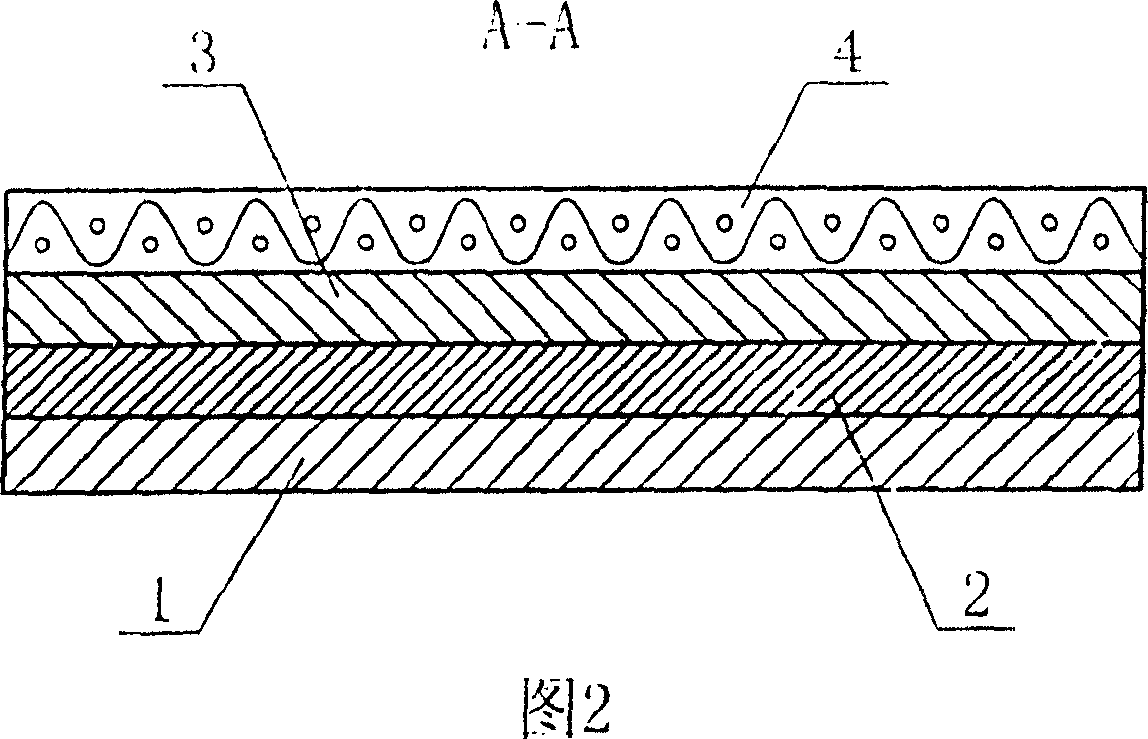

Surface treatment method and device for nickel-chromium alloy wire

ActiveCN112080749AHigh chemical potentialReduce the formation temperatureSolid state diffusion coatingNickel chromium alloyNichrome

The invention discloses a surface treatment method for a nickel-chromium alloy wire. The surface treatment method comprises the steps of obtaining the nickel-chromium alloy wire, and pretreating the nickel-chromium alloy wire with an HNO3 solution to obtain a pretreated nickel-chromium alloy wire; and annealing the pretreated nickel-chromium alloy wire in an annealing furnace to obtain the nickel-chromium alloy wire with a uniform, consistent emerald green oxide film on the surface, specifically, an air agitator is arranged in the annealing furnace, an air vent is formed in a furnace cover ofthe annealing furnace, the annealing temperature is 890-930 DEG C, and the annealing time is 2.5-3.5 hours. According to the surface treatment method, the nickel-chromium alloy wire with the uniform,consistent emerald green oxide film on the surface can be obtained, the oxidation color of the nickel-chromium alloy wire is uniform and stable, the color is emerald green, the requirements of customers are met to the greatest extent, and the surface treatment method is very helpful for improving the quality of the product.

Owner:BEIJING SHOUGANG GITANE NEW MATERIALS

Method for solidifying superconducting magnet coil

InactiveCN106179905AImprove liquidityUniform and firm attachmentPretreated surfacesCoatingsSuperconducting CoilsAC power

The invention provides a method for solidifying a superconducting magnet coil. The method includes the following steps that an impregnation mold is provided, and the magnet coil is placed into the impregnation mold; a solidification binder is provided, and the impregnation mold is filled with the solidification binder; an AC power source is applied to the magnet coil; the AC power source is started to make the magnet coil vibrate; when mobility of the solidification binder is reduced to be within the design range, the AC power source is turned off; and after the solidification binder is solidified, the magnet coil is taken out from the impregnation mold. The method is good in universality, easy to operate, low in cost and capable of improving impregnation quality of the solidified coil.

