Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "To achieve the purpose of welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

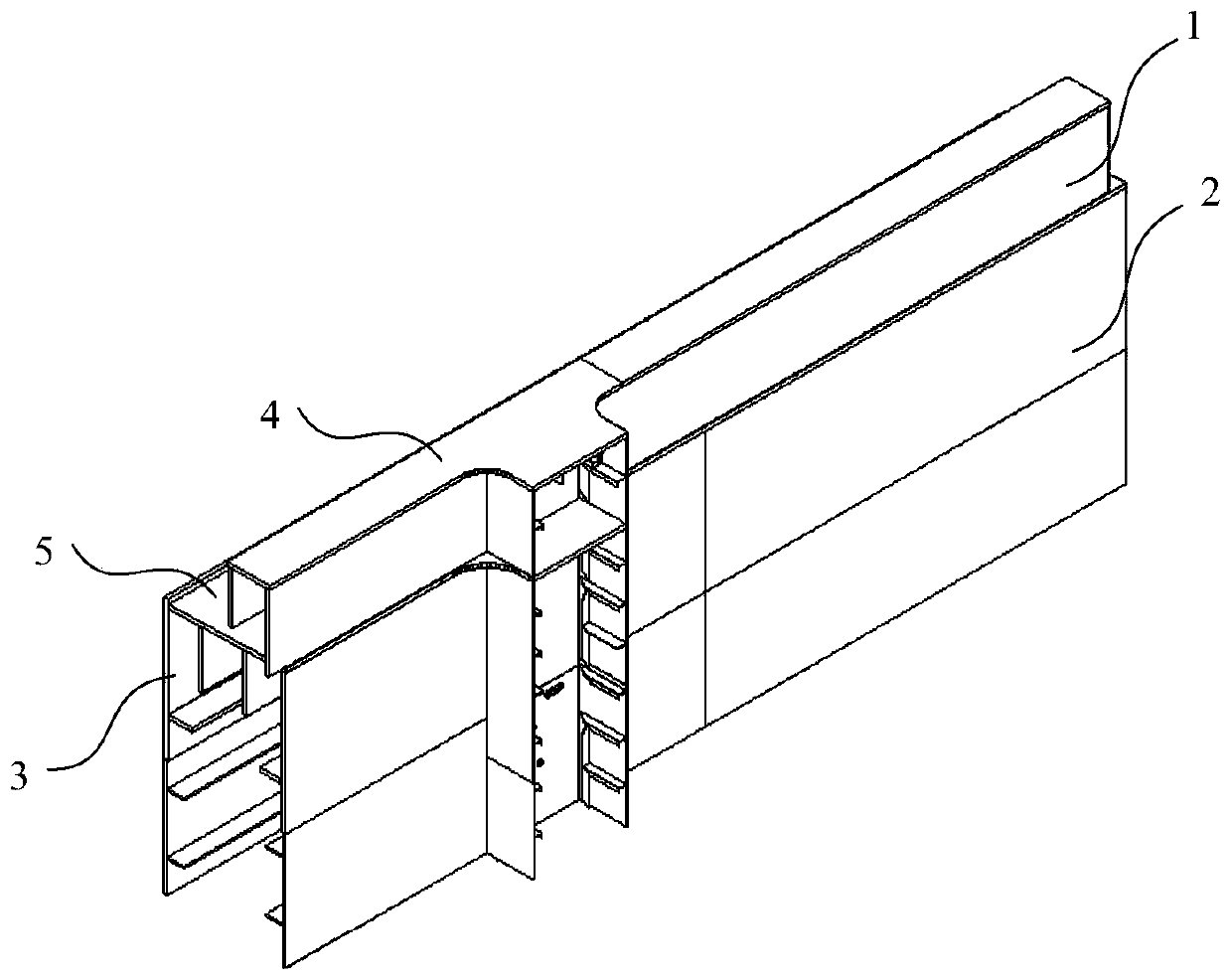

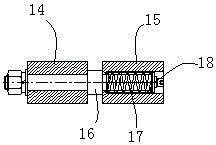

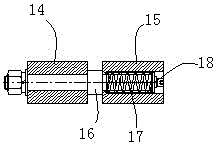

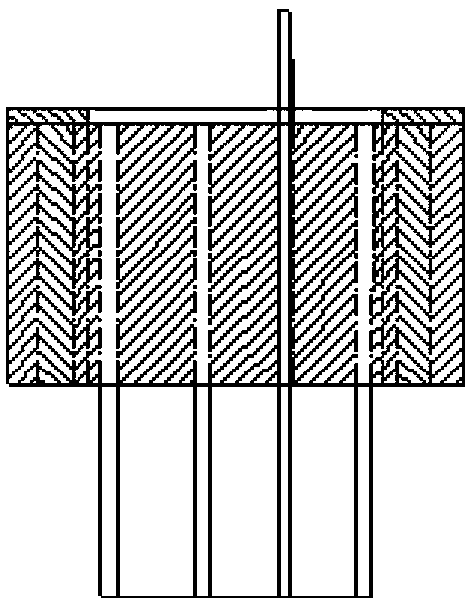

Aclinal self-upsetting, stirring and friction welding method and tool

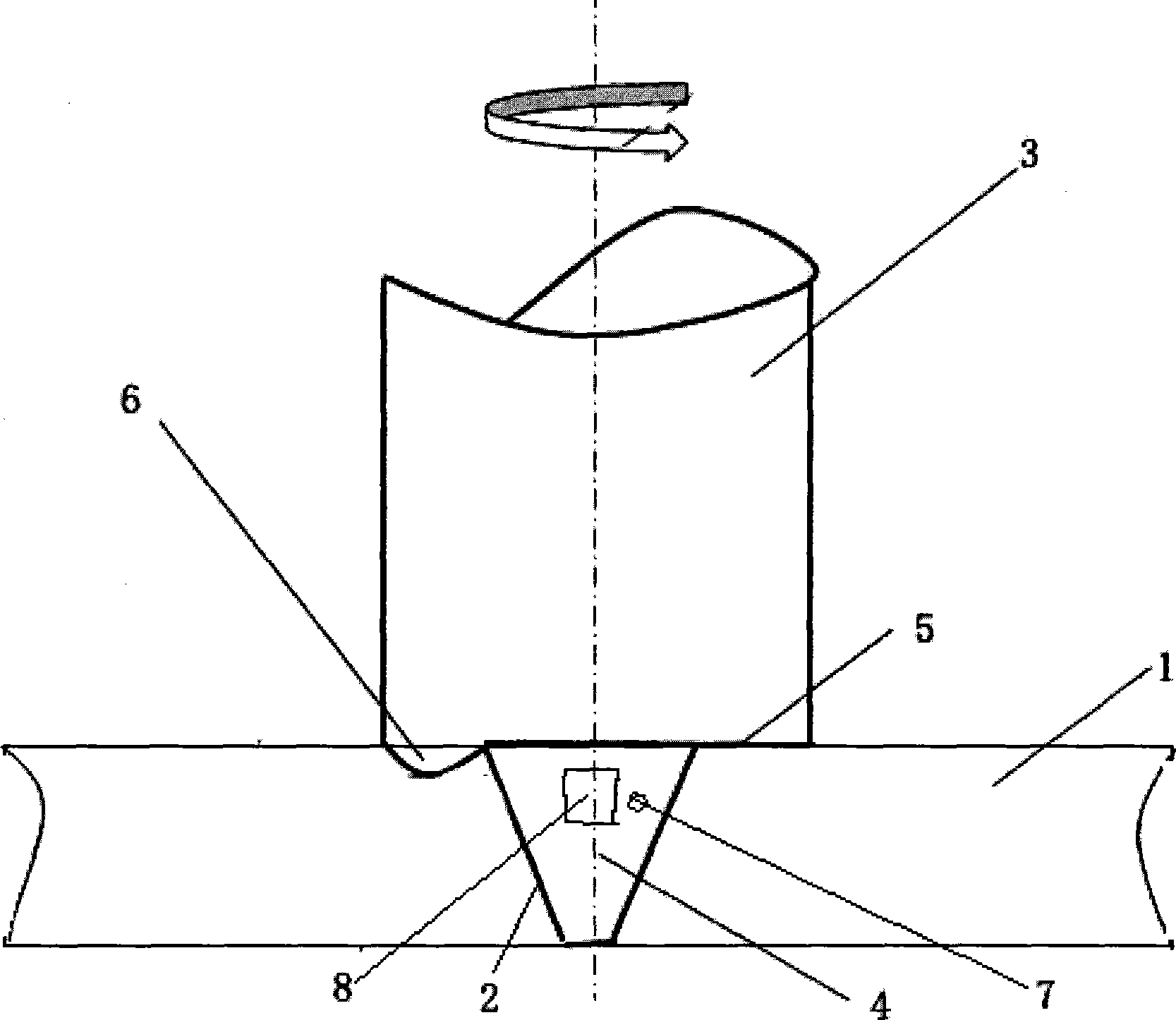

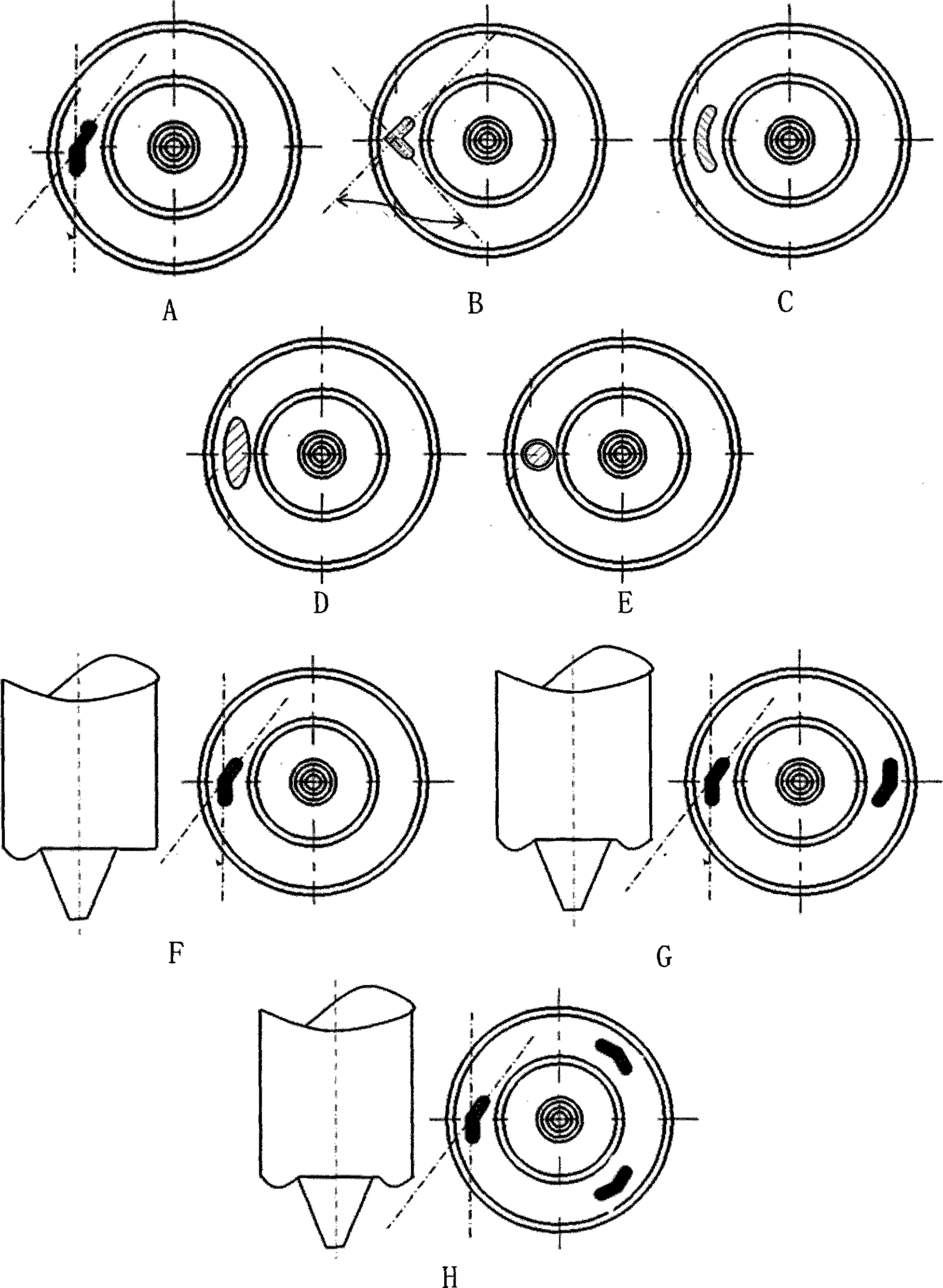

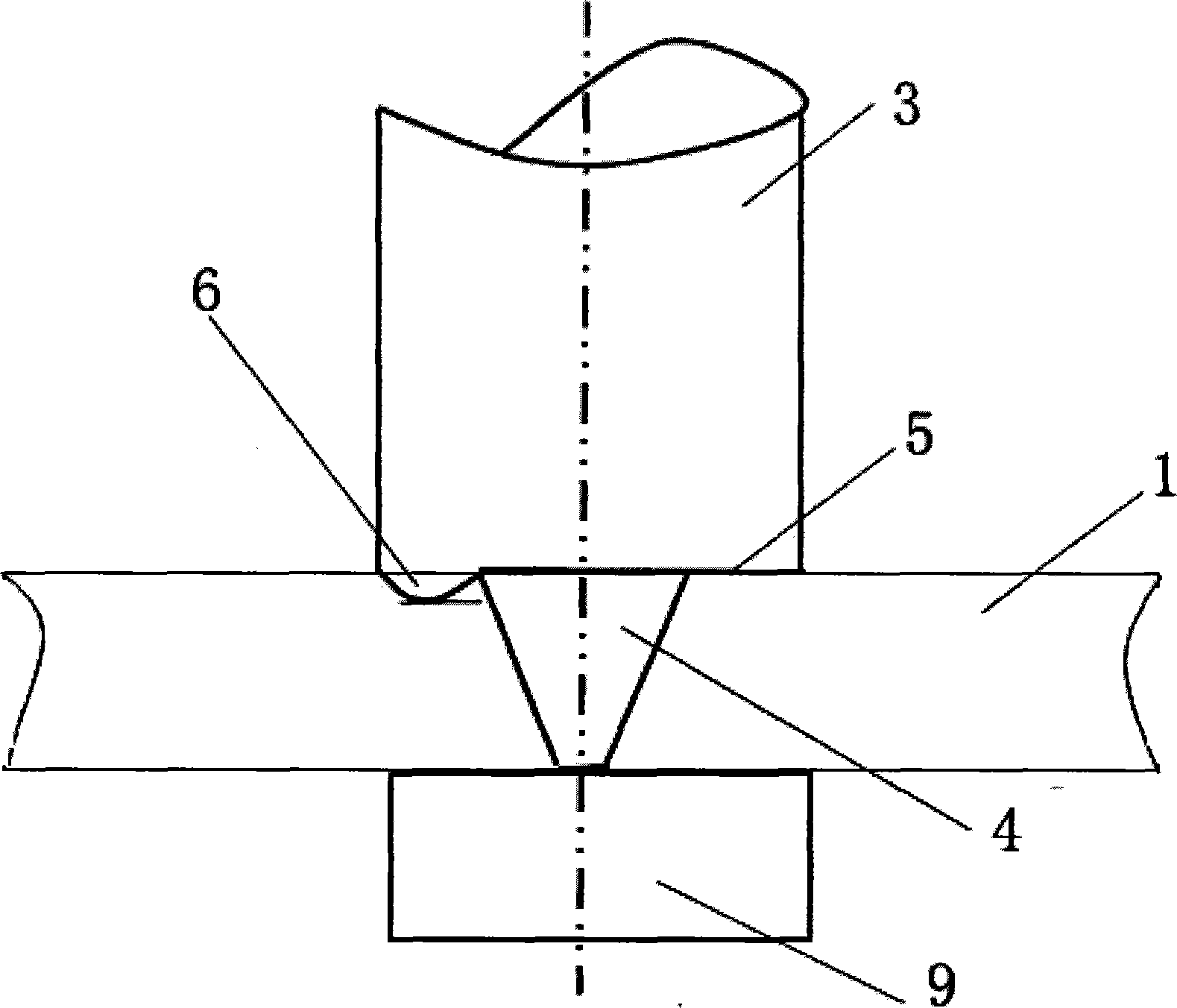

ActiveCN104014926AReduce complexityDecrease productivityNon-electric welding apparatusFriction weldingWeld seam

The invention relates to the technical field of welding, in particular to an aclinal self-upsetting, stirring and friction welding method and tool. The tool comprises a stirring head and a stirring needle, the stirring head is of a hollow structure, the stirring needle is rotatably arranged in the hollow structure of the stirring head and can stretch and retract in the stirring head, the axis of the stirring head and the axis of the stirring needle are overlapped, a shaft shoulder of the stirring head is provided with a forging boss, and the height of the forging boss is smaller than the height of the stirring portion left after the stirring needle extends out of the stirring head. In the whole welding process, a dip angle adjusting mechanism does not need to be arranged on equipment, complexity of the welding equipment is reduced, the angle between the shaft shoulder of the stirring head and a plane normal of a material to be welded is 0 degree, and accordingly aclinal stirring friction welding is achieved. When an aclinal stirring friction welding technology is adopted in two-dimensional plane welding, the angle of the stirring head does not need to be adjusted at a welding seam corner, welding procedures are reduced, meanwhile, the dip angle adjusting mechanism does not need to be arranged on the equipment, complexity of the welding equipment is reduced, and welding efficiency is improved.

