Plastic laser welding method

A technology of laser welding and plastics, applied in the field of laser welding, can solve problems such as high price, limited application field, and existence of safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

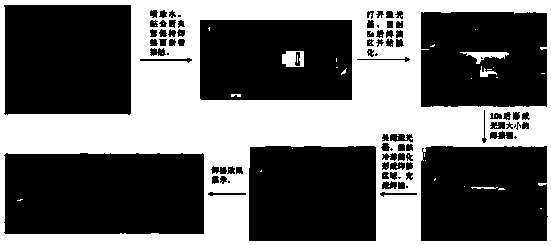

[0025] A method of laser welding plastic parts, with molecular weight 50000g / mol, thickness is 0.2mm polycaprolactone (T m ≈60°C) welding as an example, the method includes the following steps:

[0026] (1) Brush 10μl / cm on the area where the two plastic parts are to be welded 2 Butt the joints and keep the joints to be welded in close contact;

[0027] (2) Use a laser with a wavelength of 1470nm to irradiate the welding area, adjust the output power of the laser to 0.5W, the welding area will start to melt after 5s, and form a melting surface with a spot size after 10s, then turn off the laser, cool and solidify naturally to form a welding area, and complete the welding .

[0028] Cut the samples before and after welding into dumbbell shapes respectively, and carry out the tensile test. The samples before the test are as follows: image 3 as shown, Figure 4 is the stress-strain curve of the sample before and after welding at room temperature.

[0029] Depend on image ...

Embodiment 2

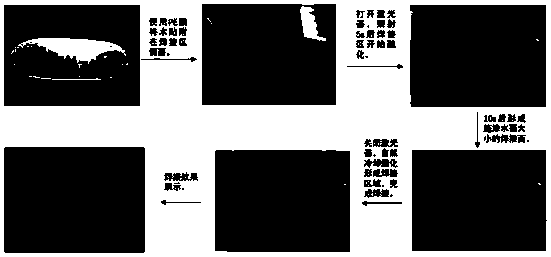

[0032] A kind of method of laser welding plastic parts, take molecular weight 50000g / mol, thickness be the polycaprolactone (PCL) plastic part welding of 1mm as example, described method comprises the following steps:

[0033] (1) Spray 10μl / cm on the area where the two plastic parts are to be welded 2 water, and keep the joints to be welded in close contact;

[0034] (2) Use a laser with a wavelength of 1910nm to irradiate the welding area, and adjust the output power of the laser to 0.5W. After 5s, the welding area begins to melt, and after 10s, a melting surface with a spot size is formed. Then turn off the laser, cool and solidify naturally to form a welding area, and complete the welding. .

Embodiment 3

[0036] A method of laser welding plastic parts, with molecular weight 80000g / mol, thickness is 0.2mm polycaprolactone (T m ≈60°C) welding of plastic parts as an example, the method includes the following steps:

[0037] (1) Wipe 6 μl / cm on the area where the two plastic parts are to be welded 2 water, and keep the joints to be welded in close contact;

[0038] (2) Use a laser with a wavelength of 1470nm to irradiate the welding area, and adjust the output power of the laser to 0.5W. After 5s, the welding area begins to melt, and after 10s, a melting surface with a spot size is formed. Then turn off the laser, cool and solidify naturally to form a welding area, and complete the welding. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com