Electric soldering iron

An electric soldering iron and heating core technology, applied in soldering irons, metal processing equipment, manufacturing tools, etc., can solve the problems of burnt components and losses, and achieve the effect of convenient welding and overall beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

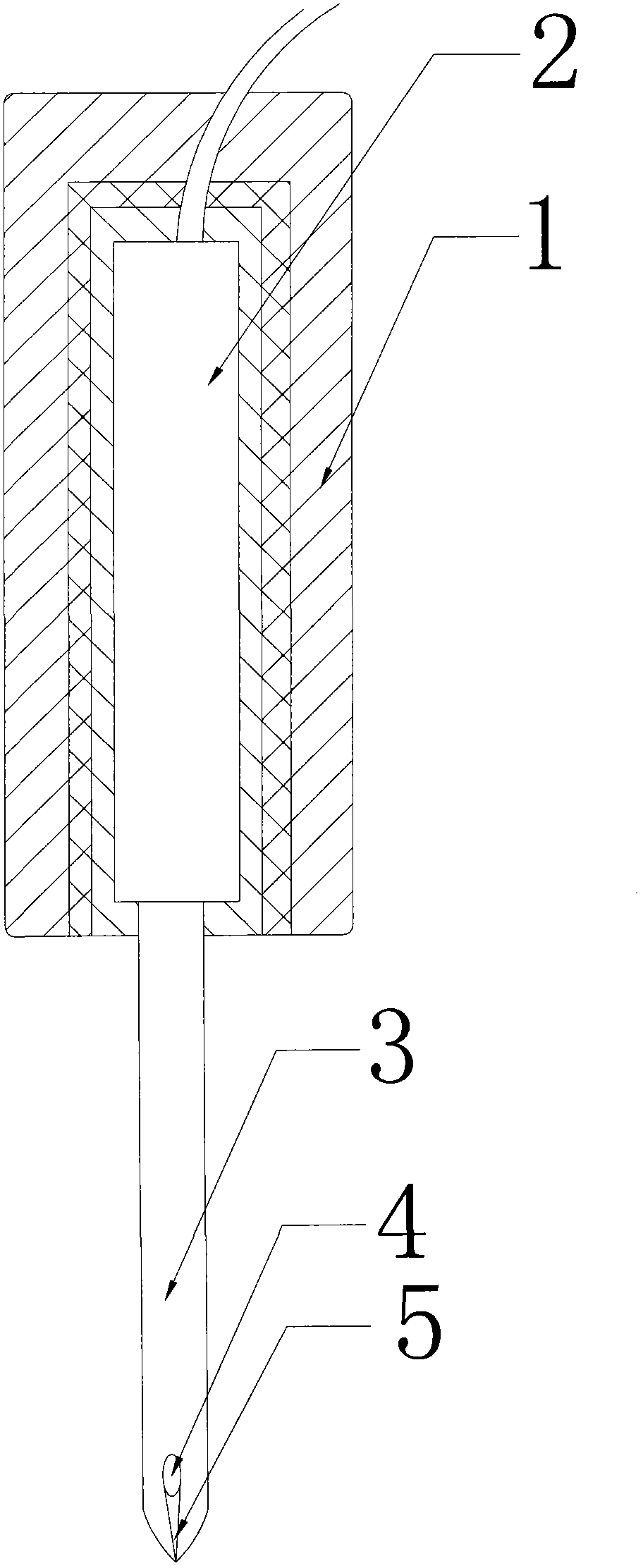

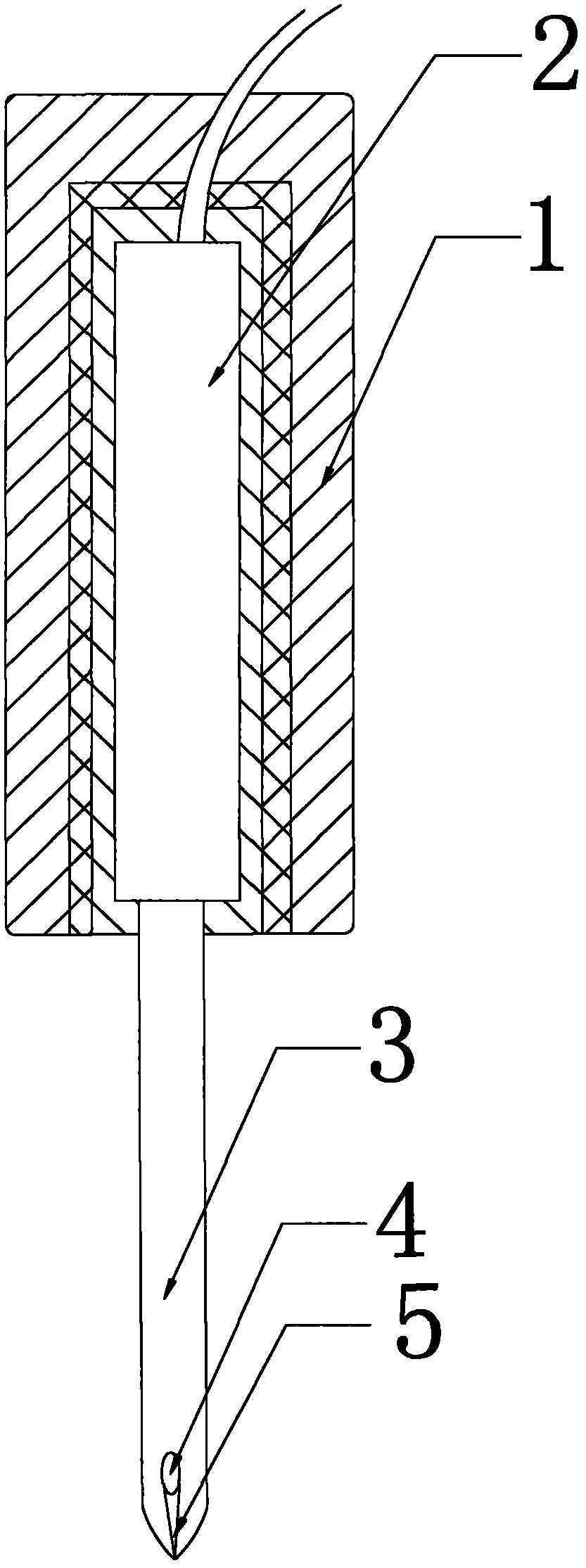

[0010] Such as figure 1 As shown, the electric soldering iron includes a handle 1, a heating core 2 and a welding head 3. The heating core 2 is placed in the handle 1, and the heating core 2 is in contact with the welding head 3. The lower part of the welding head 3 has a semi-conical structure. There is a groove 4 on the bottom of the groove 4, and a flow channel 5 is also opened below the groove 4. One end of the flow channel 5 communicates with the groove 4, and the other end leads to the lower end of the welding head 3, so that when welding Put the electric soldering iron horizontally, place the groove 4 facing upwards, place the welding wire in the groove 4, and after the welding wire melts, move the horizontal welding head of the electric soldering iron to the joint of the circuit, and gently lift the handle 1 so that The molten welding wire drips on the joint of the line to achieve the purpose of welding. This not only ensures that the molten welding wire will not drip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com