Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Laser transmission welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser Weldable Label and Shaped Composite Article Therewith

InactiveUS20080317979A1Improve adhesionEfficiently maskedStampsSynthetic resin layered productsAdhesiveOptical transmittance

The laser-transmissive welding label of the present invention is a resin label which comprises at least a resin layer and is affixable to a resin shaped article by a laser welding, wherein the resin layer has a light-scattering property, and the transmittance of the resin layer relative to a laser beam having an oscillation wavelength within the range of 740 to 1100 nm is not less than 20%, and the total light transmittance of the resin layer relative to a visible light (in accordance with ASTM D1003) is not more than 50%. The resin layer may comprise a thermoplastic resin which may have a compatibility with a resin for the resin shaped article. The label may be able to mask the resin shaped article, or may be colored with a coloring agent. A shaped composite article (e.g., a toner cartridge) may be formed by bonding the label to the resin shaped article with use of the laser welding. The present invention provides the resin label which is affixable to the resin shaped article in an easy and simple way, without an adhesive.

Owner:DAICEL POLYMER LTD +1

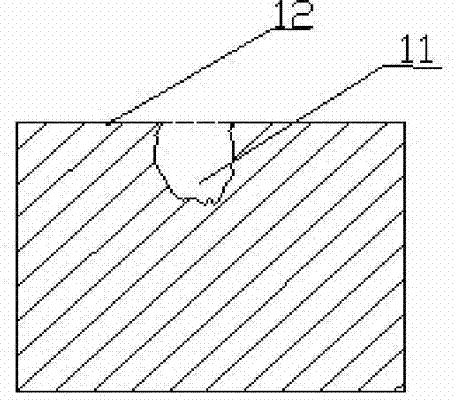

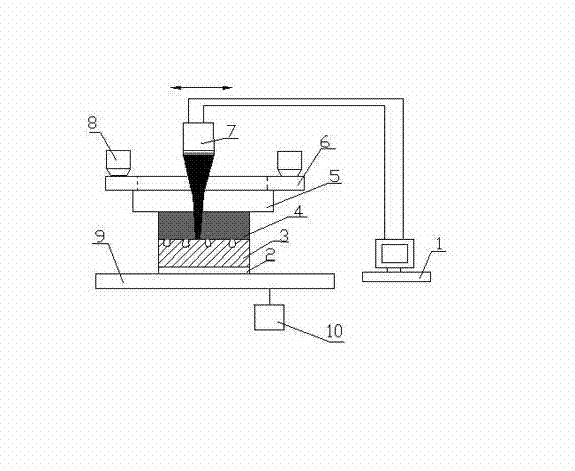

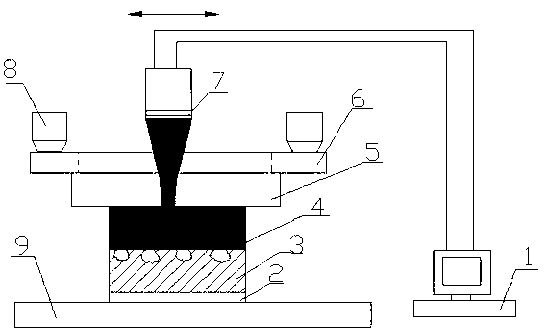

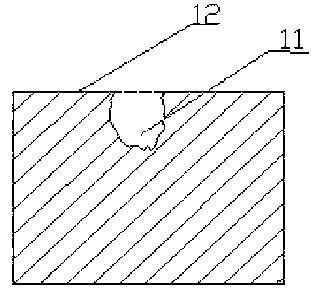

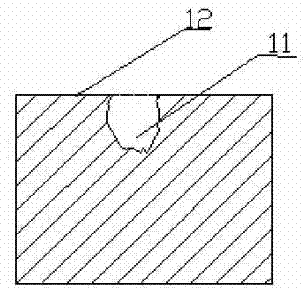

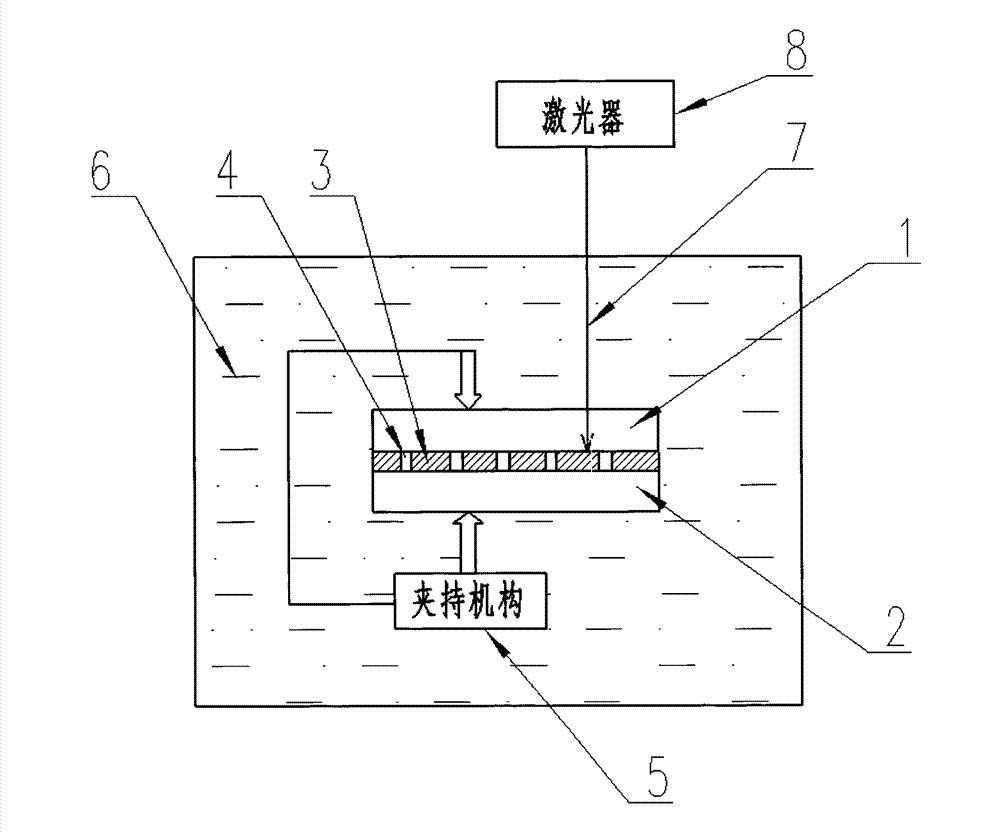

Method for improving laser transmission welding connection strength

The invention discloses a method for improving laser transmission welding connection strength, belonging to the field of laser transmission welding technology, and especially refers to laser transmission welding of metals and polymers. The method comprises pulsed laser treatment is performed to the surface of a metal material which needs welding to form pits on the surface; during the welding, the metal treated by pulsed laser is used as a lower layer light-absorbing material, and the polymer is used as a top layer light transmitting material, by adopting an overlapping connection type, a restrained layer is used for clamping tightly and the welding pressure is applied; a semiconductor laser with continuous energy is used for laser transmission welding to make a surface temperature quickly reaches the melting point of the top layer polymer, so the polymer surface is melted; because pits are formed on the lower metal surface after pulsed laser treatment, the melted polymer on the top surface flows into the pits by the action of the welding pressure to form an engaging interface with a riveting structure at a welding line, thereby improving laser transmission welding connection strength.

Owner:JIANGSU UNIV

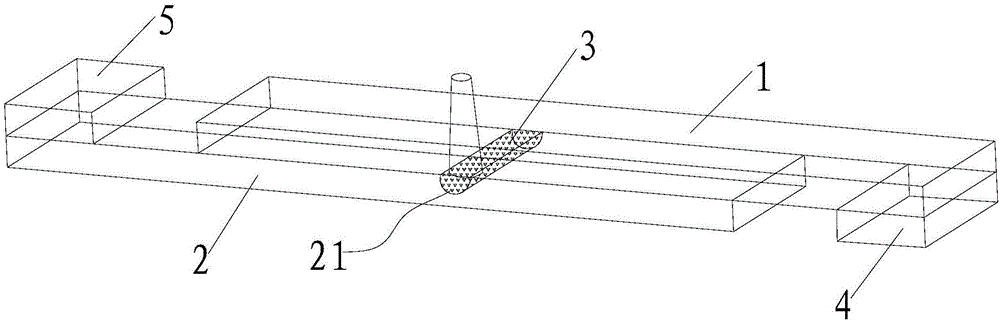

Device and method for welding plastic materials in laser transmission manner

The invention provides a device for welding plastic materials in a laser transmission manner. The device comprises a supporting plate, a laser light source and a pressure regulating mechanism, wherein the pressure regulating mechanism comprises a pressing plate mechanism, a supporting plate, a guide rail and a drive mechanism; the pressing plate mechanism is connected with the drive mechanism andis connected with the supporting plate through the guide rail; the pressing plate mechanism is provided with a light-transmitting window consisting of a light-transmitting window opening and a light-transmitting window body; plastic materials to be welded are positioned on the supporting plate and correspondingly arranged below the light-transmitting window; and the laser light source is sequentially connected with the light-transmitting window and the plastic materials to be welded through laser beams. The invention also provides a welding method realized by the device. According to the invention, the plastic materials to be welded are under proper pressure, and further generate secondary polarization to be combined together, thus welding quality and welding strength are ensured.

Owner:光机电(广州)科技研究院有限公司

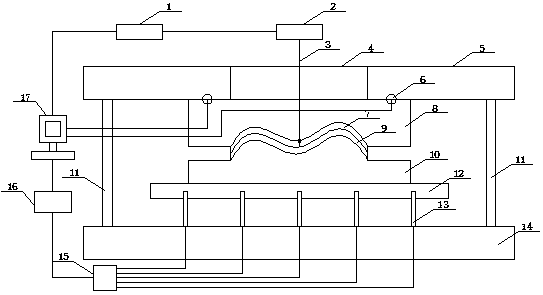

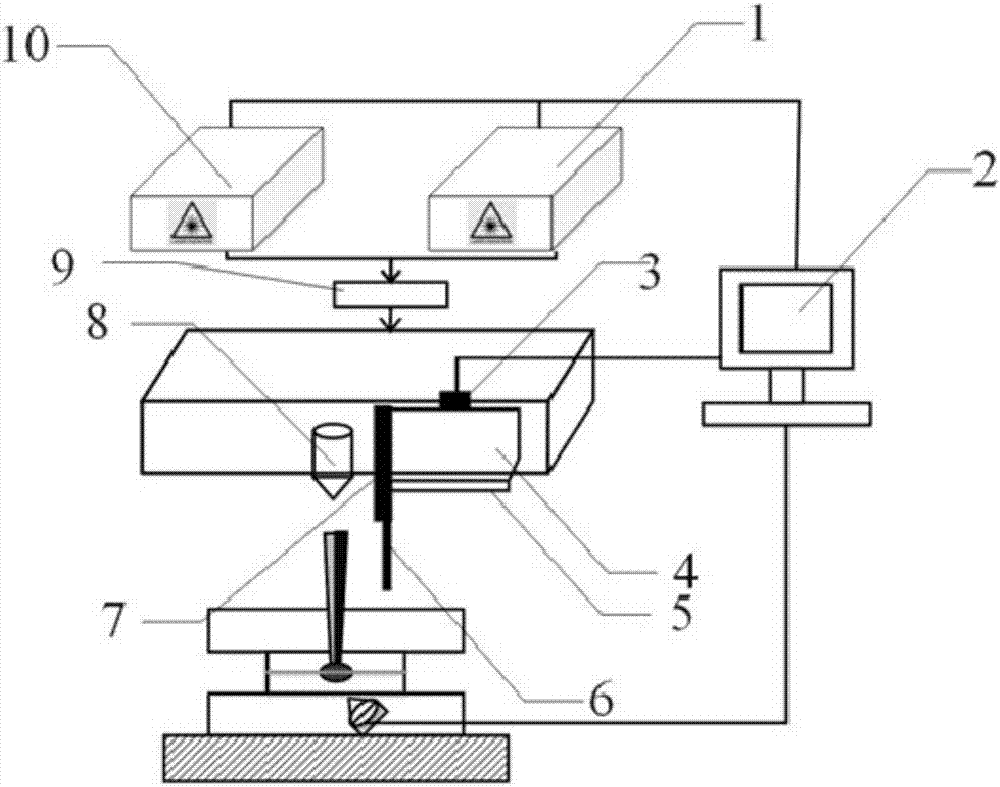

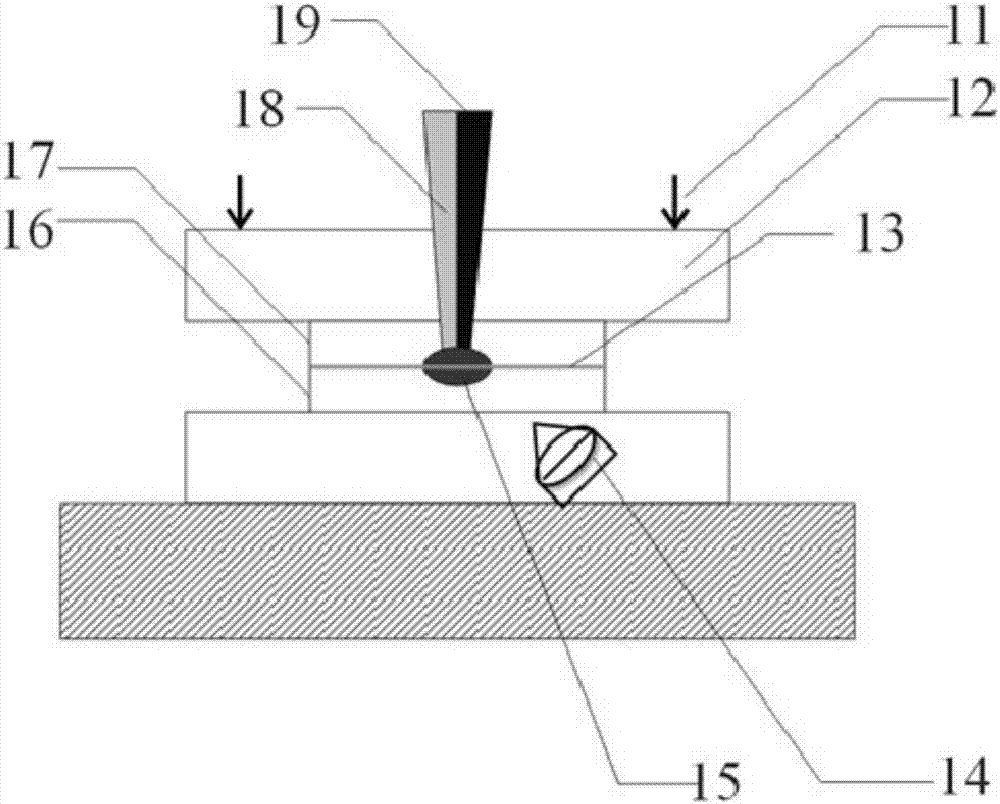

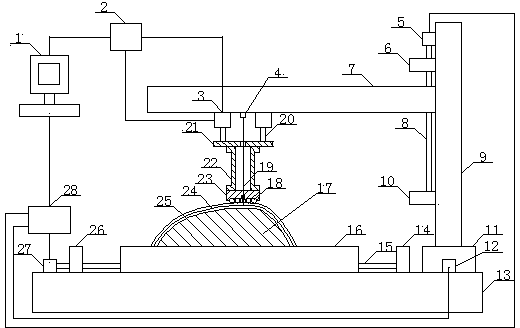

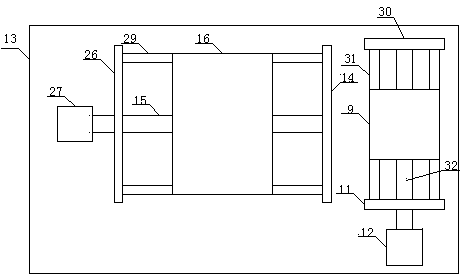

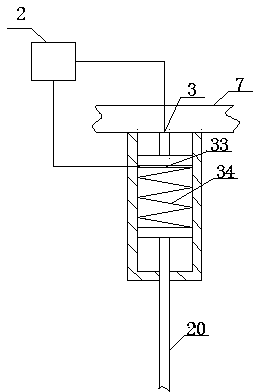

Laser transmission welding clamping apparatus capable of achieving any curved surface welding