Owner:SHANGHAI CHENGUANG MEDICAL TECH

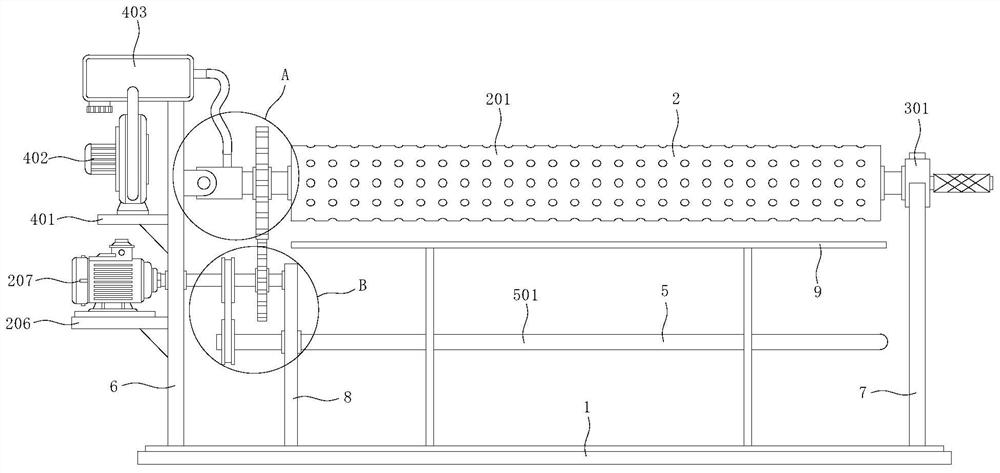

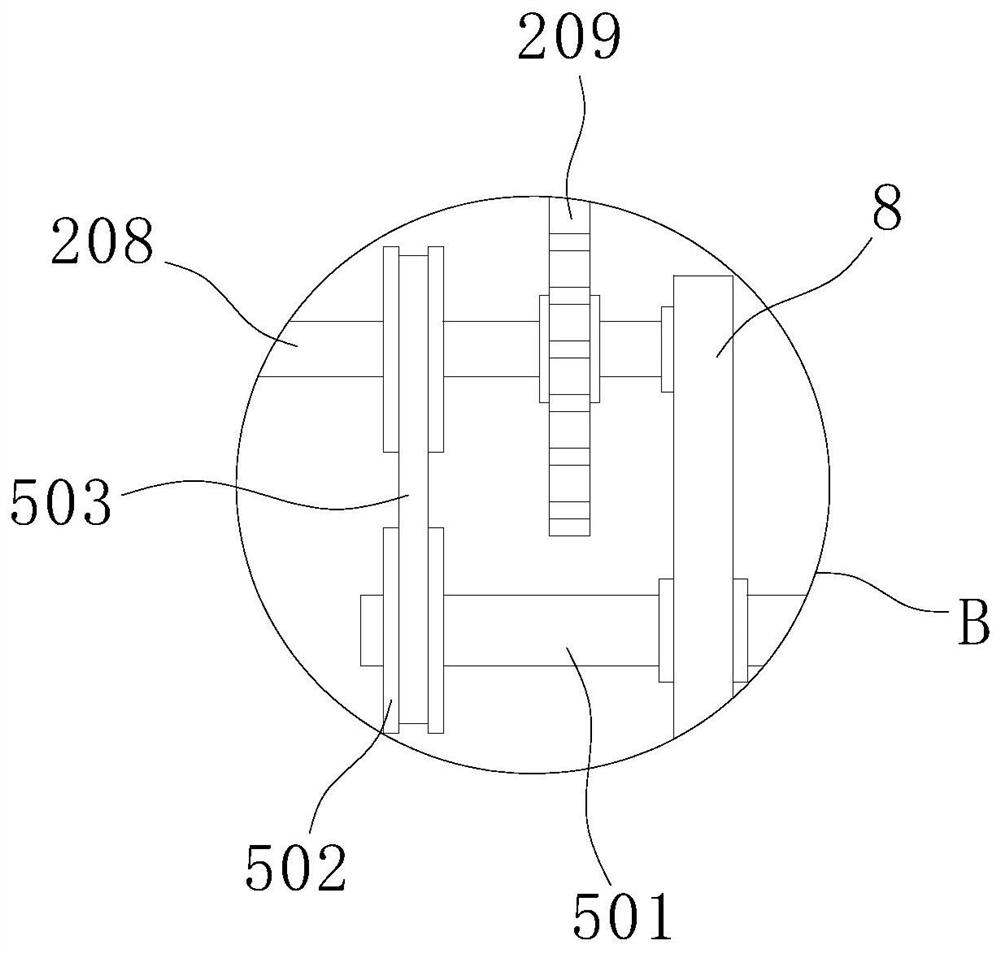

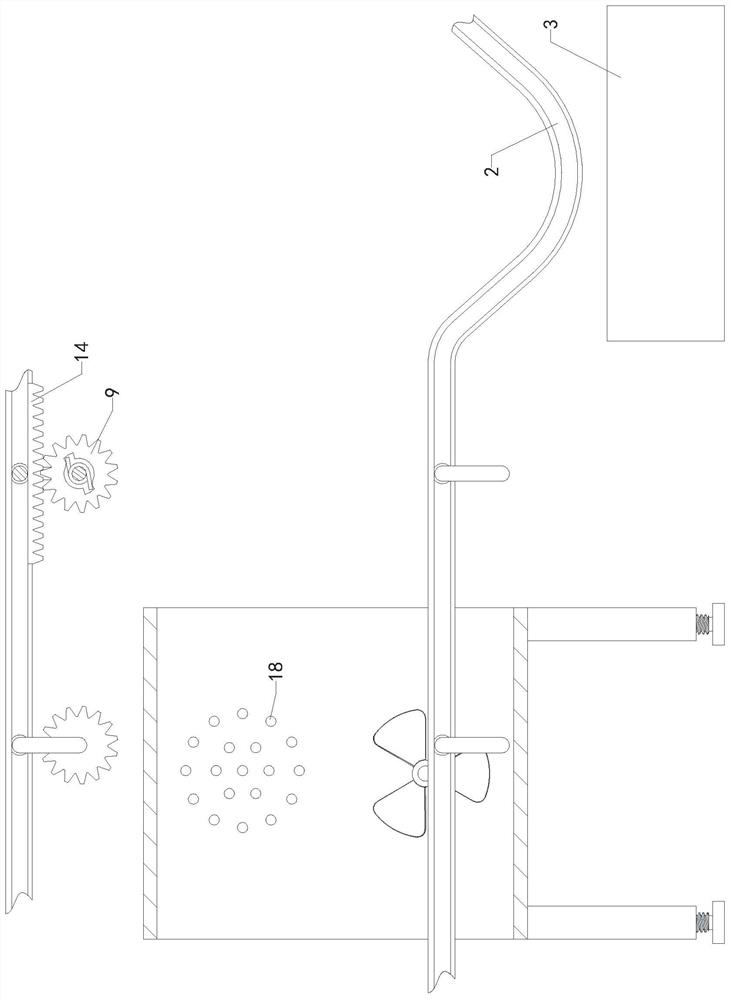

Drum-type receiving lapper for melt-blown non-woven fabric production

ActiveCN113430718AImprove production and processing efficiencyReduce labor burdenTextile disintegration and recoveryNon-woven fabricsNonwoven fabricMechanical engineering

The invention discloses a drum-type receiving lapper for melt-blown non-woven fabric production, and relates to the technical field of non-woven fabric production. The drum-type receiving lapper for melt-blown non-woven fabric production comprises a base; a left supporting plate, a right supporting plate and a mounting plate are fixedly mounted at the top of the base; the mounting plate is located between the left supporting plate and the right supporting plate; a receiving mechanism is arranged above the base; a limiting mechanism is arranged at the top of the right supporting plate; a negative pressure mechanism is arranged on one side of the left supporting plate; and a collecting mechanism is arranged on the mounting plate. According to the drum-type receiving lapper for melt-blown non-woven fabric production, a receiving drum adopts a hinged structural design, so that an overturning function is realized on the premise of not influencing transmission, an operator can conveniently sleeve a non-woven fabric winding drum on the receiving drum before web forming, the non-woven fabric does not need to be manually wound on the receiving drum, the labor burden of the operator is relieved, the overall production and processing time is shortened, and the production and processing efficiency of the melt-blown non-woven fabric is improved.

Owner:湖州创塑新材科技有限公司

Stainless steel surface nano-pore array film and preparation method thereof

InactiveCN102268713BLess investmentLow priceMaterial nanotechnologyAnodisationElectrochemical anodizationElectrochemistry

The invention particularly relates to a stainless steel surface nano-pore array film and a preparation method thereof. The technical scheme is that: stainless steel treated by surface pretreatment is used as an anode and is placed in a phosphate buffer solution to perform electrochemical anodic oxidation treatment; the time for the electrochemical anodic oxidation treatment is 0.1-4 h; a nano-pore array film is obtained on the treated stainless steel surface; the voltage for the electrochemical anodic oxidation is 10-80 V, and the temperature for the electrochemical anodic oxidation is -5 to 40 DEG C. The preparation method of the invention is simple, effective, environment-friendly, and low in cost; the stainless steel surface nano-pore array prepared by the method has a structured and ordered structure, a high density, a controllable pore diameter and pore depth, and no other impurity elements intervened, is firmly combined with the substrate, and has strong corrosion resistance andhigh hardness.

