Gas shielded welding wire steel casting blank heating method and heating furnace

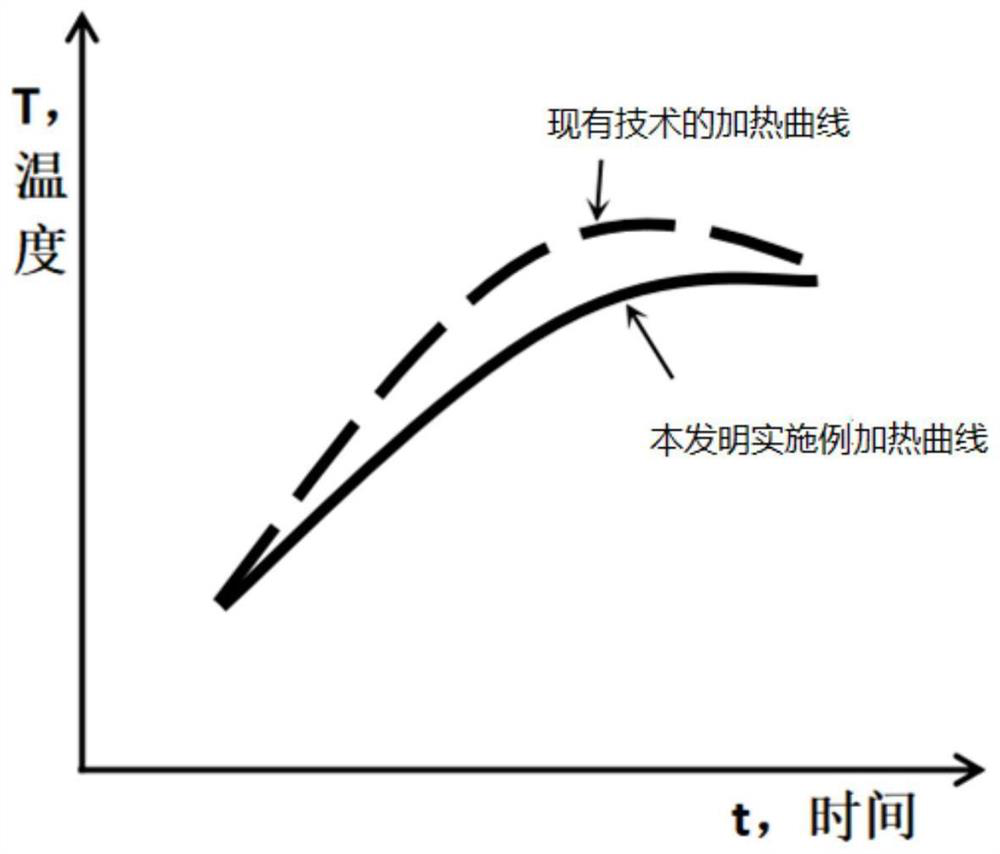

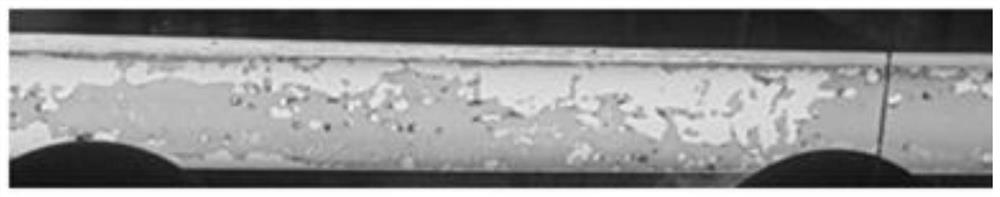

A heating method and gas shielded welding technology, applied in the field of heating furnace heating, can solve the problems of falling off, drawing and breaking, copper plating on the surface of the finished welding wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