InactiveCN104385577ASimple 2D WeldingPrecise control of welding positionThermoplasticStress concentration

The invention relates to a laser transmission welding clamping apparatus used between thermoplastic plastics or between a thermoplastic plastic and a metal material and capable of achieving any curved surface welding. The laser transmission welding clamping apparatus comprises a PC machine, a PLC controller, a hydraulic system, a pressure sensor and a light source control system, and further comprises a pressure applying system, a pressing component and a periphery fixation member, wherein the pressure applying system applies uniform pressing force on the surface of the two-dimensional pressing component, the pressing component transmits the pressing force to the upper work-piece and the lower work-piece and the pressing force is uniformly distributed so as to achieve the clamping on the complex work-piece, and laser performs the welding on the work-piece under the control of the PC machine. According to the present invention, with the laser transmission welding clamping apparatus of the thermoplastic plastic, the welding on the any curved surface work-piece can be achieved, the welding path and the pressing force can be precisely controlled, the whole strength and the stiffness of the welded member can be increased, the pressing of the upper mold and the lower mold is adopted, the pressing force is uniformly distributed on the surface, the stress concentration after processing is voided, and the quality of the processed work-piece is improved.

Owner:JIANGSU UNIV

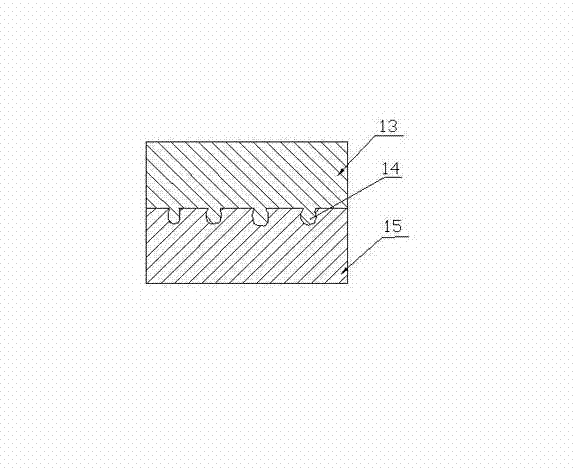

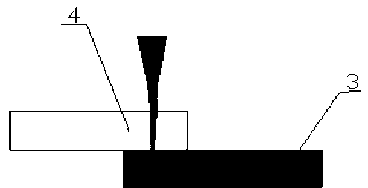

High-strength laser transmission connecting method

InactiveCN103071922AImprove connection strengthStrong local connectionLaser beam welding apparatusPolymeric surfaceMetallic materials

The invention discloses a high-strength laser transmission connecting method, belongs to the technical field of laser transmission welding, and especially relates to the laser transmission welding between polymers. The method comprises the following steps: treating a to-be-welded surface of a metal material by adopting a drilling machining method and forming pits on the surface; at a welding moment, taking the metal with the surface subjected to the drilling machining treatment as a lower-layer light-absorbing material and taking the polymer as an upper-layer light-transmitting material; adopting a lapped connecting mode and using a restraint layer for clamping and applying welding pressure; and using a semiconductor laser device for performing laser transmission welding, causing the surface temperature to quickly reach the melting point of the upper-layer polymer and melting the surface of the polymer. The pits are formed on the polymer surface through drilling mechanical treatment, so that under the action of a welding pressure, the melted polymer flows into the pits, an occlusion interface with a riveted structure is formed at a welding joint, and the high-strength laser transmission welding is realized. The high-strength laser transmission connecting method can be widely applied to the field of the laser transmission welding with higher demand on the connecting strength.

Owner:JIANGSU UNIV

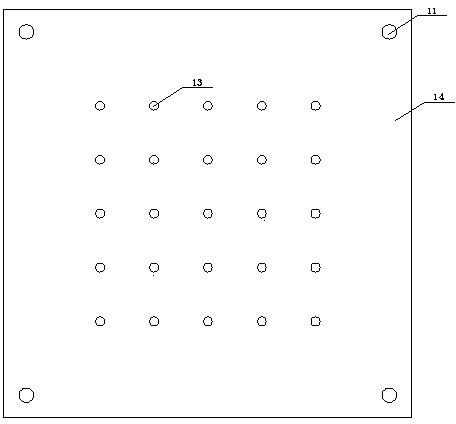

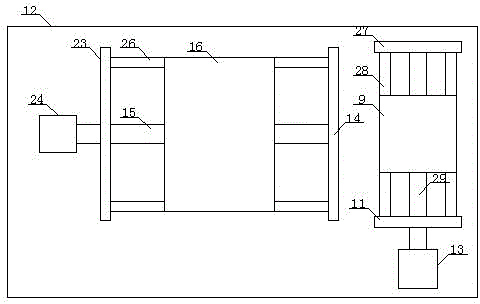

Laser transmission welding follow-up clamping device

The invention provides a laser transmission welding follow-up clamping device, which is a welding and clamping device used for laser transmission welding plastic material or plastic and metal plastic. The device is characterized by comprising a support assembly, a pressure head assembly and a pressure head fixing assembly; the support assembly consists of hydraulic thimble components which are arranged in a square array and a support plate; each hydraulic thimble component schedules any one hydraulic thimble component through a PC (personal computer) terminal program; the overall support plate is controlled by a hydraulic control system to perform Z-directional movement; the pressure head assembly consists of a laser head, a pressure sensor and a compressing small roller wheel; the pressure head component performs X and Y directional movement under the driven of a servo motor; the compressing roller wheel can be adaptively adjusted at Z direction, so as to interact with a follow-up thimble under the compressing roller wheel to realize follow-up clamping for workpieces. According to the device provided by the invention, the extension height of the thimble rod required to be adjusted is satisfied, thus, the workpiece in any shapes can be adapted by the device, and the clamping problem of the curved surface type welding seam can be effectively solved.