Owner:WUHAN UNIV OF SCI & TECH

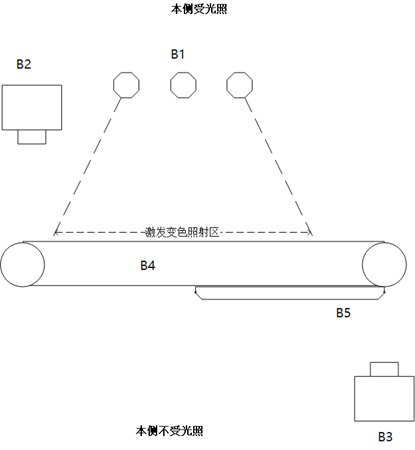

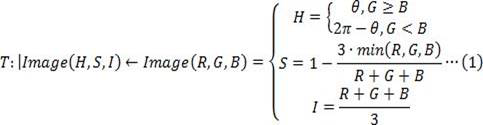

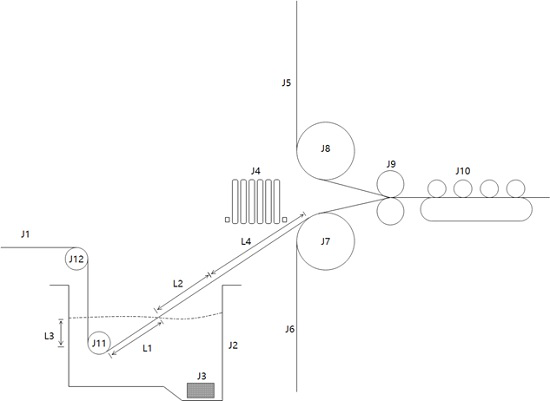

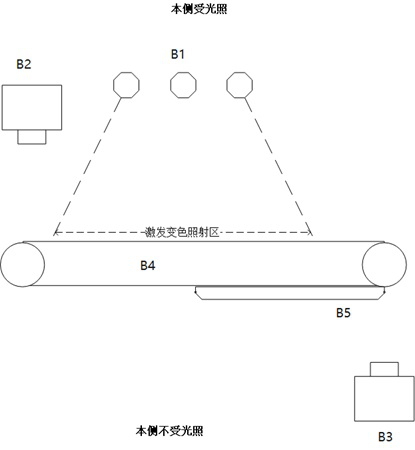

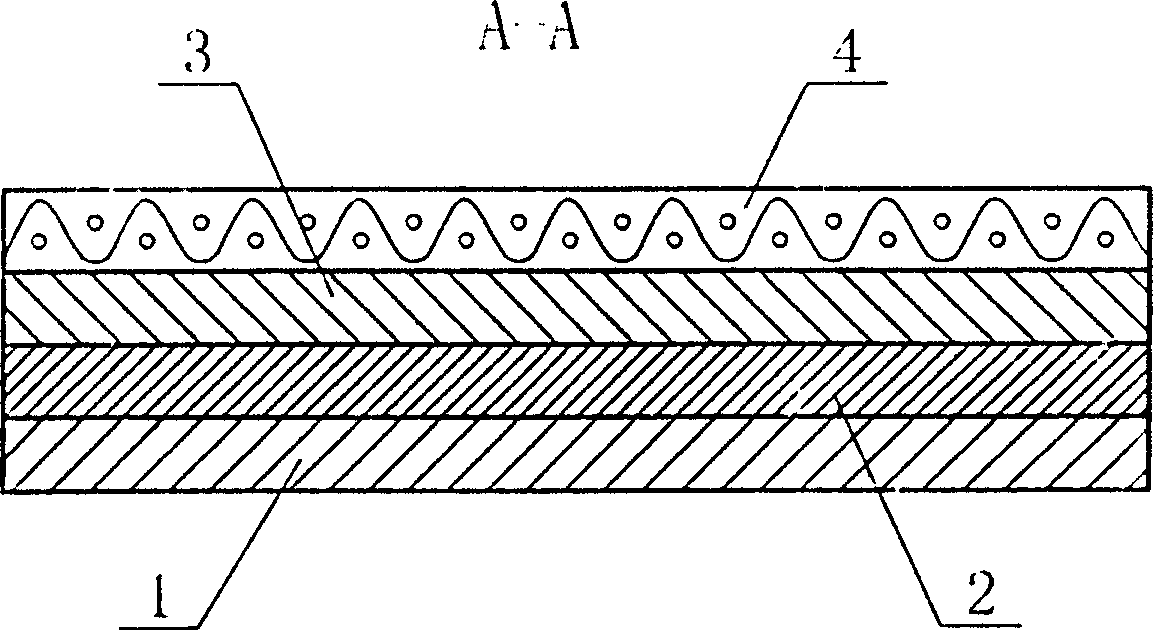

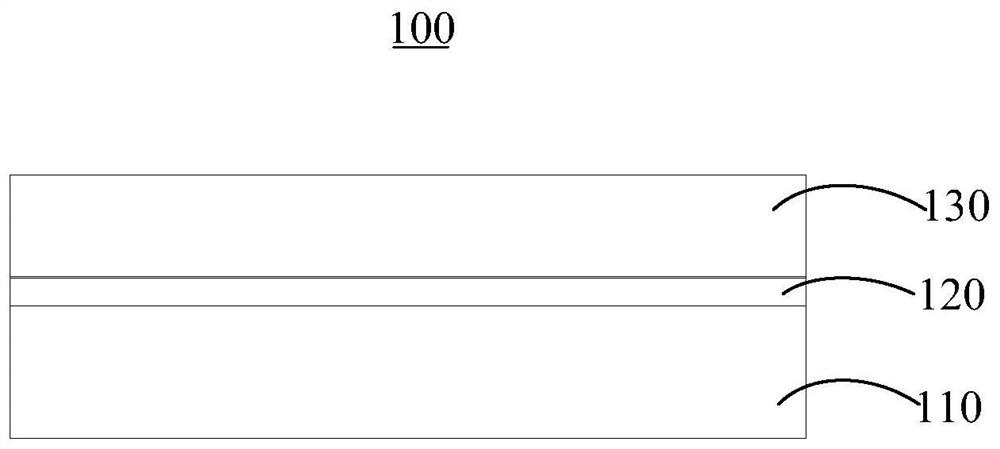

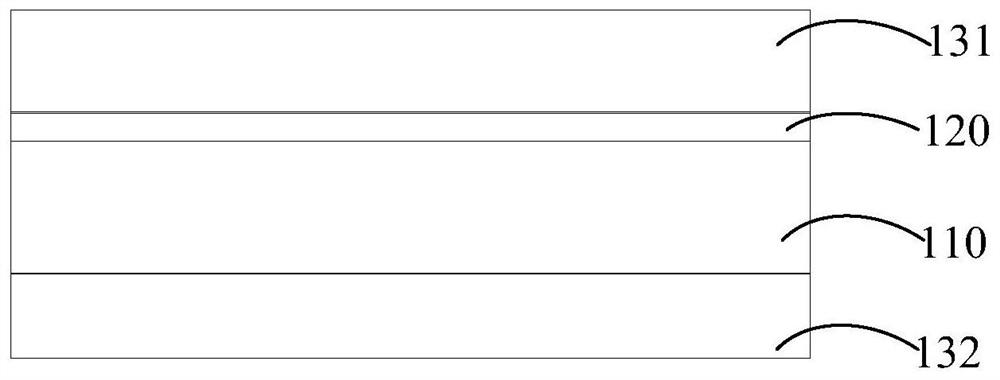

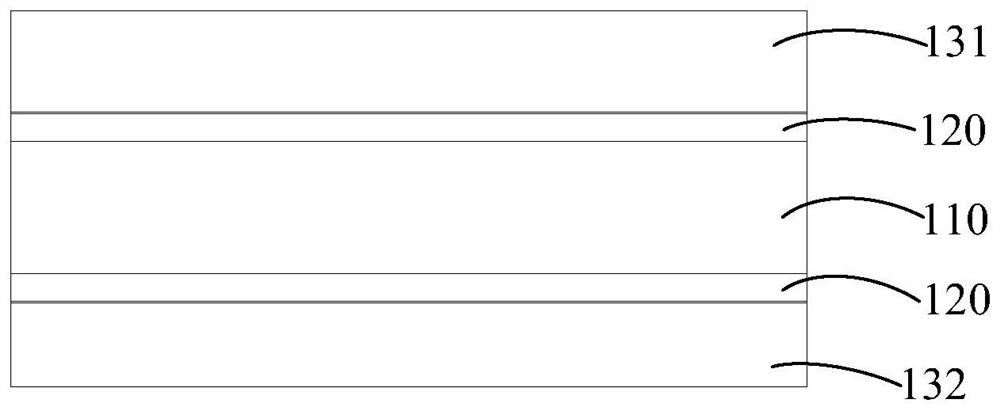

Production process of durable photochromic PET (Polyethylene Terephthalate) film

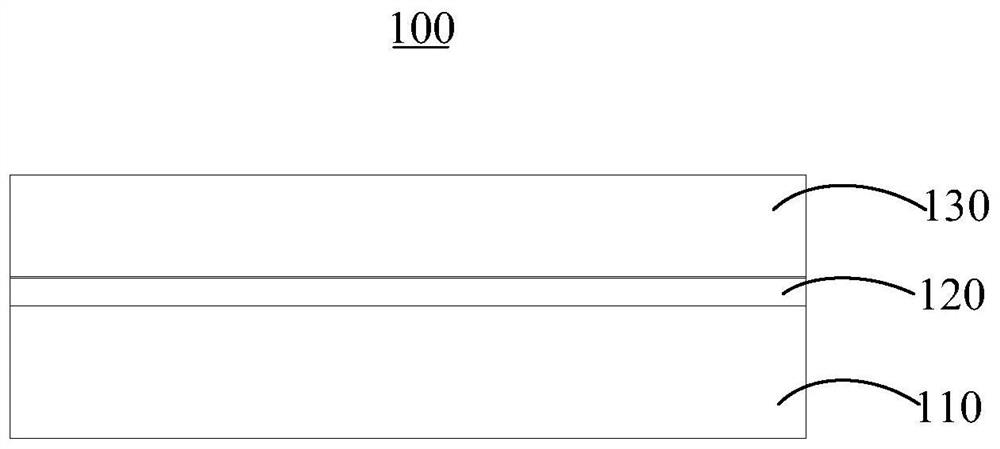

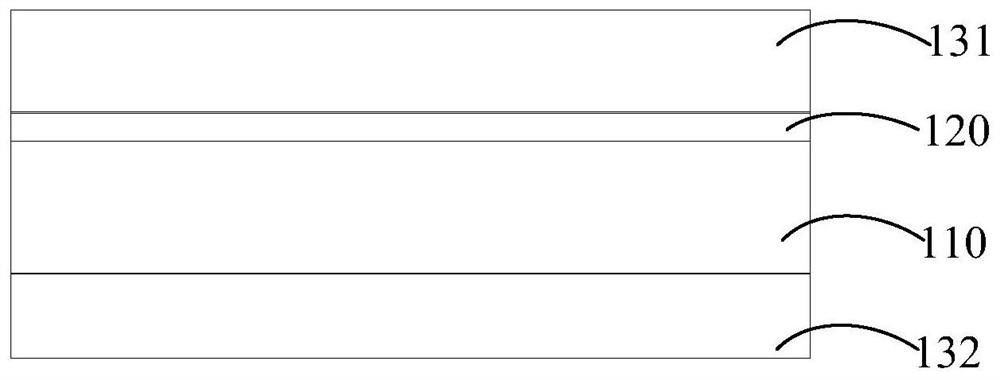

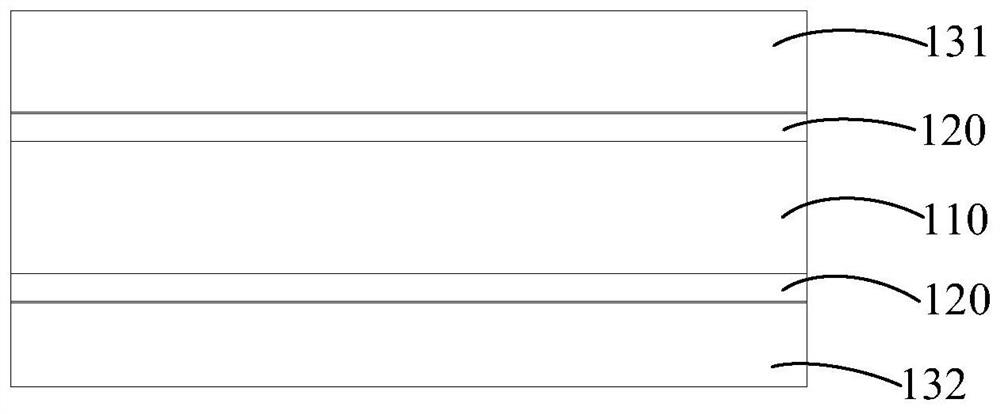

ActiveCN114559688AGood optical performanceNot easy to peel offFlat articlesPolymer sciencePolyethylene terephthalate

A preparation technology of a photochromic PET film capable of being used durably comprises the steps that a glycerol solution with the concentration of 8% is added into composite sol with the molecular ratio of WO3 to TiO2 to ZnO being 22: 1: 1-15: 1: 1, and a photochromic solution is formed; a PET base film is conveyed into a soaking kettle, after vertical soaking, oblique soaking, liquid control and drying are conducted, an upper guide roller guides an upper covering film, a lower guide roller guides the PET base film and a lower covering film, and the upper covering film, the upper photochromic layer, the PET base film, the lower photochromic layer and the lower covering film are laminated to finally form a formed film with the structure of the upper covering film, the upper photochromic layer, the PET base film, the lower photochromic layer and the lower covering film. Therefore, the formed film has uniform and excellent optical performance, meanwhile, stripping between the films is avoided, and the use durability is better.

Owner:河南银金达新材料股份有限公司

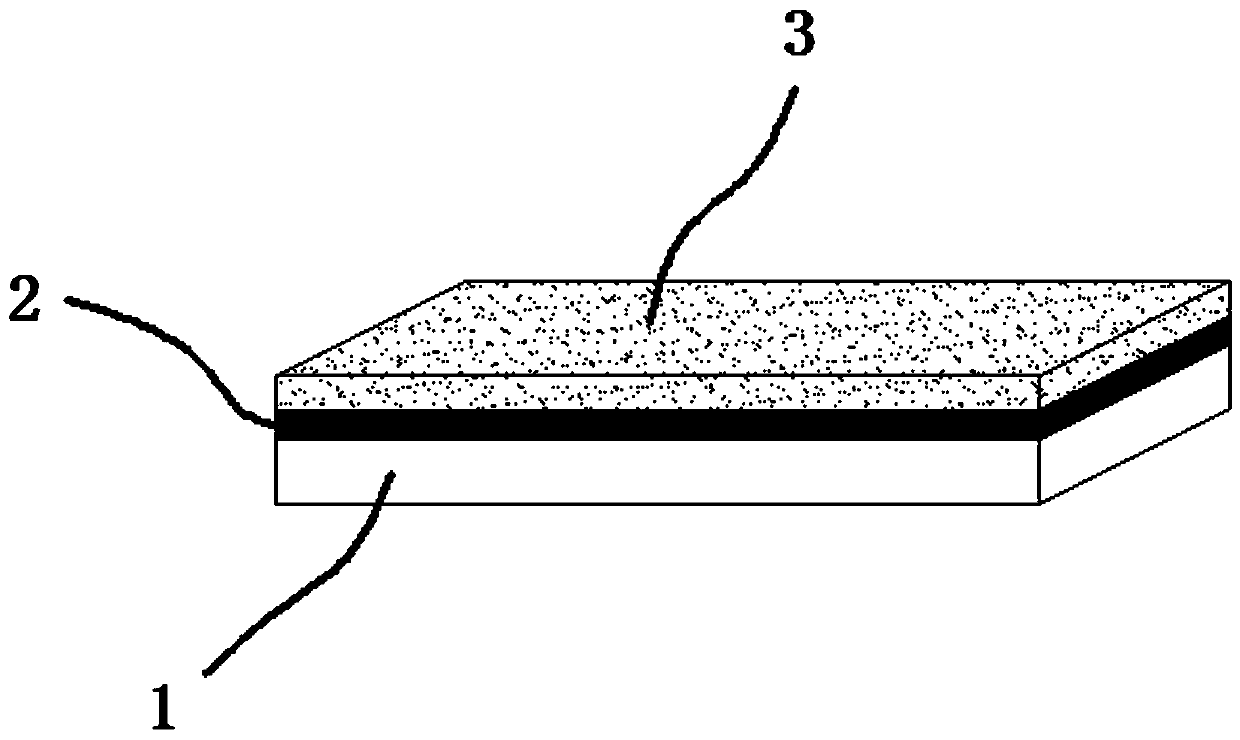

A flame-retardant and high-temperature-resistant polyimide composite board and its preparation method

ActiveCN106188598BImprove flame retardant performanceImprove stabilityFireproof paintsFlexural strengthSlurry

Owner:苏州凯姆勒绝缘材料有限公司

A kind of cold and hot alternate chemical bath method prepares the method for cdse thin film