Owner:BEIJING FSW TECH

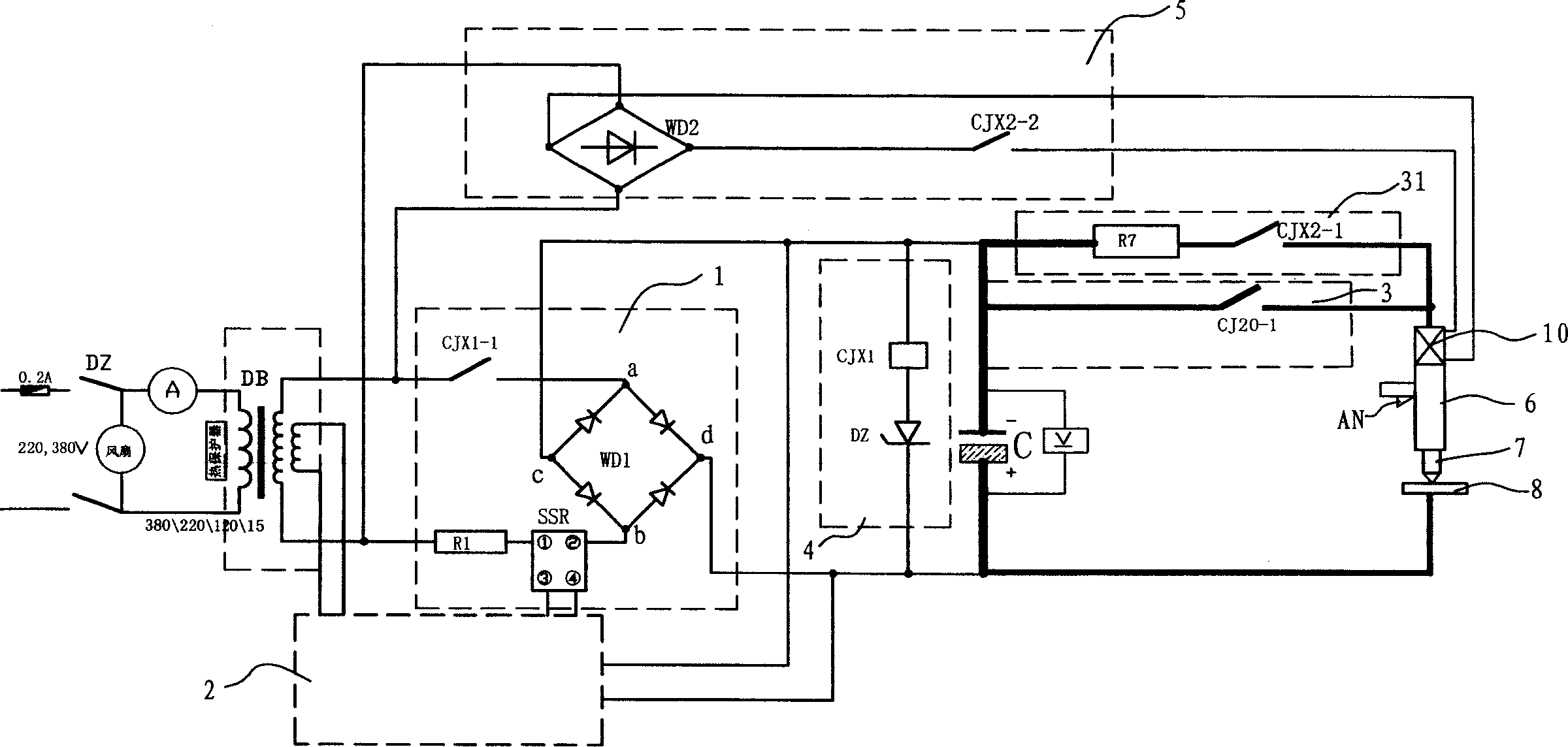

Energy-storage arc pulling type spindle welding machine

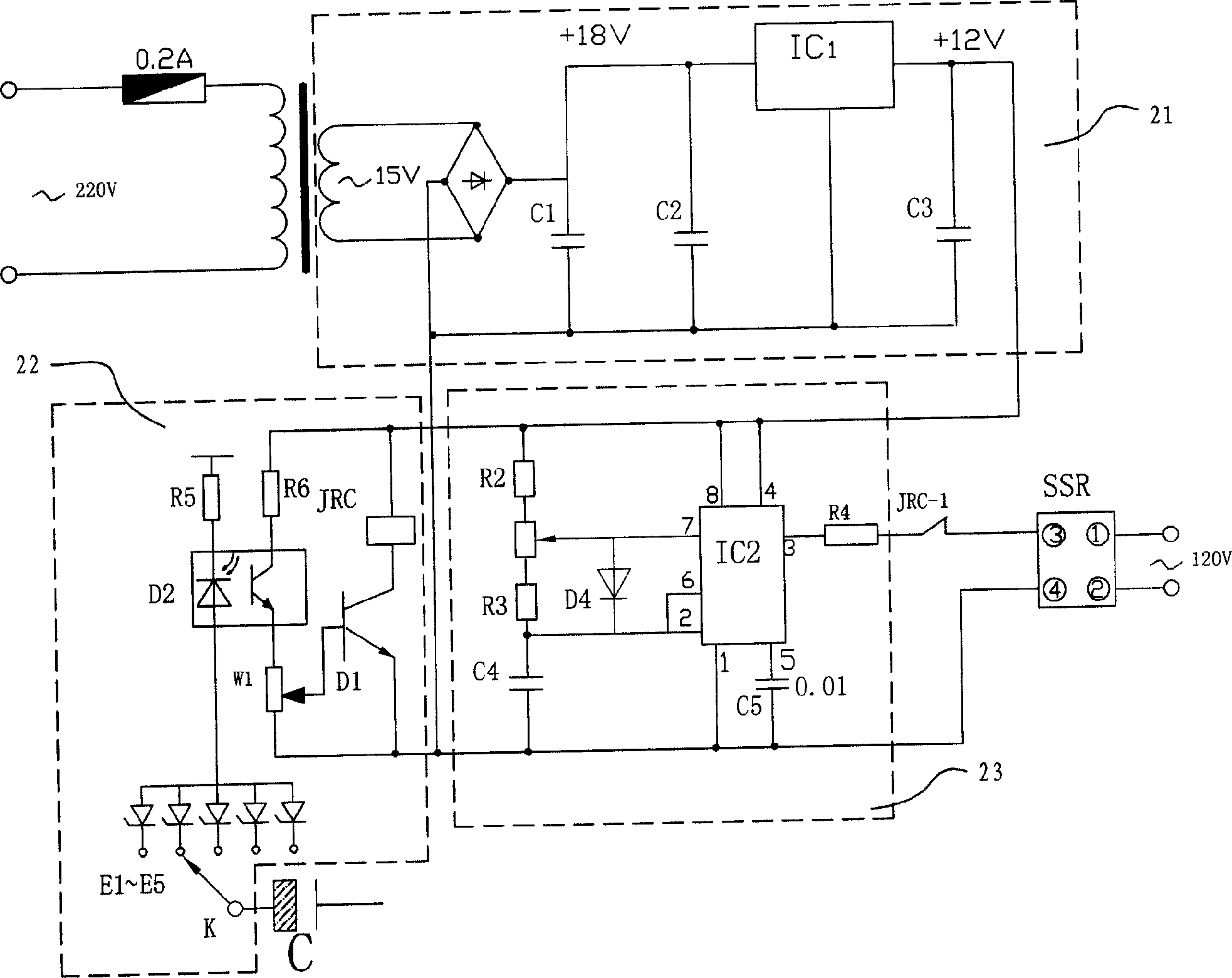

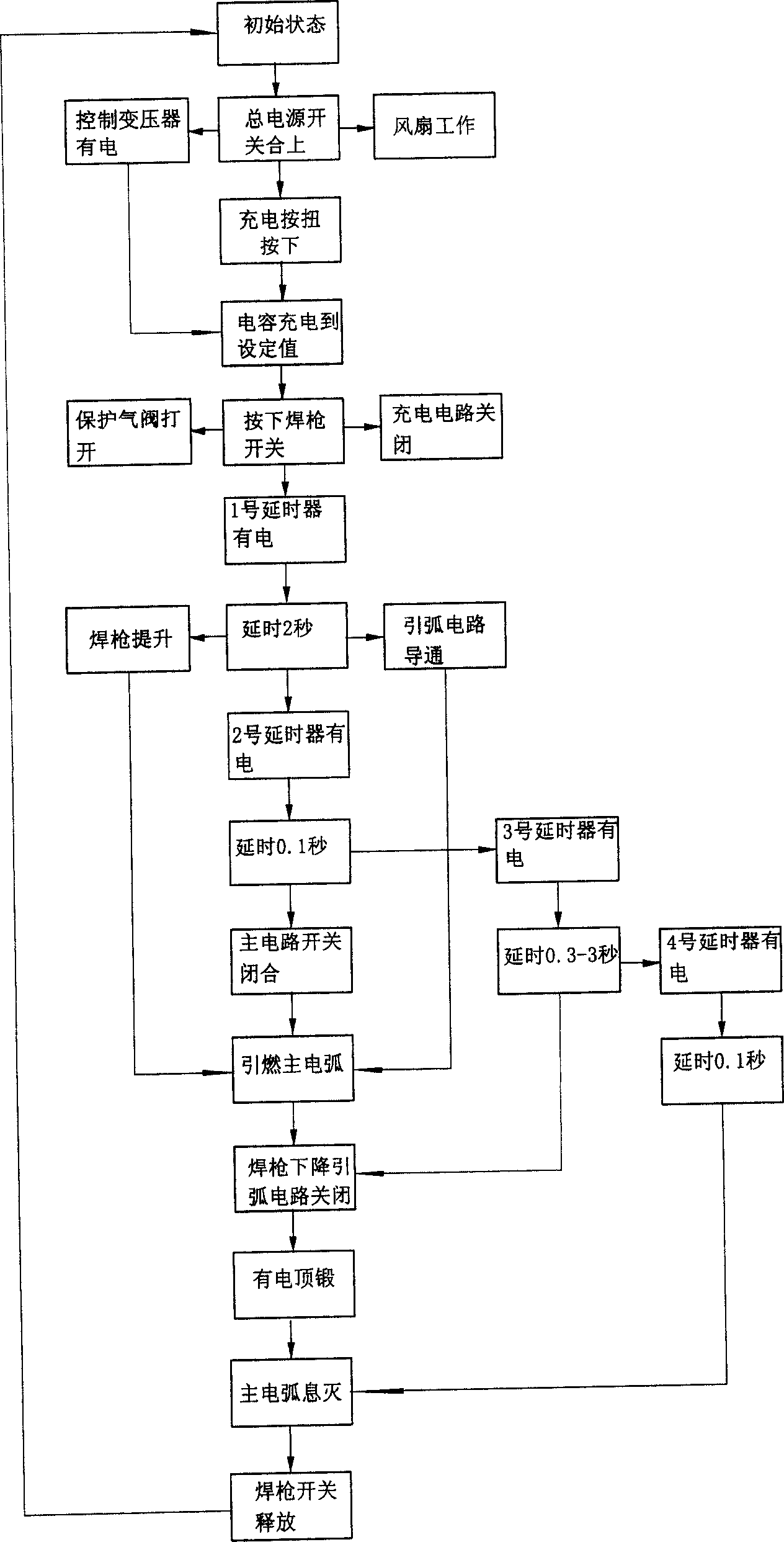

InactiveCN1911585ATo achieve the purpose of weldingDepth of melting layerArc welding apparatusTransformerSupercapacitor

The energy-storing arc type stud welding machine includes a casing, a transformer, a control panel, a welding gun and an inner circuit comprising electric elements. The inner circuit includes a welding gun circuit, a rectifying and charging circuit, a discharging circuit, a control module and an energy storing device. The discharging circuit includes the normally closed contact of the first relay; the energy storing device has super capacitor, which constitutes the charging circuit and the discharging circuit together which other parts; and the control module constitutes the control loop together with the rectifying and charging circuit and the super capacitor. Compared with available technology, the present invention has the advantages of small size, light weight, high welding quality, capacity of connecting external capacitor and low cost.