Owner:JIANGSU UNIV

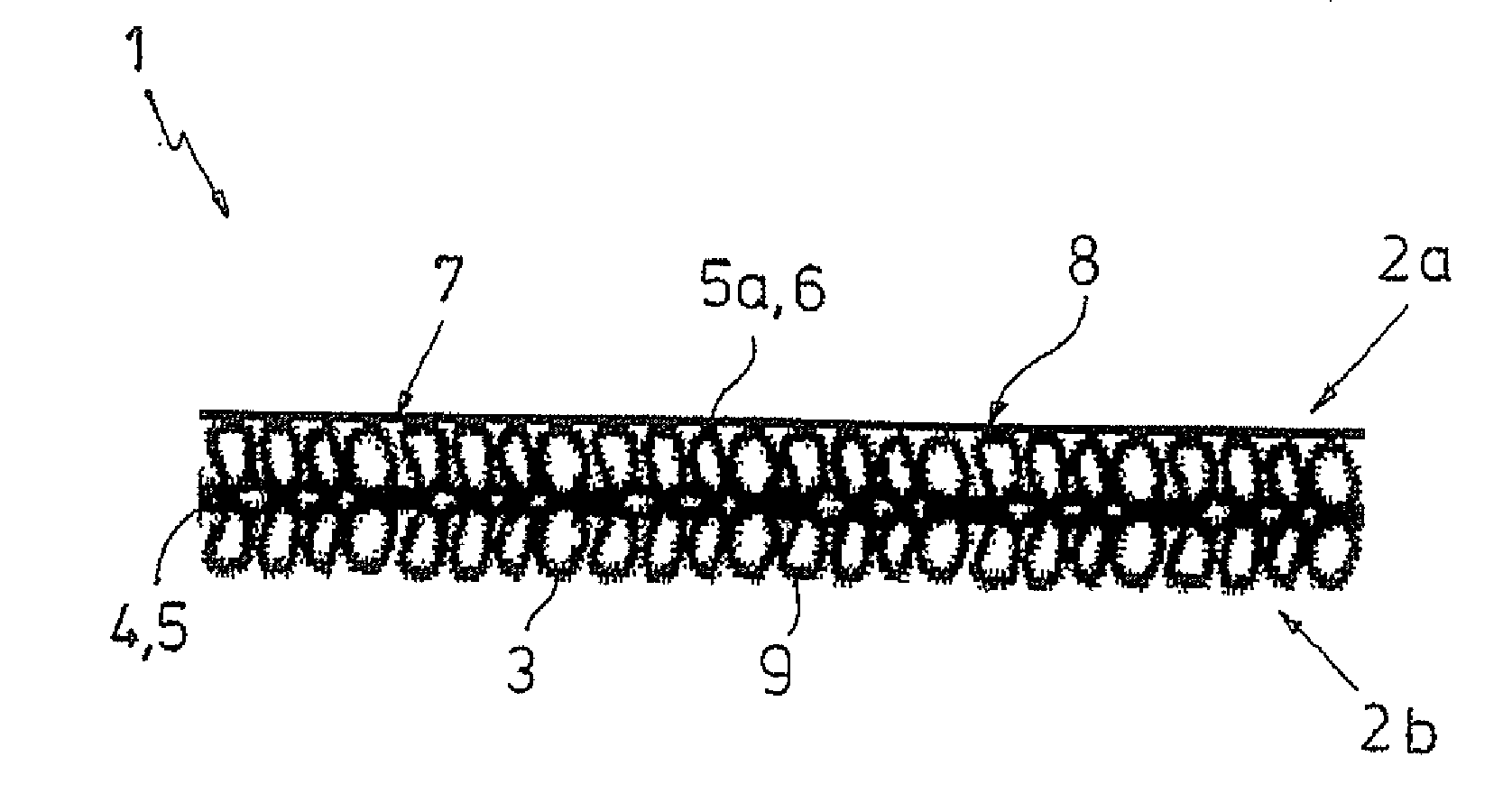

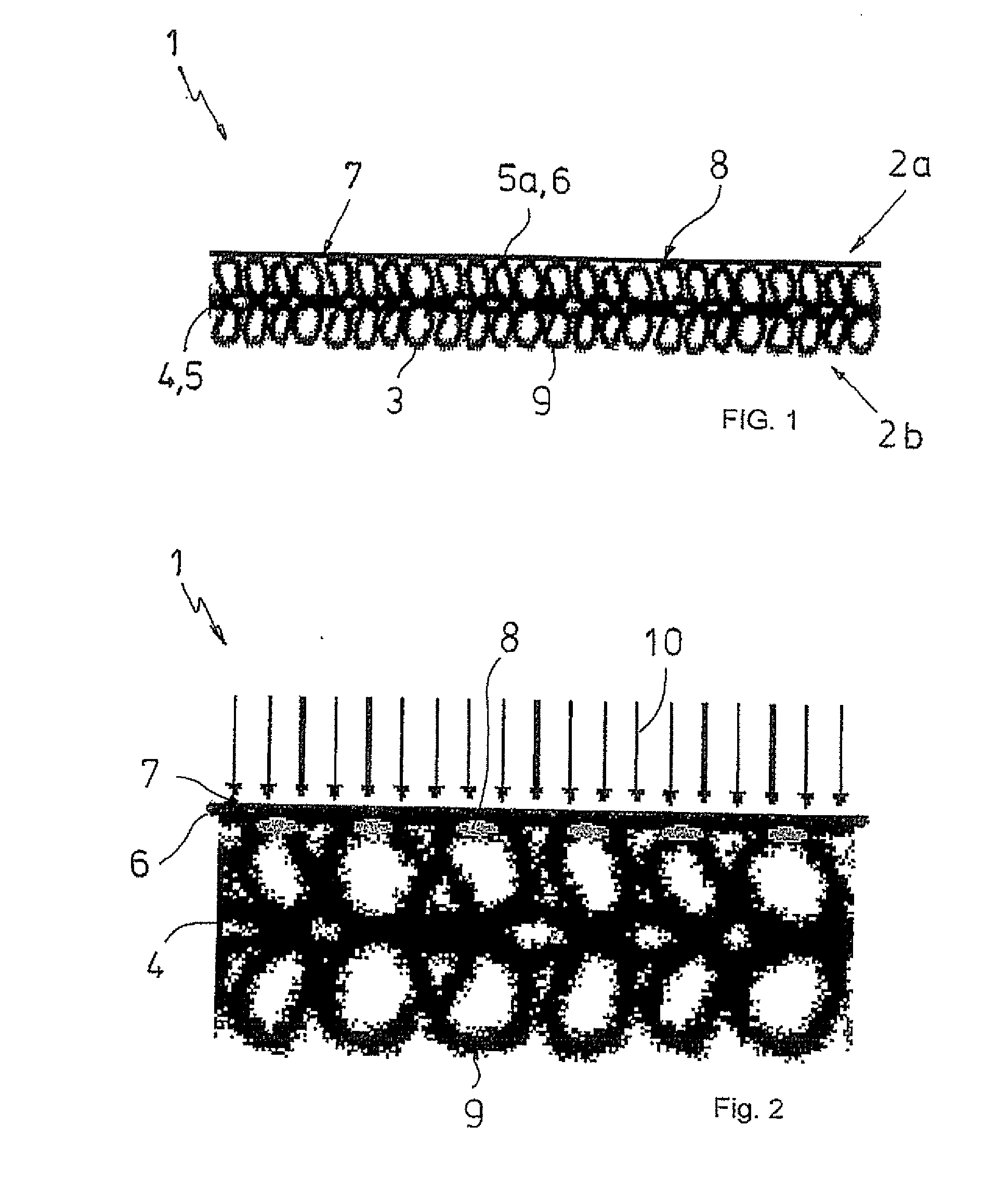

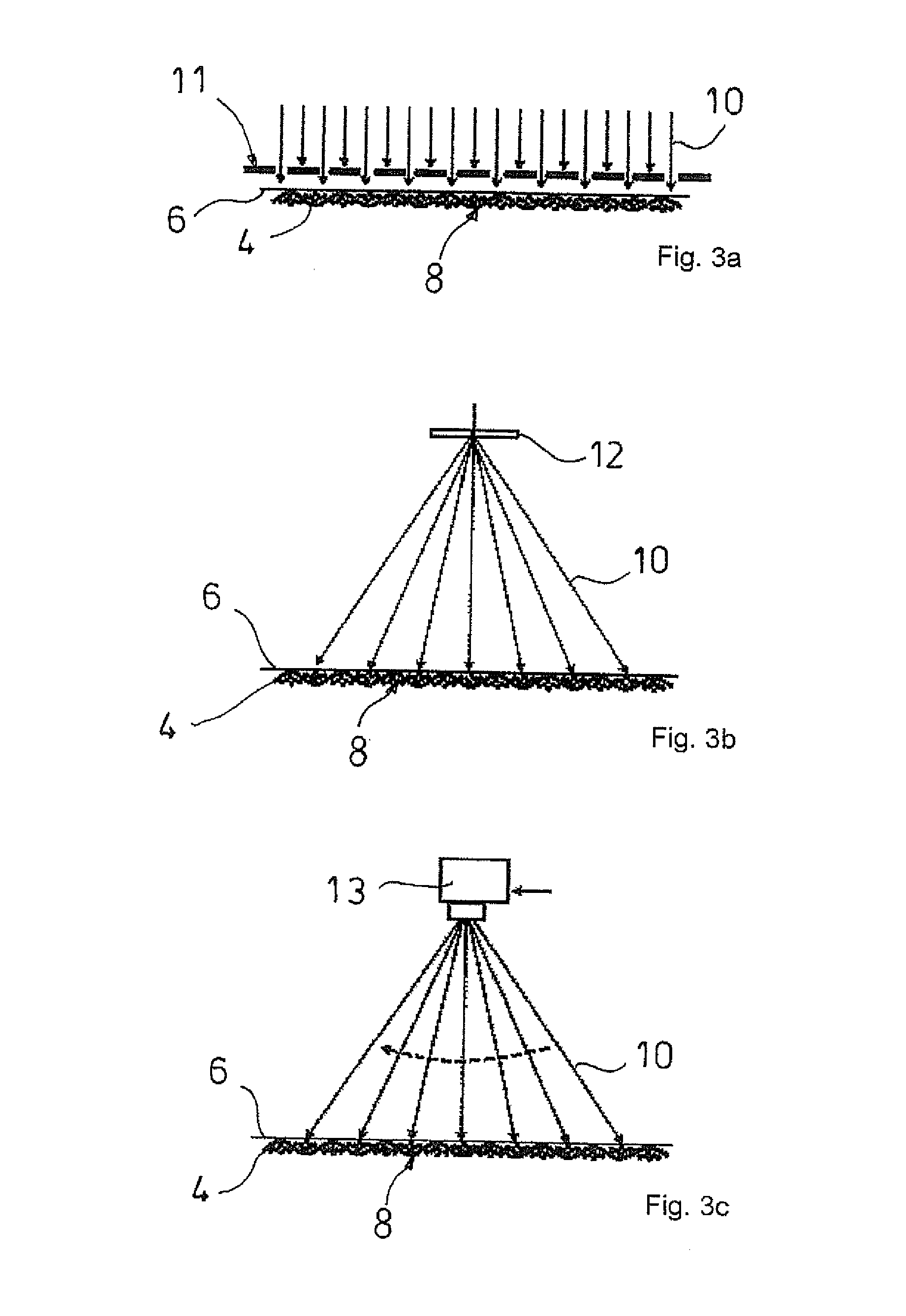

Water vapor permeable, waterproof textile laminate and method for production thereof

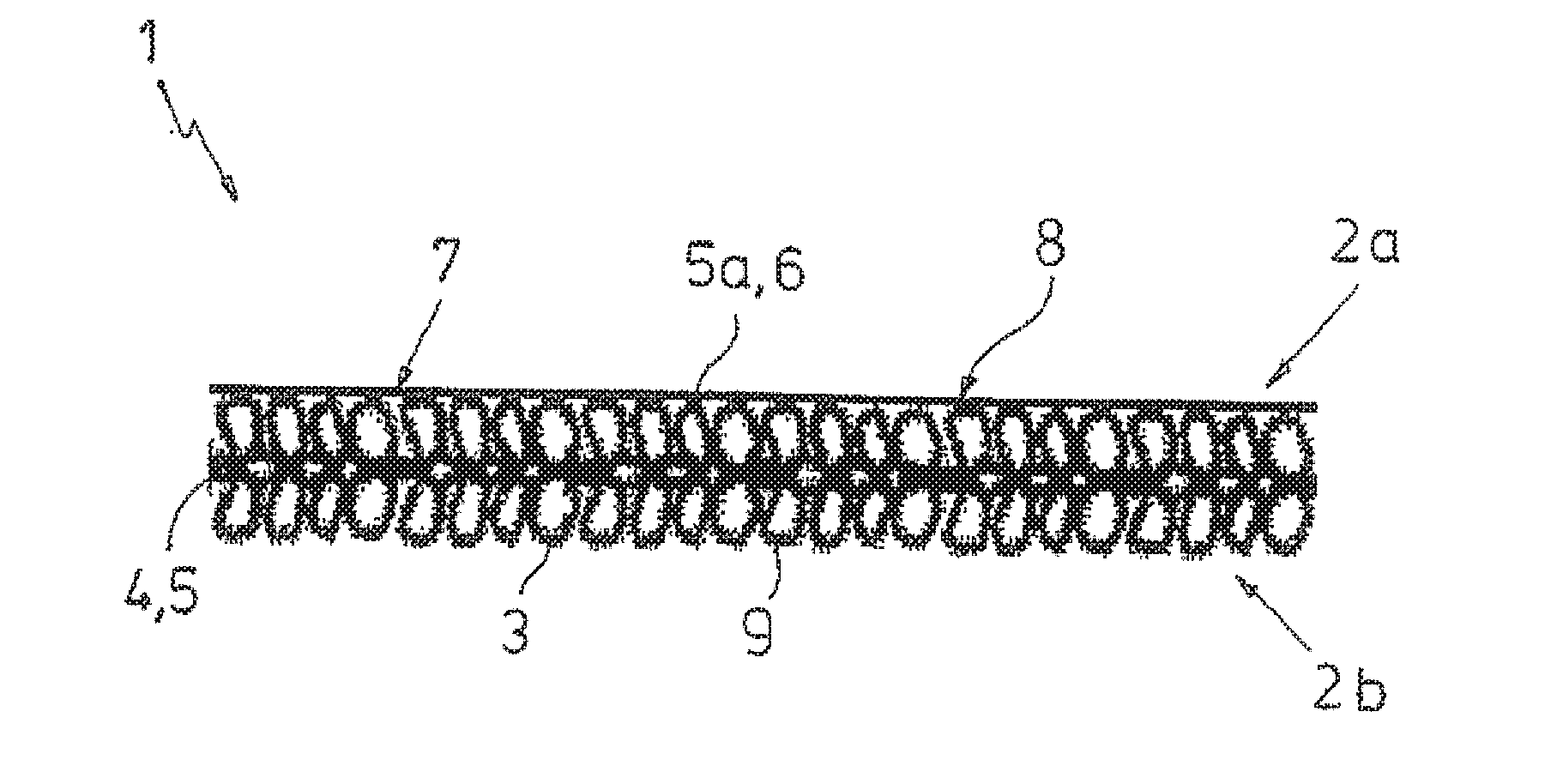

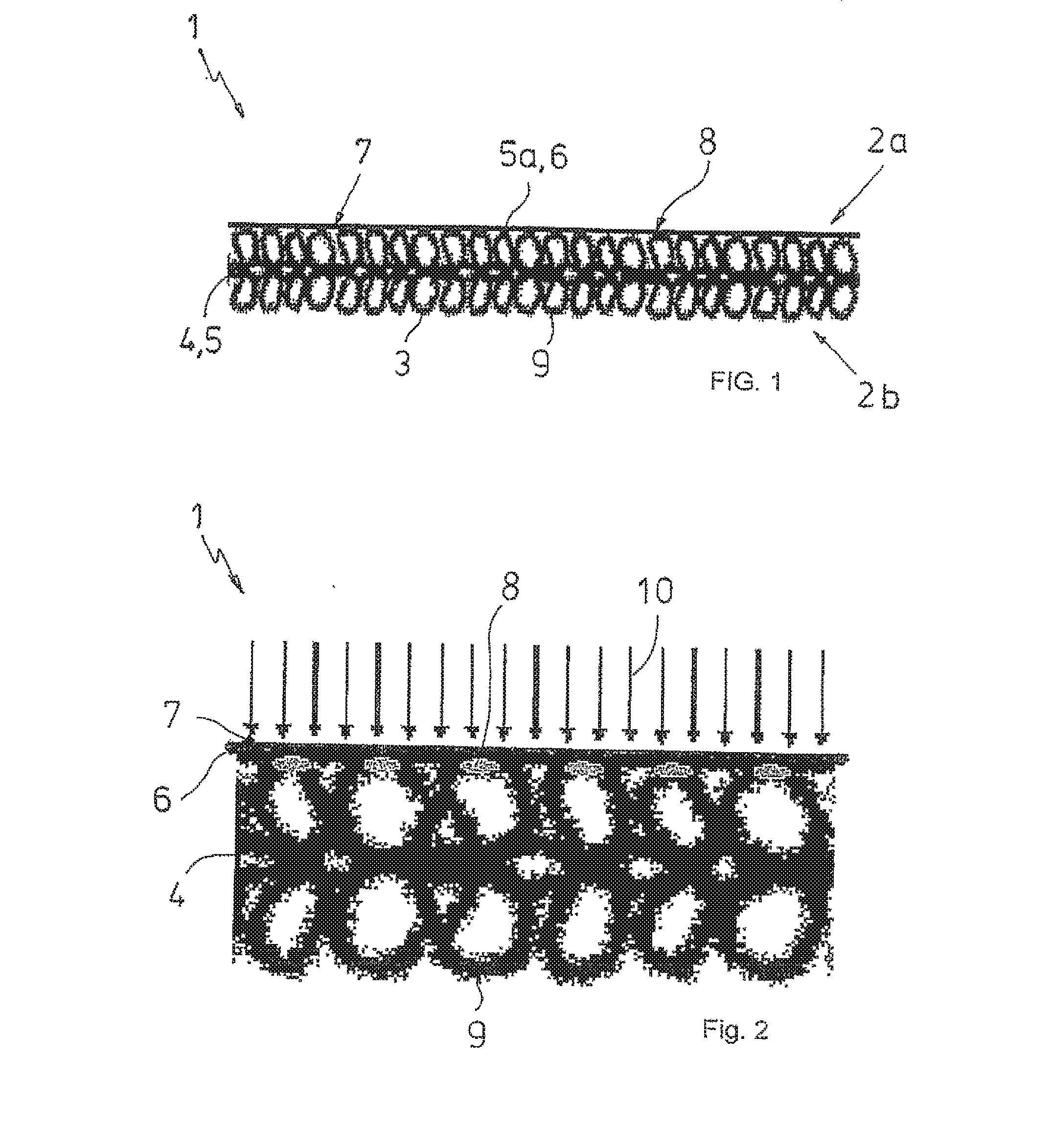

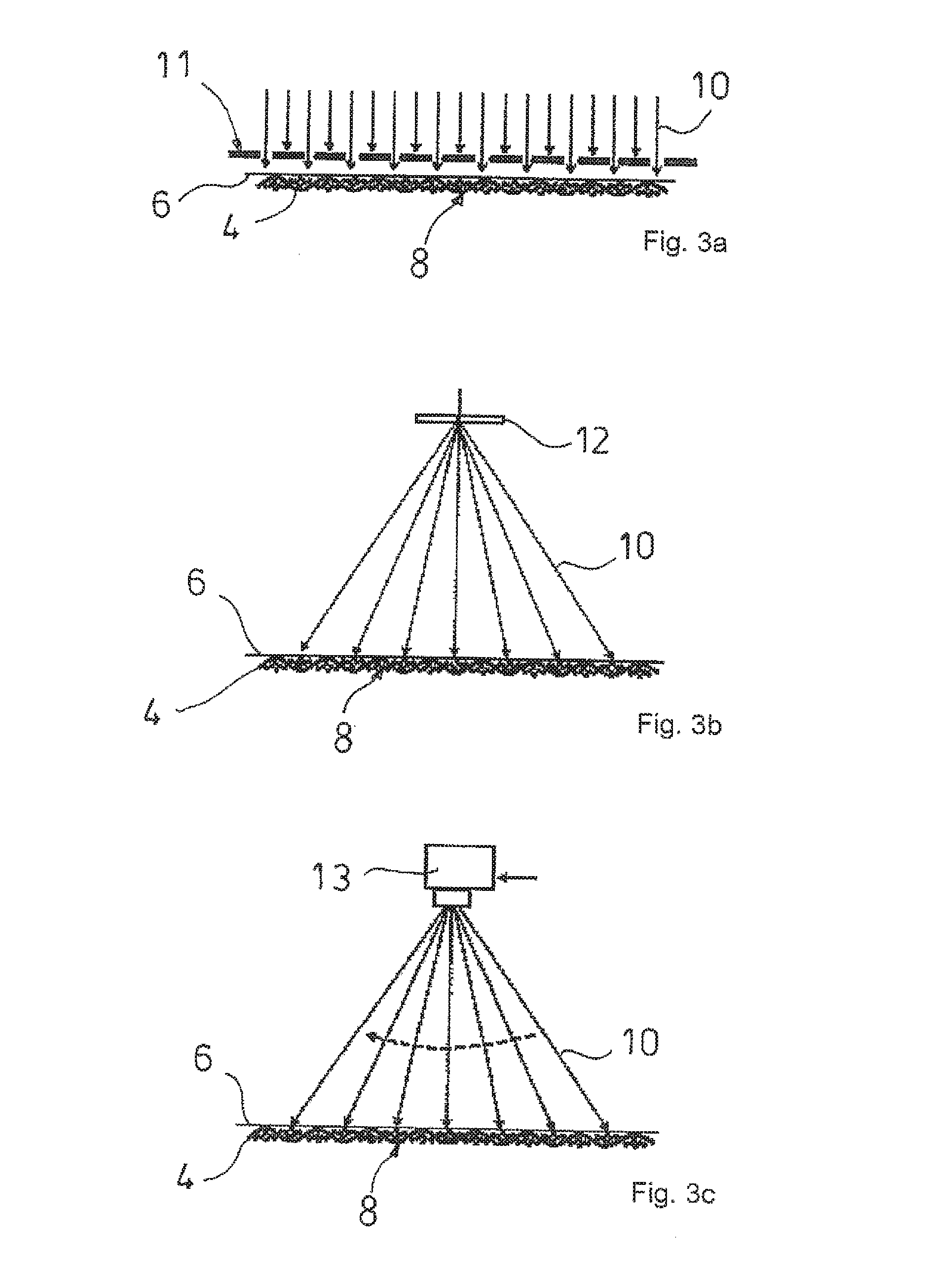

InactiveUS20140363636A1Equally distributedEasy to pullLamination ancillary operationsLayered product treatmentFiberWater vapor

A water vapor permeable, waterproof textile laminate, comprising at least two layers made of planar web material, which are disposed on top of each other and bonded to each other, wherein an open fabric web comprising polymer fiber threads forms a top tier and a film-like, water vapor permeable, waterproof thermoplastic membrane web forms a bottom tier. The polymer fiber threads of the fabric web comprise raised thread regions, which are held bearing against the membrane web and / or are partially fused into the membrane web, wherein the membrane web comprises integral fusion areas with the raised thread regions, which are generated according to the invention by way of laser light in a laser transmission welding method.