The invention discloses a method for preparing a CdSe film by adopting a cold-heat alternating chemical bath method. The method comprises the following steps of: (1) placing 20 mL of Cd(NO3) with the concentration of 0.03-0.10 mol / L into an ice-water bath as a cold solution A; (2) mixing 10 mL of KBH4 with the concentration of 0.42-0.6 mol / L and 10 mL of Na2SeO3 with the concentration of 0.06 mol / L, heating to 70-80 DEG C, reacting a solution to a red-brown color, and fast turning into an achromatic color within 4-8 seconds as a heat solution B; (3) vertically immersing a clean ITO (Indium Tin Oxid) conductive glass into the cold solution A obtained from the step (1), taking out after 5-60 seconds, fast immersing into the heat solution B obtained from the step (2), and also sustaining for 5-60 seconds; (4) repeating the step (3) for 4-20 times to generate the CdSe film in the red brown color on an ITO surface. The method disclosed by the invention is short in preparation time, can be used for controlling the thickness of the CdSe film by changing the cycle times of a cold-heat alternating chemical bath without using a toxic organic solvent and has the characteristic of firmly absorbing the CdSe film on ITO.

Owner:佛山市顺德区汇强包装彩印有限公司

A kind of antibacterial stainless steel and preparation method thereof

The invention particularly relates to antibacterial stainless steel and a preparing method thereof. According to the technical scheme of the antibacterial stainless steel and the preparing method thereof, stainless steel obtained after surface pretreatment is put into a dopamine buffer solution to be deposited for 0.1 h to 72 h under the condition with the temperature ranging from -5 DEG C to 40 DEG C; then the obtained stainless steel is put into a solution containing titanium ions to be deposited for 0.1 h to 6 h; and finally the obtained stainless steel is put into a solution containing silver ions to be deposited for 0.1 h to 6 h, and therefore the antibacterial stainless steel is obtained. The concentration of the dopamine buffer solution ranges from 0.01 mol / L to 1 mol / L, the concentration of the solution containing the titanium ions ranges from 0.001 mol / L to 1 mol / L, and the concentration of the solution containing the silver ions ranges from 0.001 mol / L to 1 mol / L. By means of the antibacterial stainless steel and the preparing method thereof, the technology is simple, environment friendliness is achieved, and the cost is low; the surface antibacterial nanometer film layer structure of the antibacterial stainless steel prepared through the method is well-defined and orderly, is firmly combined with a base material, is high in corrosion resistance and hardness and has good antibacterial performance both under the illumination condition and the non-illumination condition.