Owner:俞岳皋

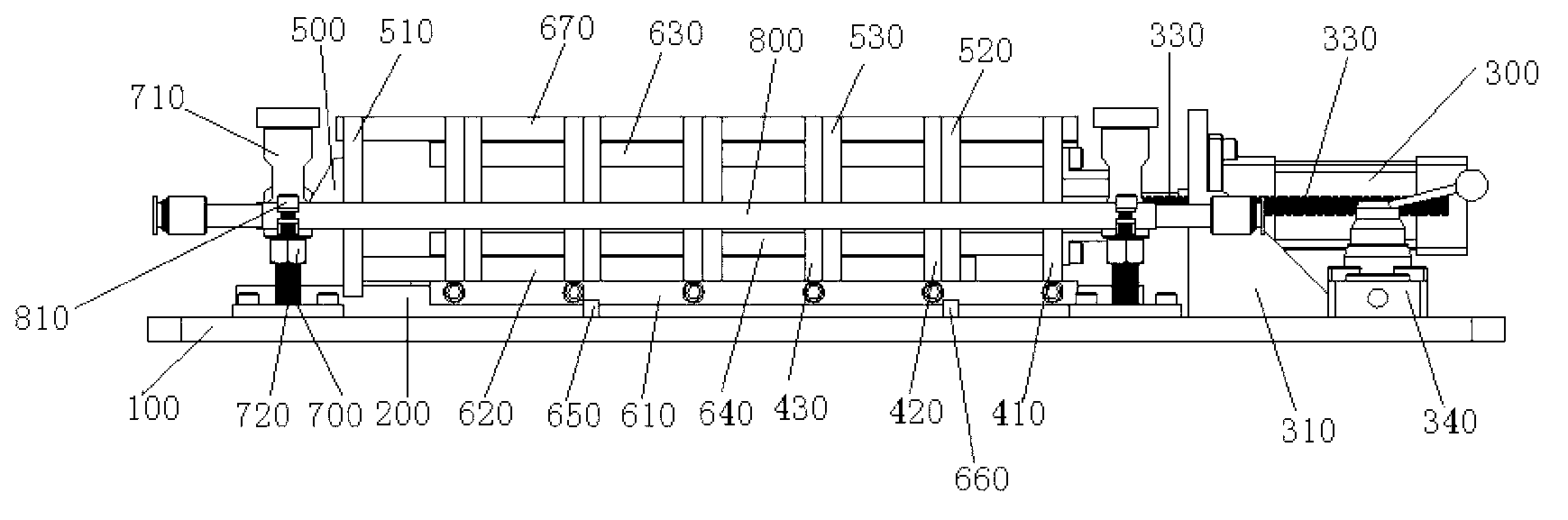

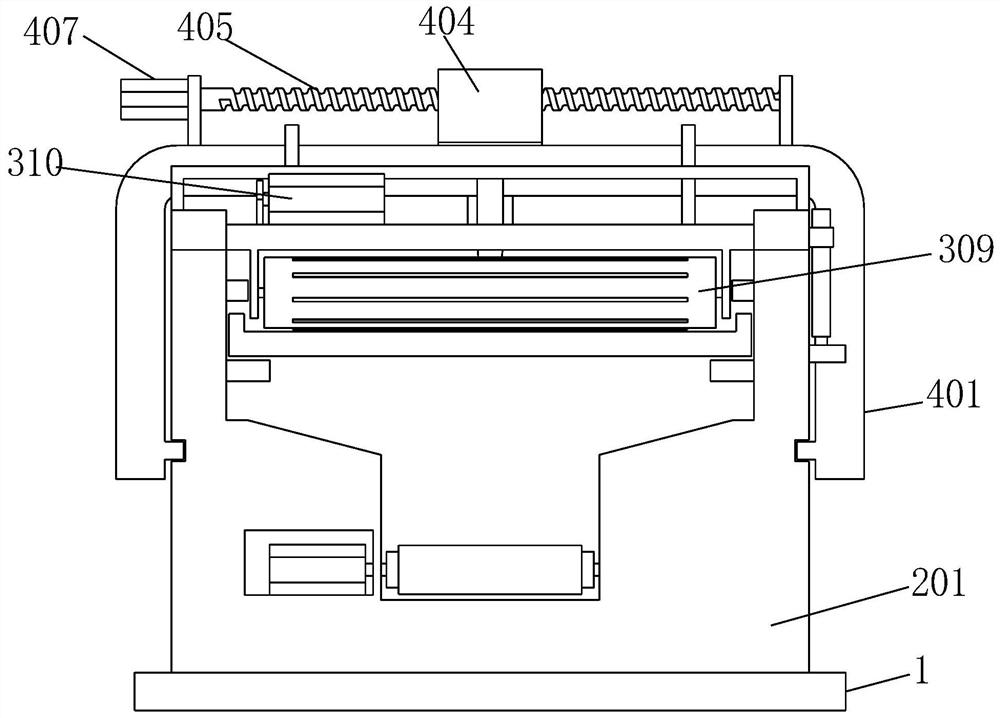

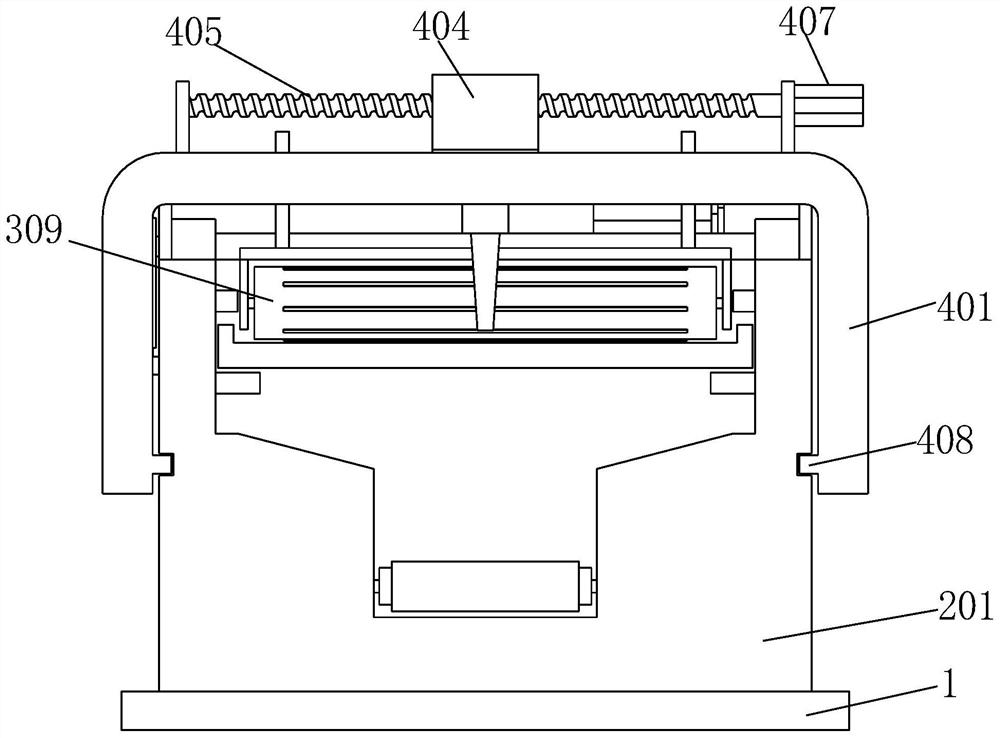

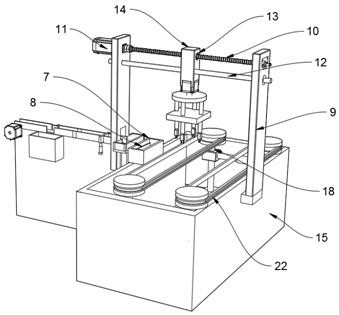

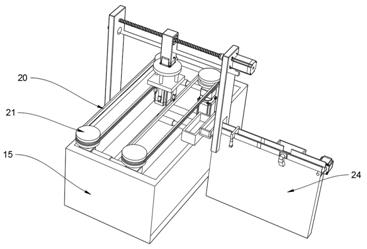

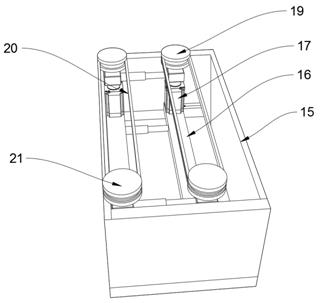

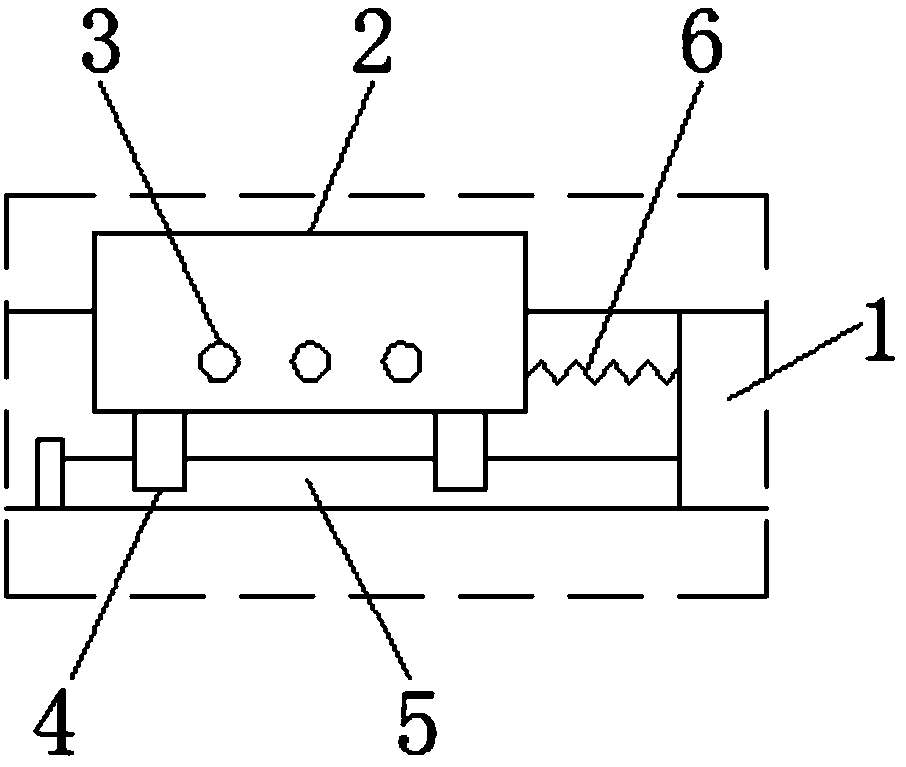

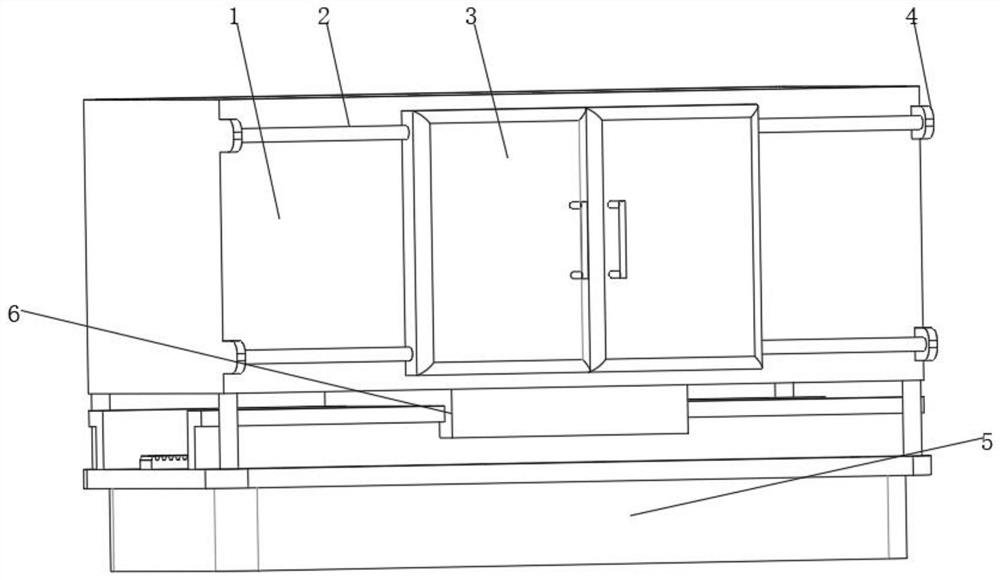

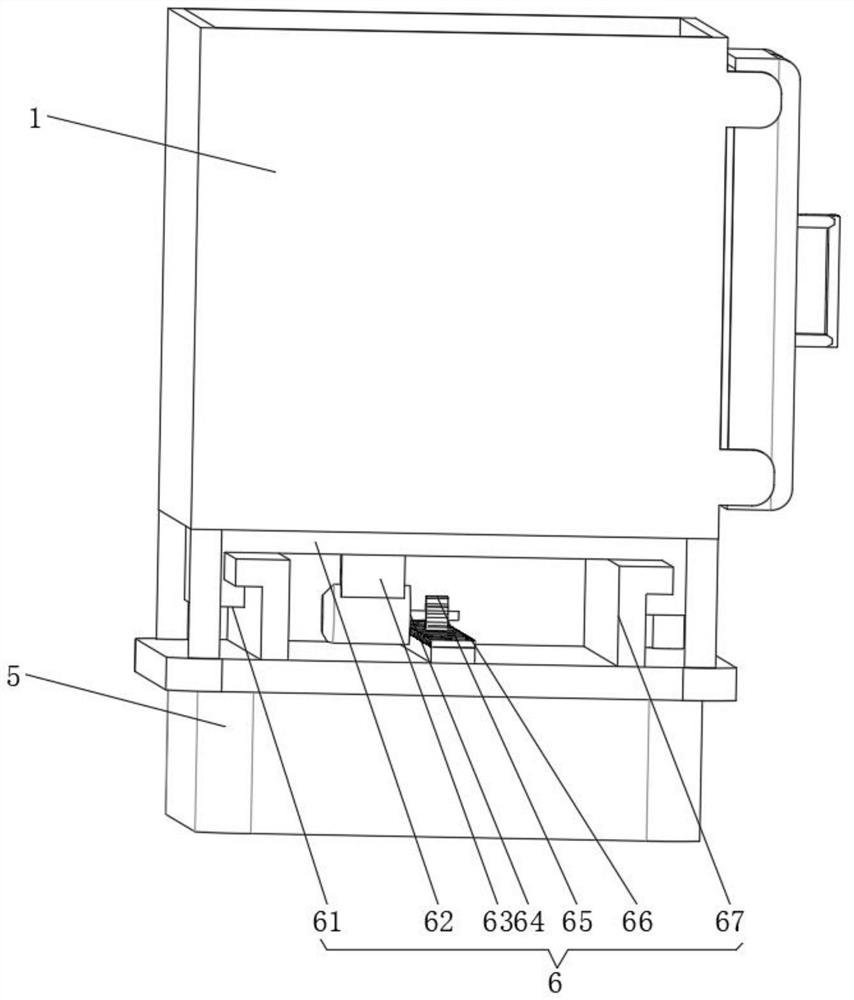

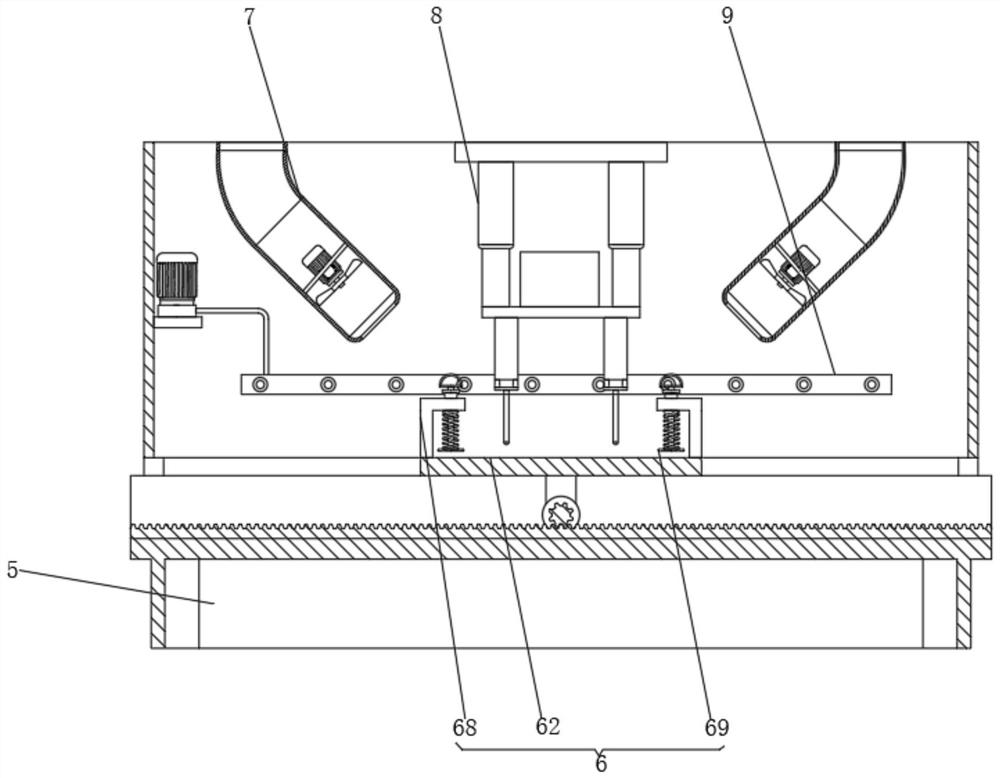

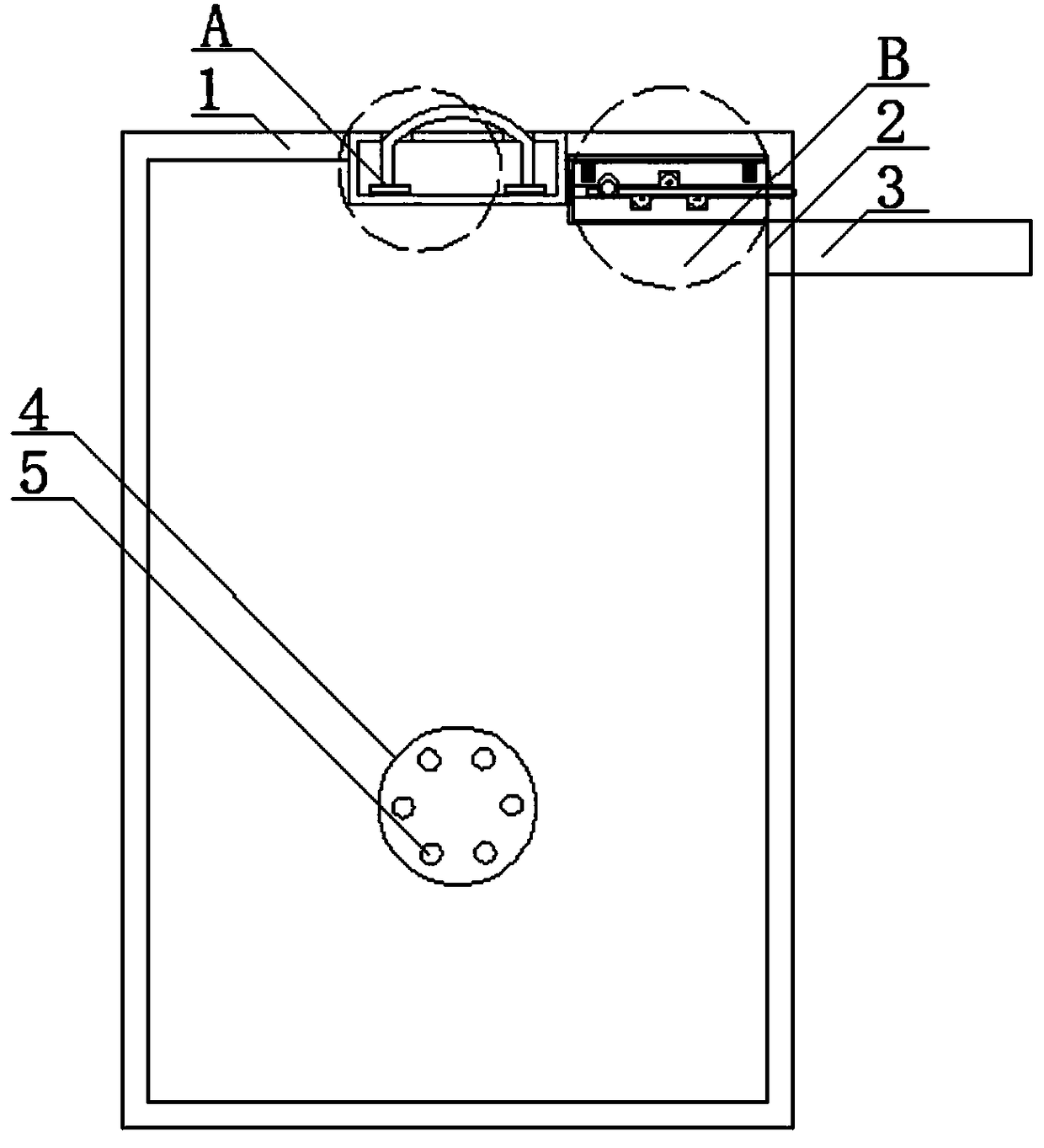

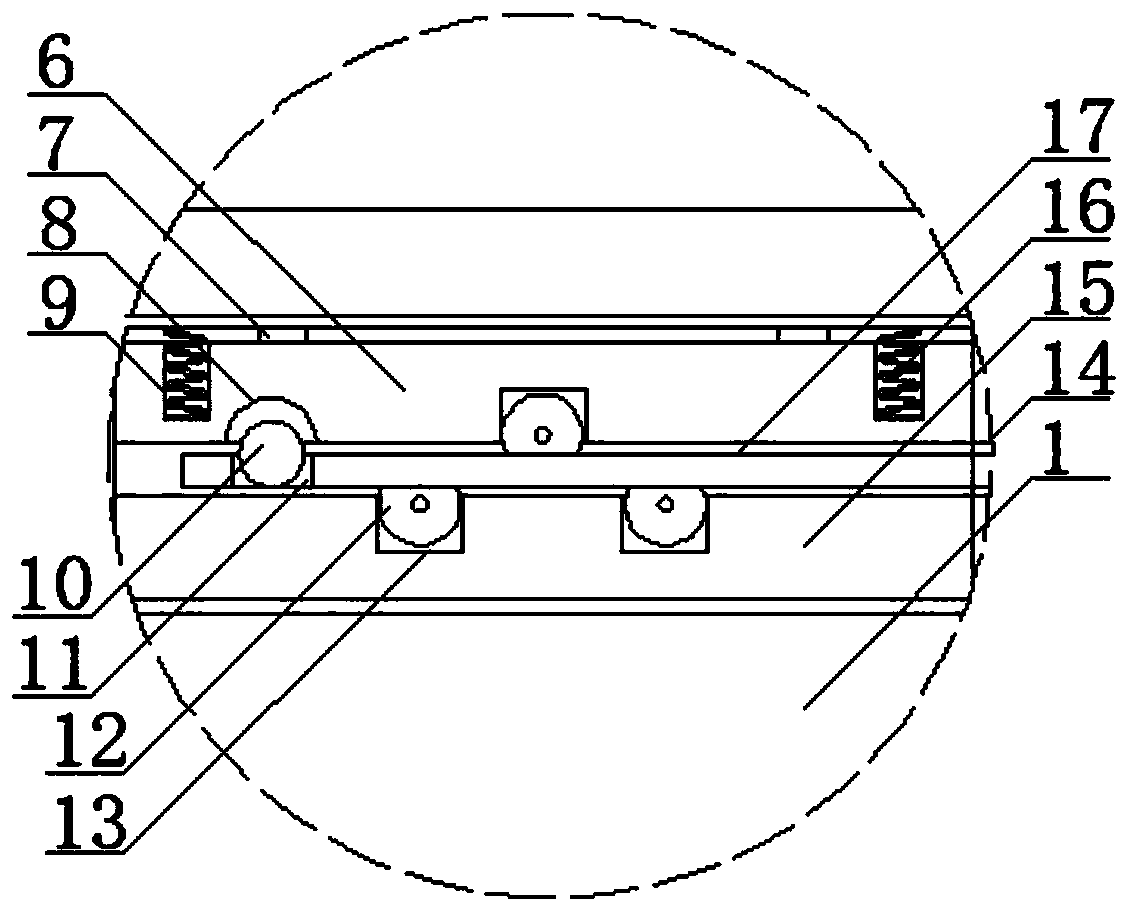

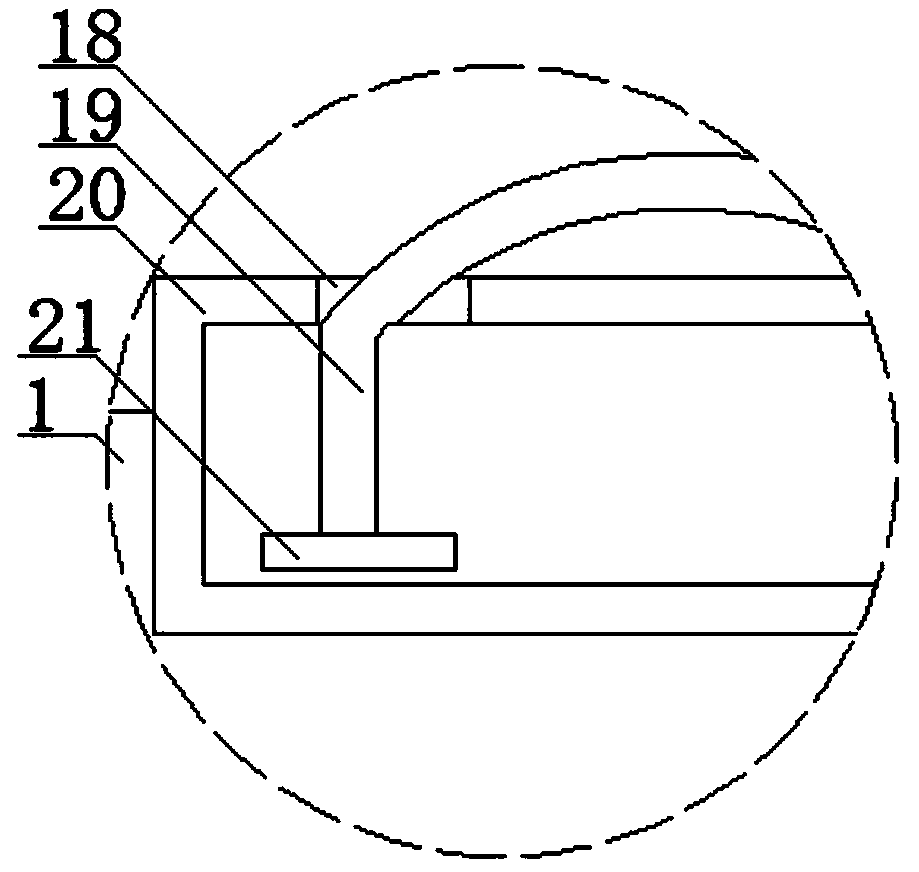

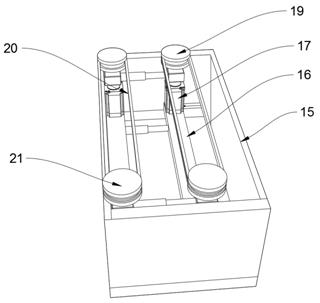

Battery pole group welding device and method

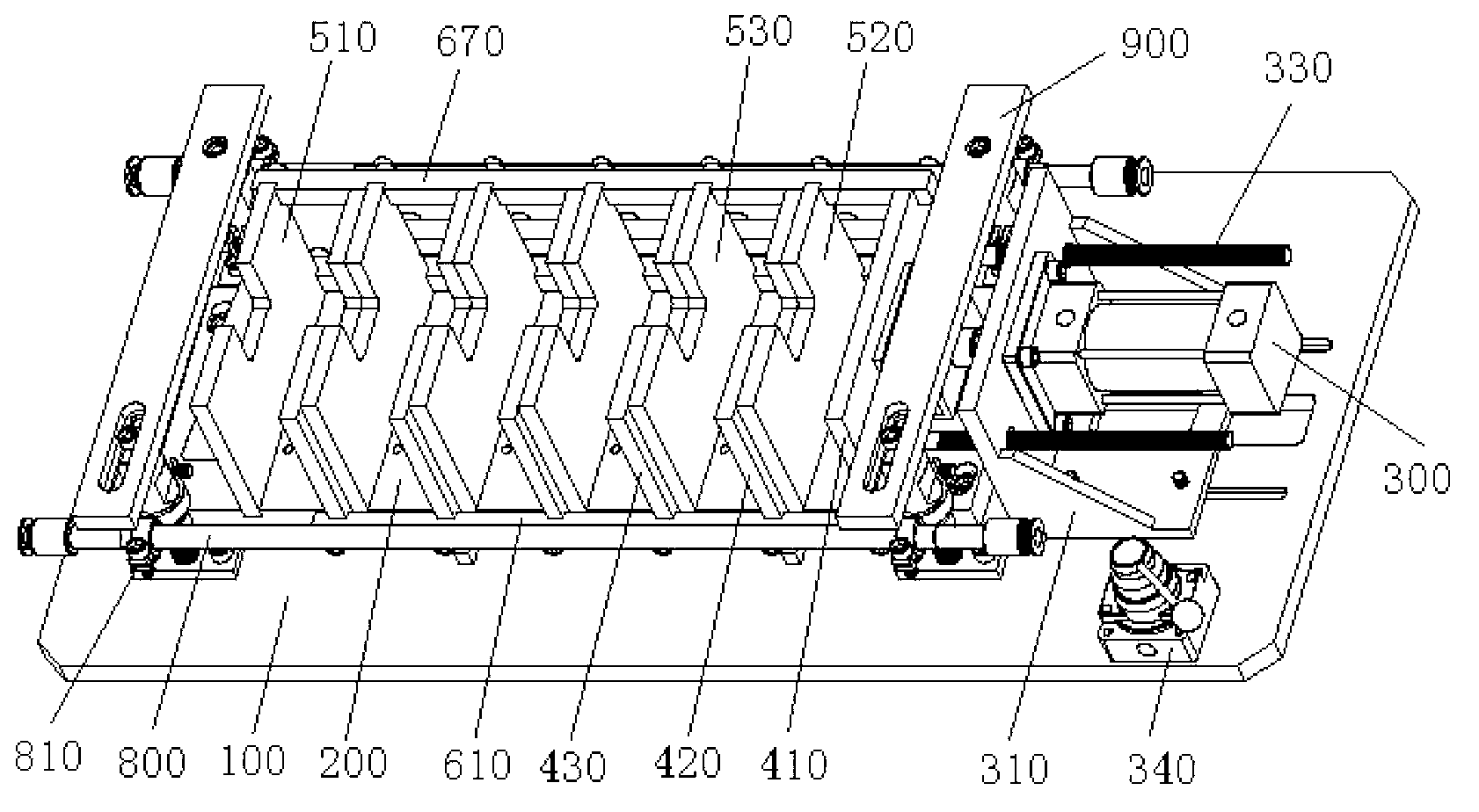

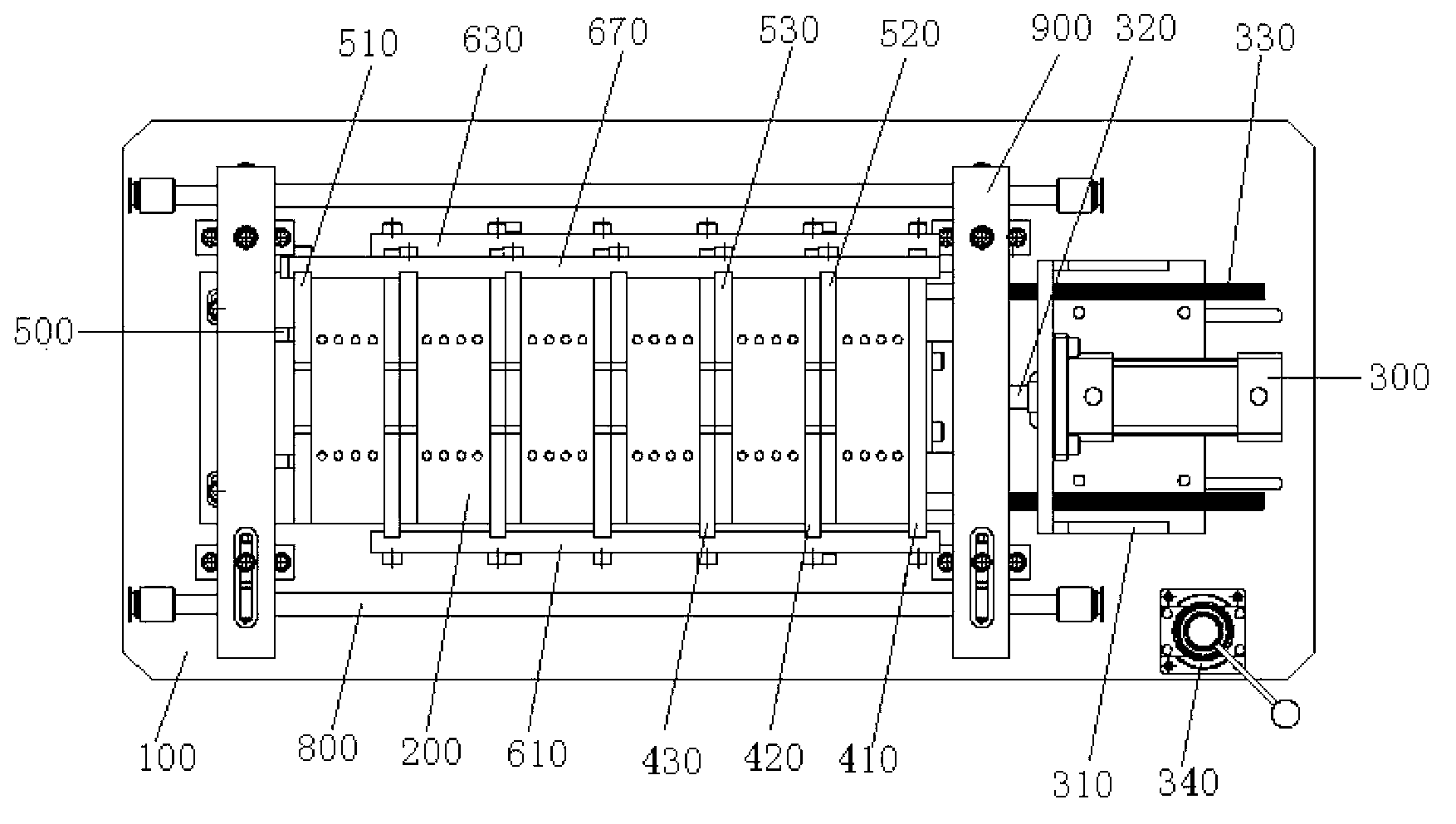

ActiveCN103071884APrevent short circuitsReduce manufacturing costFinal product manufactureWelding/cutting auxillary devicesElectrical batteryEngineering

The invention discloses a battery pole group welding device. The battery pole group welding device comprises a base, a battery pole group clamping mechanism and a pneumatic compressing mechanism, wherein the battery pole group clamping mechanism and the pneumatic compressing mechanism are in driving connection. The battery pole group welding device further comprises a mold box base plate which is arranged on the base, wherein the battery pole group clamping mechanism is arranged on the mold box base plate and comprises a movable side plate group and a fixed side plate group. The invention further discloses a battery pole group welding method. According to the device and the method, a first movable side plate, a second movable side plate, a first fixed side plate and a second fixed side plate which are connected with the pneumatic compressing mechanism are arranged, the first movable side plate is pushed by the pneumatic compressing mechanism, the second movable side plate is driven by the first movable side plate through a first connecting rod, and battery poles and separation plates, which are placed between the movable side plate group and the fixed side plate group are simultaneously compressed, so that the aim that whole groups of battery poles are welded together can be realized.

Owner:ZHAOQING LEOCH BATTERY TECH

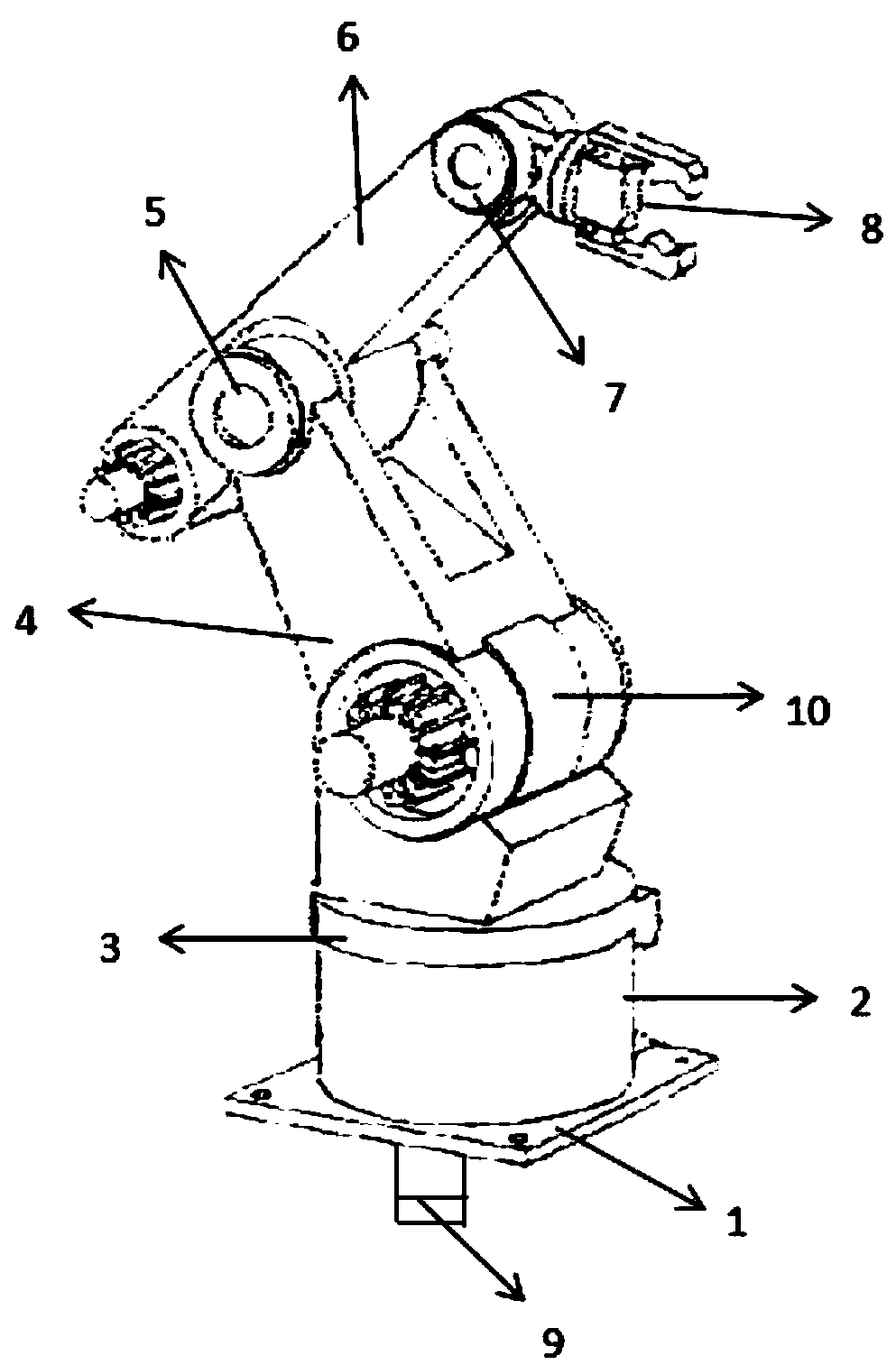

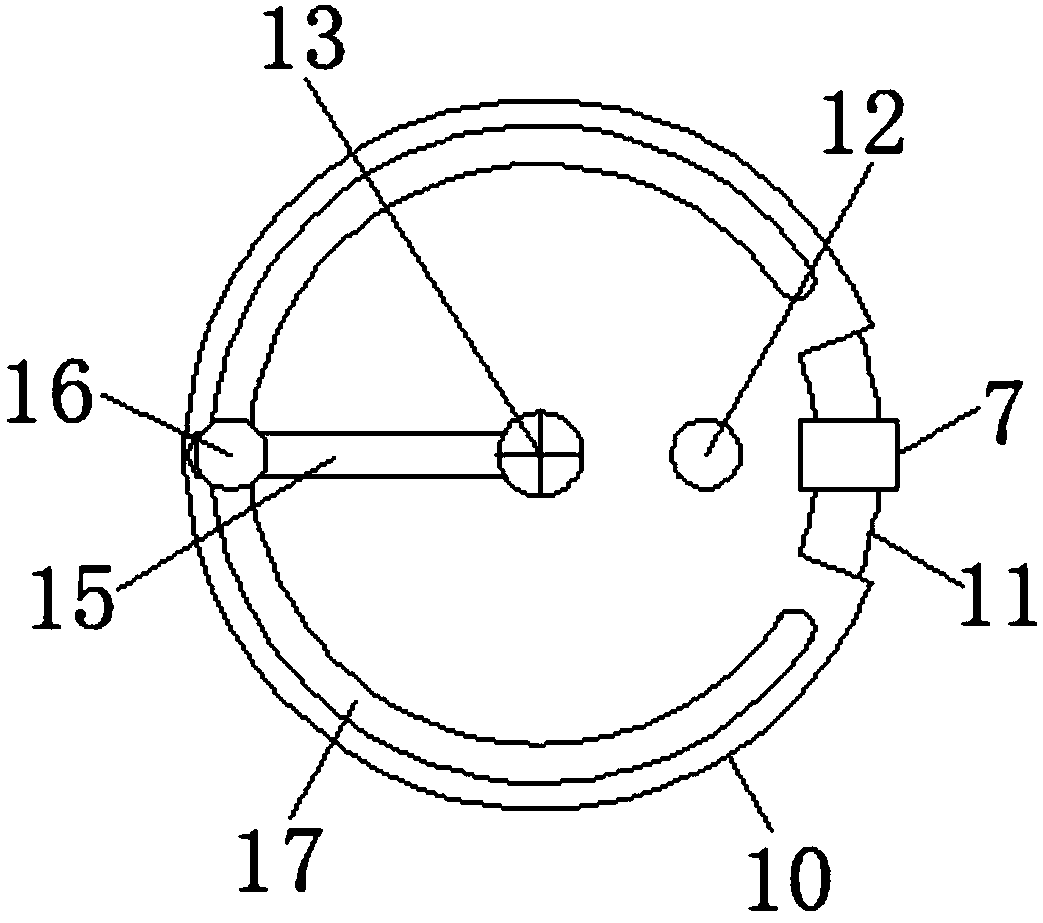

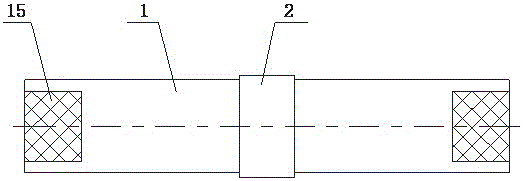

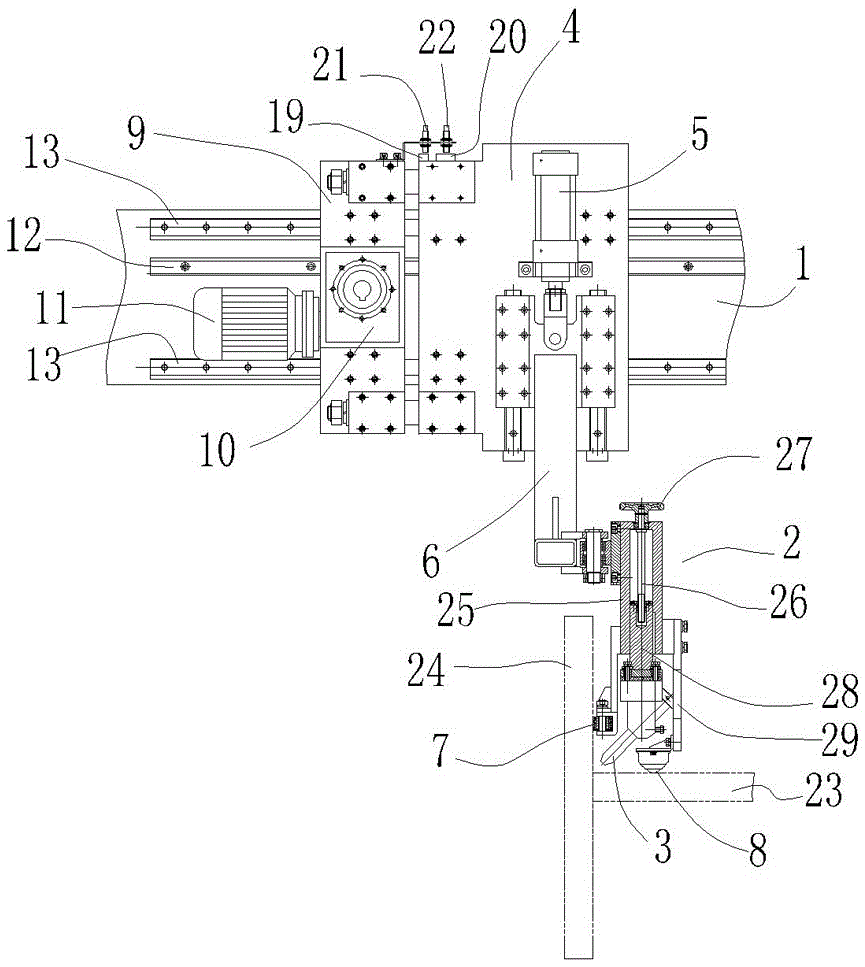

Mechanical arm device is used for automatic welding of stainless steel pipes.