Owner:LEISTER TECHNOLOGIES

Laser transmission welding method of transparent thin glass

InactiveCN107382044ARealize preheating before weldingSlow cooling after weldingGlass reforming apparatusCoatingsLap jointSlow cooling

The invention provides a laser transmission welding method of transparent thin glass. The method comprises the following steps of cleaning upper glass and lower glass to be welded, lapping the treated upper glass and the lower glass, putting on a base, putting light-transmission glass on the upper glass, applying a uniform clamping force on the light-transmission glass, allowing an ultraviolet wavelength laser beam and an infrared wavelength laser beam to pass through a collimation focusing system, focusing the ultraviolet wavelength laser beam at a lap joint for preheating, using the infrared wavelength laser beam to assist the ultraviolet wavelength laser beam in welding after the preheating is finished, shutting down an infrared wavelength laser after the welding is finished, and continuing using the ultraviolet wavelength laser beam for postwelding slow cooling of the welded lap joint. The method achieves the weld preheating and the postwelding slow cooling of a workpiece, can effectively reduce residual stress of the workpiece, limits processing cost even improves welding efficiency and welding quality.

Owner:JIANGSU UNIV

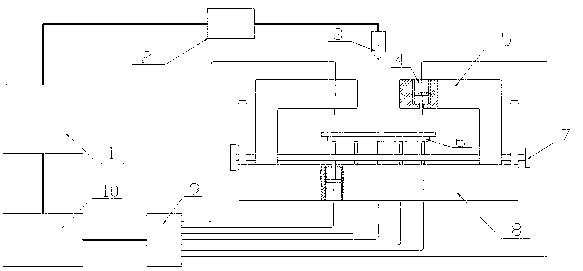

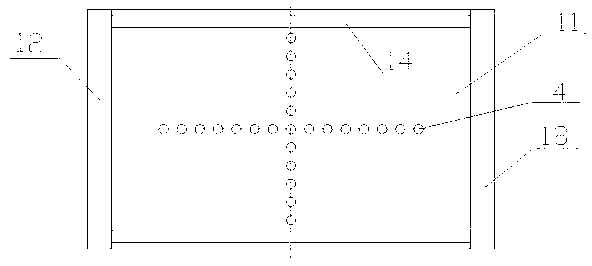

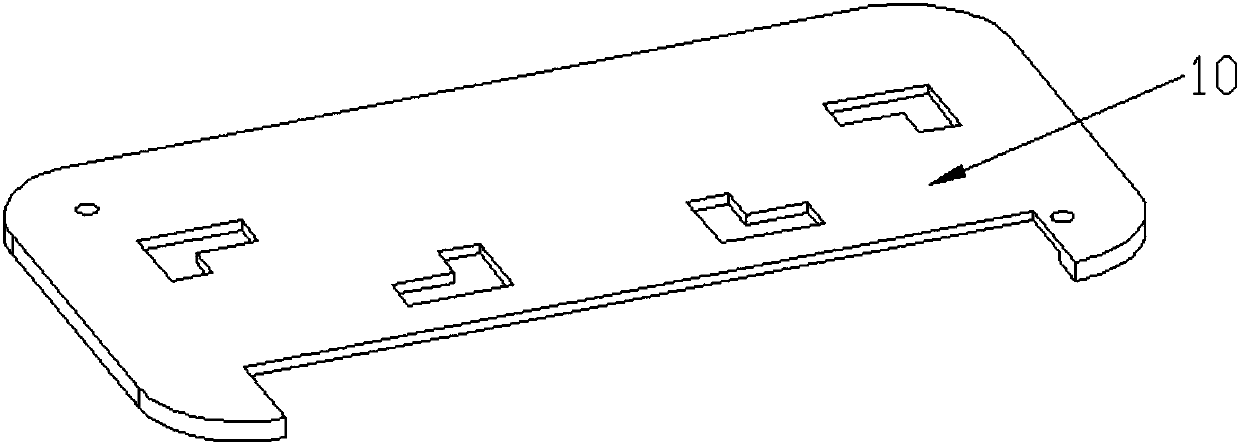

Laser transmission connection double-face clamping device

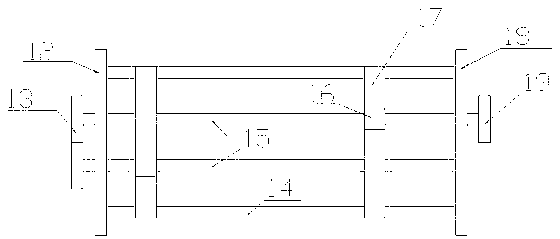

The invention discloses a laser transmission connection double-face clamping device and relates to the field of laser transmission welding, in particular to a clamping device for laser transmission welding plastic materials or plastic and metal materials. The laser transmission connection double-face clamping device comprises an upper pressing plate assembly, small hydraulic ejector pin assemblies, a hand wheel adjusting mechanism, a lower base plate assembly and a laser head. The upper pressing plate assembly consists of two oppositely-arranged L-shaped plates, wherein the L-shaped plates are placed vertically, a horizontal beam of each L-shaped plate is provided with a row of counter bores, and the small hydraulic ejector pin assemblies are arranged in the counter bores. Each small hydraulic ejector pin assembly can be invoked through computer programs. The lower base plate assembly consists of a working table, a left blocking plate and a right blocking plate, wherein the left blocking plate and the right blocking plate are fixed at two ends of the working table, the working table is provided with cross grooves, counter bores are evenly arranged in the grooves, and the small hydraulic ejector pin assemblies are arranged in the counter bores. The laser transmission connection double-face clamping device achieves workpiece welding, and the Z-direction control aims at guaranteeing constant defocusing amount in the welding process and facilitating table welding quality.

Owner:JIANGSU UNIV

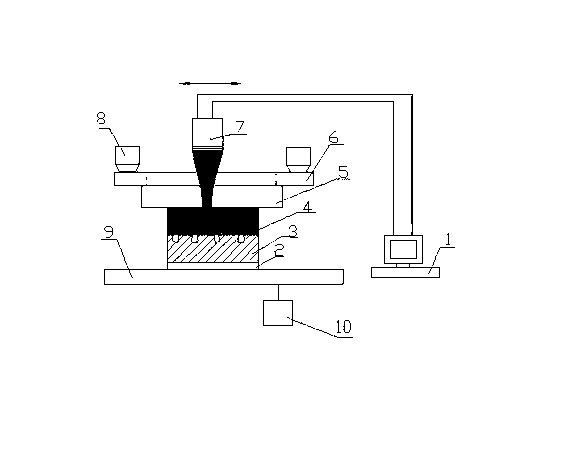

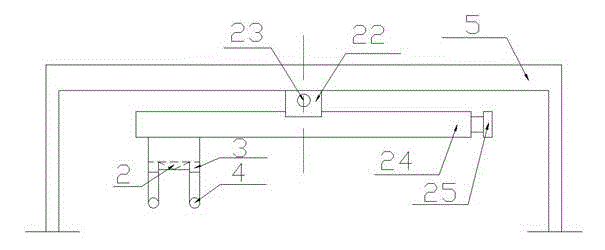

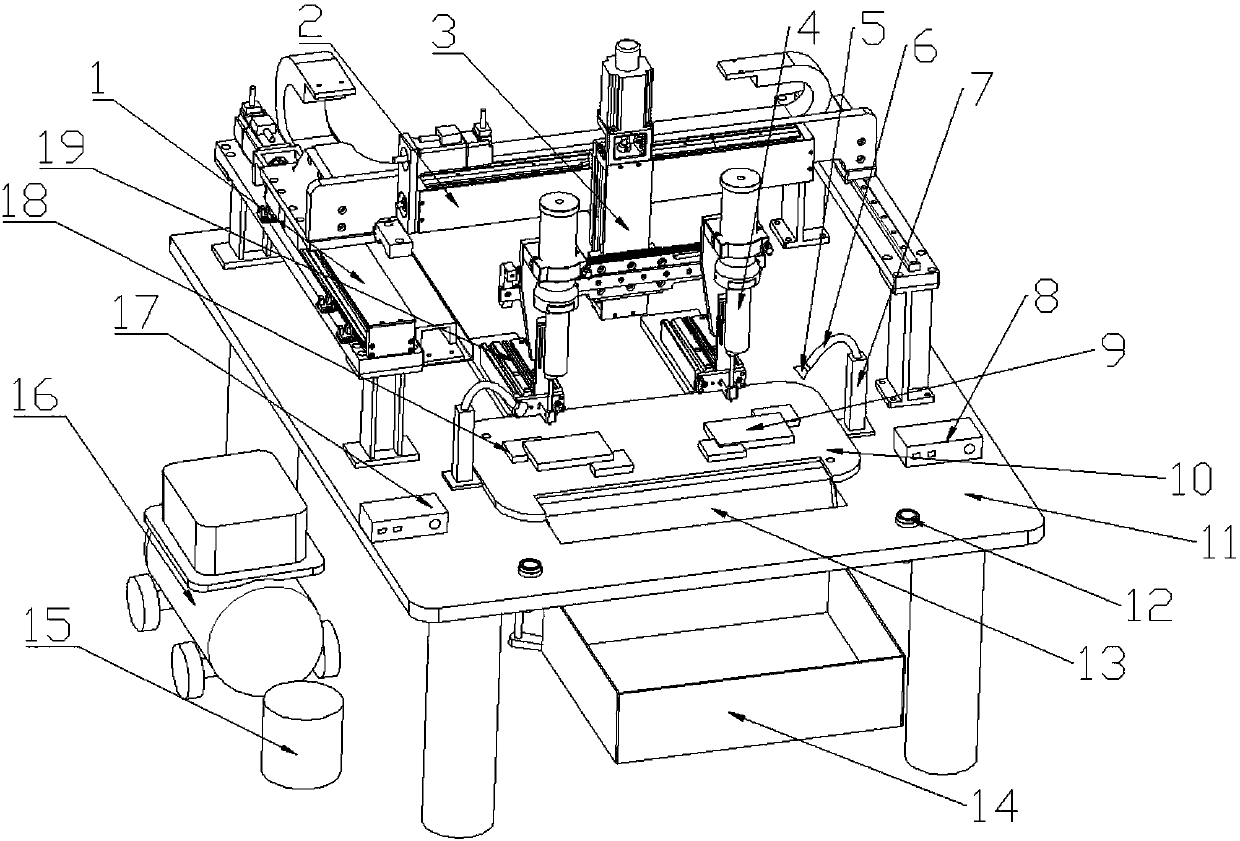

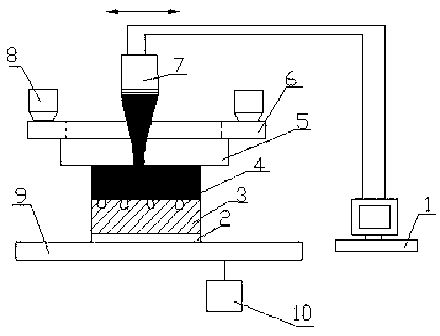

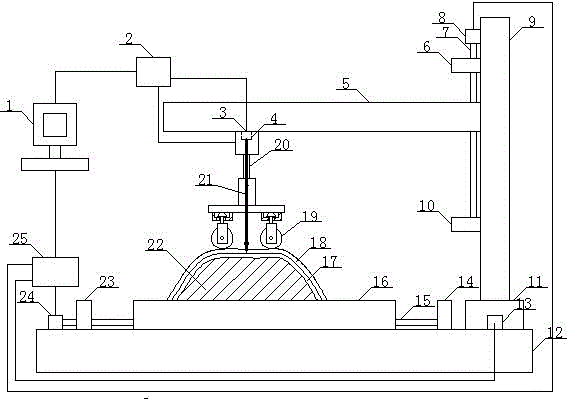

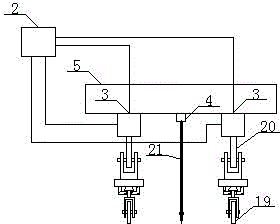

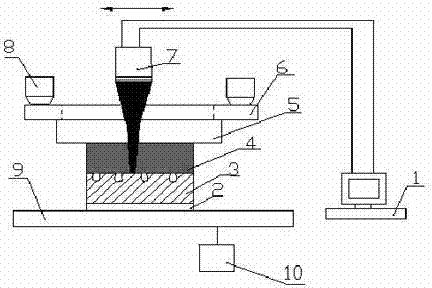

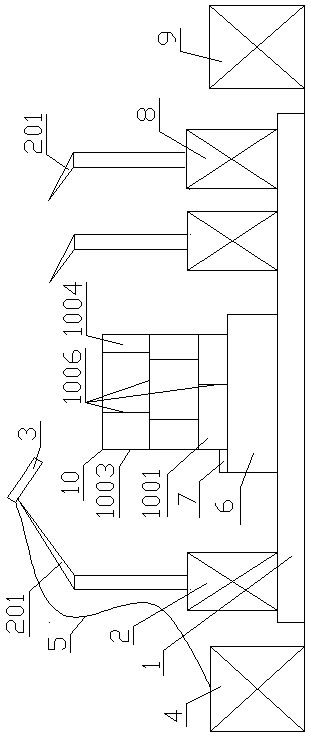

Automatic and uniform painting device and method for laser transmission welding absorption layer

ActiveCN107737698AImprove painting efficiencyRealize automatic unloadingLiquid surface applicatorsCoatingsControl systemInfrared lamp

The invention provides an automatic and uniform painting device and method for a laser transmission welding absorption layer. The device comprises a painting system, a drying system, a discharging system and a control system, wherein the painting system comprises a working platform, double starting buttons, a support plate, limiting blocks, screw motors, motor mounting plates, support imitation blocks and a painting device; the drying system comprises infrared lamps, flexible tubes and support seats; the discharging system comprises air cylinders, a beveled guide groove and a material collecting box; and the control system comprises a computer, an X-axis module, a Y-axis module, a Z-axis module, a dispensing machine and a switching power supply. The automatic and uniform painting device and method for the laser transmission welding absorption layer have the benefits as follows: the flow rate of dispensing valves is adjusted by utilizing the dispensing machine, the flow rate of a blackpaint is controlled in the painting process of needle brushes, both the thickness and uniformly of the black paint are controlled by adopting a multiple painting method, the black paint is quickly dried by utilizing the infrared lamps, the automatic discharging of plastic plates is realized by utilizing the air cylinders, any two pieces of plastic plates can be painted simultaneously through the device, and the efficiency is greatly increased.