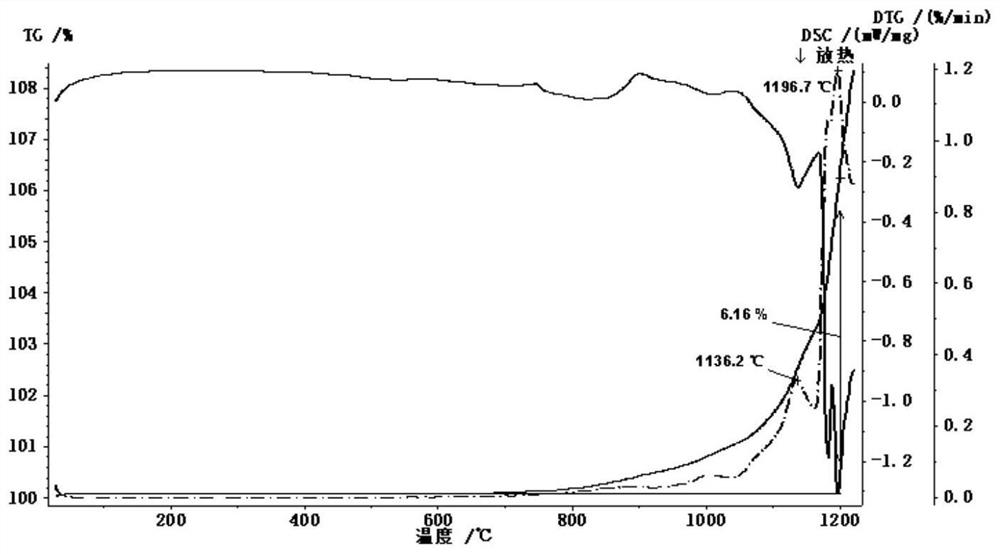

Method used

Image

Examples

Embodiment 1

[0086] The chemical composition mass percent of the gas-shielded welding wire steel slab used in Example 1 is: C: 0.07%, Si: 0.89%, Mn: 1.43%, P: 0.012%, S: 0.006%, and the balance is Fe and unavoidable Impurities. The size of the billet is 160mm×160mm×12000mm.

[0087] Furnace charging system: enter one empty one.

[0088] The heating process of the heating furnace is: the preheating temperature is the furnace temperature of 730°C, the preheating time is 8min, the temperature of the first stage of heating is 770°C, the heating time of the first stage of heating is 32min, the temperature of the second stage of heating is 990°C, and the heating time of the second stage of heating is 40min. The temperature of the soaking section is 1080°C, and the soaking time is 40 minutes. The total heating time is 120min.

[0089] Coke oven gas is used as fuel.

[0090] Residual oxygen content: 2-3%.

Embodiment 2

[0092] The mass percent of the chemical composition of the gas-shielded welding wire steel slab used in Example 2 is: C: 0.05%, Si: 0.80%, Mn: 1.46%, P: 0.014%, S: 0.015%, Ti: 0.19%, and the balance is Fe and unavoidable impurities. The size of the billet is 160mm×160mm×12000mm.

[0093] Furnace charging system: enter one empty two.

[0094] The heating process of the heating furnace is: the preheating temperature is 760°C, the preheating time is 6 minutes, the temperature of the first stage of heating is 790°C, the heating time of the first stage of heating is 24 minutes, the temperature of the second stage of heating is 990°C, and the heating time of the second stage of heating is 30 minutes. The temperature in the hot section is 1090°C, and the heating time in the soaking section is 30 minutes. The total heating time is 90min. The size of the billet is 160mm×160mm×12000mm.

[0095] Coke oven gas is used as fuel.

[0096] Residual oxygen content: 1-2.5%.

Embodiment 3

[0098] The chemical composition mass percent of the gas-shielded welding wire steel slab used in Example 3 is: C: 0.05%, Si: 0.77%, Mn: 1.46%, P: 0.012%, S: 0.015%, Ti: 0.20%, and the balance is Fe and unavoidable impurities. The size of the billet is 160mm×160mm×12000mm.

[0099] Furnace charging system: enter one empty two.

[0100] The heating process of the heating furnace is: the preheating temperature is 760°C, the preheating time is 5min, the temperature of the first stage of heating is 790°C, the heating time of the first stage of heating is 21min, the temperature of the second stage of heating is 1000°C, and the heating time of the second stage is 26min. The temperature in the hot section is 1110°C, and the heating time in the soaking section is 26 minutes. The total heating time is 78min.

[0101] Coke oven gas is used as fuel.

[0102] Residual oxygen content: 1-2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com