InactiveCN110480225AExpand the scope of operationEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesElectricityControl system

The invention discloses a mechanical arm device is used for automatic welding of stainless steel pipes. The mechanical arm device comprises an input power source, a moving device, an executing arm anda control system, the moving device, the executing arm and the control system are electrically connected with the input power source respectively, the moving device and the executing arm are in meshed connection through a gear, the executing arm is electrically connected with the control system. According to the mechanical arm device, a modern intelligent mechanical technology is adopted, a mechanical arm device capable of moving along the arc-shaped rail and realizing multi-azimuth multi-angle welding operation is designed, a large amount of labor cost and labor are saved, and the productionefficiency is greatly improved.

Owner:富田不锈钢有限公司

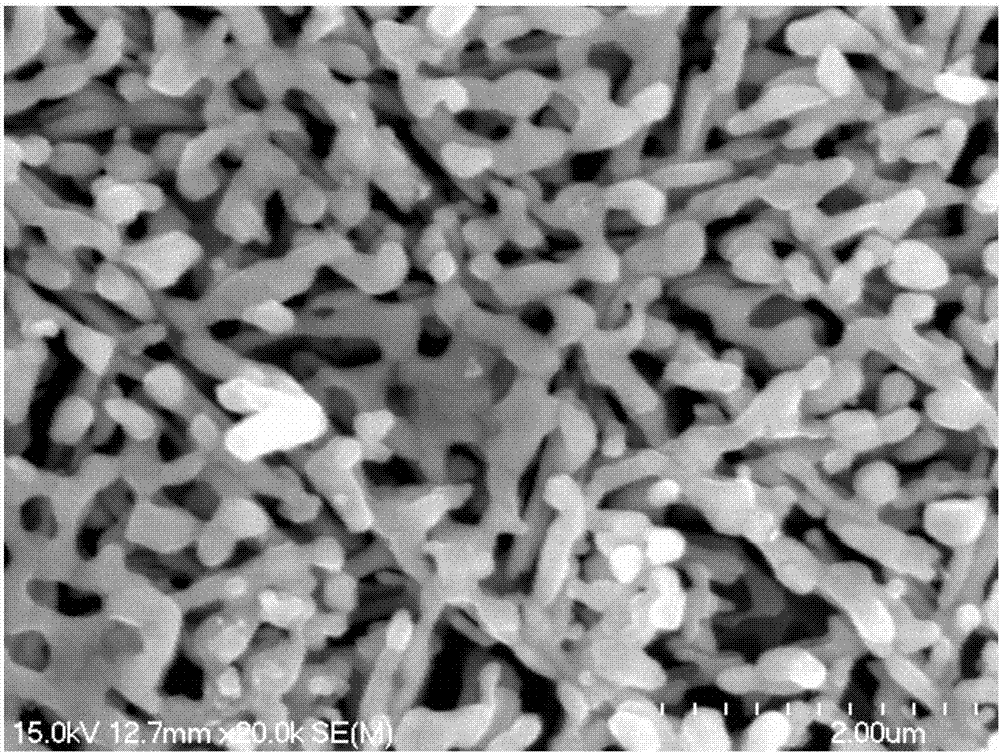

High-temperature brazing filler metal for foam silver filling based on metal tin and preparing method of high-temperature brazing filler metal

InactiveCN107052612ATo achieve the purpose of weldingImprove impact resistanceHot-dipping/immersion processesWelding/cutting media/materialsMetal alloyLiquid metal

The invention provides a preparing method for high-temperature brazing filler metal for foam silver filling based on metal tin. The high-temperature brazing filler metal is a metal sheet formed by filling the foam silver with nanoscale pores through the metal tin, wherein the foam silver piece is obtained by corroding a silver-based metal alloy sheet through a de-alloying method. The foam silver is filled with the liquid metal tin under the capillary action, and preparing of a brazing filler metal sheet is achieved. The brazing filler metal sheet is used for welding so that low-temperature (240 DEG C) welding can be achieved, welding points can bear the high-temperature (480 DEG C) service, welding point reliability and weld joint stability are greatly improved, and the preparing method can be widely applied to various high-temperature welding fields.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

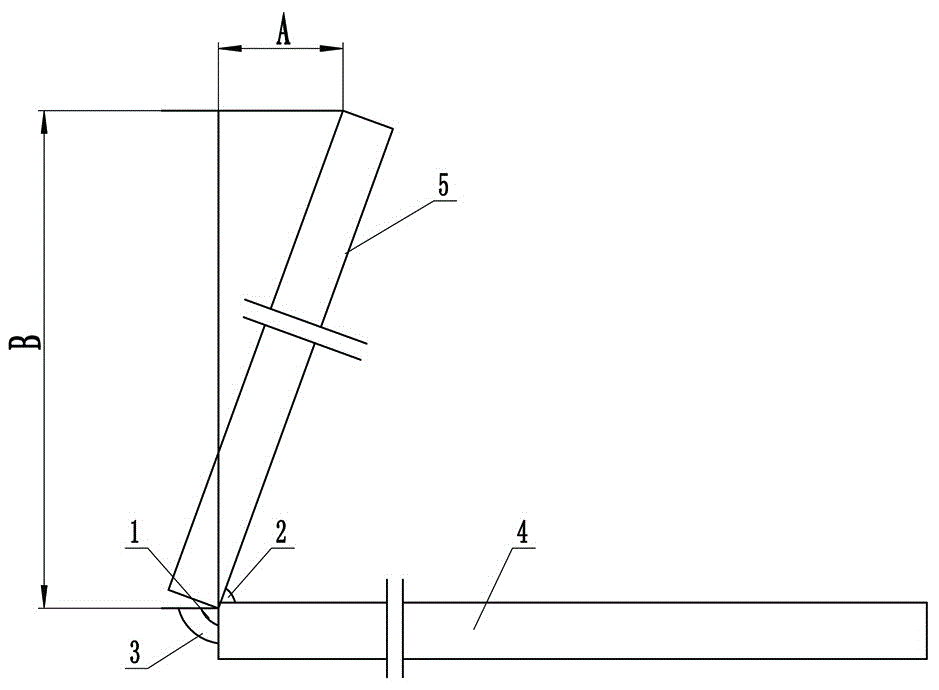

Assembling welding method of side guard plate of hydraulic support

ActiveCN105921861ASmall overall deformationTo achieve the purpose of weldingArc welding apparatusStructural engineeringProduction quality

The invention provides an assembling welding method of a side guard plate of a hydraulic support. The side guard plate of the hydraulic support comprises a side plate and a top plate. The assembling welding method comprises the following steps: measuring the width of the top plate, and determining reverse deformation according to the width; enabling the bottom of the top plate to be in contact with the side plate; obliquely moving the top of the top plate to change the reverse deformation; and then welding three welded joints along a part, which is in contact with the top plate, of the side plate, and naturally cooling after welding is finished, wherein the top plate deforms along the side plate so that the top plate is perpendicular to the side plate. The assembling welding method of the side guard plate of the hydraulic support has the advantages of scientific design, simplicity in operation, low production cost, reliable production quality and small deformation after welding.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

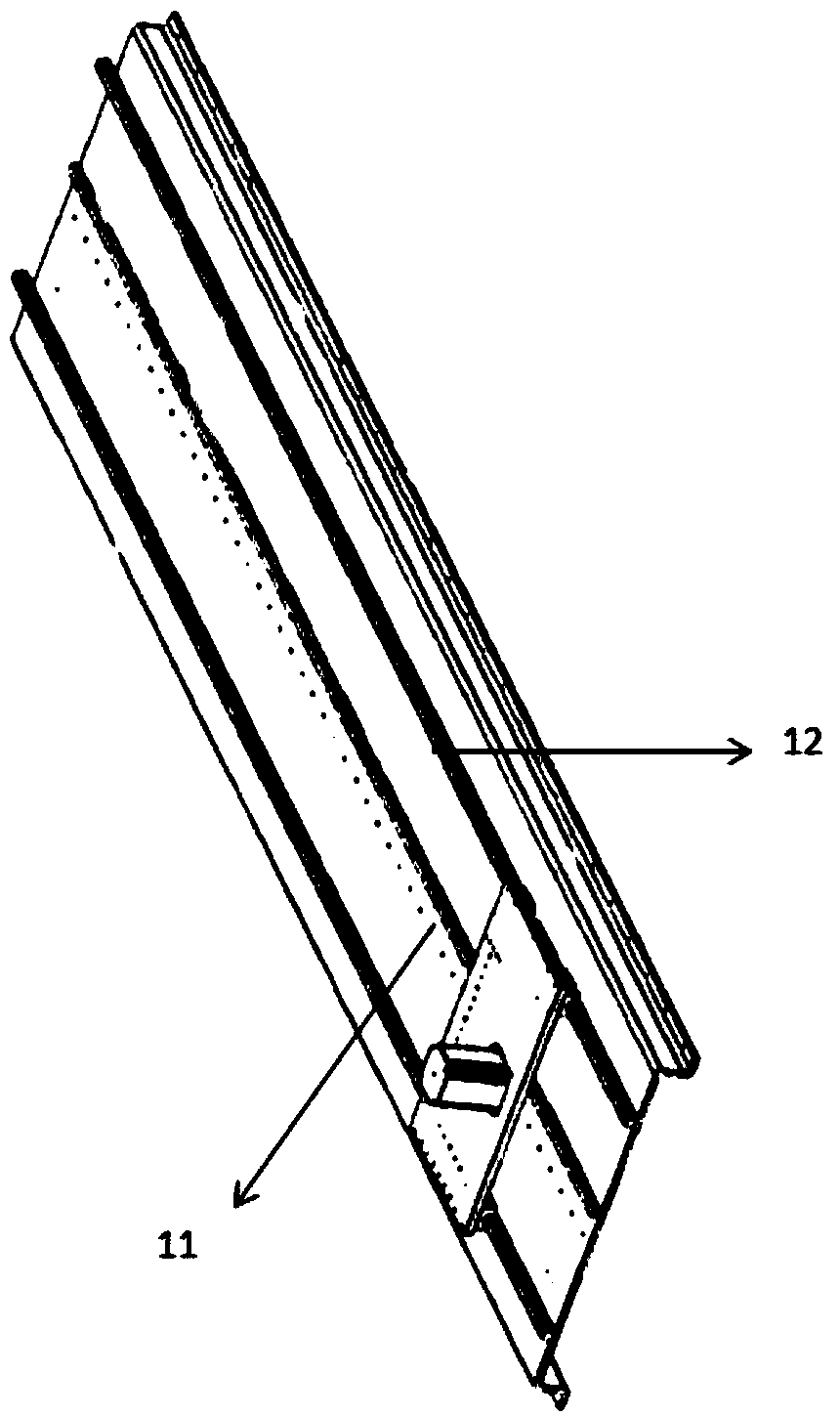

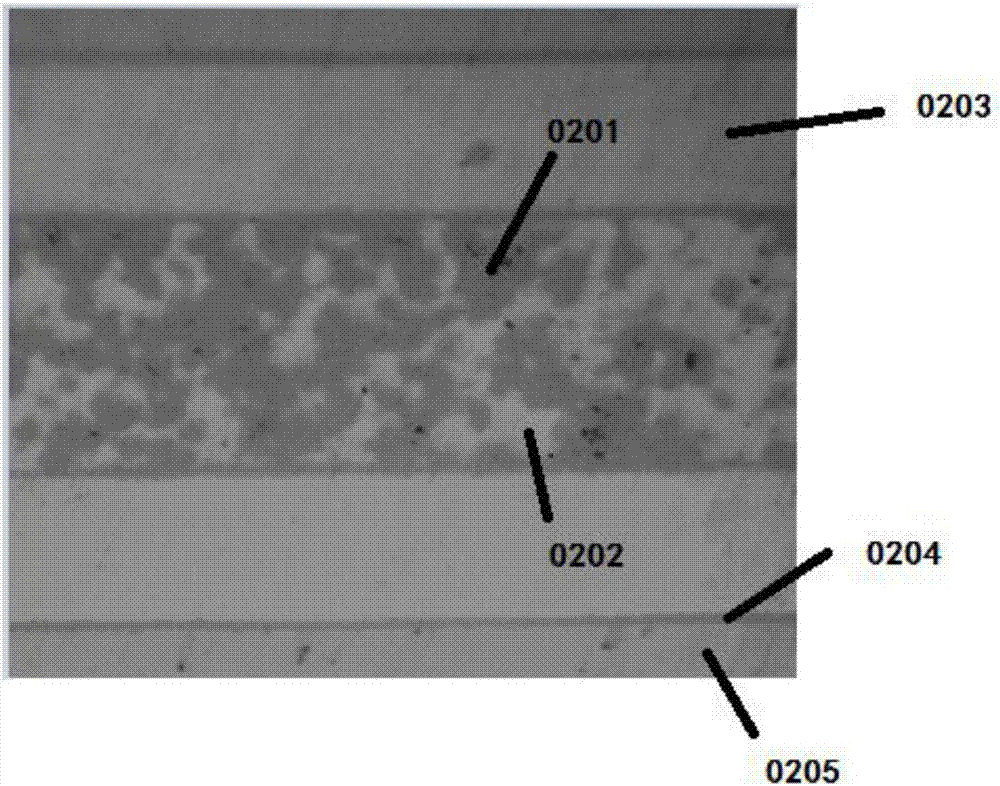

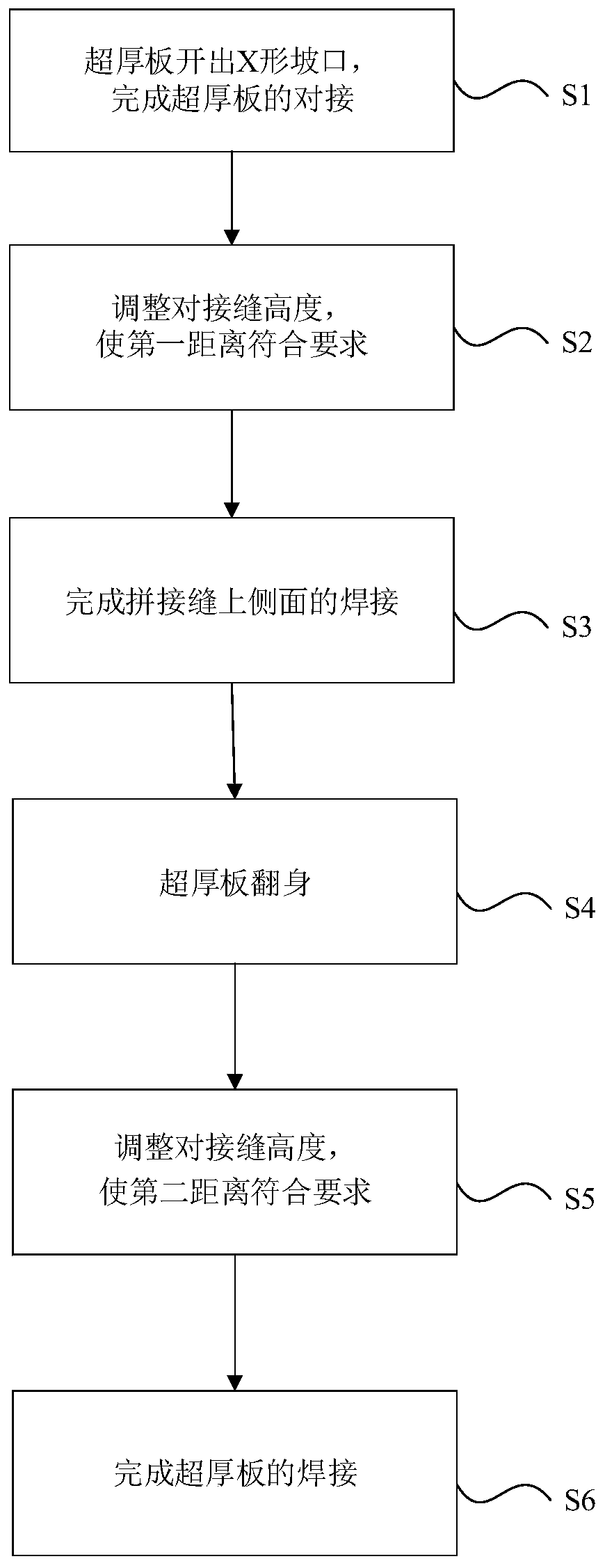

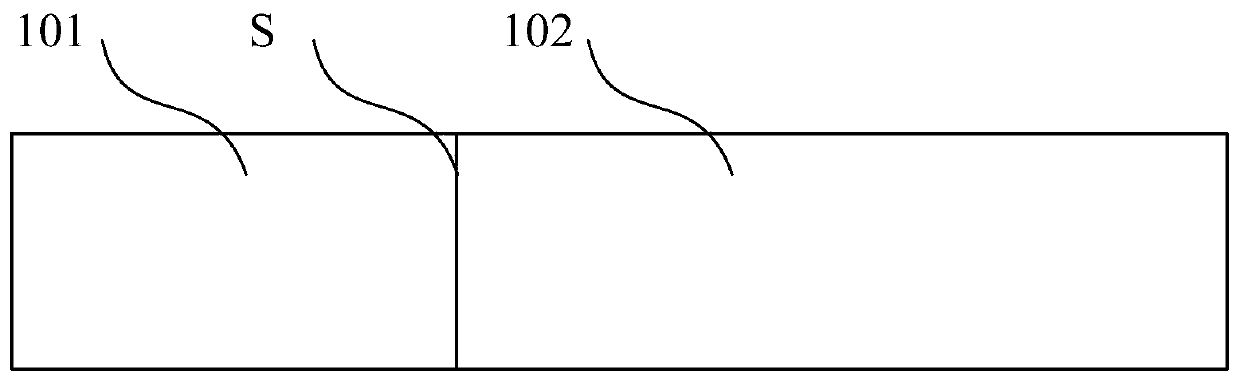

Super-thick plate splicing method

InactiveCN109986226APrevent movementControl post-weld deformationWelding apparatusThick plateButt joint

The invention discloses a super-thick plate splicing method. The method comprises the following steps that S1, an X-shaped notch is formed in super-thick plates, and butt-joint of the super-thick plates is completed; S2, the splice joint height is adjusted, and a first distance is made to meet requirements; S3, welding on the upper side surface of a splice joint is completed; S4, the super-thick plates are overturned; S5, the splice joint height is adjusted, and a second distance is made to meet requirements; and S6, welding on the super-thick plates is completed. According to the super-thickplate splicing method, by propping up the splice joint, the thicknesses of the super-thick plates are adjusted, different reverse deformation heights are arranged for different super-thick plates, andpre-set reverse deformation is adsorbed by heat shrinkage produced after welding. Meanwhile, pressing blocks are used for pressing the super-thick plates after the super-thick plates are overturned,and post welding deformation is further controlled. According to the super-thick plate splicing method, on the premise that the welding quality of the super-thick plates is guaranteed, the purpose that welding can be completed after the super-thick plates are overturned for one time is achieved, the splicing time is saved, and the splicing cost for the super-thick plates is lowered.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

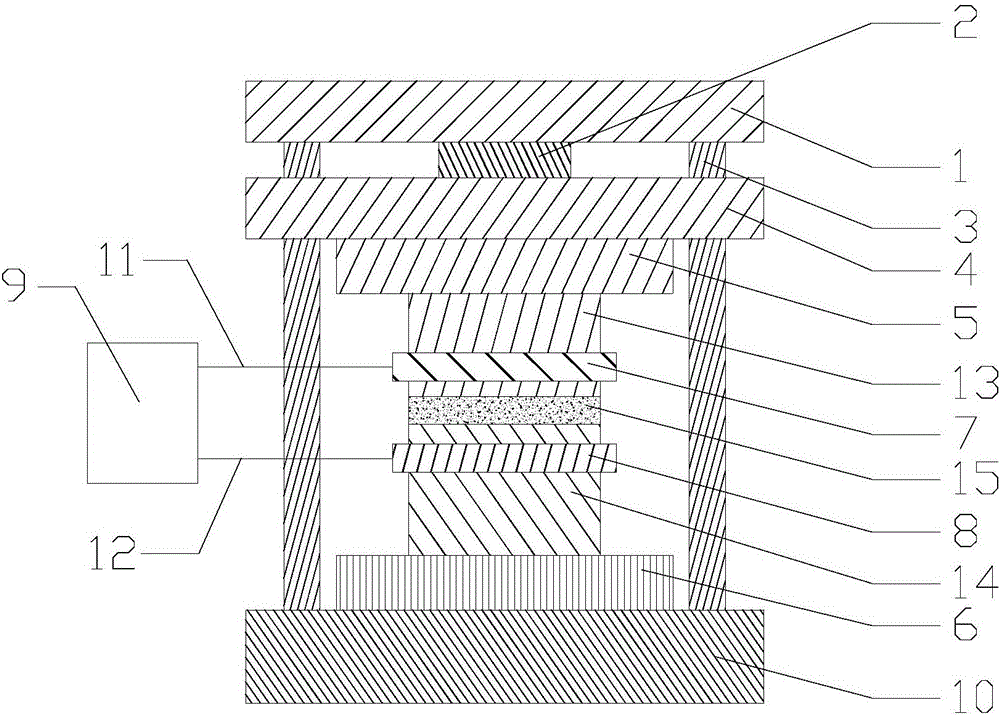

Pulse current auxiliary self-resistance heating device and method for partial quick brazing by utilizing same

ActiveCN106312218APrevent leakageGuaranteed accuracyHeating appliancesPulse power supplyPartial heating

The invention provides a pulse current auxiliary self-resistance heating device and a method for partial quick brazing by utilizing the same, relates to a heating device and a method for quick brazing by utilizing the heating device, and aims to solve the problems that during existing welding, a base material and brazing filler metal need to be heated integrally, the energy consumption is high, the heating range is large when partial heating is performed, and a temperature field is uneven. The device comprises a press machine upper plate, a press machine main cylinder, two press machine guide rails, a press machine sliding block, a first ceramic insulating plate, a second ceramic insulating plate, a first electrode, a second electrode, a pulsed power supply, a press machine platform, a first wire and a second wire. The method comprises the steps of adjusting the press machine sliding block to press a first welding base body, the welding brazing filler metal and a second welding base body; causing the pulsed power supply to supply power to the first electrode and the second electrode, heating an area between the first electrode and the second electrode, applying pressure, maintaining the pressure, and performing welding. The device is suitable for partial quick brazing.