Owner:南通宁竞信息科技有限公司

Novel method of laser transmission welding connection

InactiveCN103056525AImprove connection strengthStrong local connectionLaser beam welding apparatusPolymeric surfaceMetallic materials

The utility model discloses a novel method of laser transmission welding connection, and belongs to the technical field of laser transmission welding, in particular to a laser transmission welding of mental and polymer. According to the novel method of laser transmission welding connection, chemical corrosion is performed towards the surface of metal material which will be welded so that concave pits can be formed in the surface and the appearance and shape of the surface will be changed. The surface corroded material is as the low layer light-suction material, and the polymer is as the upper layer light-suction material. The metal and the polymer are connected in overlapped mode. The metal and the polymer are clamped by restraint layer and are imposed with welding pressure. Semiconductor laser generator conducts laser transmission welding so that surface temperature can reach the melting point of the upper layer polymer rapidly and the surface melts. The molten polymer flows into the concave pits under the influence of welding pressure and an engaged interface which is in riveted structure is formed on the welding seam, accordingly the connection strength of laser transmission welding is improved. Besides, the novel method of laser transmission welding connection can be widely applied in the field of laser transmission welding requiring high connection strength.

Owner:JIANGSU UNIV

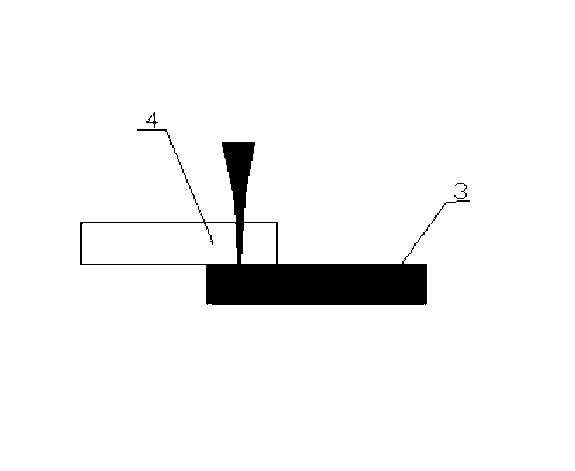

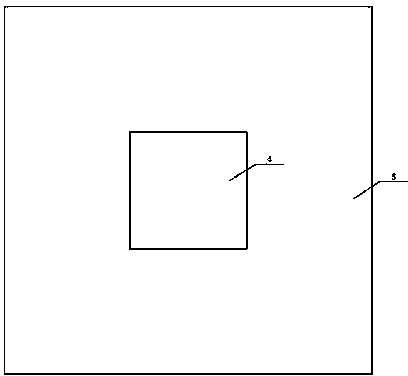

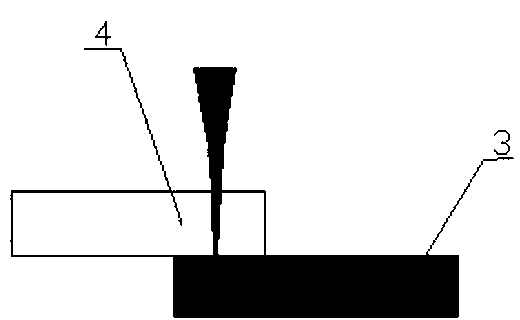

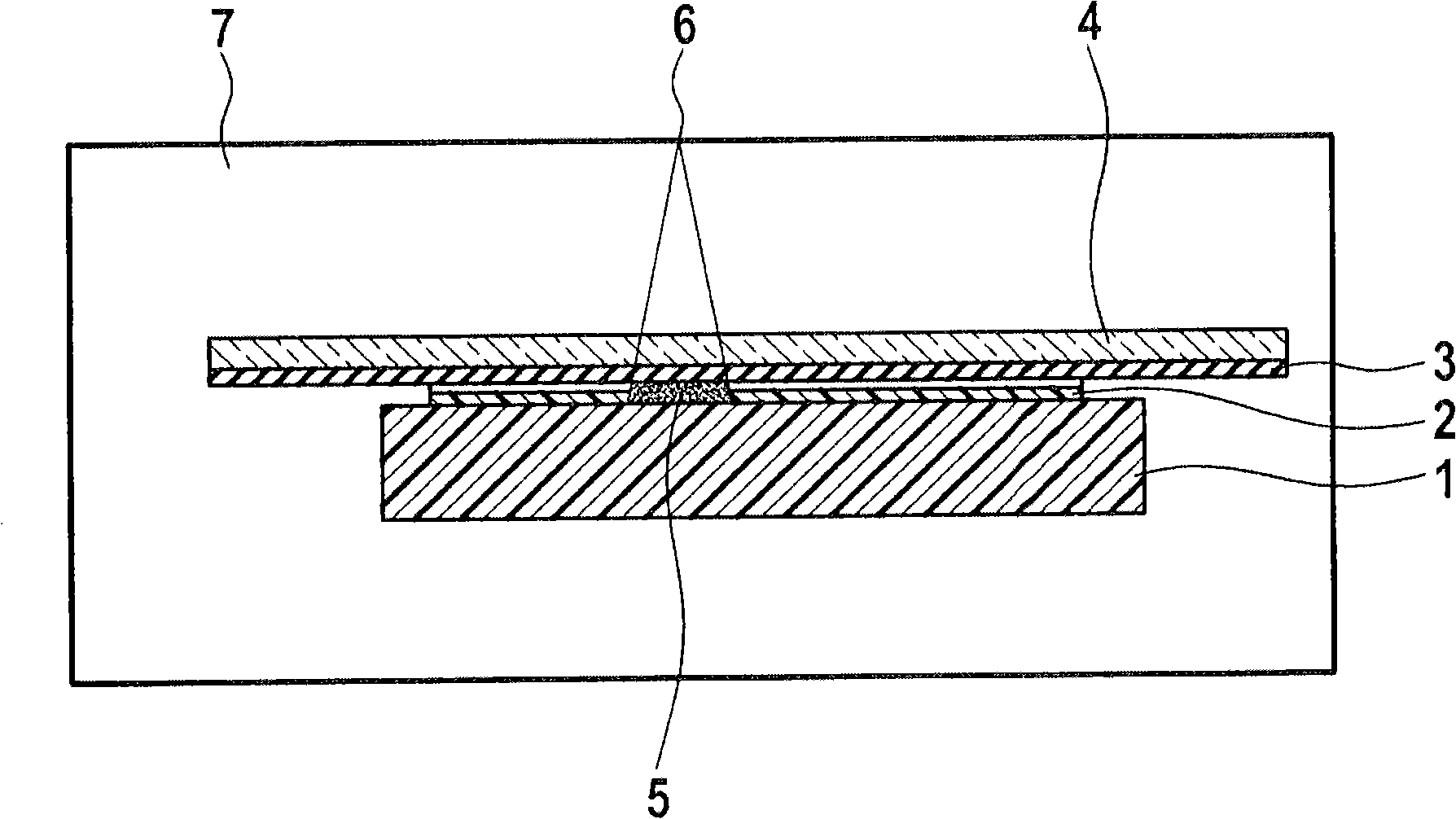

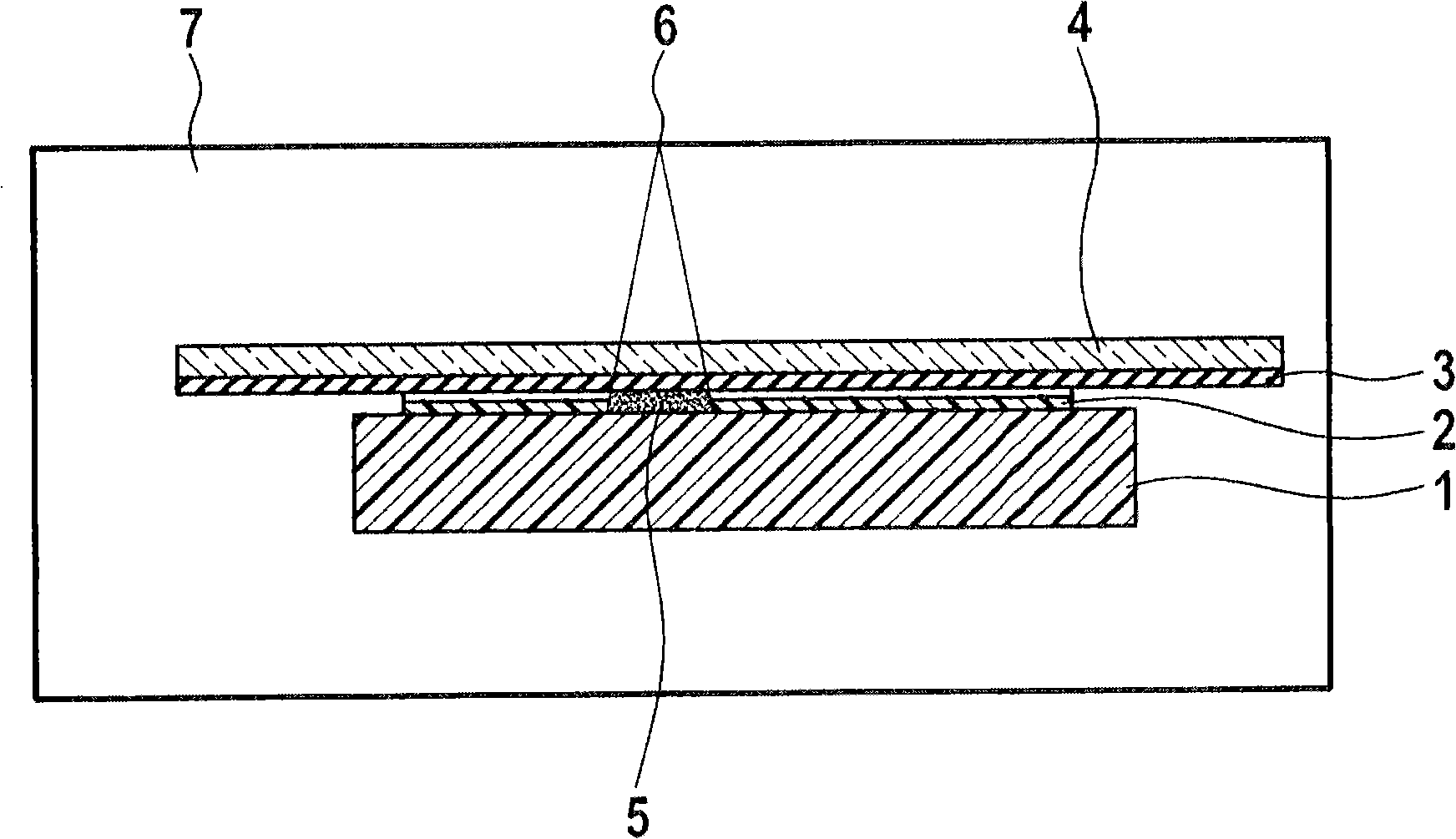

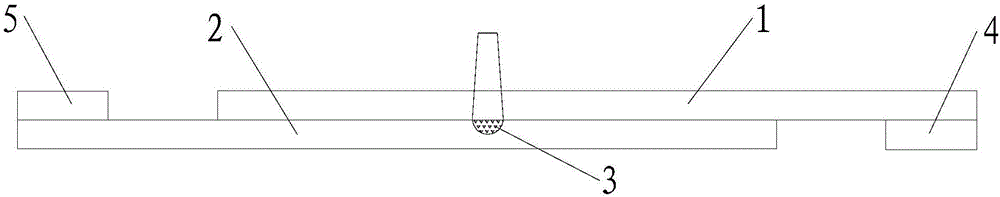

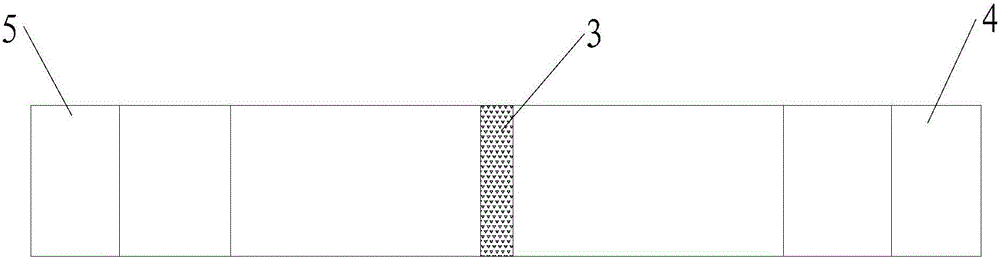

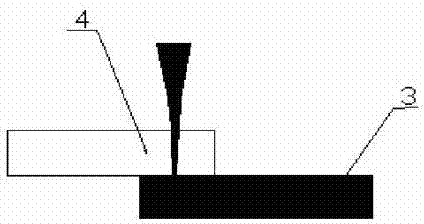

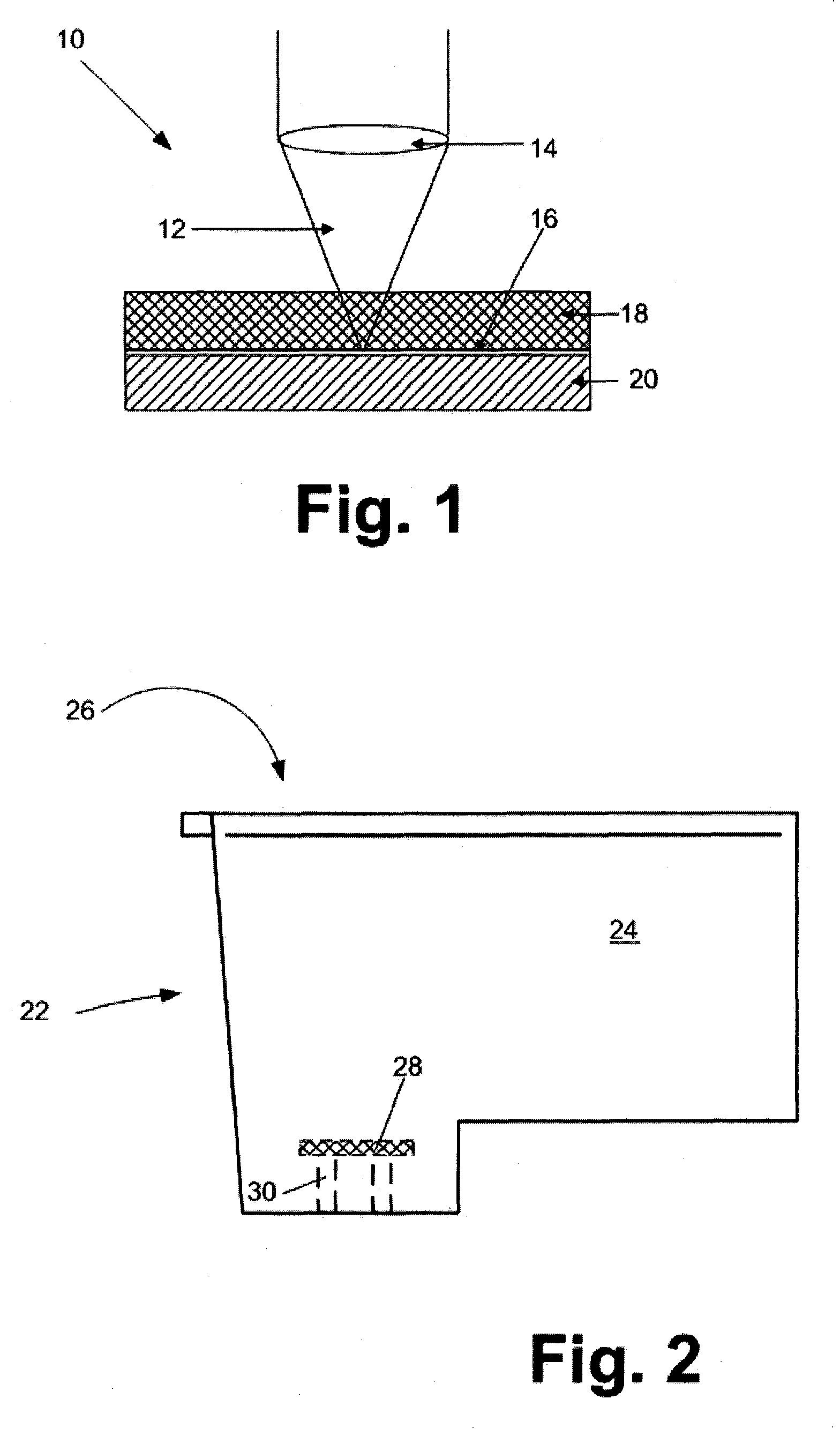

Method for producing a composite part by transmission laser welding

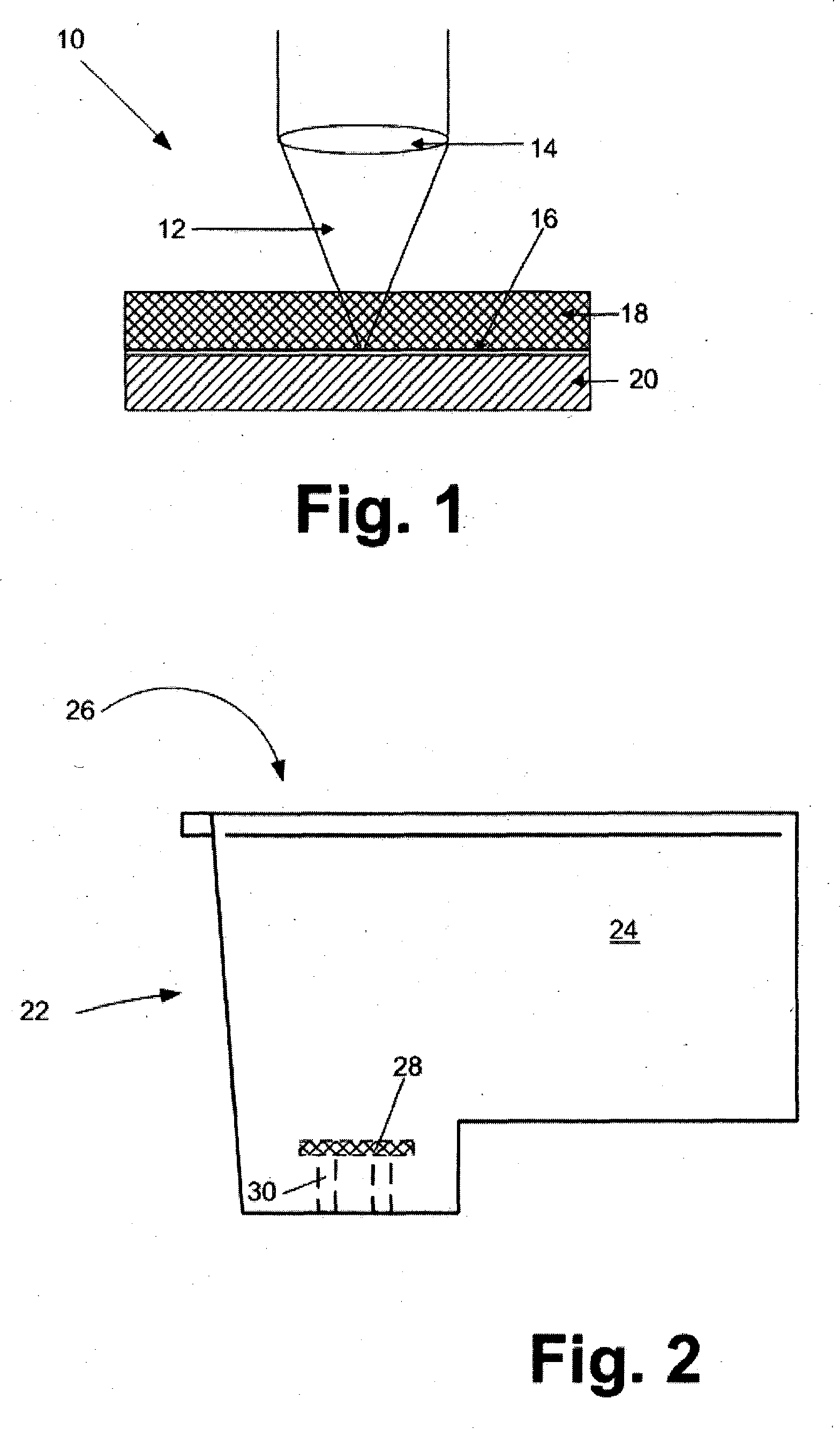

ActiveCN102112294ADimensionally stableLayered product treatmentSynthetic resin layered productsEngineeringLaser light