Owner:WUHAN UNIV OF SCI & TECH

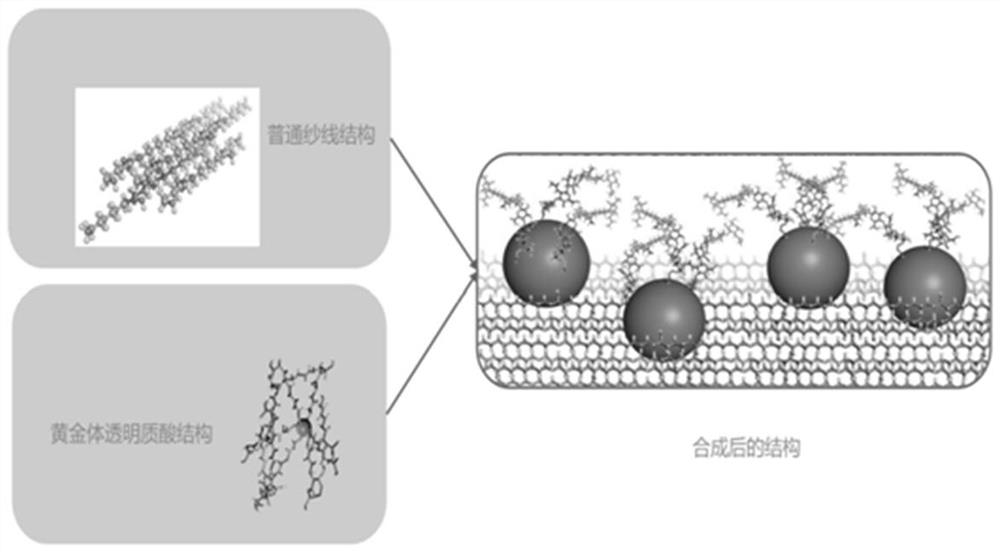

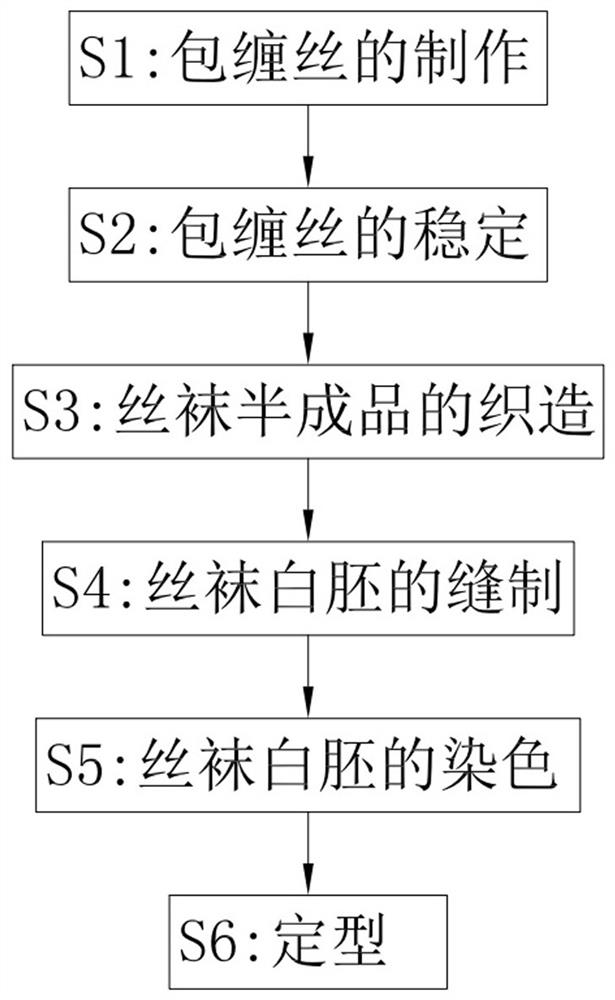

Moisturizing silk stockings and production process thereof

PendingCN114468401AEasy to synthesizeWith moisturizing functionWeft knittingFibre typesYarnEngineering

Owner:江园平

A durable photochromic pet film production process

ActiveCN114559688BGood optical performanceNot easy to peel offFlat articlesPolymer scienceOptical property

A kind of photochromic PET film preparation process that can be durable, including WO 3 , TiO 2 The 8% glycerol solution was added to the composite sol with a molecular ratio of 22:1:1-15:1:1 to ZnO to form a photochromic solution; the PET base film was transferred to the soaking kettle, and after vertical soaking, After oblique soaking, liquid control, and drying, the upper guide roller guides the upper film, and the lower guide roller guides the PET base film and the lower film. The final structure of the three lamination is the upper film-upper photochromic layer-PET Film formation of the base film-under the photochromic layer-under the cover film. The film formed in this way has uniform and excellent optical properties, while avoiding inter-film peeling, and has better durability in use.

