A durable photochromic pet film production process

A technology of photochromism and production technology, which is applied in the field of material science, can solve the problems of unsuitable polyester film production line, unsuitable for large-scale production, and unable to be used in factories, so as to achieve excellent optical performance and avoid uneven and uniform optical performance The effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

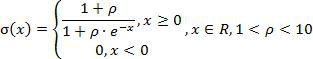

Method used

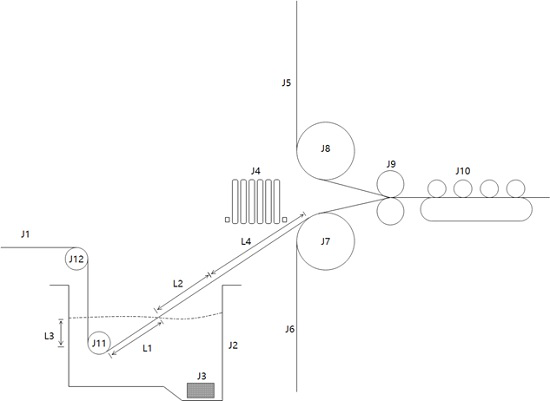

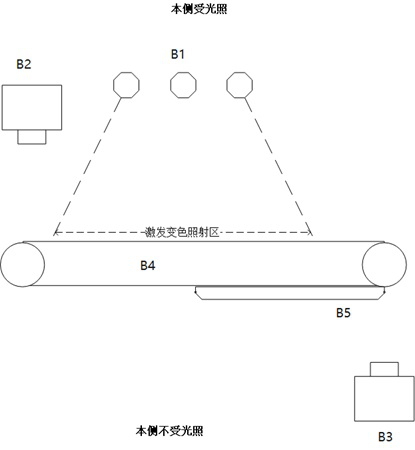

Image

Examples

Embodiment Construction

[0038] (1) Preparation of photochromic sol solution

[0039] Step 1: WO 3 Preparation of sol: adding Na to ultrapure water 2 WO 4 ·2H 2 O, stir to dissolve, and add mineral acid solution to acidify to PH=4 to obtain WO 3 solution. Adding oxalic acid to ultrapure water to dissolve, heating and stirring during the dissolving process to obtain an oxalic acid solution. The heating temperature is 45-63°C, and the stirring time is 5-10min. will WO 3 Mix the solution with oxalic acid solution, add ultrapure water for dilution and stirring, and form colorless and transparent WO after standing for 6-10h 3 Sol, 0.3M concentration.

[0040] Step 2: TiO 2 Preparation of the sol: The C 16 H 36 O 4 Ti (butyl titanate) was added to anhydrous ethanol, and then ultrapure water was added to the solution to cause a polycondensation reaction to prepare TiO with a sol concentration of 0.3 M 2 sol.

[0041] Step 3: Preparation of ZnO sol: (CH 3 COO) 2 Zn·2H 2 O was dissolved in anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com