The present invention relates to a method for producing a composite part by transmission laser welding, comprising the steps: a) flat arrangement of a multilayer film (2) comprising a joining layer on a hard plastic part (1) such that the joining layer abuts the hard plastic part (1), wherein the joining layer comprises an absorber for laser light, b) pressing the multilayer film (2) onto the hard plastic part (1) using a pressing tool (4) pervious to laser light, and c) irradiating the arrangement obtained in step b) with laser light from the side of the multilayer film (2). The invention further relates to a composite part that can be obtained by said method and to a composite part welding arrangement used in said method.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Laser-transmission welded connection method

The invention discloses a laser-transmission welded connection method, which belongs to the technical field of laser transmission welding, and particularly relates to laser transmission welding between metals and polymers. The laser-transmission welded connection method comprises the following steps of: firstly, carrying out micro-ultrasonic electrolysis combined machining process on the to-be-welded surface of a metal material so as to form concave pits in the surface of the metal material; connecting a lower-layer light absorption material which is the metal the surface of which is subjected to the micro-ultrasonic electrolysis combined machining process, and an upper-layer light absorption material which is a polymer in an overlapping manner, clamping the two light absorption materials by a restraint layer, and applying a welding pressure to the light absorption materials; and carrying out laser transmission welding on the light absorption materials by a semiconductor laser so as to enable a surface temperature to fast reach a melting point of the upper-layer polymer and the surface of the polymer to be melted, thus forming an holding-on interface with a riveted structure at a weld joint and improving the connecting strength of laser-transmission welding since the concave pits are formed in the surface subjected to the micro-ultrasonic electrolysis combined machining process of the lower-layer metal, and the polymer with the melted surface layer flows into the concave pits under the action of the welding pressure.

Owner:JIANGSU UNIV

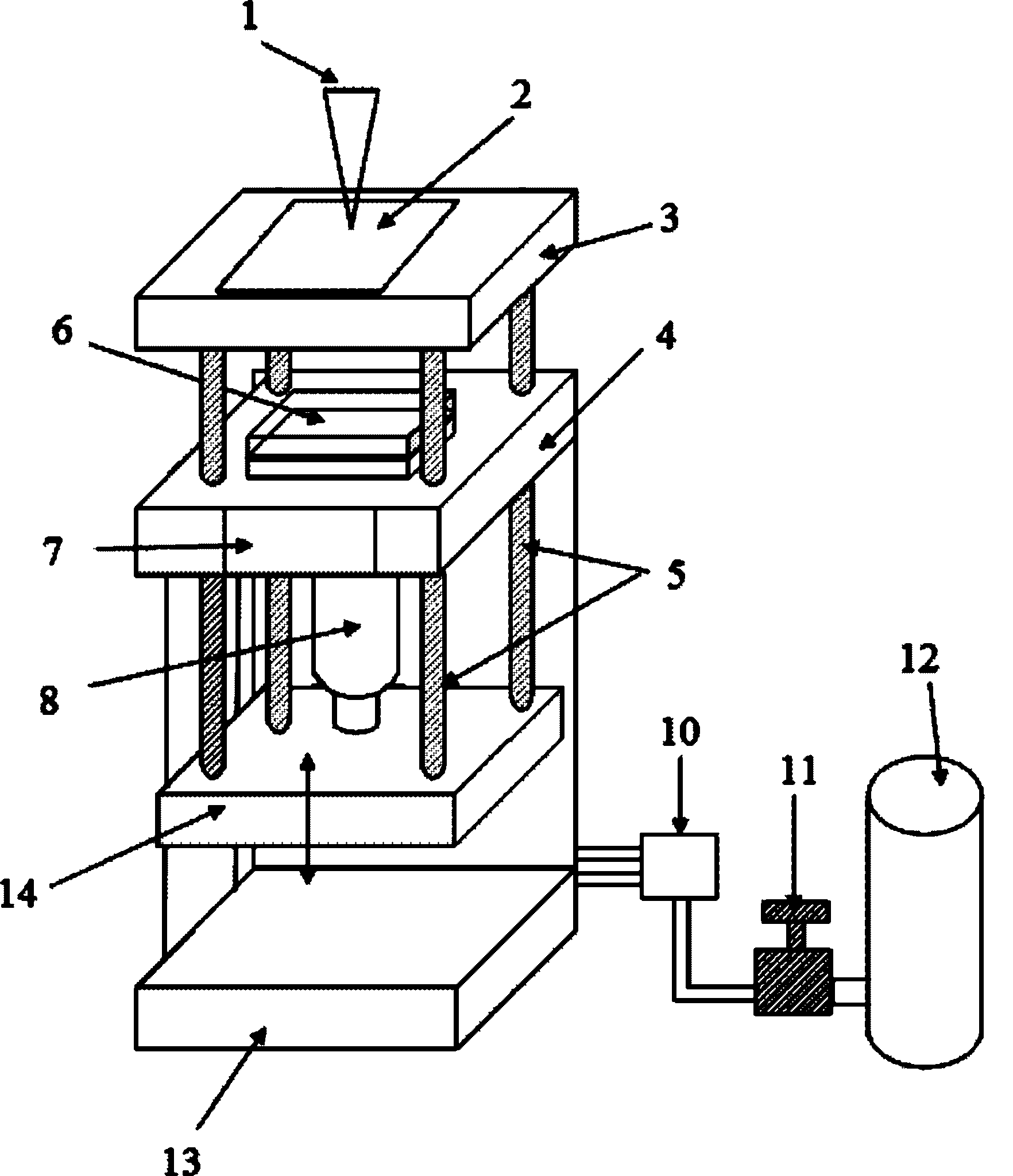

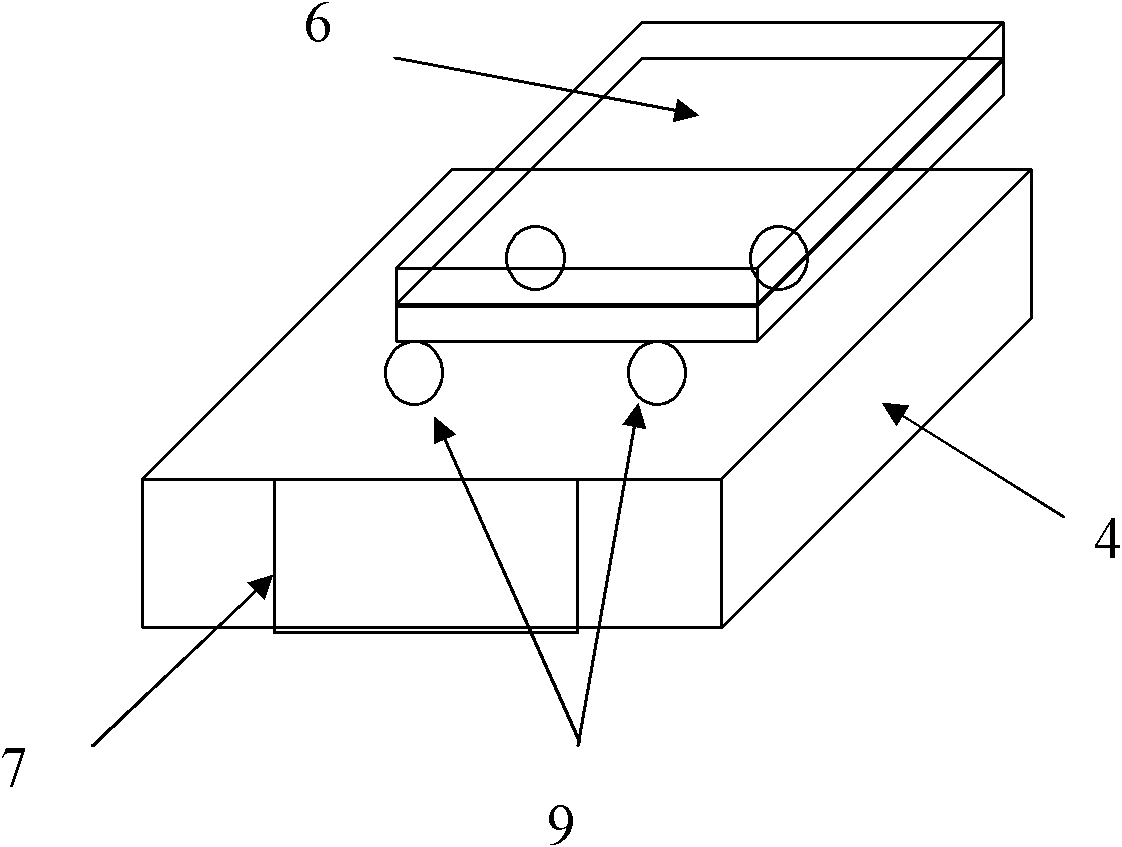

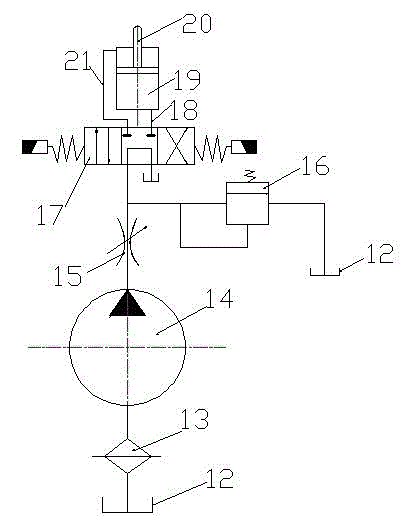

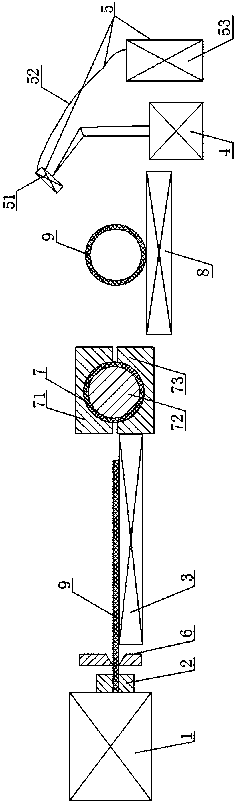

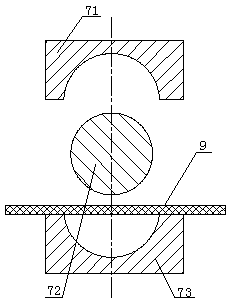

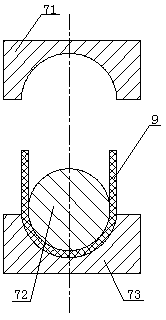

Ball type laser transmission welding clamping device

InactiveCN104191606ASimple 2D WeldingPrecise control of welding positionThermoplasticElectric machinery