Owner:河南银金达新材料股份有限公司

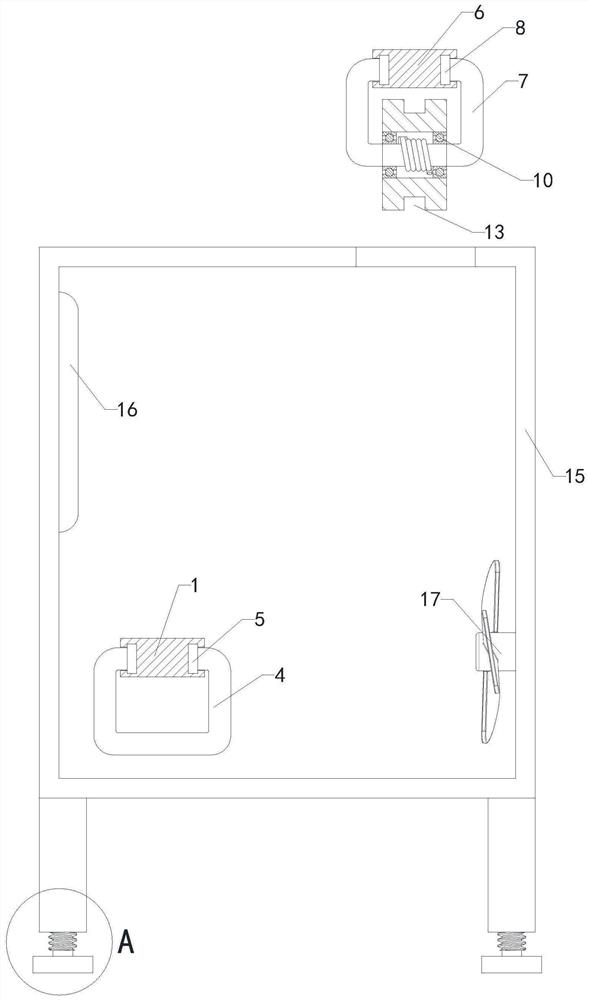

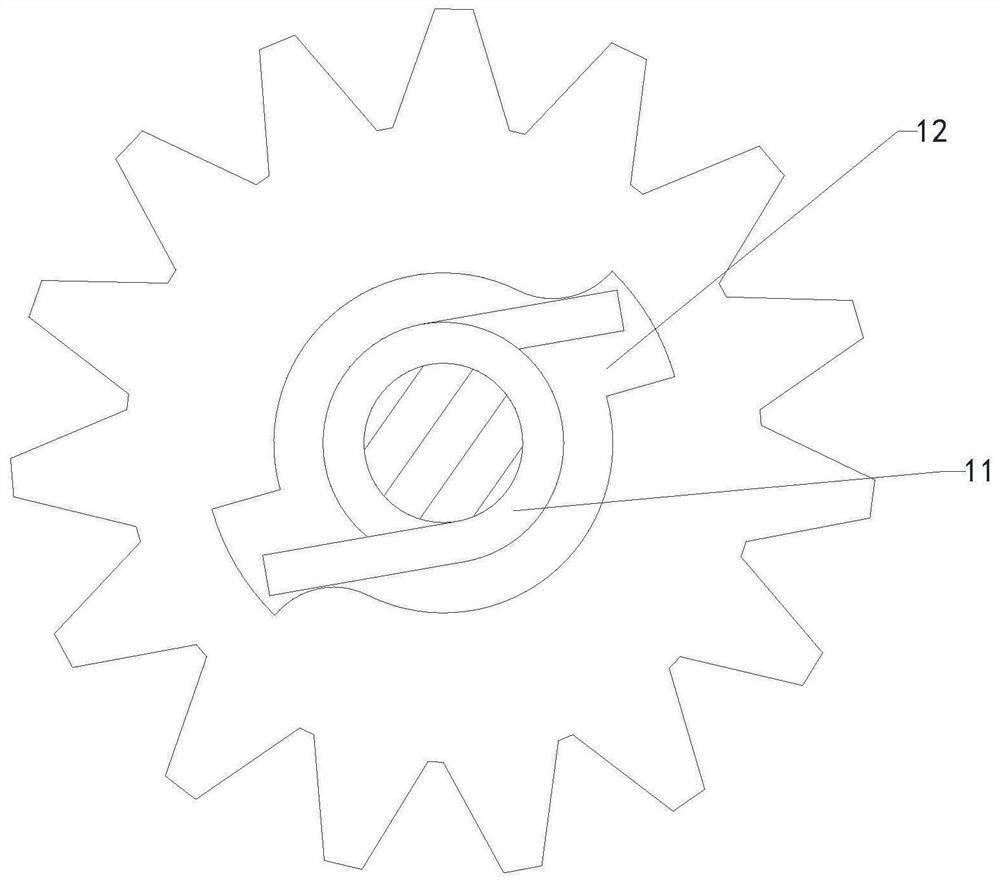

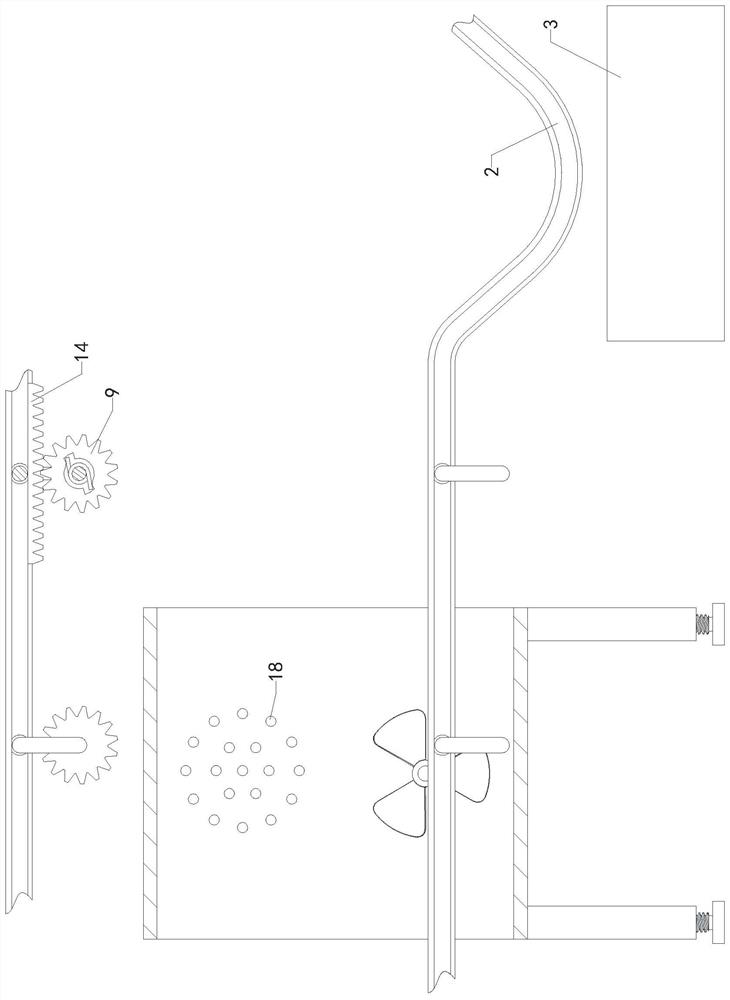

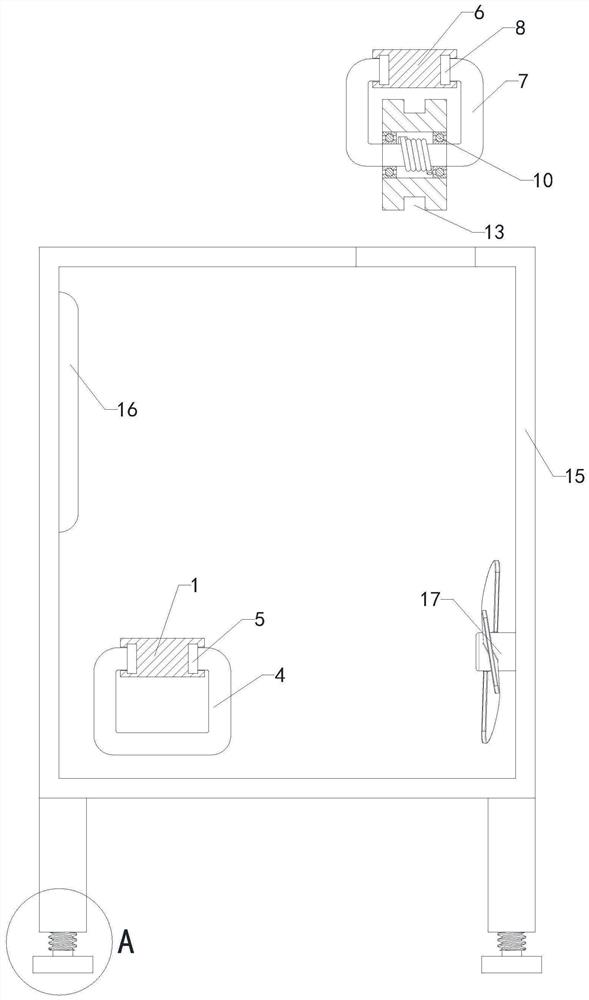

A production line for surface coating of mechanical metal parts

ActiveCN112856998BUniform and firm attachmentQuality improvementDrying gas arrangementsElectrophoretic coatingsProduction lineGear wheel

The invention relates to the technical field of painting, in particular to a surface painting production line for mechanical metal parts, which makes the paint evenly and stably adhere to the surface of the parts, improves the quality of painting and improves practicability; a groove, a first moving ring and a first sliding block, the right part of the first sliding rail is provided with a curved arc, the electrophoresis groove is installed under the curved arc, and the first moving ring is slidably connected to the first sliding rail through two sets of first sliding blocks; It also includes a second sliding rail, a second moving ring, a second sliding block, a gear, a bearing, a torsion spring and a heating tube, the second sliding rail is installed obliquely above the first sliding rail, and the second moving ring passes through two sets of second sliding The block is slidably connected with the second sliding rail, the gear is rotatably connected with the bottom of the second moving ring through two sets of bearings, the inner ring of the torsion spring is connected with the outer ring of the second moving ring, and two sets of clamping grooves are arranged in the middle of the gear.

Owner:江苏光明环境设备有限公司

A method of producing automobile molds by lost foam casting process

ActiveCN110614346BUniform and firm attachmentFully filledCasting plantsMoulding toolsMechanical engineeringLost-foam casting

The invention provides a method for producing a car mold through a lost foam casting process, and particularly relates to the technical field of car mold manufacturing. The lost foam casting method isadopted for preparing the car mold, after a foam model is coated with a coating, shock chilling drying is carried out, the coating is evenly and stably attached to the model, through a turnover sandadding vibration compaction method of a sand box, quartz sand is filled fully, and is not prone to collapse and burning, the method is simple and easy to operate, the parameters are controllable, andthe method is suitable for large-scale production. The prepared car mold has two types, one type is composed of an upper mold and a lower mold, the other type is composed of a female mold, a male moldand a blank holder, the hardness reaches above 310 HB, the tensile strength reaches above 370 MPa, and the two types both have the higher wear-resistance and anti-deforming properties.