Owner:哈尔滨宇航精创科技有限公司

Welding device for steel structure

ActiveCN112958968ATo achieve the purpose of weldingEasy to useEdge grinding machinesWelding/cutting auxillary devicesHydraulic pressureWelding

The invention relates to the technical field of steel structure welding devices, and discloses a welding device for a steel structure. The welding device for the steel structure comprises a bottom plate, wherein a supporting mechanism is fixedly mounted at the top of the bottom plate, and comprises a base; limiting grooves are formed in the two sides of the base; a material groove is formed in the middle of the base; a grinding mechanism is arranged in front of the top of the base; a welding mechanism is arranged behind the top of the base; and the two limiting grooves penetrate through the front end and the rear end of the base. According to the welding device for the steel structure provided by the invention, sliding rods and compression springs are arranged on the two sides of a moving plate, a triangular plate is arranged on the right side of the moving plate, when the grinding mechanism operates and a grinding roller grinds a steel component, a second hydraulic push rod pushes the triangular plate to ascend, then the triangular plate is in sliding connection with a cylinder, then the moving plate compresses the compression springs to the bottom, then the compression springs push the moving plate through elastic force, and the process is repeated, so that the grinding roller can quickly grind the steel component to be flat.

Owner:浙江浙建钢结构有限公司

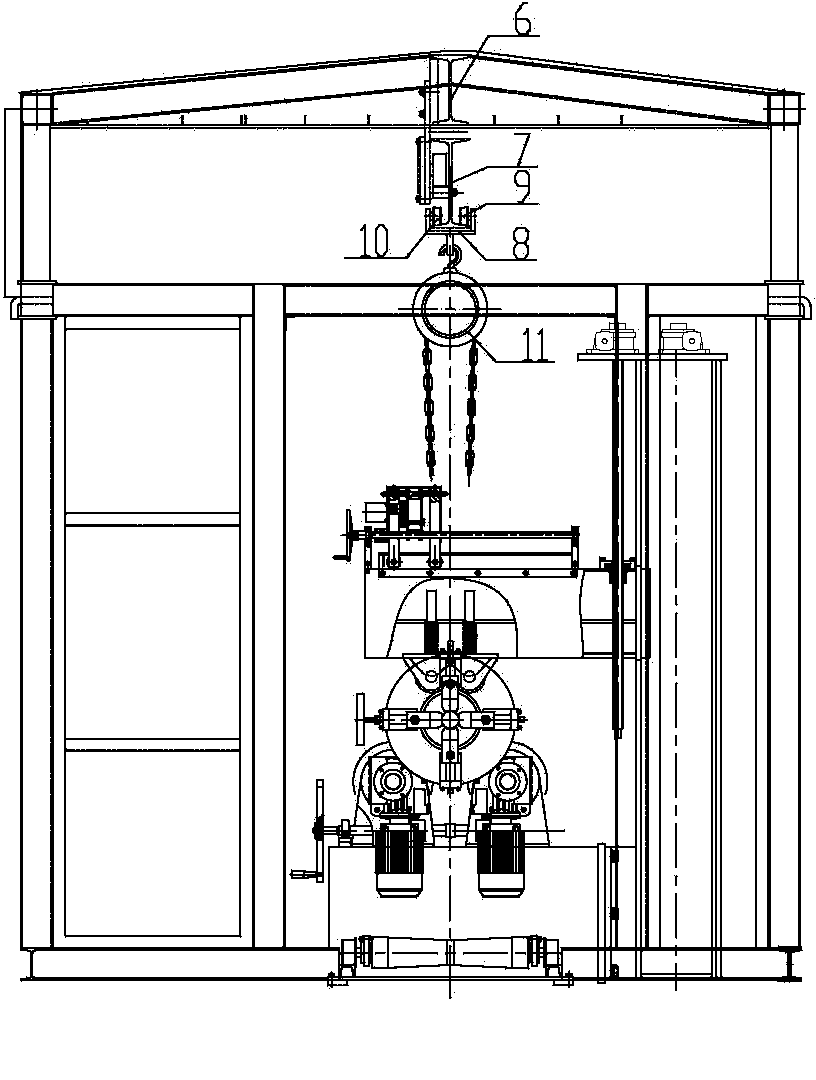

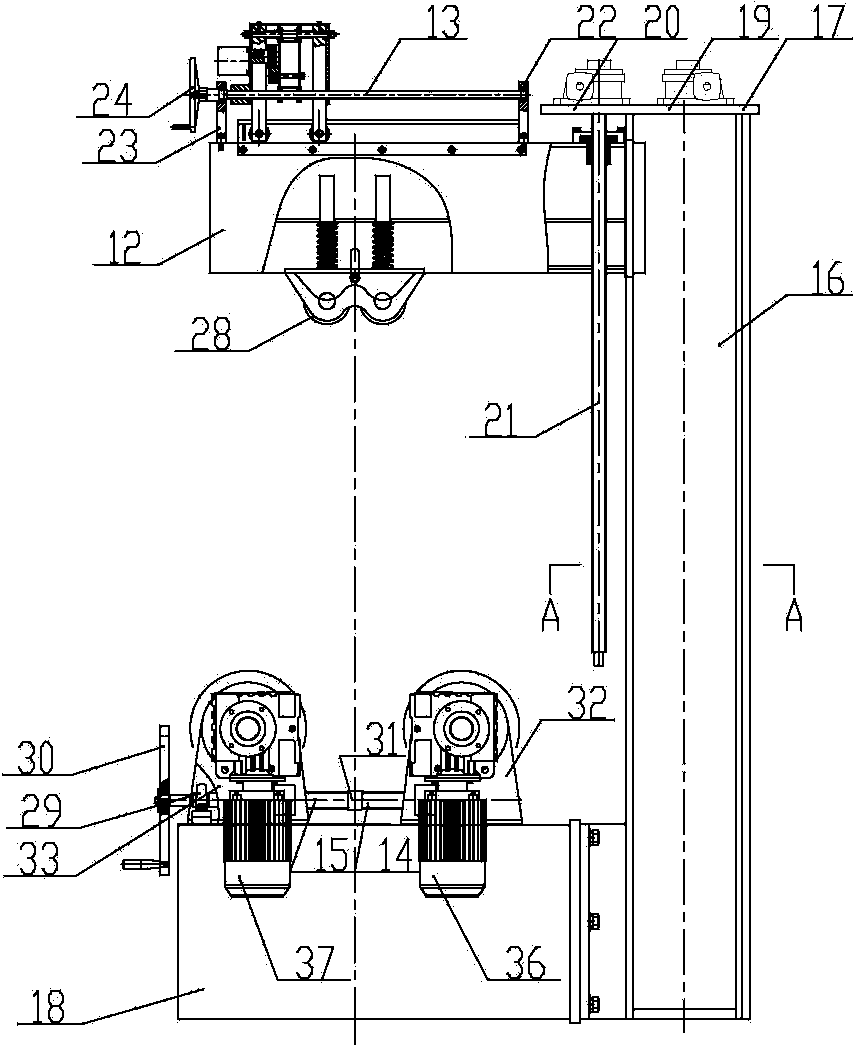

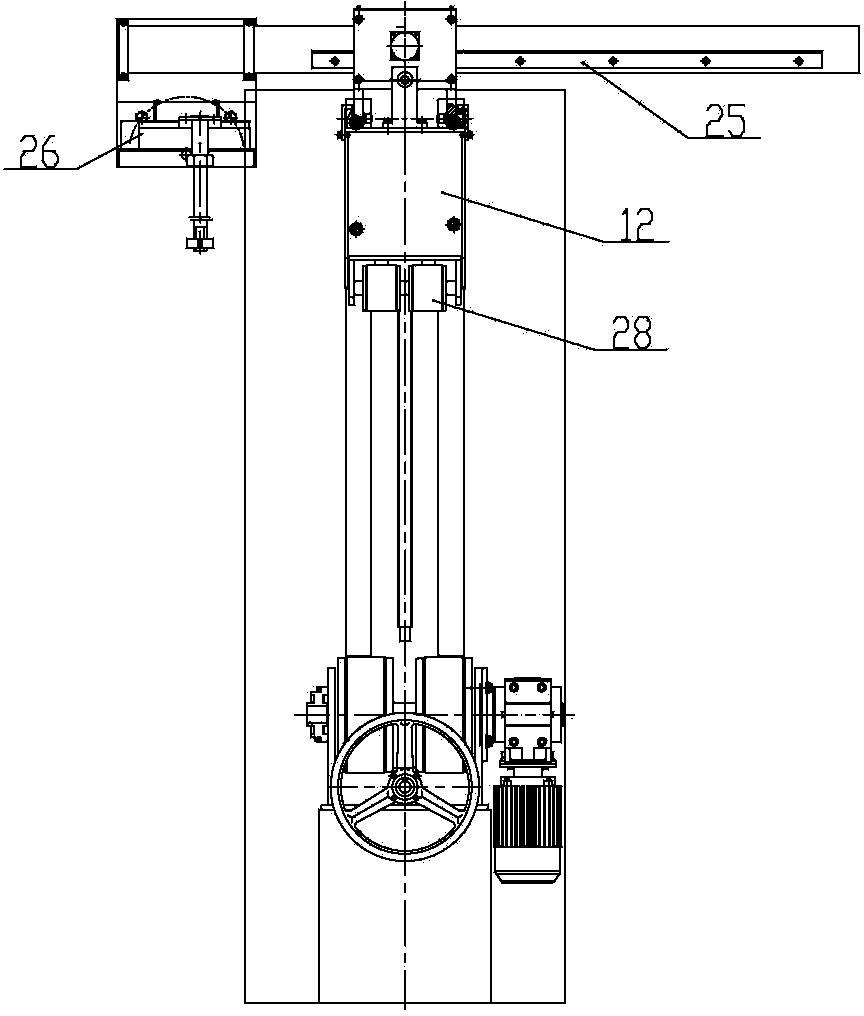

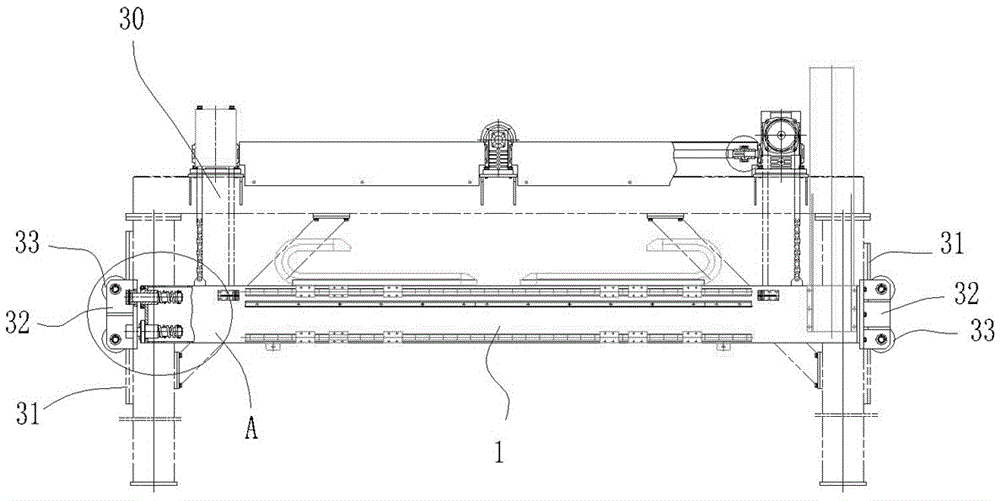

Process pipeline welding working station

ActiveCN103447723ARealize transportationTo achieve the purpose of weldingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingPipe

The invention relates to the technical field of an auxiliary device for pipeline welding, in particular to a process pipeline welding working station. The process pipeline welding working station comprises a horizontal track and a workshop, wherein the workshop is fixedly arranged on the middle part of the horizontal track; the left side and the right side of the workshop are provided with a material inlet and a material outlet which are communicated with the horizontal track respectively; the left part and the right part of the horizontal track are provided with a left bracket trolley and a right bracket trolley respectively; the horizontal track between the left bracket trolley and the right bracket trolley is provided with at least two conveying roller carriers; the upper part in the workshop is fixedly provided with a lifting device. The process pipeline welding working station has a rational and compact structure and is convenient to use; the purposes of transporting and lifting pipe fittings and welding between the pipe fittings are realized through cooperative use of the horizontal track, the workshop, a lifting, clamping and welding device and the lifting device; the process pipeline welding working station has the characteristics of flexibility and convenience in disassembly, safety and reliability, the operation is facilitated, the welding quality and the welding efficiency are improved, and the labor intensity and the production cost of operation personnel are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Automatic plug-in machine for plug-in mounting production of specially-shaped electronic elements

ActiveCN113710006ATo achieve the purpose of weldingIncrease productivityPrinted circuit assemblingSortingEngineeringElectronic component

The invention discloses an automatic plug-in machine for plug-in mounting production of specially-shaped electronic elements, which comprises a plug-in moving assembly, one end of the plug-in moving assembly is connected with a plug-in mounting assembly, a transmission assembly is arranged below the plug-in mounting assembly, one side of the transmission assembly is provided with an electronic component conveying assembly, the plug-in mounting assembly comprises a servo motor, and one end of the servo motor is connected with a rotating plate. One end of the rotating plate is connected with four first electric telescopic rods and clamp connecting plates arranged at the ends, away from the rotating plate, of the first electric telescopic rods. According to the invention, an insertion end of an electronic component is dipped into tin liquid in a tin liquid box by a micro electric clamp; and then the micro electric clamp inserts the insertion end of the electronic component into the circuit board, so that the purpose of welding when the electronic component is inserted into the circuit board is achieved; and compared with the traditional technology, the production efficiency of the specially-shaped electronic component is greatly improved, and the current production requirement is met.

Owner:南通祥峰电子有限公司

Welding assistant powder for cast iron spot welding

InactiveCN1704200AEasy to operateImprove welding strengthWelding/cutting media/materialsSoldering mediaCast ironMetallic Nickel

The invention relates to a welding flux used to cast iron and point welding. It is formed by mixing graphite powder, nickel powder, copper powder and iron powder together with each element's weight ratio: graphite powder 30-40úÑ, nickel powder10-20úÑ, copper powder10-20úÑ and iron powder 30-40úÑ. It locates the welding flux between the two parts waiting for welding, and uses the welding high temperature of the point welding machine to oxide graphite powder and changes it into CO.2. gas which has protecting function; the alloy which is formed by fusing the nickel powder, copper powder and iron powder can diffuse into cast iron material to form welding layer.

Owner:袁媛

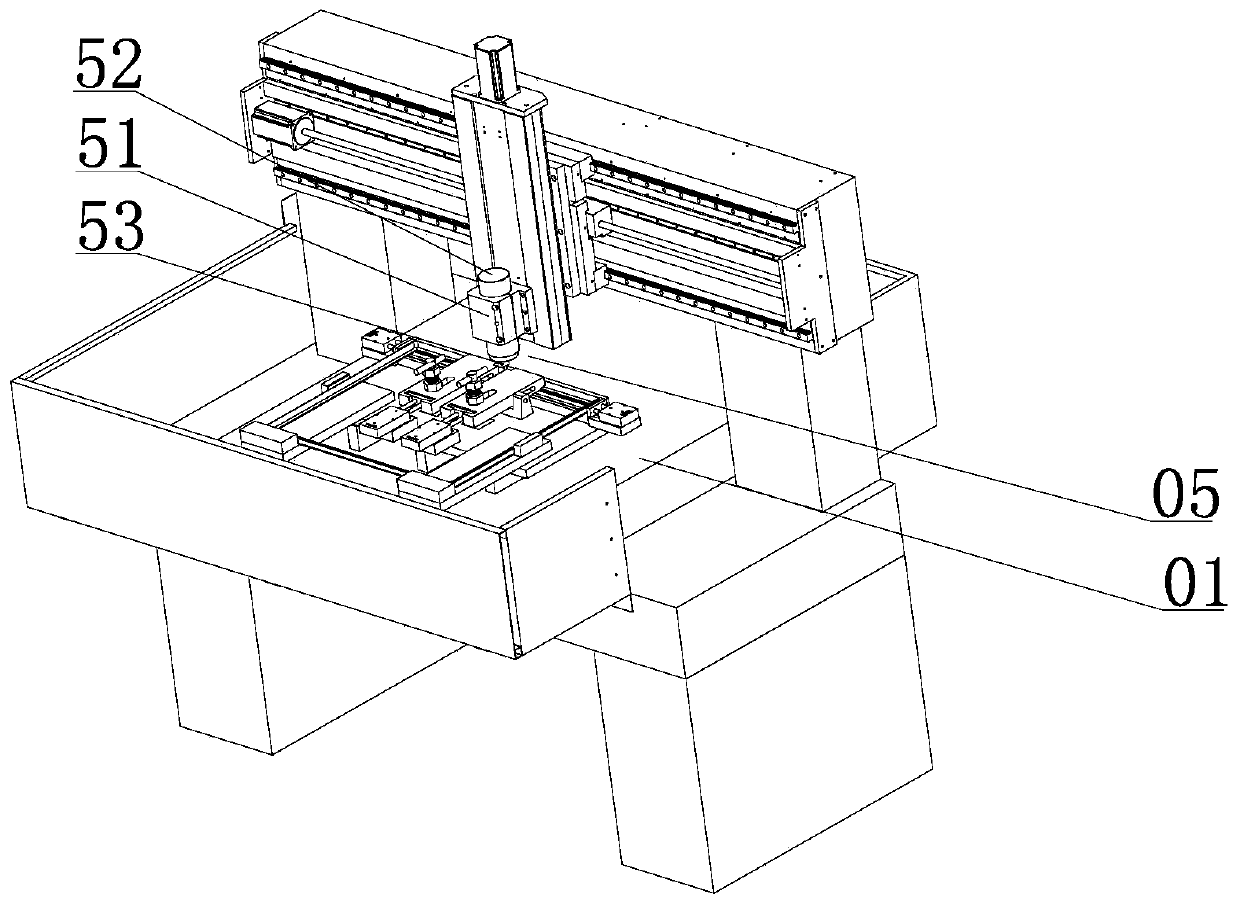

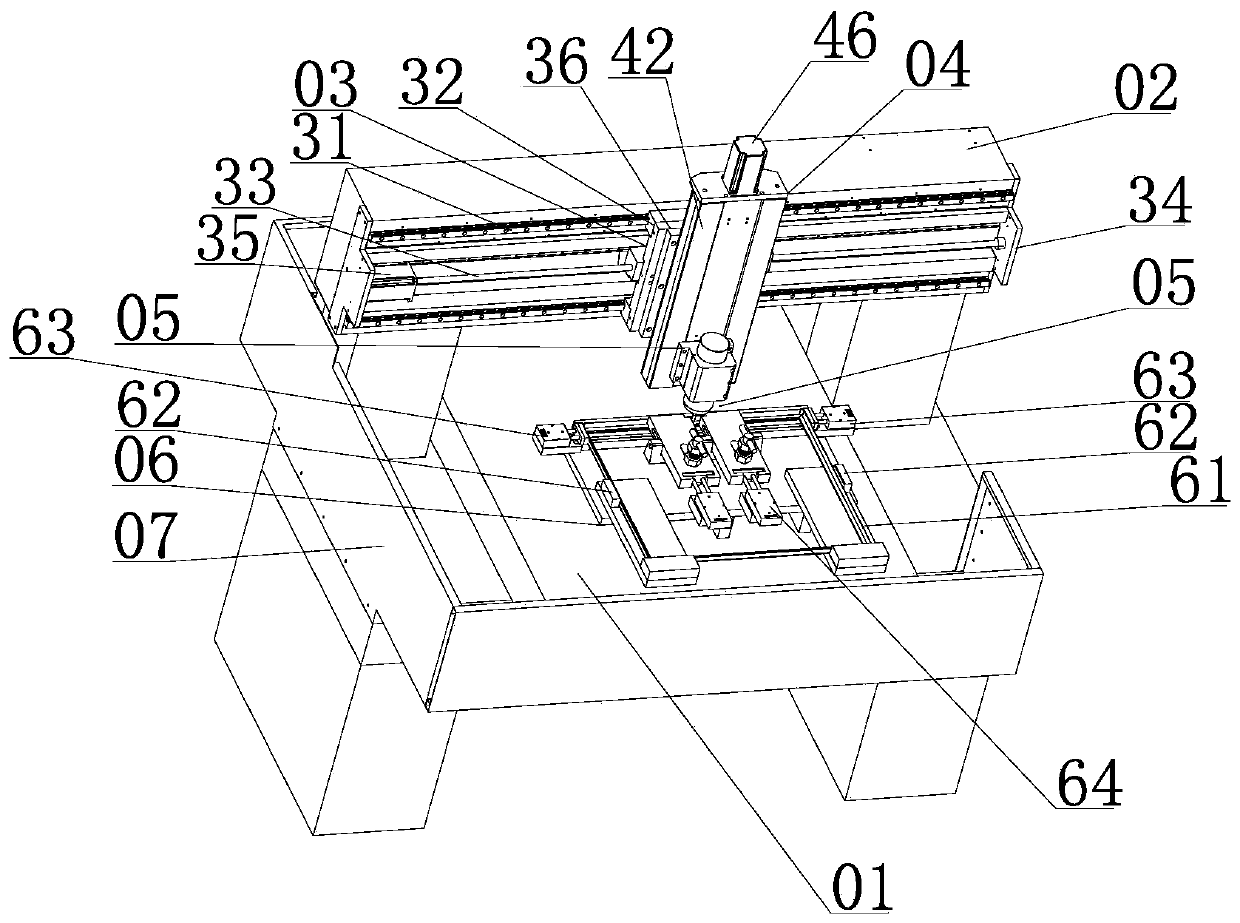

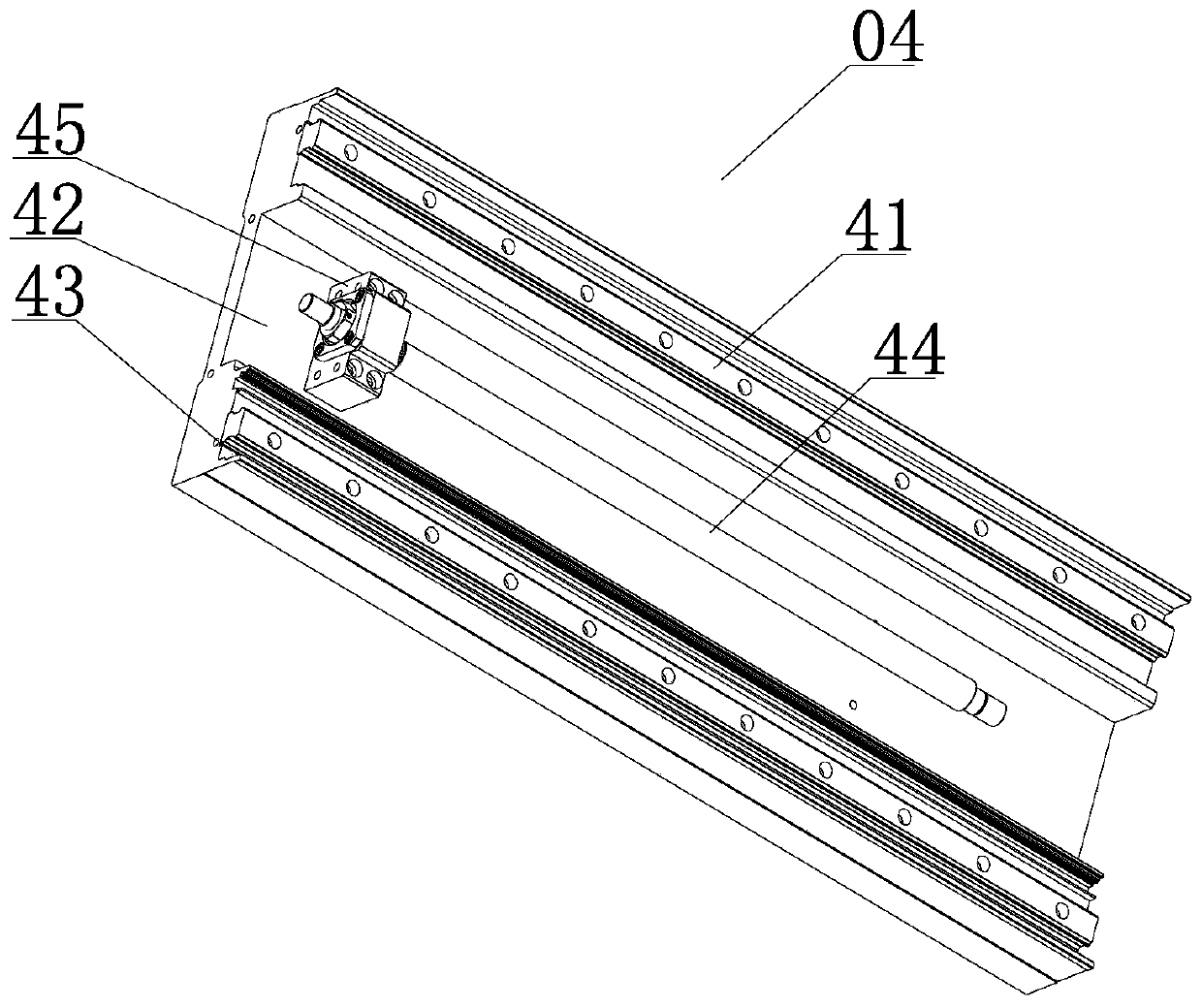

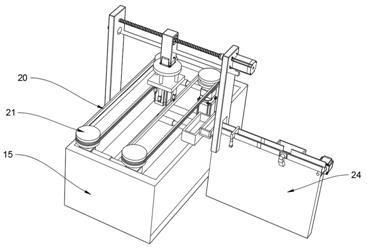

Television frame friction-welding device

PendingCN111151866AStable supportImprove welding strengthWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention discloses a television frame friction-welding device which comprises a working table, a portal frame arranged on the working table, a horizontally-moving translation device arranged on the portal frame, a lifting device arranged on the translation device, a friction-welding tool arranged on the lifting device, and a product fixing device arranged at the position, under the friction-welding tool, on the working table. The television frame friction-welding device provided by the invention has the effects of energy conservation and environment protection, high welding strength, anddifficulty in cracking a formed product.