A ball type laser transmission welding clamping device comprises a PC (personal computer), a stepping motor control system, X-axis, Y-axis and Z-axis feed mechanisms, pressure application mechanisms, a connecting mechanism and a pressing mechanism, wherein a hydraulic control system adjusts a small hydraulic ejector pin, so that the sum of downward pressing force of four press rods is equal to a pre-pressing force; the connecting mechanism transfers the pressing force to a clamping mechanism, so that the downward pressing force of a pressing block is equal to the pre-pressing force; a bottom die in the pressing mechanism is matched with an upper pressing device to clamp an upper workpiece and a lower workpiece, so that the curved surface workpiece is clamped; and the stepping motor control system controls laser to move along a preset line, and the curved surface workpiece is welded. The laser transmission welding clamping device for thermoplastic plastics can weld the curved surface workpiece, meanwhile, the welding path and pressing force can be accurately controlled, the overall strength and stiffness of a weld assembly are improved, a plurality of balls are used for pressing, single-point contact is avoided, and the quality of a processing workpiece is improved.

Owner:JIANGSU UNIV

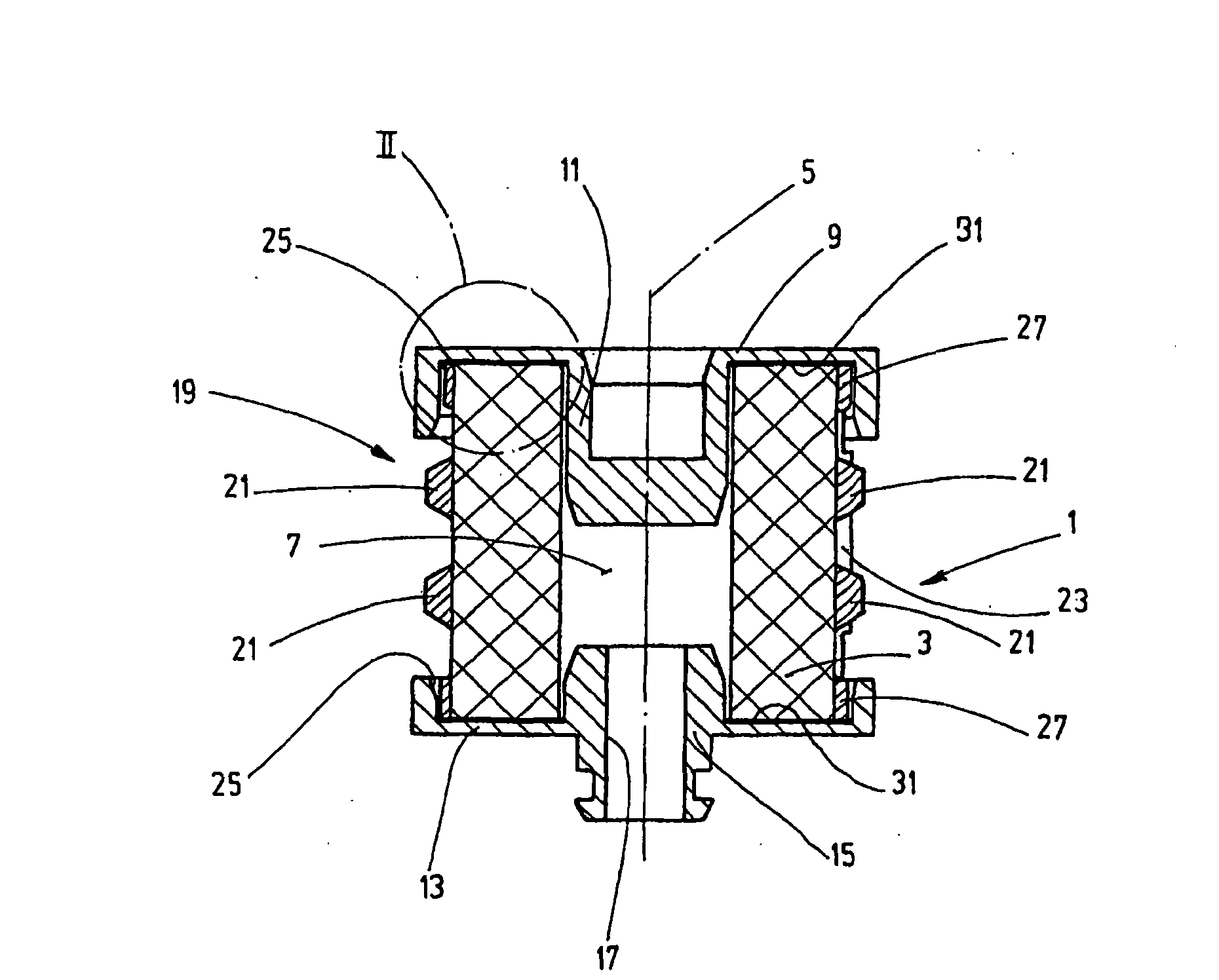

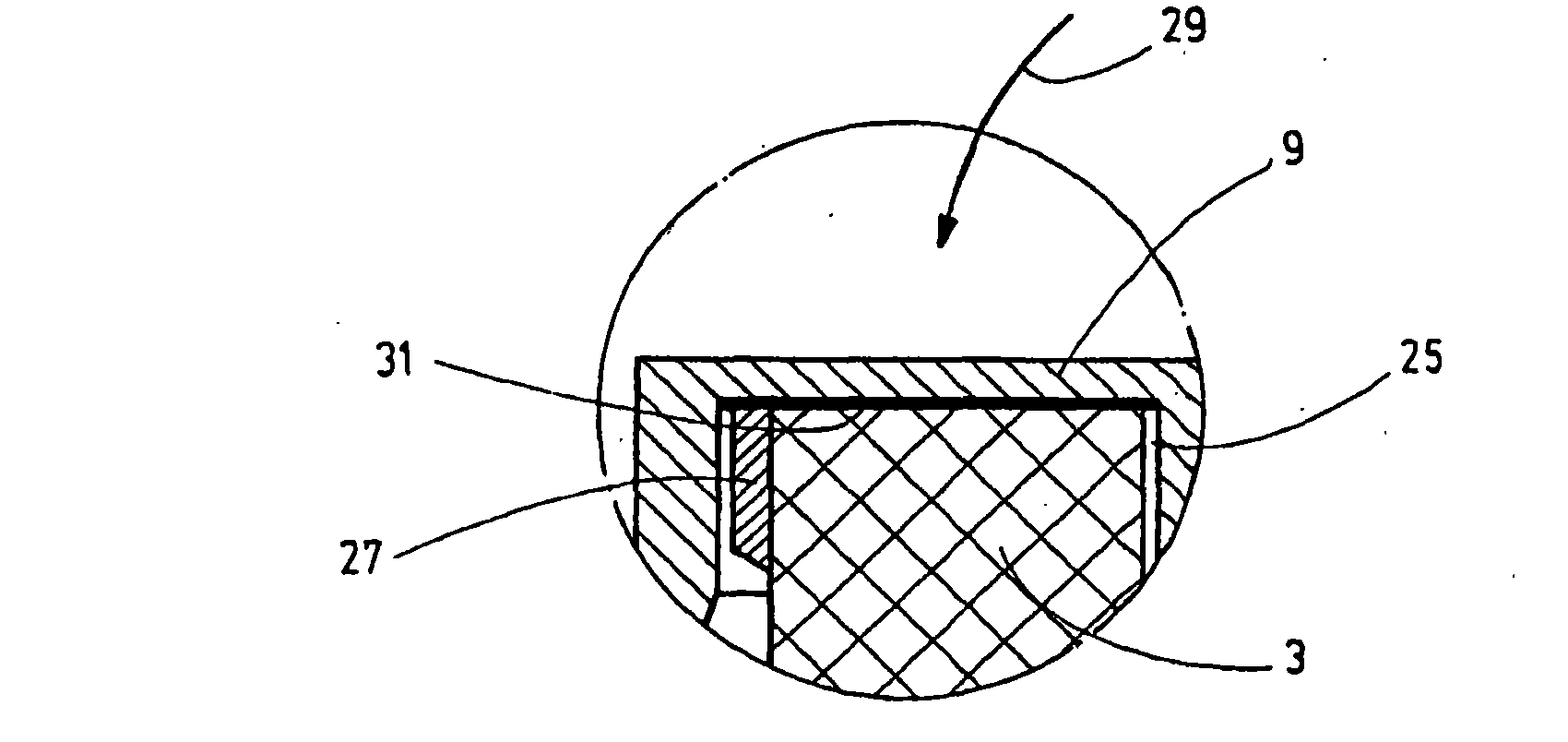

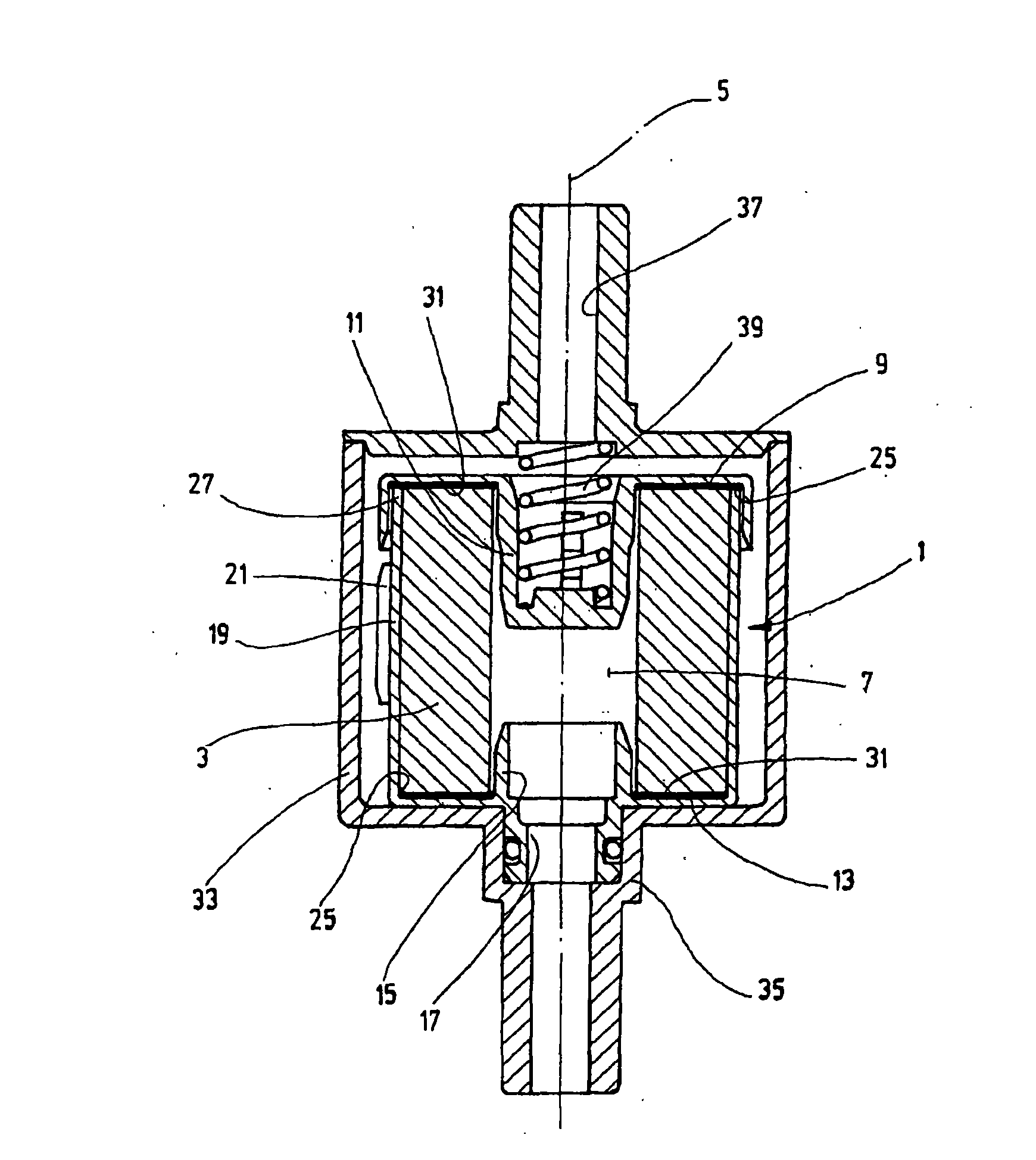

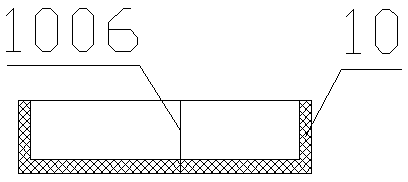

Method for the production of a filter element and filter element produced according to said method

ActiveCN101636212AGuaranteed absorptionReasonably preparedDomestic articlesStationary filtering element filtersFilter mediaEngineering

1. A method for the production of a filter element. 2. A method for the production of a filter element (1) comprising the steps: a) Providing a filter medium (3) surrounding an inner filter cavity (7) and comprising a heat-sealable material; b) Providing at least one end cap (9, 13) made of thermoplastic, laser-permeable material, forming a covering of the filter cavity (7) on at least one end; c) Forming a laser-impermeable barrier layer (31) between the end cap (9, 13) and the adjacent end of the filter medium (3) and d) Welding the end cap (9, 13) and filter medium (3) by irradiating laser-permeable material adjacent to the barrier layer (31) with laser energy such that, by heating the region adjacent to the barrier layer (31), a welding volume is provided as a joining element for the welded joint created by laser-transmission welding.