Owner:柳州市顺昇机械有限公司

Golden foil material in use for various tablets, business cards, album, mural painting and deocration

InactiveCN1660610AGood antioxidant propertiesGood strength and toughnessNatural patternsBusiness cardWrinkle

Owner:王建雄

Surface coating production line for mechanical metal parts

ActiveCN112856998AUniform and firm attachmentQuality improvementDrying gas arrangementsElectrophoretic coatingsProduction lineElectrophoresis

The invention relates to the technical field of coating, in particular to a surface coating production line for mechanical metal parts.By means of the production line, coating is evenly and stably attached to the surfaces of the parts, the coating quality is improved, and the practicability is improved. The surface coating production line comprises a first sliding rail, an electrophoresis tank, a first moving ring and first sliding blocks, wherein a bent arc is arranged on the right portion of the first sliding rail, the electrophoresis tank is installed below the bent arc, and the first moving ring is slidably connected with the first sliding rail through the two first sliding blocks. The surface coating production line further comprises a second sliding rail, a second moving ring, second sliding blocks, a gear, bearings, a torsional spring and a heating pipe, wherein the second sliding rail is installed on the inclined upper portion of the first sliding rail, the second moving ring is slidably connected with the second sliding rail through the two second sliding blocks, the gear is rotatably connected with the bottom of the second moving ring through the two bearings, an inner ring of the torsional spring is connected with an outer ring of the second moving ring, and two clamping grooves are formed in the middle of the gear.

Owner:江苏光明环境设备有限公司

Preparation method of silane modified graphene, sheet metal part, air conditioner indoor unit and air conditioner

ActiveCN111808451AImprove the effect of cathodic protectionUniform and firm attachmentLighting and heating apparatusHeating and ventilation casings/coversSilanesPhysical chemistry

The invention discloses a preparation method of silane modified graphene, a sheet metal part, an air conditioner outdoor unit and an air conditioner, wherein the preparation method of silane modifiedgraphene comprises the following steps: adding graphene oxide and a solvent into a reactor; stirring for 12 h-36 h at the normal temperature, and carrying out ultrasonic oscillation for 30 min-60 min;adding a silane coupling agent into the reactor; heating to 50 DEG C-200 DEG C, stirring to react for 12 h-36 h, and stopping the reaction when a mixed solution is gradually changed from golden brownto black brown. The silane modified graphene prepared by the preparation method can effectively improve the corrosion resistance of the sheet metal part in a heavy corrosion environment.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Surface treatment method and device for nickel-chromium alloy wire

ActiveCN112080749BHigh chemical potentialReduce the formation temperatureSolid state diffusion coatingNickel chromium alloyNichrome

Owner:BEIJING SHOUGANG GITANE NEW MATERIALS

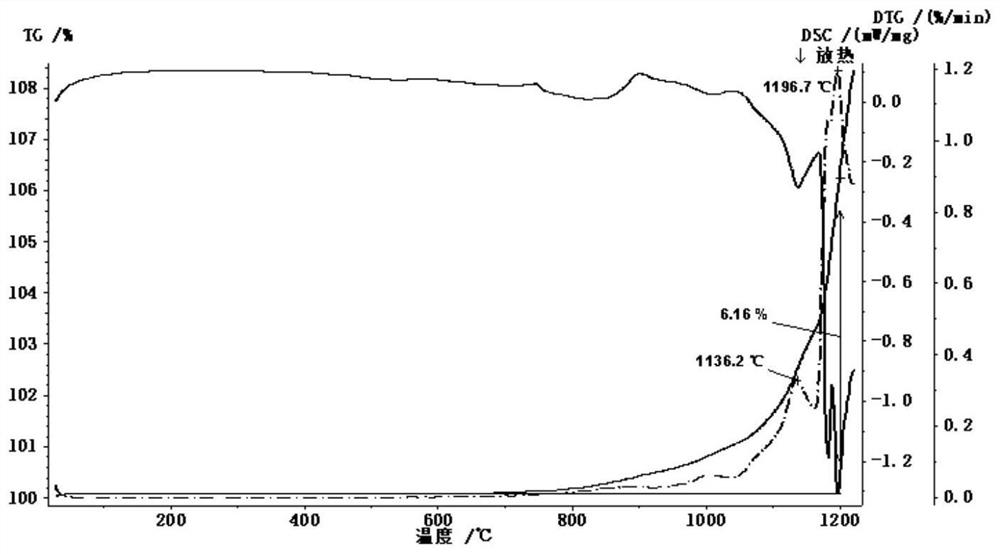

Flame-retardant type high temperature-resistant polyimide composite plate and application thereof

InactiveCN109320745AImprove flame retardant performanceImprove stabilityFireproof paintsFlexural strengthSlurry

The invention discloses a flame-retardant type high temperature-resistant polyimide composite plate and application thereof. The flame-retardant type high temperature-resistant polyimide composite plate is prepared by the following steps of soaking the polyimide plate into a coating slurry, fetching out after 3 to 5 min, heating for 5 to 8 min at the temperature of 90 DEG C, soaking into the coating slurry again, fetching out after 8 to 12 min, and heating for 10 to 15 min at the temperature of 110 DEG C; finally, treating for 40 to 55 min at the temperature of 155 DEG C under the vacuum condition, so as to obtain the flame-retardant type high temperature-resistant polyimide composite plate; the thickness of the polyimide plate is equal to 92 to 95% of the thickness of the flame-retardanttype high temperature-resistant polyimide composite plate; proved by testing, the glass transition temperature of the prepared flame-retardant type high temperature-resistant polyimide composite plateis 302 DEG C, the initial thermal weight loss temperature is 406 DEG C, the oxygen index is 45, the residual rate at the temperature of 700 DEG C is 37%, the bending strength is 62 MPa, the knife isnot stuck in edge fetching, and the knife is not replaced within the 500 m range.

Owner:SUZHOU KAIMULE INSULATED MATERIALS CO LTD

Golden foil material in use for various tablets, business cards, album, mural painting and deocration

InactiveCN1310773CWith reflective effectImprove antioxidant capacityNatural patternsBusiness cardAdhesive

Owner:王建雄

Preparation method of silane-modified graphene, sheet metal parts, air conditioner outdoor unit and air conditioner

ActiveCN111808451BImprove the effect of cathodic protectionUniform and firm attachmentLighting and heating apparatusHeating and ventilation casings/coversGraphiteGraphene

The invention discloses a preparation method of silane-modified graphene, a sheet metal part, an air conditioner outdoor unit, and an air conditioner, wherein the preparation method of the silane-modified graphene comprises the following steps: adding graphene oxide and Solvent; stir at room temperature for 12h-36h, ultrasonically oscillate for 30min-60min; add silane coupling agent to the reactor; heat up to 50°C-200°C, stir for 12h-36h, until the mixture gradually turns from golden brown to black Brown, no reaction. The silane-modified graphene prepared by the invention can effectively improve the anti-corrosion performance of sheet metal parts in heavy corrosion environments.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

