Television frame friction-welding device

A friction welding and frame technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of harsh welding conditions, poor support stability, low welding strength, etc., and achieve high welding strength, not easy to crack, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, invention is described in further detail.

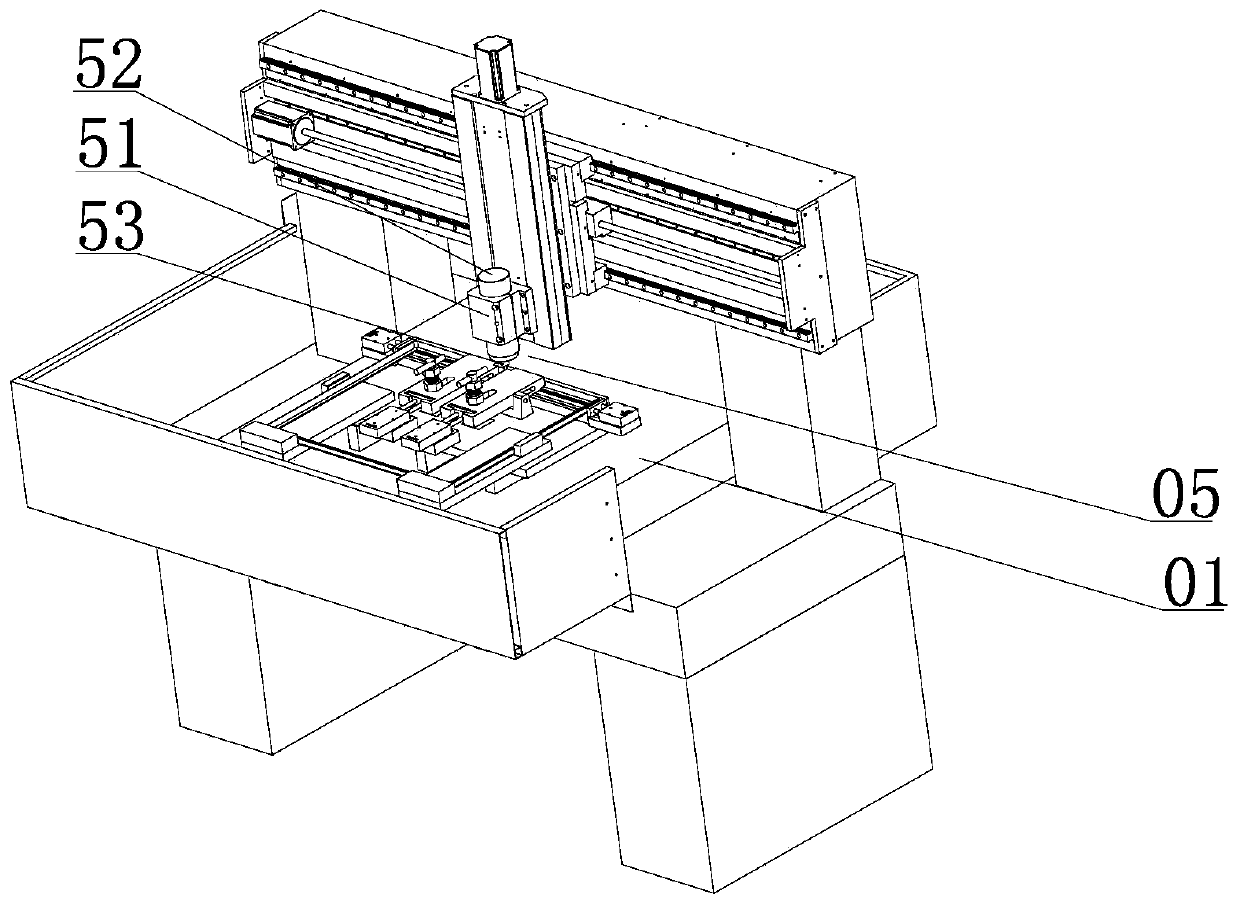

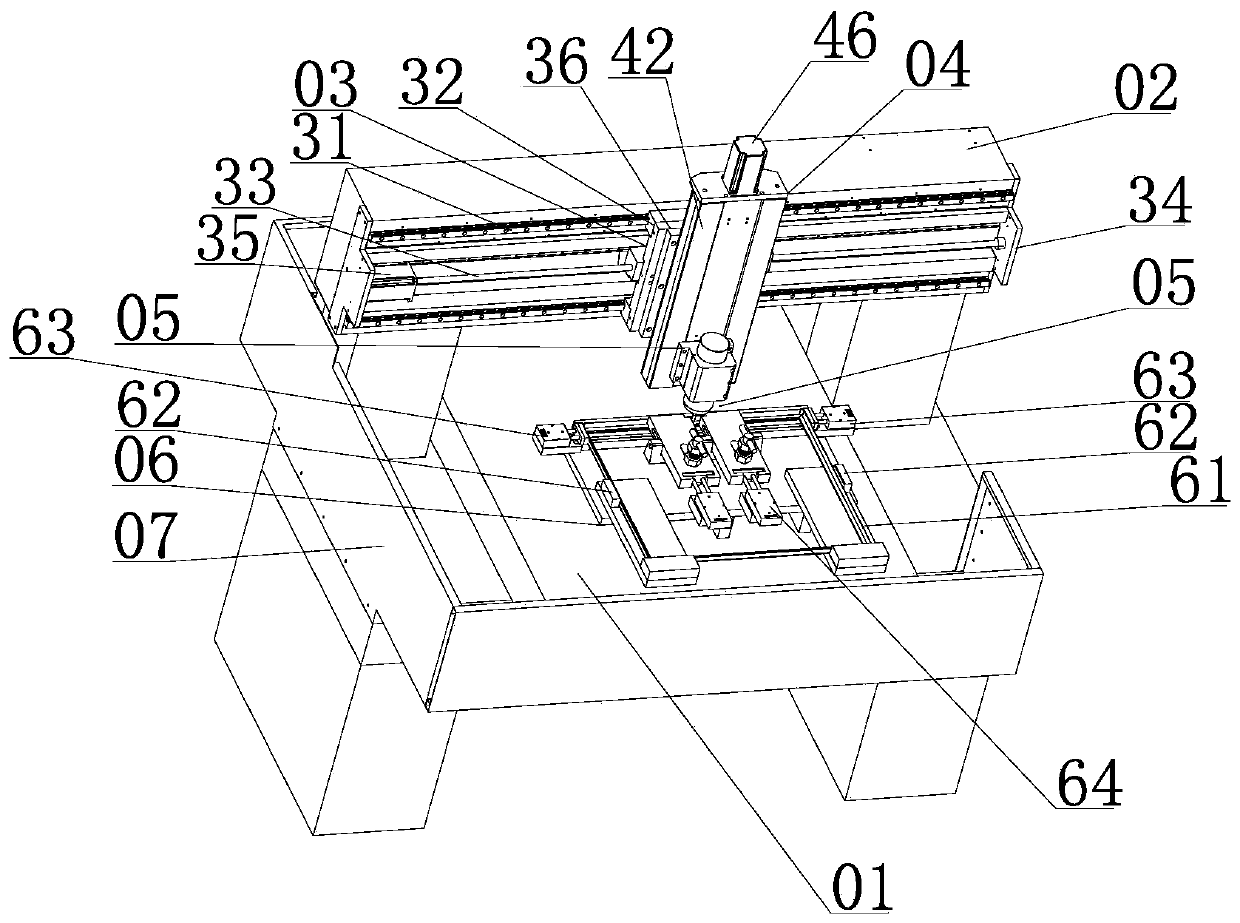

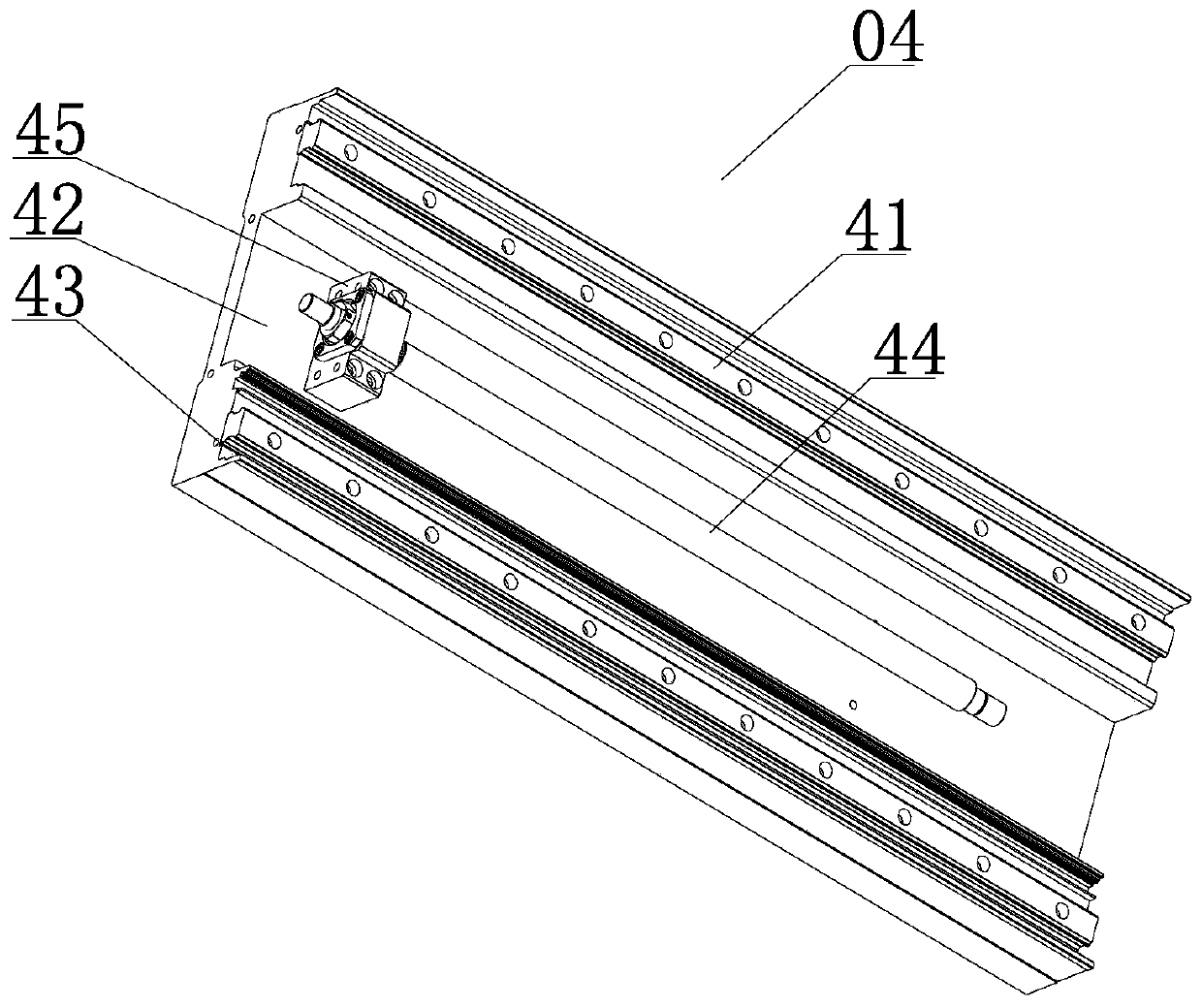

[0013] Such as Figure 1-4 As shown, a TV frame friction welding device includes a workbench 01, a gantry 02 provided on the workbench 01, a translation device 03 for horizontal movement on the gantry 02, and a translation device 03 provided on the gantry 02. The lifting device 04 and the friction welding tool 05 provided on the lifting device 04, and the product fixing device 06 provided on the workbench 01 below the friction welding tool 05. The translation device 03 includes two first guide rails 31 that are transversely parallel to each other on the side of the gantry frame 02 , sliders 32 that are respectively provided on the two parallel first guide rails 31 , and one side of the first guide rail 31 . The provided first screw mandrel 33 is provided with a fixed block 34 connected to the gantry frame 02 on one end of the first screw mandrel 33 , and a translation block fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com