Owner:FUJI CHINON M&E ZHUHAI CO LTD

Base welding device for swivel chair

InactiveCN108406182AEfficient weldingStable positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a base welding device for a swivel chair. The base welding device comprises a base, a spring, a fan and a through groove, an object containing plate is installed on the upper end face of the base, a round hole is formed in one side of the object containing plate, a fixing block is arranged on the lower end face of the object containing plate, the spring is installed on theother side of the object containing plate, a supporting plate is arranged at the end of the base, the fan is installed on the inner side of the supporting plate, a supporting rod is arranged on the upper end face of an operation plate, a motor is installed inside the operation plate, a connecting shaft is arranged at the end of the motor, the through groove is formed in the operation plate, and anelectric stretchable rod is installed inside the through groove. According to the base welding device for the swivel chair, the motor rotates to drive a fixed rod to slide in the through groove, andthe object welding aim is achieved; and as a swivel chair base is mostly connected with a supporting device through a circular structure, a moving track of a welding head is of a round structure, andwelding is more efficient.

Owner:安吉龙鑫家具有限公司

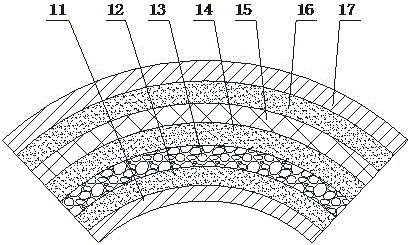

Novel steel wire mesh framework plastic composite pipe

InactiveCN105782595AStrong resistance to axial tensionTo achieve the purpose of weldingThermal insulationPipe protection by thermal insulationInterconnectionHeat fusion

A novel steel wire mesh framework plastic composite pipe is a whole pipe formed by interconnection of a plurality of segments of composite pipe components sequentially through electric heat fusion joints in a welding manner, each segment of composite pipe component is formed by mutual wrapping of two or more layers of plastic pipes made of high density polyethylene, a steel wire mesh framework is arranged between two adjacent layers of plastic pipes, and the steel wire mesh frameworks and the plastic pipes are spliced into a whole through bonding layers. The electric heat fusion connection manner is adopted, the connecting strength and the sealing effect are obvious, and axial-tension-resisting capability of pipes obtained after connection is high. The novel steel wire mesh framework plastic composite pipe is formed by compositing two materials of steel and plastic, the phenomenon that plastic pipes difficultly overcome rapid stress cracking is avoided, and strength, rigidity and impact resistance superior to those of a common pure plastic pipe are achieved; the beneficial effect that the plastic pipes are small in weight is achieved, and mounting is convenient; double-face anti-corrosion performance the same with that of the plastic pipes is achieved, and the heat conductivity coefficient is low; the service life of the pipes is prolonged; and through adjustment of diameters of steel wires, thickness of plastic layers and the like, the pipes with different pressure grades are manufactured.

Owner:HUBEI SHUIZHIYI TECH CO LTD

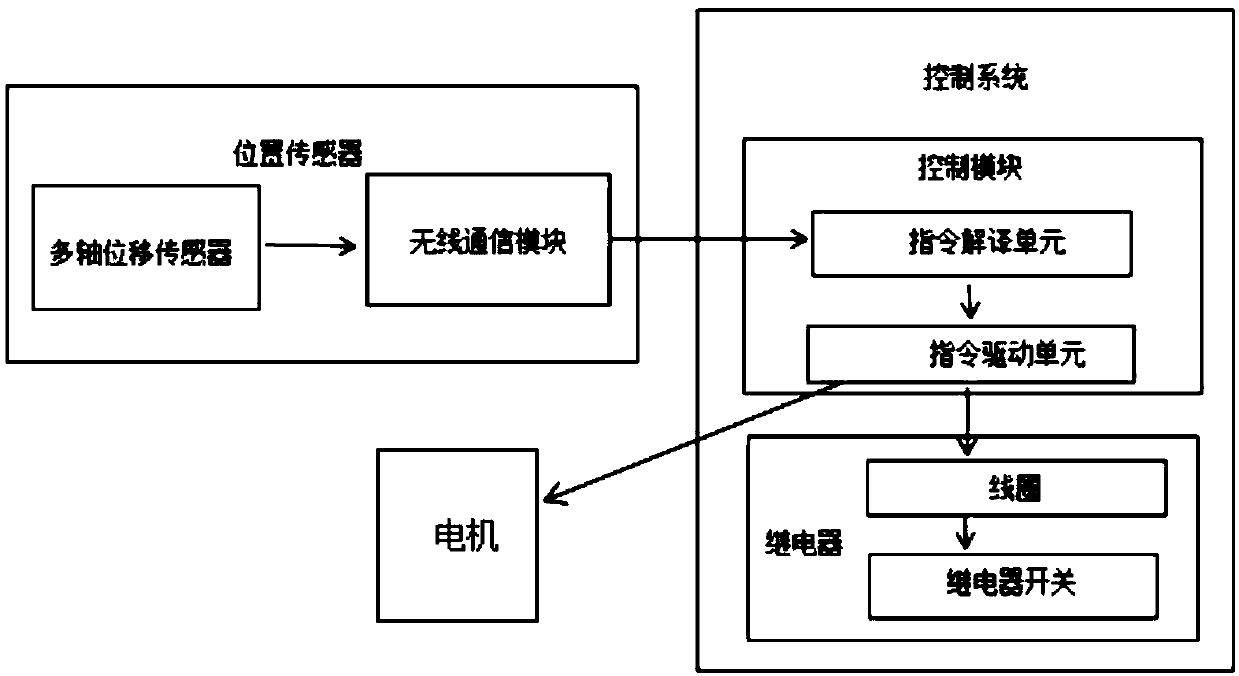

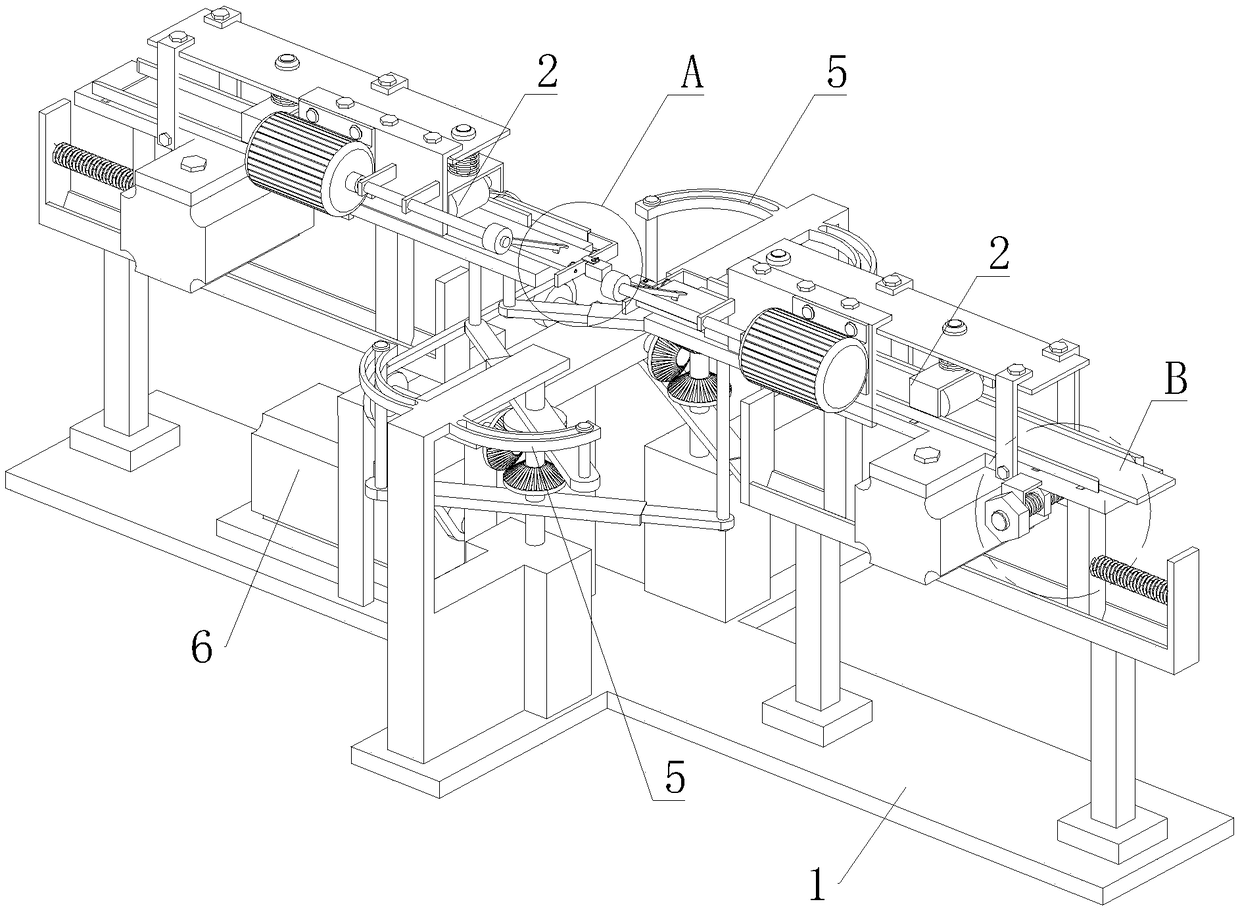

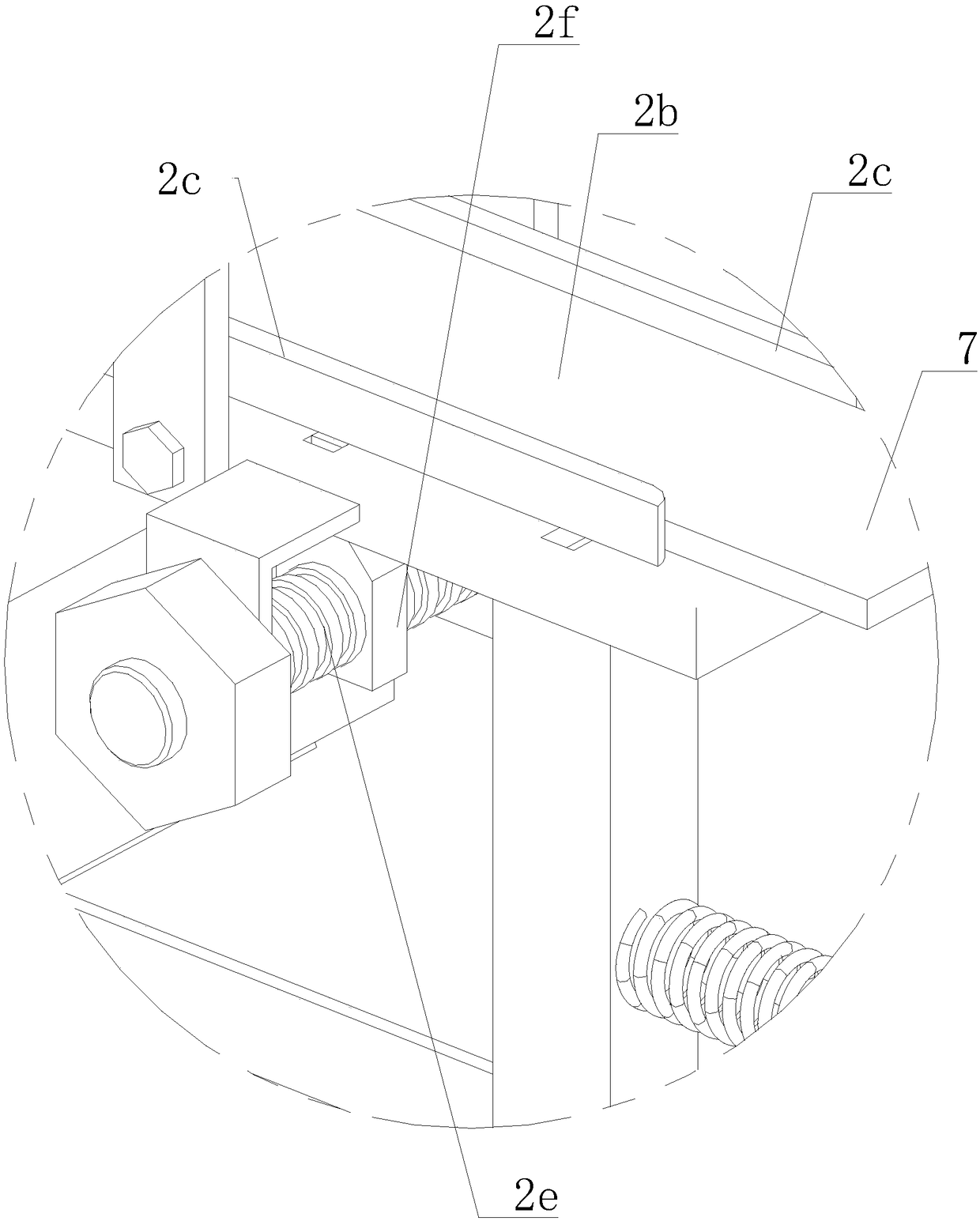

Welding tracking system of variable cross section steel welding device

ActiveCN105965183ATo achieve the purpose of weldingPrecise welding effectWelding/cutting auxillary devicesAuxillary welding devicesWeld seamPosition sensor

The invention relates to a welding tracking system of a variable cross section steel welding device. The system comprises a crossbeam and a welding frame; a welding gun is disposed on the welding frame; a mobile plate is disposed on the crossbeam and can slide horizontally along the crossbeam; an air cylinder is disposed on the mobile plate; the piston rod of the air cylinder is connected with a floating frame; the floating frame is pivoted with the welding frame by a vertical pivot; a side guide wheel is disposed on the welding frame; the system also comprises a driving plate with a horizontal driving apparatus; the driving plate can be moved horizontally along the crossbeam by the horizontal driving apparatus; the driving plate is connected with the mobile plate by an elastic apparatus disposed therebetween; when compressed, the elastic apparatus enable the mobile plate to have the tendency to move to the driving plate; a first induction block and a second induction block are disposed on the mobile plate; and a first position sensor used for sensing the position of the first induction block and a second position sensor used for sensing the position of the second induction block are disposed on the driving plate. The system disclosed by the invention can realize automatic tracking according to the variation of the cross section of the section steel to achieve the aim of weld seam tracking in welding process and to obtain an accurate welding effect.

Owner:NINGBO JINFENG WELDING & CUTTING MACHINERY MFR

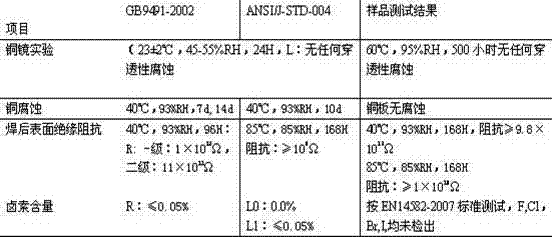

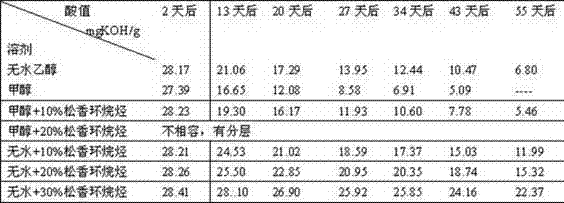

Disposable scaling powder used for high-temperature soldering

ActiveCN103692113AGood storage stabilityLess smokeWelding/cutting media/materialsSoldering mediaCapacitanceCycloparaffins

The invention discloses disposable scaling powder used for high-temperature soldering. The disposable scaling powder is characterized by comprising the following ingredients in parts by weight: 1-5 parts of modified rosin, 0.5-2 parts of dicarboxylic acid active agent, 0.1-0.5% part of non-ionic surface active agent, 20-30 parts of rosin cycloparaffin, 60-75 parts of alcohols solvent, 0.05-0.5 part of heterocyclic compound. Due to the adoption of the technical scheme, the scaling powder has the characteristics that the energy storage stability is high, the smoke is little when passing by a furnace, the insulation resistance left after welding is high, the corrosivity is low, the electrical property is excellent and the like, and is suitable for the cleaning-free process of industries such as electrical inductance, network transformer and capacitance.