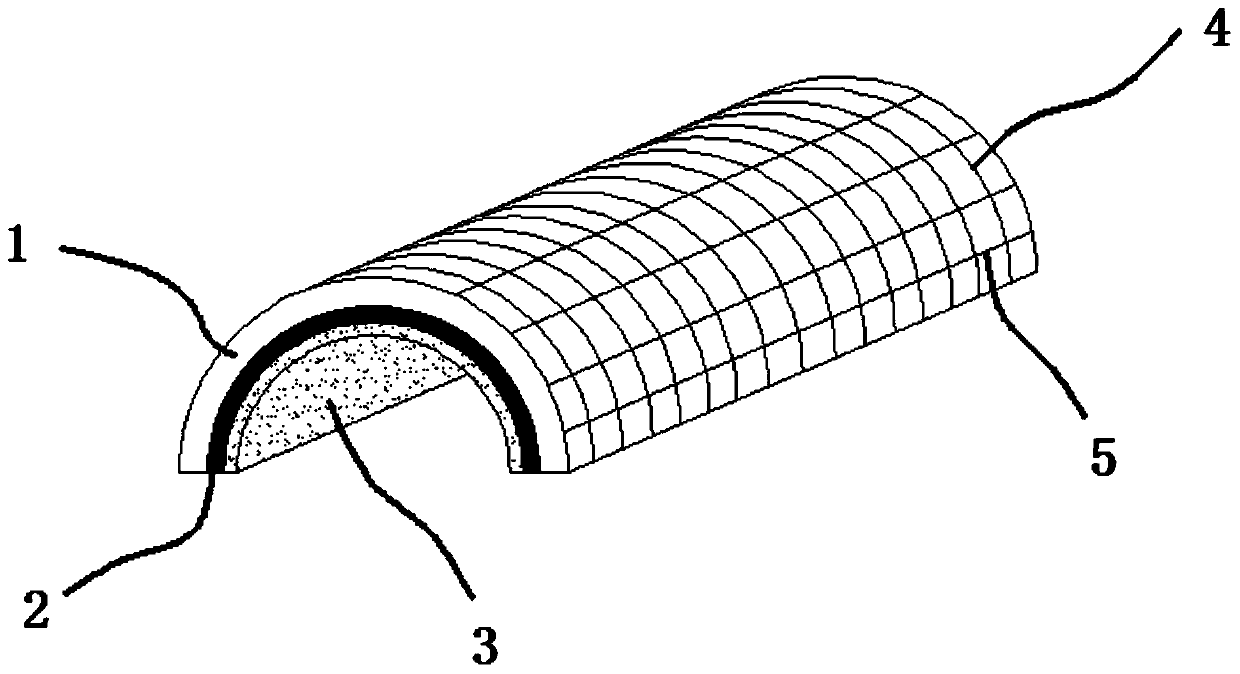

Agricultural non-point source restoration system based on cement blanket

InactiveCN109807172AImprove willfulnessHigh strengthContaminated soil reclamationEnvironmental resistanceAgricultural engineering

The invention relates to an agricultural non-point source restoration system based on a cement blanket. The system comprises degrading bacteria and cloth, wherein the cloth is formed by interweaving aplurality of strands of warp yarns and a plurality of strands of weft yarns; cement powder is filled in a space defined by the interwoven warp yarns and weft yarns; a layer of degrading bacteria is coated onto the inner side of the cloth; the degrading bacteria can perform agricultural non-point source restoration; through the water spreading onto the surface of the top of the cloth, cement powder in the cloth can be solidified through hydration, so that the cloth is fixed to form an arc-shaped upper cover; a layer of paste is coated between the degrading bacteria and the cloth; the partiallyhydrated cement slurry is prevented from dripping onto the surface of the agricultural non-point source through the paste; the environmental-friendly function is realized; the degrading bacteria areslowly released to flow into the soil for agricultural non-point source restoration; the restoration capability of the degrading bacteria is improved.

Owner:湖南高岭环保科技有限公司

A preparation method of zinc oxide nanorod array on stainless steel surface

ActiveCN106191985BLess investmentLow priceMaterial nanotechnologyPolycrystalline material growthNano structuringSS - Stainless steel

The invention relates to a preparation method of a zinc oxide nano-rod array on a stainless steel surface. The preparation method comprises orderly carrying out ultrasonic cleaning on stainless steel through anhydrous ethanol and distilled water, carrying out blow-drying, immersing the stainless steel in a mixed solution and carrying out irradiation on the stainless steel through a microwave oven 1-5 times to obtain the zinc oxide nano-rod array on the stainless steel surface, wherein in each irradiation process, irradiation time is in a range of 0.5-10min and irradiation interval time is in a range of 5-10s. The mixed solution comprises a zinc ion solution, an ammonia ion solution and a graphene oxide solution, the zinc ion solution has a concentration of 0.001-0.1mol / L, the ammonia ion solution has a concentration of 0.001-0.1mol / L and the graphene oxide solution has a concentration of 0.01-2g / L. The preparation method has simple processes, is fast and environmentally friendly and has a low cost. The zinc oxide nano-rod array on the stainless steel surface has excellent photocatalytic and photoelectrochemical performances, nanostructured morphology, a controllable microstructure, firm combination with a base, good corrosion resistance and high hardness.

Owner:WUHAN UNIV OF SCI & TECH

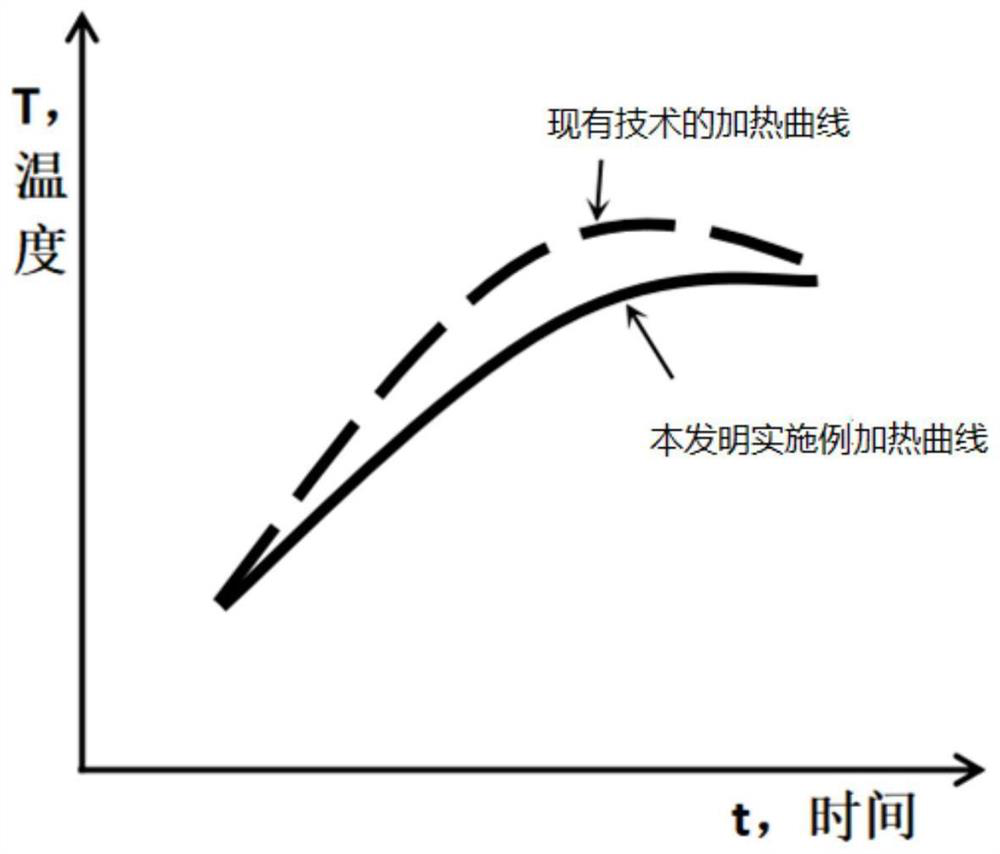

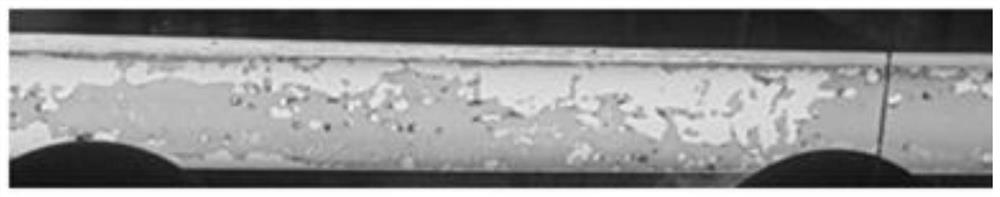

Gas shielded welding wire steel casting blank heating method and heating furnace

PendingCN112547825AReduce the binding forceLess quantityWelding/cutting media/materialsSoldering mediaWire rodCopper coating

The invention provides a gas shielded welding wire steel casting blank heating method and a heating furnace. The method comprises the following steps: preheating and first heating are carried out on agas shielded welding wire steel casting blank with the mass fraction of Si being greater than or equal to 0.7% to obtain a first heated casting blank; the first heating casting blank is secondarily heated to the temperature smaller than or equal to 1000 DEG C within the time smaller than or equal to 60 min to obtain a second heating casting blank; and the second heating casting blank is subjectedto third heating within the time smaller than or equal to 60 min till the temperature is smaller than or equal to 1120 DEG C to finish heating of the gas shielded welding wire steel casting blank. According to the heating method provided by the invention, the embedding depth of the oxide scale of a produced wire rod does not exceed 25 microns, and the drawing fracture rate is less than or equal to 0.5 times / ton when the welding wire is manufactured by cold drawing, so that the wire rod has good processing performance, meanwhile, a copper plating layer is uniformly and firmly attached, and thewelding wire is ensured to have high surface quality.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com