Owner:ZHUHAI CHANGXIAN CHEM TECH

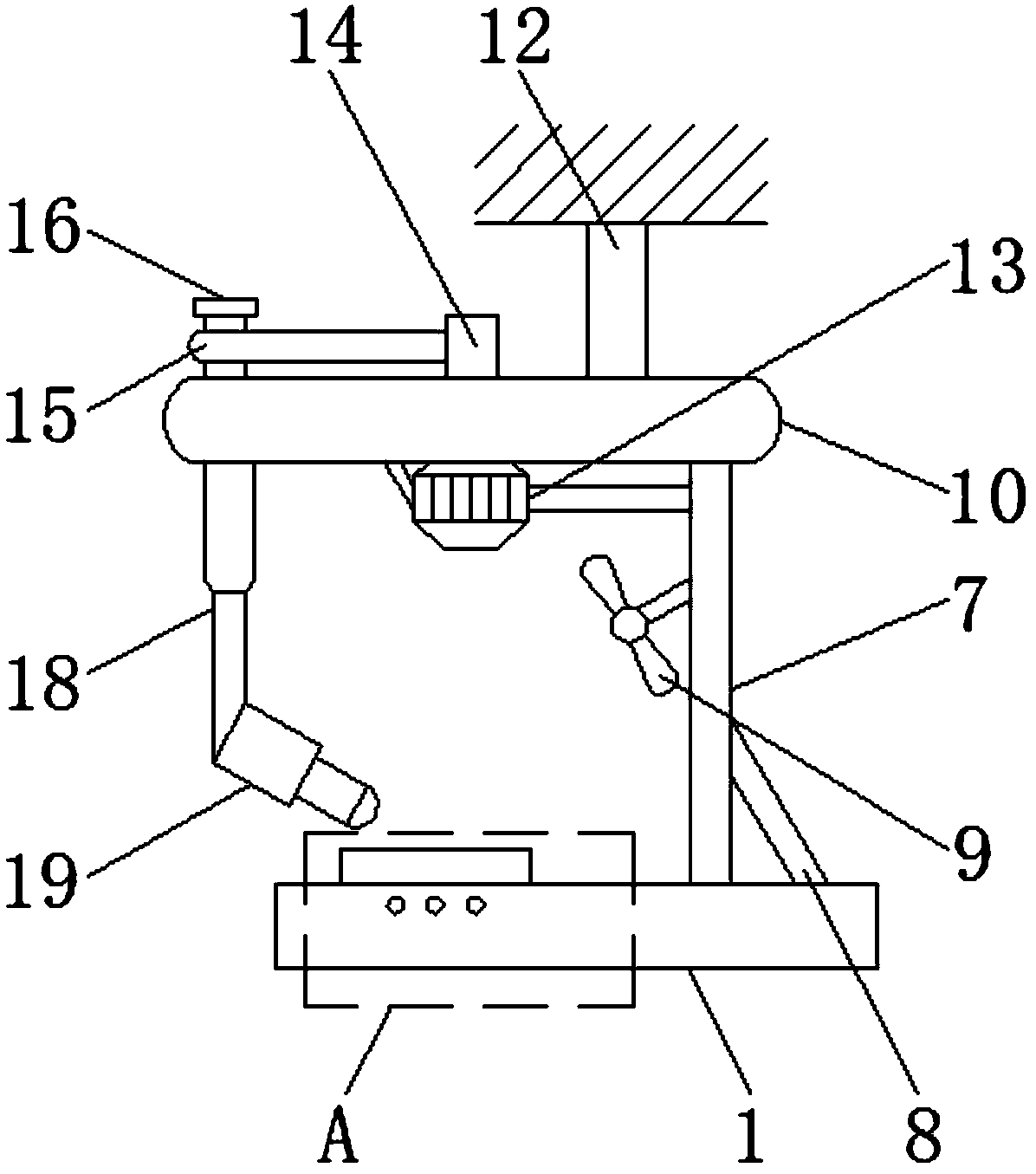

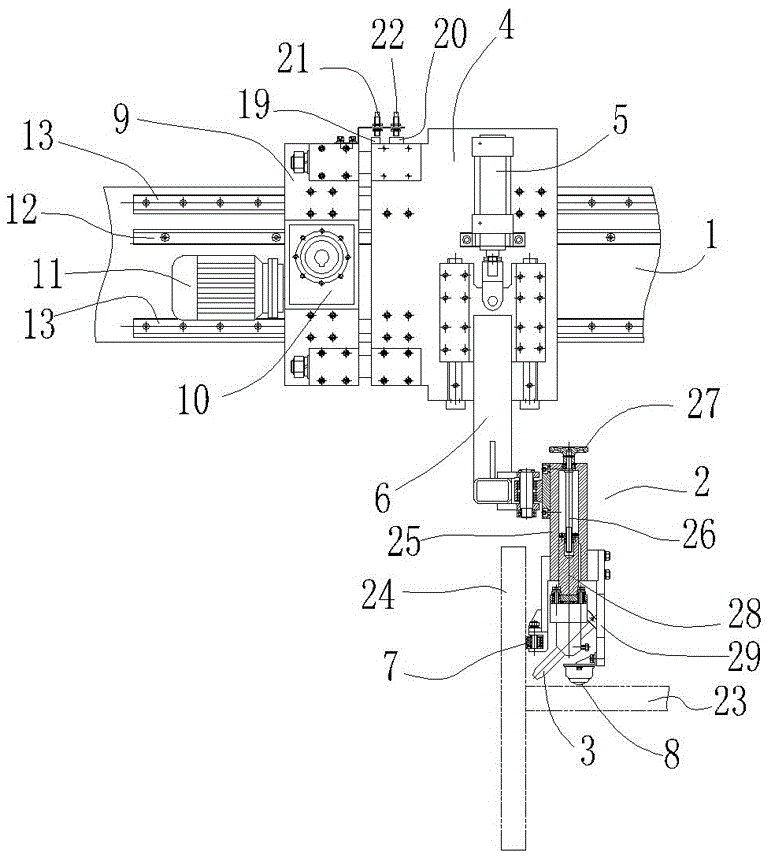

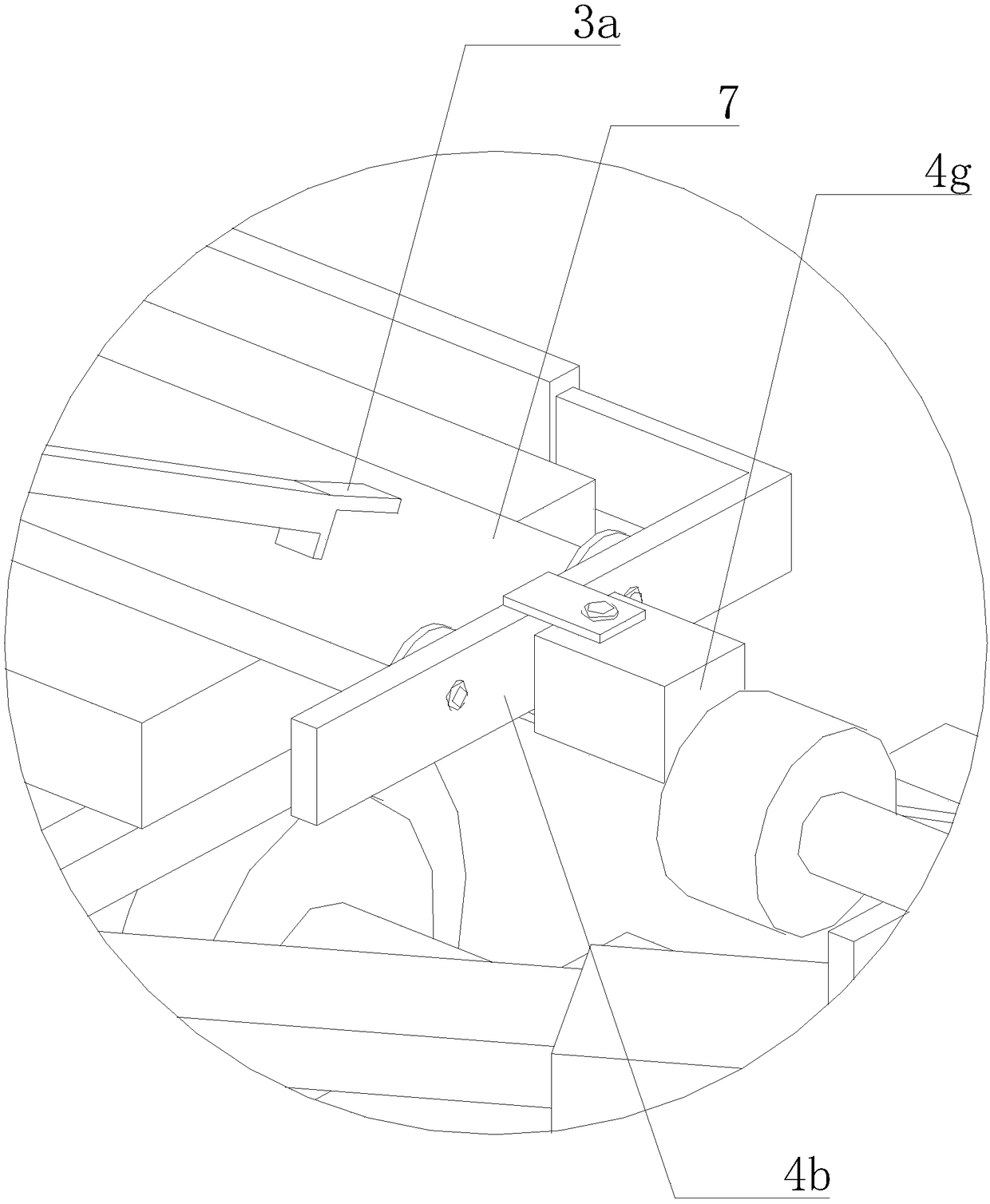

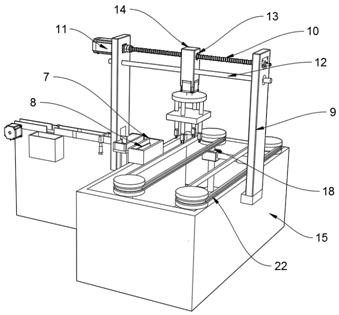

Welding device for structural steel with variable cross sections

ActiveCN106001857ATo achieve the purpose of weldingPrecise welding effectWelding/cutting auxillary devicesElectrode holder supportersEngineeringPortal frame

A welding device for structural steel with variable cross sections comprises a base, a portal frame arranged on the base in a sliding mode, and a crossbeam which is arranged on the portal frame and can ascend and descend. The welding device further comprises a welding frame. The crossbeam is provided with a moving plate which is provided with an air cylinder. A piston rod of the air cylinder is connected with a floating frame which is in pivoted connection with the welding frame. The welding frame is provided with a lateral guide wheel. Moreover, the welding device comprises a driving plate with a transverse movement driving device. The driving device is connected with the moving plate through an elastic device. The moving plate is provided with a first sensing block and a second sensing block. The driving plate is provided with a first position sensor for sensing the position of the first sensing block and a second position sensor for sensing the position of the second sensing block. Vertical wheel rails are arranged on the two sides of the portal frame. Guide wheel frames are arranged at the two ends of the crossbeam. The guide wheel frame of at least one end of the crossbeam is elastically and movably connected with the crossbeam. Guide wheels are arranged on the guide wheel frames. The welding device can conduct automatic tracking according to changes of the cross sections of the structural steel, thereby realizing the purpose of conducting welding by tracking weld joints and achieving an accurate welding effect.

Owner:NINGBO JINFENG WELDING & CUTTING MACHINERY MFR

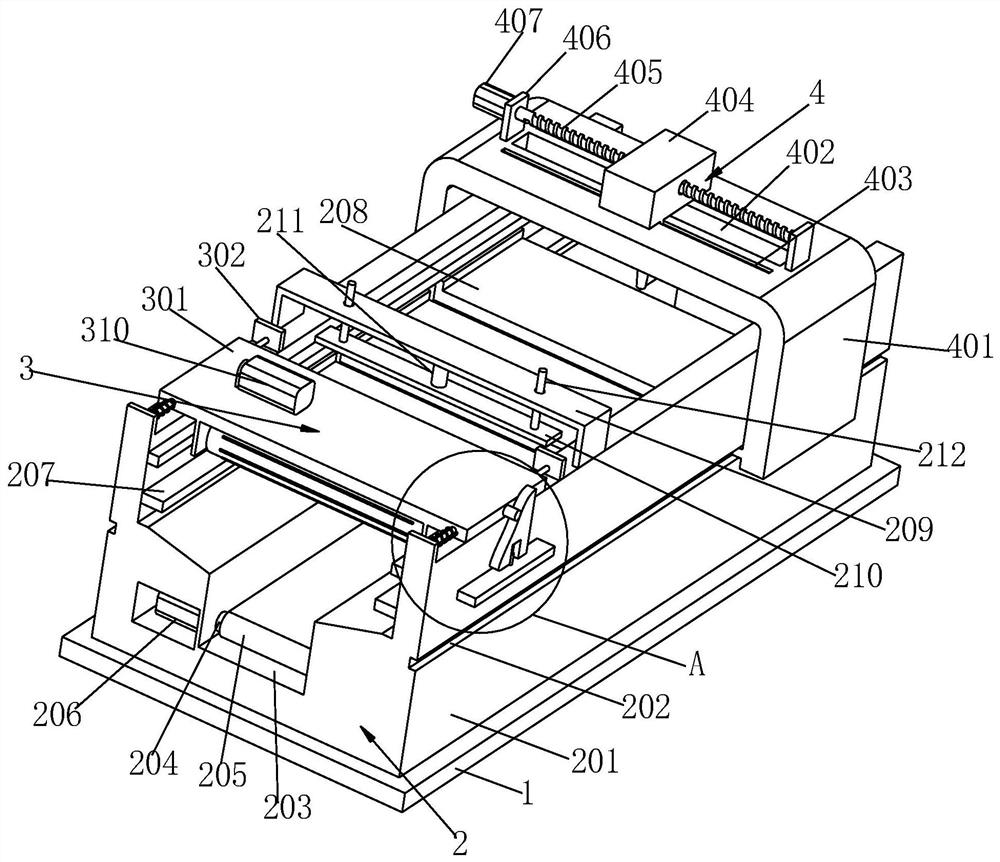

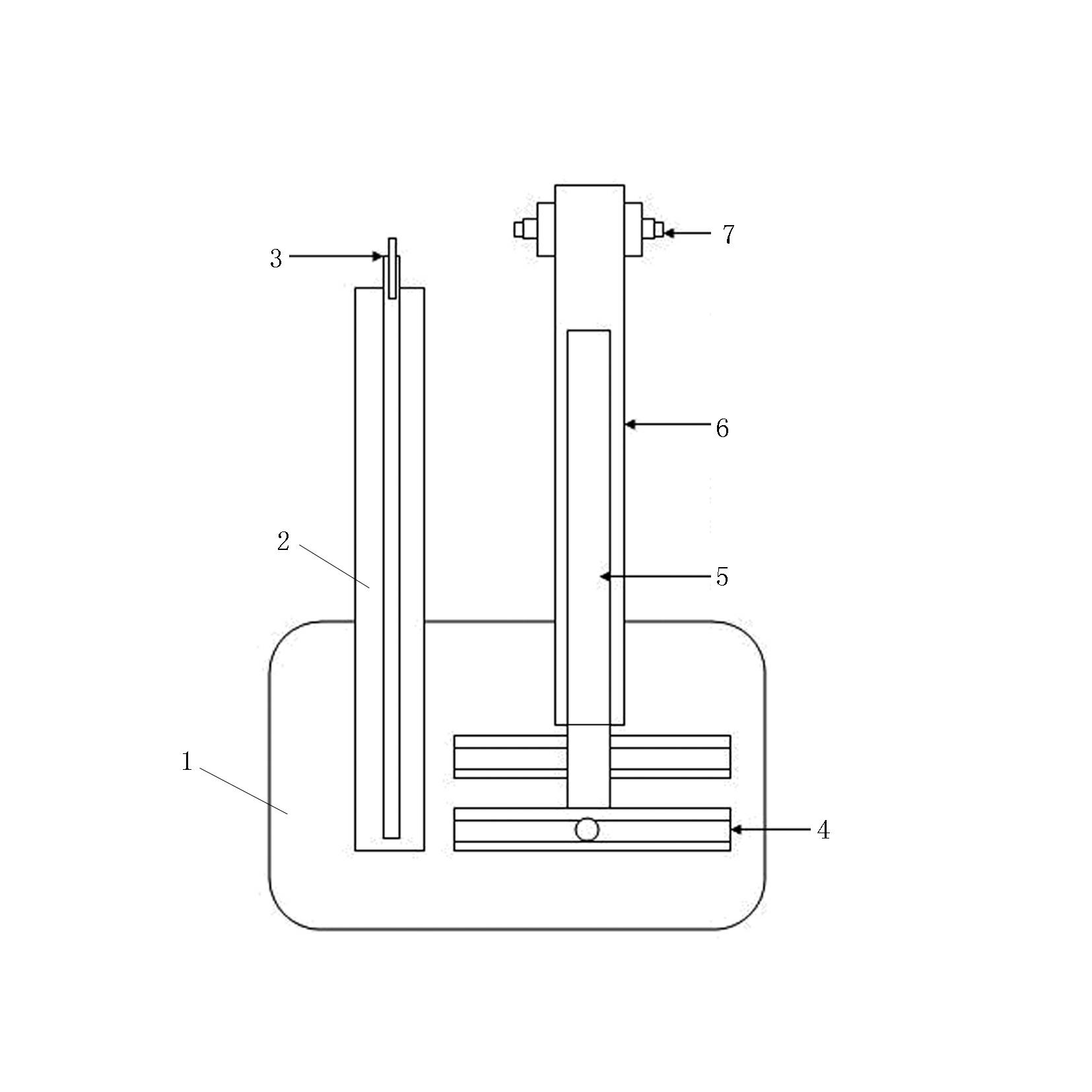

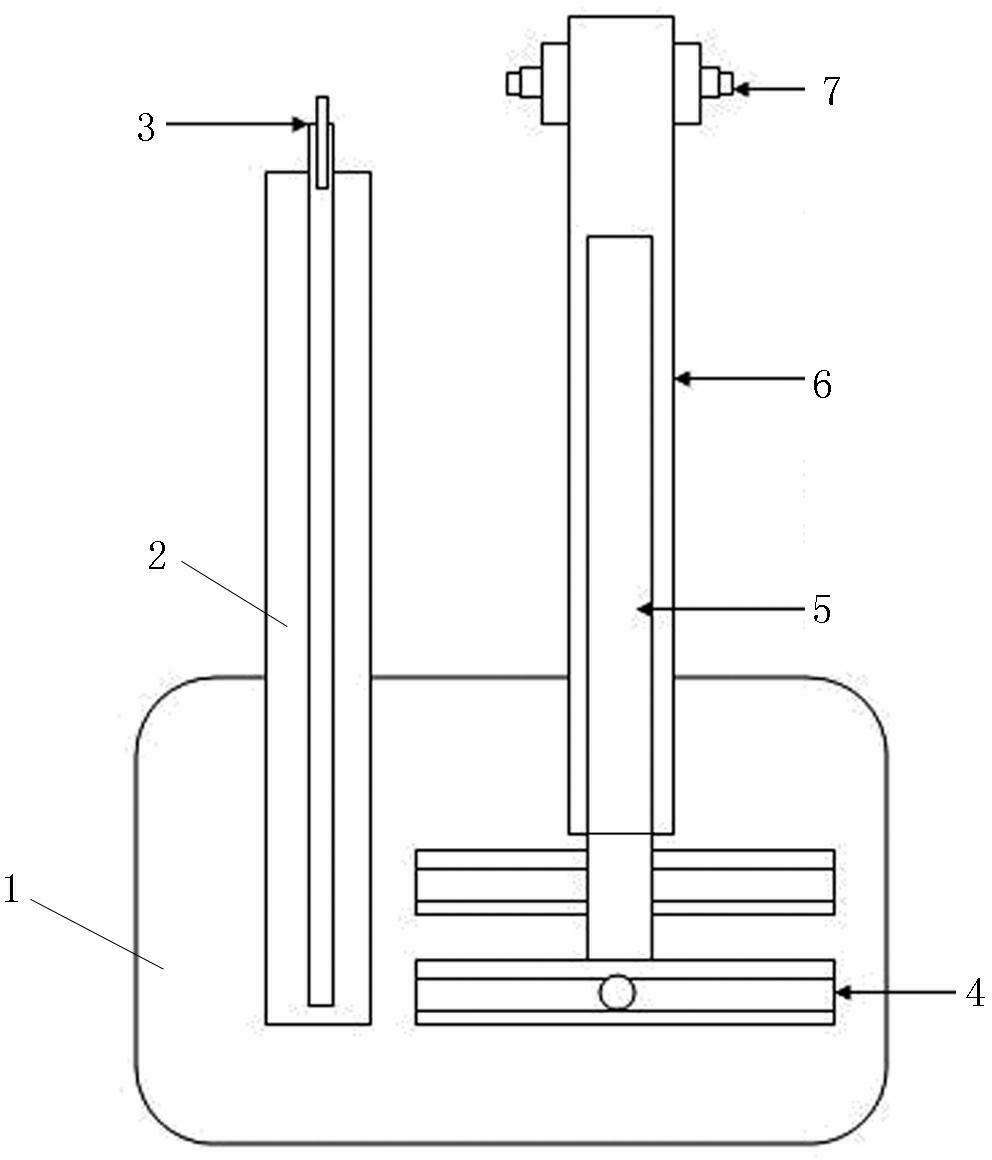

Positioning device of high-precision laser butt welding machine

PendingCN109277749ATo achieve the purpose of blankingTo achieve the purpose of weldingWelding/cutting auxillary devicesAuxillary welding devicesButt weldingButt joint

The invention relates to the field of laser welding auxiliary equipment, in particular to a positioning device of a high-precision laser butt welding machine. The positioning device comprises a base,a power mechanism, two butt joint mechanisms and two positioning mechanisms which are symmetrically arranged on the top of the base and have the same structures. The two butt joint mechanisms are symmetrically arranged between the two positioning mechanisms. Each positioning mechanism comprises a guide seat, a positioning clamp, an intercepting part and a pressing part. The positioning clamps canbe movably arranged above the guide seats through tension springs, the two intercepting parts are arranged at the close ends of the two positioning clamps, the intercepting parts can rotate through rotary motors, the two pressing parts are arranged above the close ends of the two positioning clamps, the two butt joint mechanisms are connected with one ends of the two positioning clamps, and the power mechanism is in transmission connection with the two butt joint mechanisms. Two pre-welded base materials can be accurately in butt joint automatically, the problems that gaps are too large and the surfaces are not smooth after butt joint are completely eradicated, and therefore the following welding quality is improved.

Owner:ANHUI SCI & TECH UNIV

Portable welding device for communication coaxial cable joint

The invention relates to a portable welding device for a communication coaxial cable joint, and is particularly applied to the welding of the communication coaxial cable joint. The structure of the portable welding device is that: a welding component and transverse sliding ways are arranged on a base; a welding heating component is arranged on the upper part of the welding component; a fixed rod is arranged on the transverse sliding ways; a sliding round tube is sleeved on the fixed rod; and a plug and a socket are arranged on the upper part of the sliding round tube respectively. Cable joints special for communication can be stably welded within a short time, quality is high, the workload of later maintenance is also reduced, and high-efficiency welding is ensured. The device is highly practical and convenient to use and carry, and occupies a small space, and welding quality is greatly improved. In terms of production and maintenance, working efficiency is improved, humanized work is realized, worry about scalds to hands holding a welding head is eliminated, a welding material is also saved, and economic benefits are remarkably improved.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

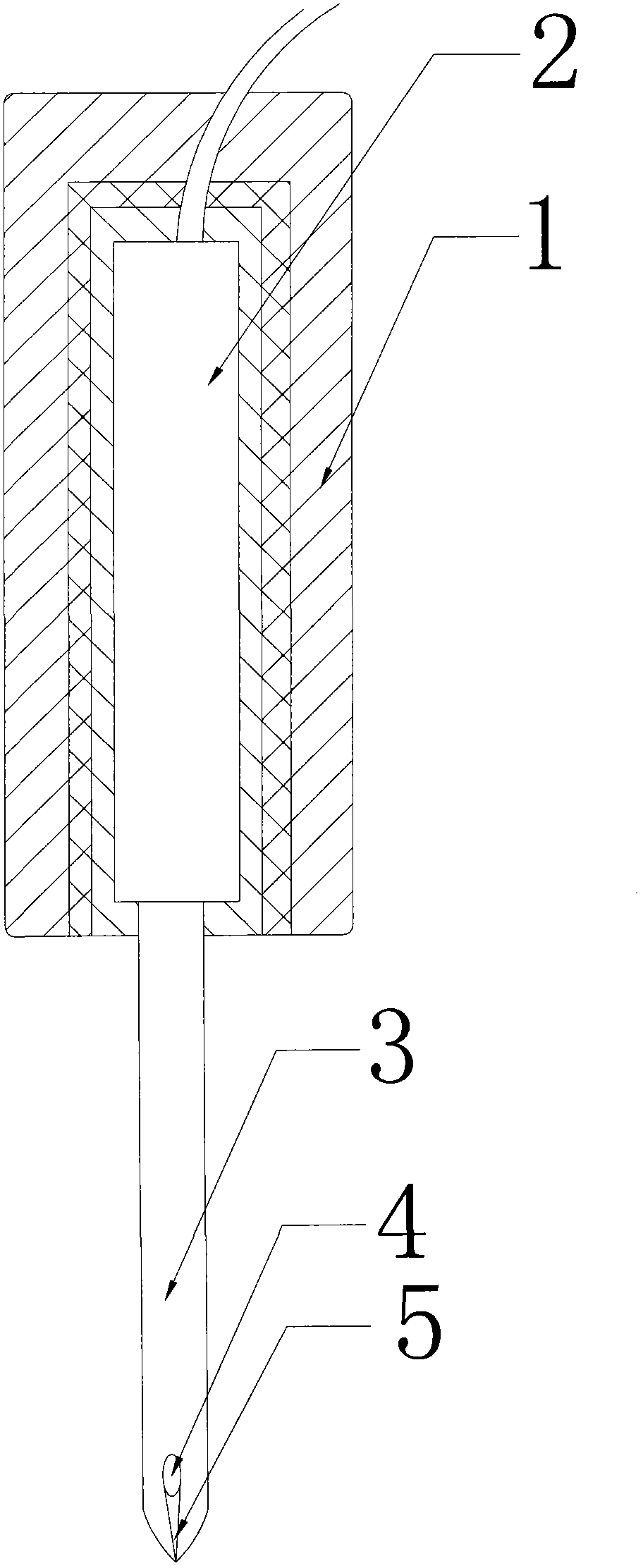

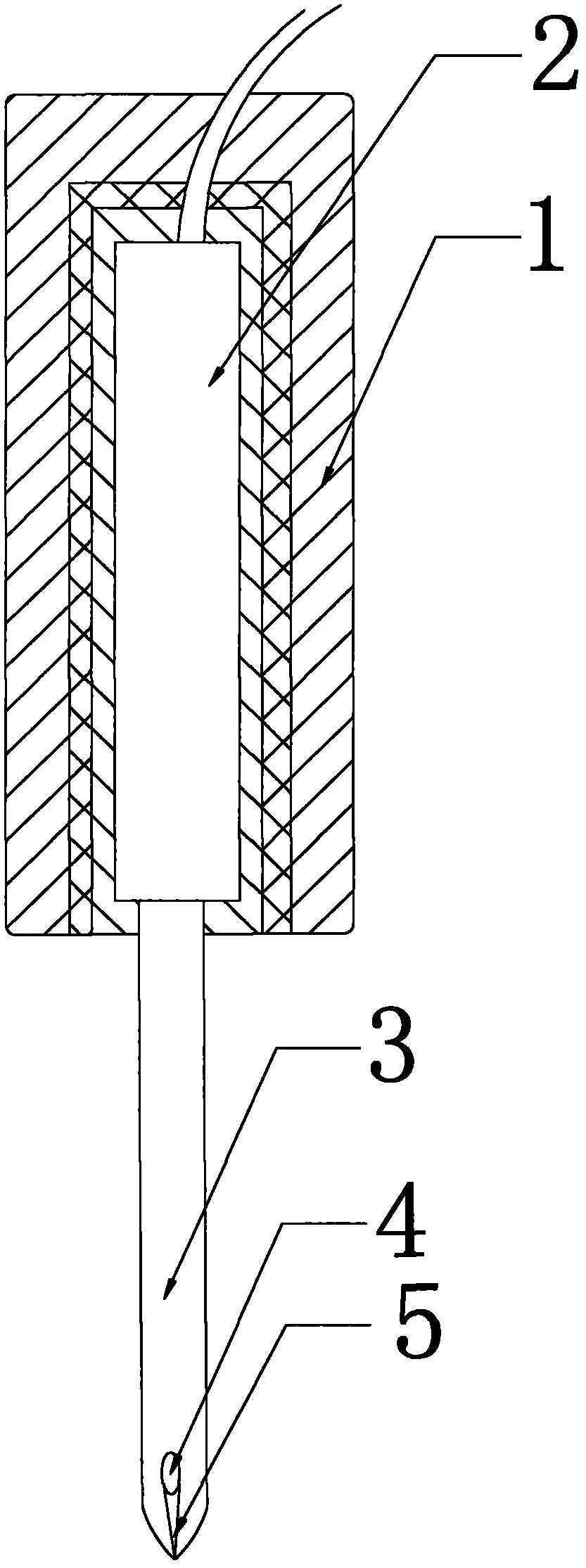

Electric soldering iron

The invention relates to an electric soldering iron, comprising a handle, a heating core and a welding head, wherein the heating core is arranged in the handle and is in contact with the welding head, and the lower part of the welding head is of a semi-conical structure. The electric soldering iron is characterized in that a groove is formed in the lower part of the welding head, a flow channel is formed below the groove, one end of the flow channel is communicated with the groove, and the other end of the flow channel is communicated all through to a tail end at the lower part of the welding head. The electric soldering iron provided by the invention has the advantages of convenience for welding, safety and reliability, and a welded circuit joint has an attractive overall appearance.

Owner:龚晓建

Metal pipe welding device for building construction

ActiveCN107695554AImprove resource utilizationReduce gapMetal working apparatusWelding apparatusArchitectural engineeringPipe welding

The invention discloses a metal pipe welding device for building construction, and the welding device is a device for carrying out complete and continuous welding on connection gaps through the rotation of pipes and for carrying out welding by cooperating with a situation that the pipes are pressed against and close to each other. The metal pipe welding device for the building construction is characterized in that a fixed box body is arranged on a main support plate, one end of a driving rod is arranged on the inner wall of one side of the fixed box body through a bearing, and the other end ofthe driving rod passes through the other side of the fixed box body through the bearing. Worm wheels are arranged on the driving rod and are located in the fixed box body, and two guide sleeves are respectively arranged on the main support plate and are parallel to each other. Two screws respectively penetrate through the fixed box body, and one ends of the two screws are respectively installed in the two guide sleeves on the main support plate. The screws are meshed with the worm wheels, a main vertical plate is arranged on the main support plate and is located on one side of the fixed box body. A through hole is formed in the main vertical plate, a baffle plate is arranged at one end of the main support plate, a second connecting cavity is arranged between the baffle plate and the mainvertical plate, and one end of a pressing rod passes through the through hole in the main vertical plate and is arranged between the main vertical plate and the baffle plate.

Owner:上海中巽科技股份有限公司

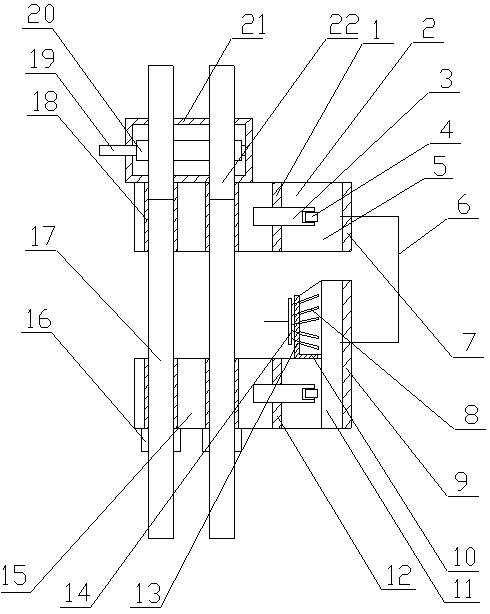

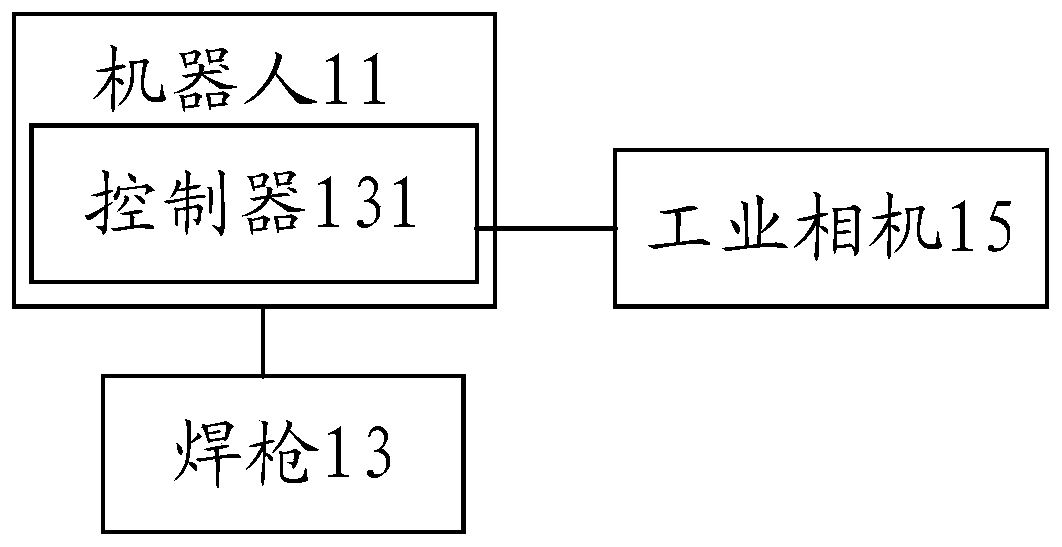

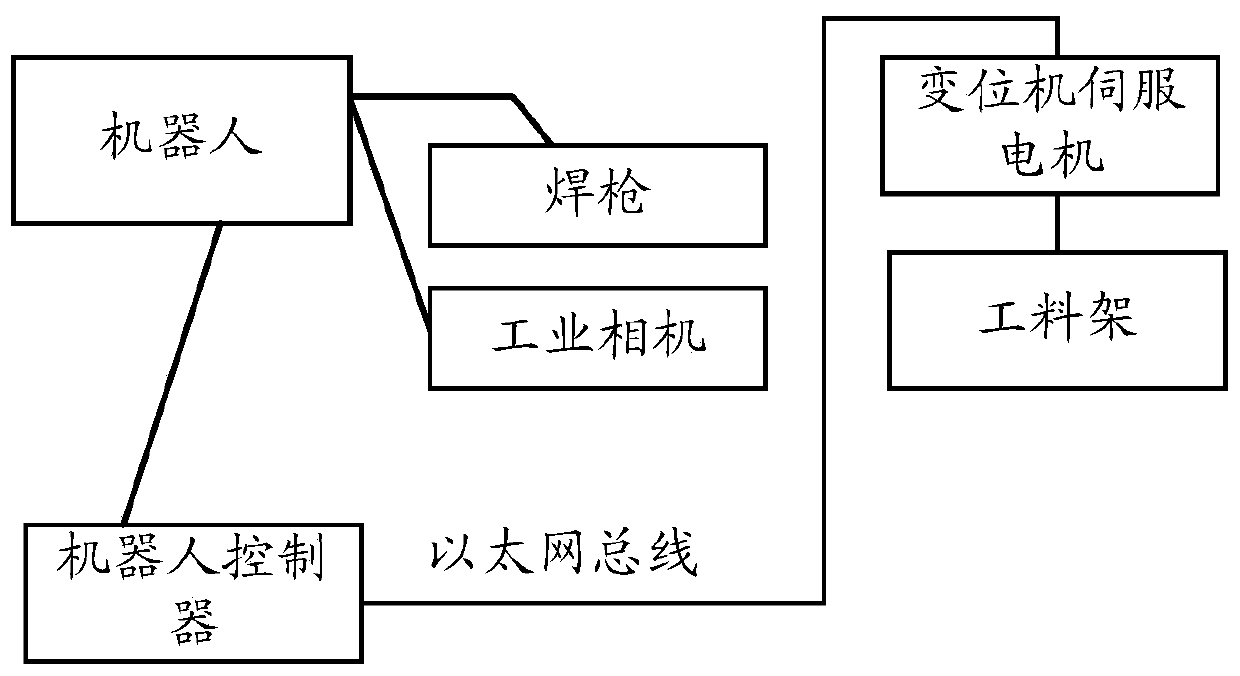

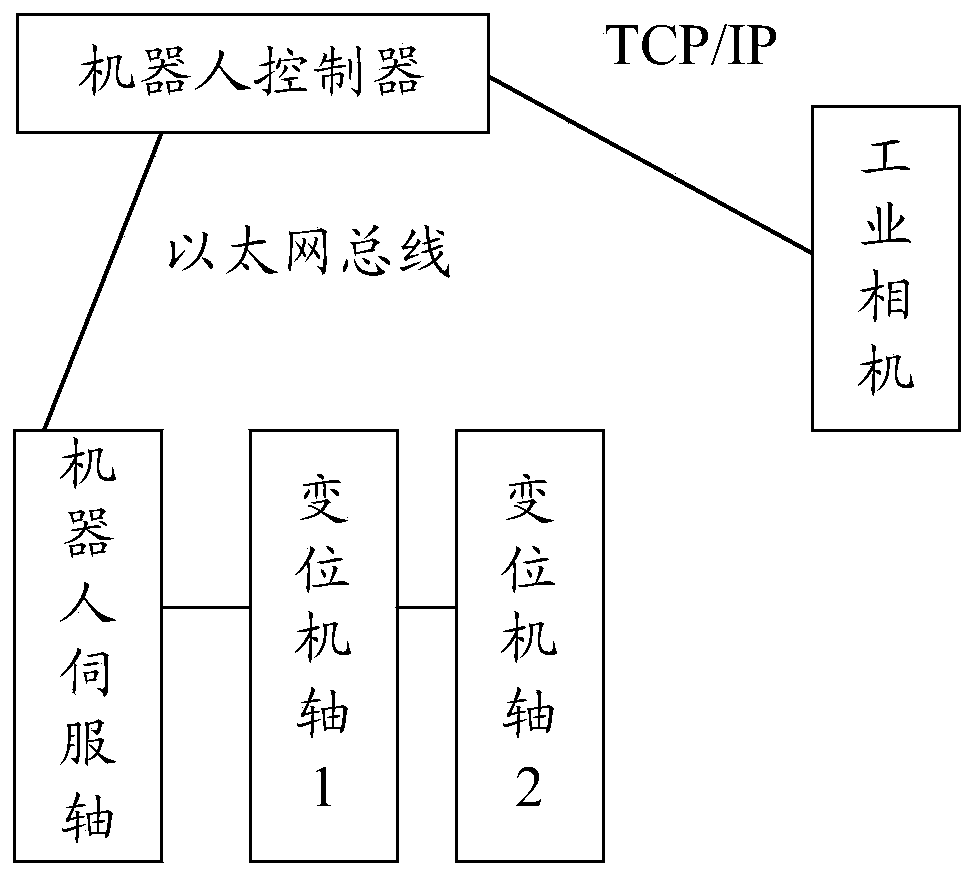

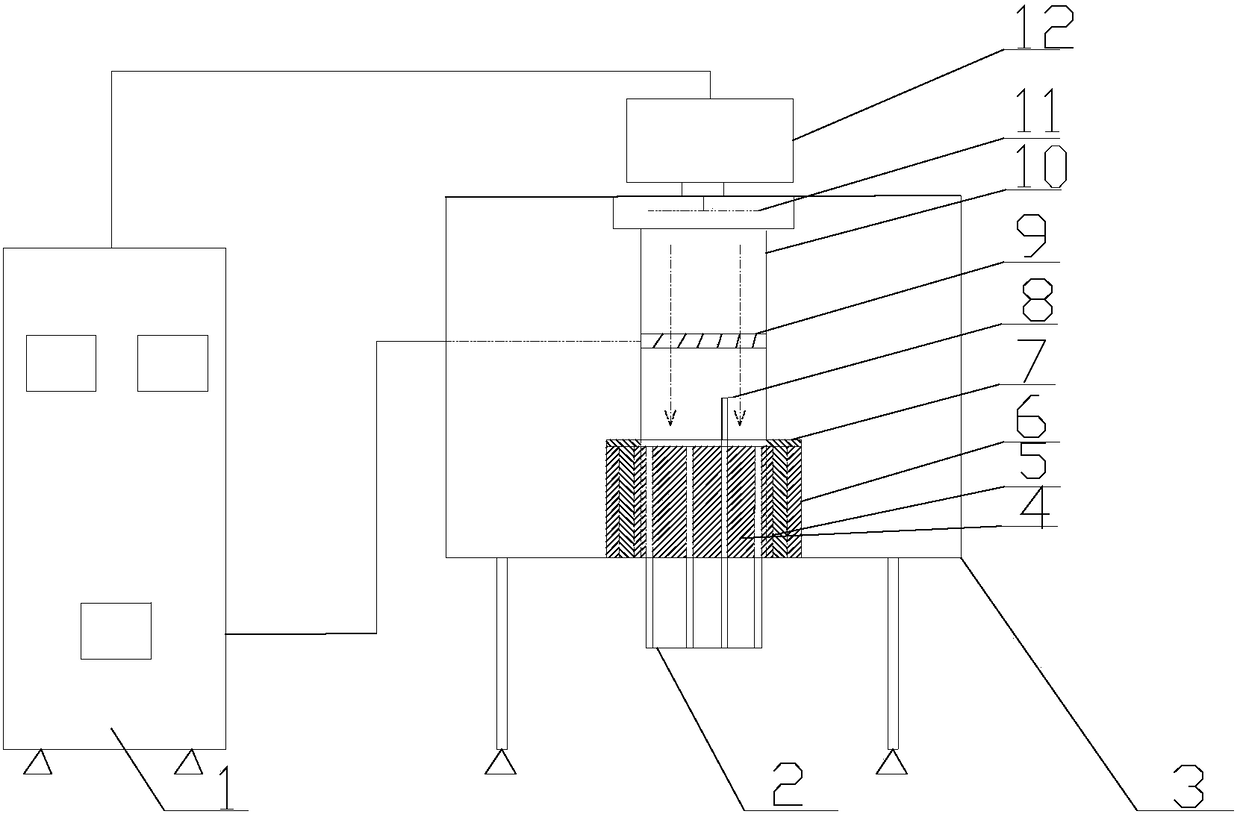

Welding system, welding method and device

InactiveCN110524134ATo achieve the purpose of weldingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesObject basedWeld seam

The invention discloses a welding system, a welding method and device. The method comprises the steps that weld joint starting point information sent by an industrial camera is obtained, and the weldjoint starting point information is used for describing a weld joint starting point of a to-be-welded object; and a welding gun is controlled to perform welding operation on the to-be-welded object based on the welding seam starting point information. According to the invention, the technical problem of low welding efficiency caused by low reliability of a mode for patrolling points of the to-be-welded object in related technologies is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Friction stir welding welding method and tool for non-inclination self-upsetting

ActiveCN104014926BReduce complexityDecrease productivityNon-electric welding apparatusFriction weldingWeld seam

The invention relates to the technical field of welding, in particular to an aclinal self-upsetting, stirring and friction welding method and tool. The tool comprises a stirring head and a stirring needle, the stirring head is of a hollow structure, the stirring needle is rotatably arranged in the hollow structure of the stirring head and can stretch and retract in the stirring head, the axis of the stirring head and the axis of the stirring needle are overlapped, a shaft shoulder of the stirring head is provided with a forging boss, and the height of the forging boss is smaller than the height of the stirring portion left after the stirring needle extends out of the stirring head. In the whole welding process, a dip angle adjusting mechanism does not need to be arranged on equipment, complexity of the welding equipment is reduced, the angle between the shaft shoulder of the stirring head and a plane normal of a material to be welded is 0 degree, and accordingly aclinal stirring friction welding is achieved. When an aclinal stirring friction welding technology is adopted in two-dimensional plane welding, the angle of the stirring head does not need to be adjusted at a welding seam corner, welding procedures are reduced, meanwhile, the dip angle adjusting mechanism does not need to be arranged on the equipment, complexity of the welding equipment is reduced, and welding efficiency is improved.

Owner:BEIJING FSW TECH

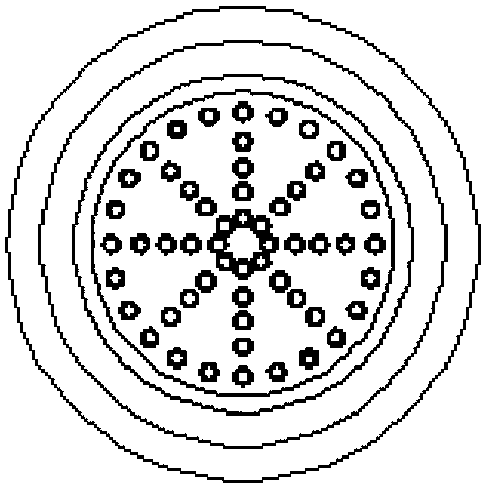

A welding device and method for a fluoroplastic heat exchange tube and a tube sheet

The invention discloses a device for welding an FEP heat exchange tube with a tube plate. The device comprises a welding machine case and an electrical control case, wherein an air supply fan driven by a motor is vertically arranged on the welding machine case; a welding machine die used for positioning FEP single tubes and the tube plate is vertically arranged below the air supply fan; an air supply channel is connected with the welding machine die and the air outlet of the air supply fan in a sealing manner; an electrical control heating plate is arranged in the air supply channel; the electrical control heating plate and the motor are connected with the electrical control case through a wire circuit. The invention further discloses a method for welding the FEP heat exchange tube with the tube plate. The device and the method provided by the invention have the advantages that the FEP single tubes and the tube plate are fusible polymers and can be converted into a viscous flow state after being heated; after the welding temperature of the interface between the FEP heat exchange tube and the tube plate surface reaches the fusing-point temperature of the FEP heat exchange tube and the tube plate, the FEP heat exchange tube and the tube plate can be fused together and the welding purpose can be fulfilled; and the degree of deformation and the energy consumption are low.

Owner:SOUTH CHINA UNIV OF TECH

Manual clamping intelligent welding tool for heavy hammer tensioning support of mine belt conveyor

InactiveCN113478127AEasy to placeEasy to stay awayWelding/cutting auxillary devicesAuxillary welding devicesGear wheelElectric machinery

The invention relates to the technical field of welding tools, and discloses a manual clamping intelligent welding tool for the heavy hammer tensioning support of a mine belt conveyor. The manual clamping intelligent welding tool comprises a base, a movable clamping mechanism is fixedly connected to the top of the base, a shell is fixedly connected to the four corners of the top of the base, and supporting blocks are fixedly connected to the four corners of the front face of the shell. A sliding rod is fixedly connected to the inner side of the supporting block, an operation door is slidably connected to the middle of the sliding rod, and a welding mechanism is fixedly connected to the middle in the shell. According to the manual clamping intelligent welding tool for the heavy hammer tensioning support of the mine belt conveyor, through the arranged movable clamping mechanism, a clamping block can be conveniently away from an operation plate through pulling of a pull ring, at the moment, a welding piece is conveniently placed on the top of the operation plate, the pull ring is loosened, and the welding piece is clamped and fixed to the top of the operation plate through the clamping block under the action of a spring; and meanwhile, a motor is started to drive a gear to rotate, the operation plate can move left and right on a sliding rail under cooperation of the gear, and therefore the high-requirement welding purpose is achieved.

Owner:山东海纳智能装备科技股份有限公司

Disassembly-free environment-friendly packaging bag

The invention discloses a disassembly-free environment-friendly packaging bag. The disassembly-free environment-friendly packaging bag comprises a bag body, wherein one side of the bag body is provided with a one-way exhaust device, a reinforcing structure is arranged inside the bag body, portable mechanisms are arranged on the two sides of the upper end of the bag body, a first opening is formedin the other side of the bag body, a feeding pipe is arranged on one side of the first opening, a fixing block is fixed on one side of the top of the bag body, and the fixing block is located at the upper end of the first opening. All the surfaces of the packaging bag are rectangular and have anti-skid strips, so that the stacking is convenient, the stacking is higher, and the packaging bag is high-grade and attractive; a filling opening is convenient to fill, and the filling opening can be plugged into a second opening to be packaged after the filling is finished, the sealing is tighter and more convenient, and the bag body is high in hardness, high in tensile strength, good in toughness, and not easy to damage, and has one-way air permeability; and the possibility of a burst bag is reduced during extrusion, the packaging bag is not disassembled, the packaging bag can be used as a raw material after the raw material in the packaging bag is used, waste of resources is reduced, and resources are saved.

Owner:衡水市聚丰塑胶科技有限公司

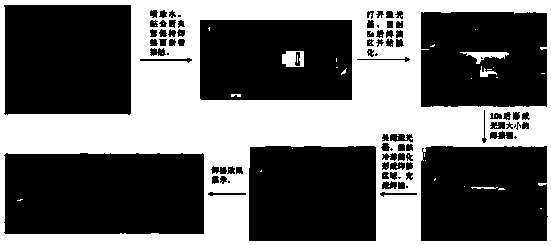

Plastic laser welding method

ActiveCN108327301AAchieve laser weldingTo achieve the purpose of weldingToxicityEnvironmental resistance

The invention discloses a plastic laser welding method. The method comprises the following steps: (1) applying water to a to-be-welded region of to-be-welded plastic so as to keep the to-be-welded region of the to-be-welded plastic in close contact; (2) irradiating the to-be-welded region with a laser to complete welding of plastic. Water is used as a solder (a photothermal conversion carrier) without doping of any other light absorption filler or pigment, so that green, environment friendliness, no toxicity and harmlessness are truly achieved; the method has great application value in fieldsof food packaging, medical devices, welding of precision and complicated plastic parts and the like.

Owner:JIANGNAN UNIV

An automatic plug-in machine for the production of special-shaped electronic components

ActiveCN113710006BTo achieve the purpose of weldingIncrease productivityPrinted circuit assemblingSortingElectronic componentServo

The invention discloses an automatic plug-in machine for inserting and producing special-shaped electronic components, comprising a plug-in moving assembly, one end of the plug-in moving assembly is connected with the plug-in assembly, a transmission assembly is arranged under the plug-in assembly, and one side of the transmission assembly is provided with an electronic The component conveying assembly, the plug-in assembly includes a servo motor, one end of the servo motor is connected with a rotating plate, one end of the rotating plate is connected with a first electric telescopic rod, the number of the first electric telescopic rod is four, and the first electric telescopic rod is far from the rotating plate. One end is provided with a clamp connecting plate. In the present invention, the insertion end of the electronic component of the micro electric clamp is dipped into the tin liquid in the tin liquid box, and then the micro electric clamp inserts the insertion end of the electronic component into the circuit board, so that the electronic component is inserted into the circuit. Compared with the traditional technology, the purpose of soldering the board greatly improves the production efficiency of special-shaped electronic components and meets the needs of current production.

Owner:南通祥峰电子有限公司

Formula and preparing method for rapidly manufacturing cast iron electrodes

InactiveCN110695568AQuality assuranceLow priceWelding/cutting media/materialsSoldering mediaSesquioxideManufactured material

The invention relates to the technical field of welding consumables, and specifically relates to a formula for rapidly manufacturing cast iron electrodes. A common steel electrode is used as a substrate, flux is applied to the substrate, the flux comprises compositions including, by mass, 80% of iron sesquioxide, 15% of ferroferric oxide and 5% of calcium carbonate. By means of the formula and themanufacturing method for rapidly manufacturing the cast iron electrodes, according to the obtained cast iron electrodes, in the welding process, powder coated on the substrate uses heat of the electrodes to participate in a redox reaction, a core wire of the substrate is oxidized and reduced into materials similar to base metal, and therefore the welding aim is achieved; the manufacturing cast issimple, fast, ready-to-use, low in formula raw material price and easy to purchase and reduces the business capital backlog and the capital cost; and the quality of the cast iron electrodes manufactured according to the manufacturing method in the embodiment is ensured, and the welding quality and effect are ensured.

Owner:湖南三创富泰设备管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com