Owner:HYDAC FILTERTECHNIK GMBH

Preparation method of absorbent for laser transmission welding of light-transmitting plastic

The invention discloses a preparation method of an absorbent for laser transmission welding of light-transmitting plastic. Black light-absorbing plastic particles and a plastic dissolving agent corresponding to the black light-absorbing plastic particles are included; the plastic dissolving agent is used for dissolving the black light-absorbing plastic particles, the mixture is stirred to form sticky plastic dissolving liquid, namely the absorbent, and finally the prepared absorbent is sealed and stored in a dissolving container; the volume ratio of the plastic dissolving agent to the black light-absorbing plastic particles is 1:(0.8-1.2); the black light-absorbing plastic particles contain substances capable of absorbing lasers. The absorbent which is high in welding quality, high in universality, easy to obtain and high in cost performance is provided for laser welding of the light-transmitting+light-transmitting plastic, and the problems concerning laser welding of the light-transmitting+light-transmitting plastic can be solved in a high-quality and high-efficiency mode. The absorbent has the advantages of being high in welding quality, high in universality, easy to obtain, high in cost performance and high in adaptability.

Owner:广东顺德华焯机械科技有限公司

Laser transmission welding method for connecting plastic pieces

ActiveCN106273416AAvoid affecting welding qualityImprove heat transfer efficiencyHeat transfer efficiencyZinc alloys

The invention discloses a laser transmission welding method for connecting plastic pieces. The method is used for laser welding between a first plastic piece and a second plastic piece; a groove is formed in the second plastic piece, and is filled with zinc alloy powder or similar metal powder with low melting point and high heat conductivity to realize heat transfer, so that the heat transfer efficiency is greatly promoted, and the transmission welding of the same type of plastic pieces can be realized; and in addition, when the light emitting of a laser in unstable, the metal powder achieves an excellent transition effect to prevent influence on the welding quality by higher moment power.

Owner:SUZHOU UNIV

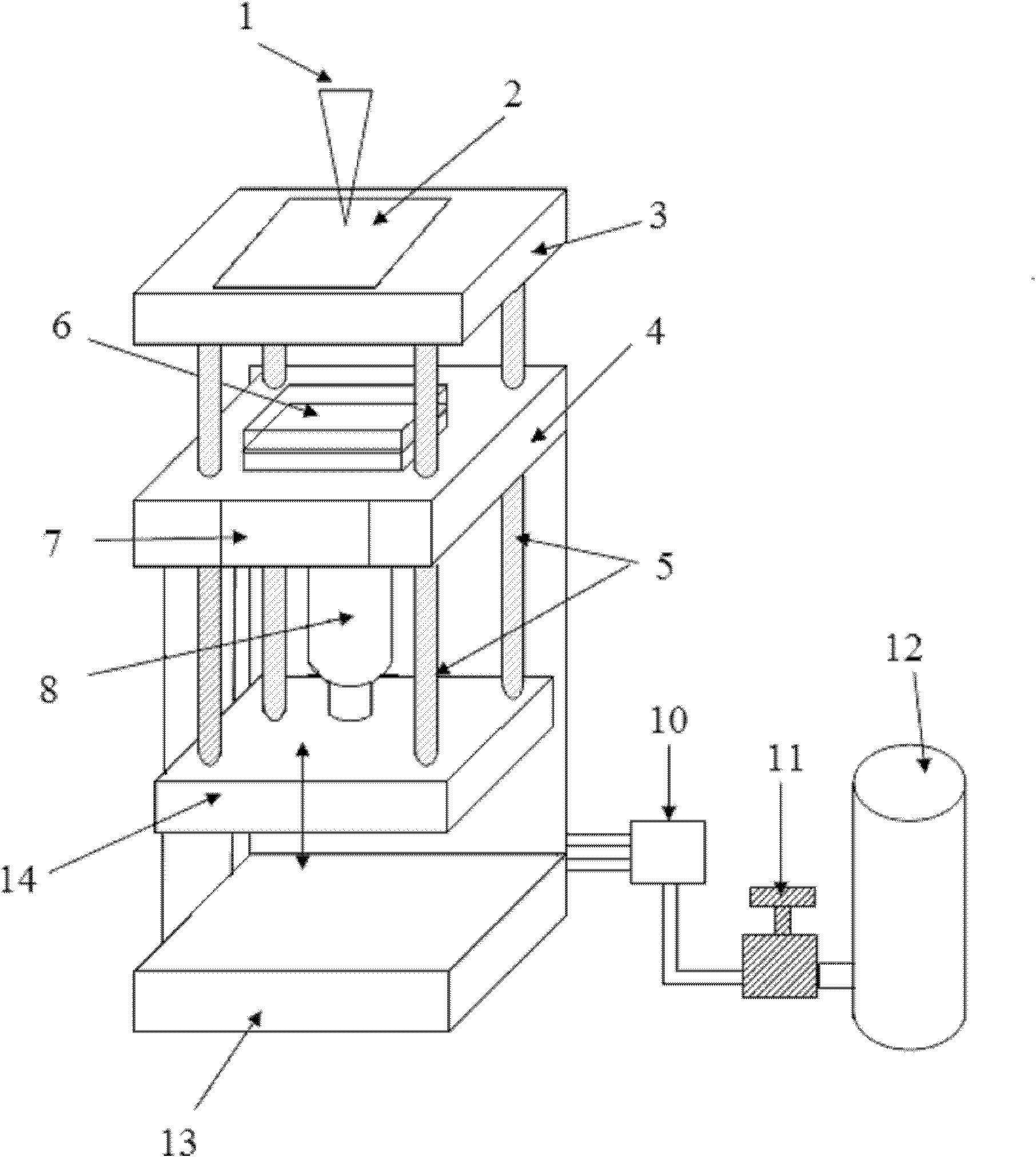

Multi-roller laser transmission welding clamping apparatus

InactiveCN104369368ASimple 2D WeldingPrecise control of welding positionThermoplasticMetallic materials

A multi-roller laser transmission welding clamping apparatus used between thermoplastic plastics or between a thermoplastic plastic and a metal material comprises a PC machine, a stepper motor control system, an X, Y, Z-axis feeding system and a laser head, and also comprises a pressing mechanism and a clamping mechanism; a hydraulic control system regulates a hydraulic small thimble to make the sum of the downward pressing forces of two rollers of each group of rollers equal to pre-pressing force and the two downward pressing forces equal to each other; a bed die and a movable pressing device in the pressing mechanism cooperate with each other to clamp an upper workpiece and a lower workpiece in order to realize a curved workpiece; and the stepper motor control system controls laser to move along a predetermined route in order to realize welding of the curved workpiece. The laser transmission welding clamping apparatus of the thermoplastic plastic can realize welding of the curved workpiece, can accurately control the welding path and the pressing force, improves the overall strength and rigidity of a welded piece, avoids single point contact by adopting multi-roller pressing, and improves the quality of the processed workpiece.

Owner:JIANGSU UNIV

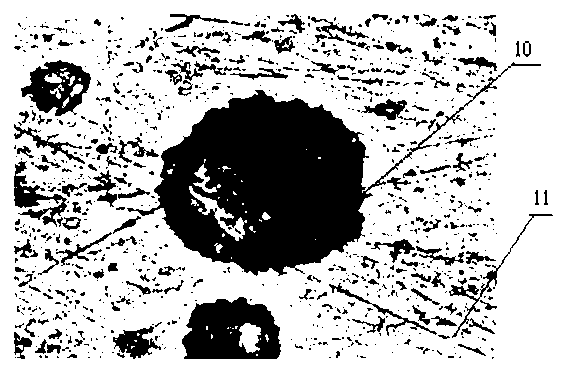

Laser transmission composite connecting method

InactiveCN103071923AImprove connection strengthStrong local connectionLaser beam welding apparatusPolymeric surfaceMetallic materials

The invention discloses a laser transmission composite connecting method, which belongs to the technical field of laser transmission welding and particularly relates to the laser transmission welding of metal and polymers. According to the method, firstly, the surface of the metal material to be welded is subjected to electric spark processing, concave pits are formed at the surface of the metal material, during the welding, the metal with the surface subjected to the electric spark processing is used as a lower layer light absorption material, the polymers are used as an upper layer light transmission material, a lap joint connection form is adopted, a restraining layer is used for clamping, in addition, the welding pressure is exerted, a semiconductor laser is used for carrying out laser transmission welding, the surface temperature can fast reach the melting point of the upper layer polymers, the surface of the polymers is melt, the surface of the lower layer metal is subjected to the electric spark processing, the concave pits are formed, so the melt polymers at the surface flow into the concave pits under the effect of the welding pressure, an engaging interface of the similar riveting structure is formed at the welding line part, and the improvement of the connection intensity of the laser transmission welding can be realized. The laser transmission composite connecting method can be widely applied to the field of the laser transmission welding with higher connection intensity requirements.

Owner:JIANGSU UNIV

Laser transmission welding method for thermoplastic plastics

The invention provides a laser transmission welding method for thermoplastic plastics. The laser transmission welding method comprises the following steps of: (1) placing a weld skeleton between upper rigid plastic and lower rigid plastic; (2) enabling the upper rigid plastic, the weld skeleton and the lower rigid plastic to be in contact compaction; (3) placing the upper rigid plastic, the lower rigid plastic and the weld skeleton in cooling liquid; (4) enabling a laser beam to enter from one side of the upper rigid plastic, and focus on the weld skeleton so as to form a weld point; (5) melting the upper rigid plastic and the lower rigid plastic which are in contact with the weld point; (6) the molten plastic is in mutual penetrating fusion through a through hole, close to the weld point, in the weld skeleton; (7) stopping irradiation and removing the laser beam; and (8) repeating the steps (4)-(7). The laser transmission welding method for the thermoplastic plastics has the advantages that the welding path and welding strength can be accurately controlled, the overall strength and rigidity of welded members are improved, the original properties of materials at local parts of welded joints are randomly changed, the occurrence of firing defects is prevented, and the welding connection and separation can be repeatedly realized.

Owner:WENZHOU UNIVERSITY

Device and method for carrying out and monitoring a plastic laser transmission welding process

InactiveCN103781618ADetailed schematic diagramSensing radiation from gases/flamesMaterial analysis by optical meansBeam sourceLaser transmission welding

Owner:LPKF LASER & ELECTRONICS

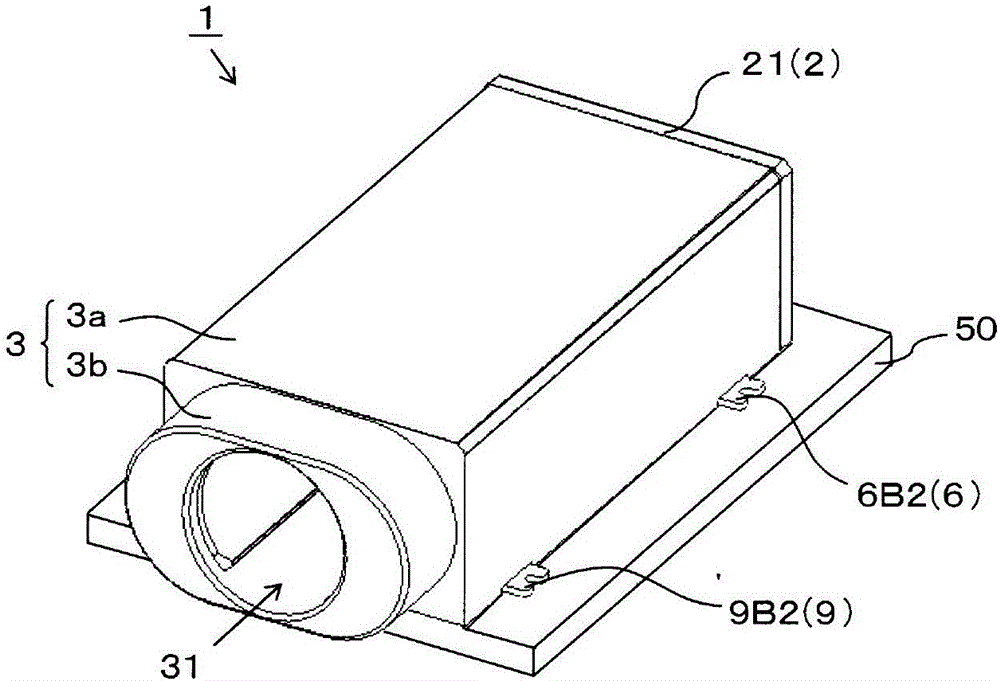

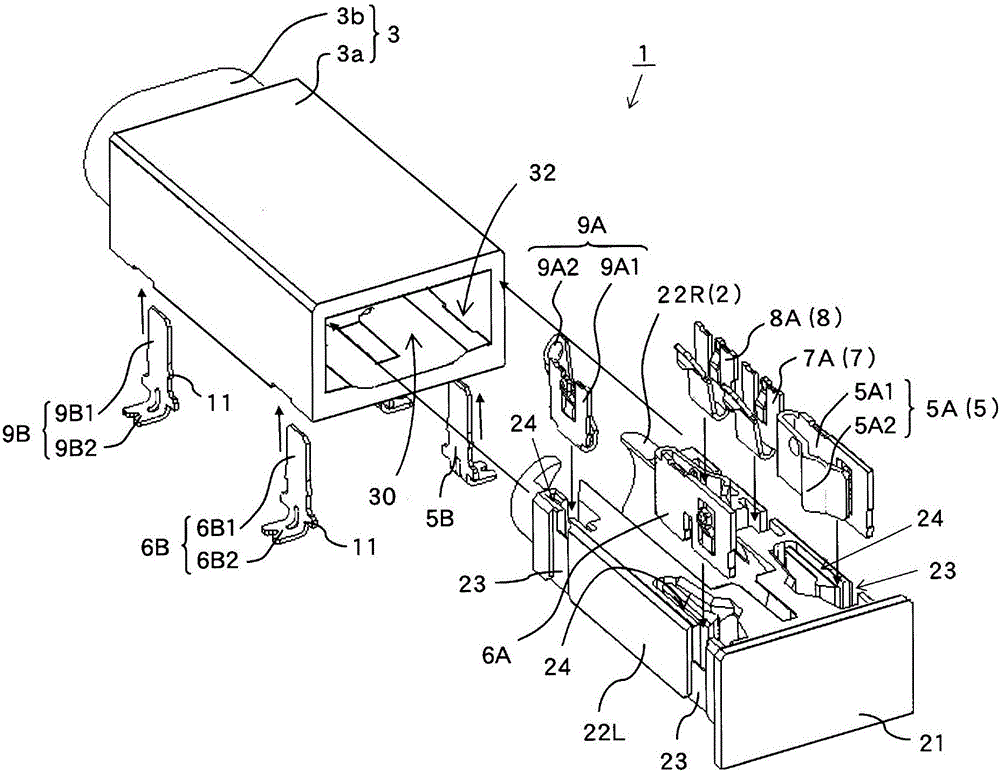

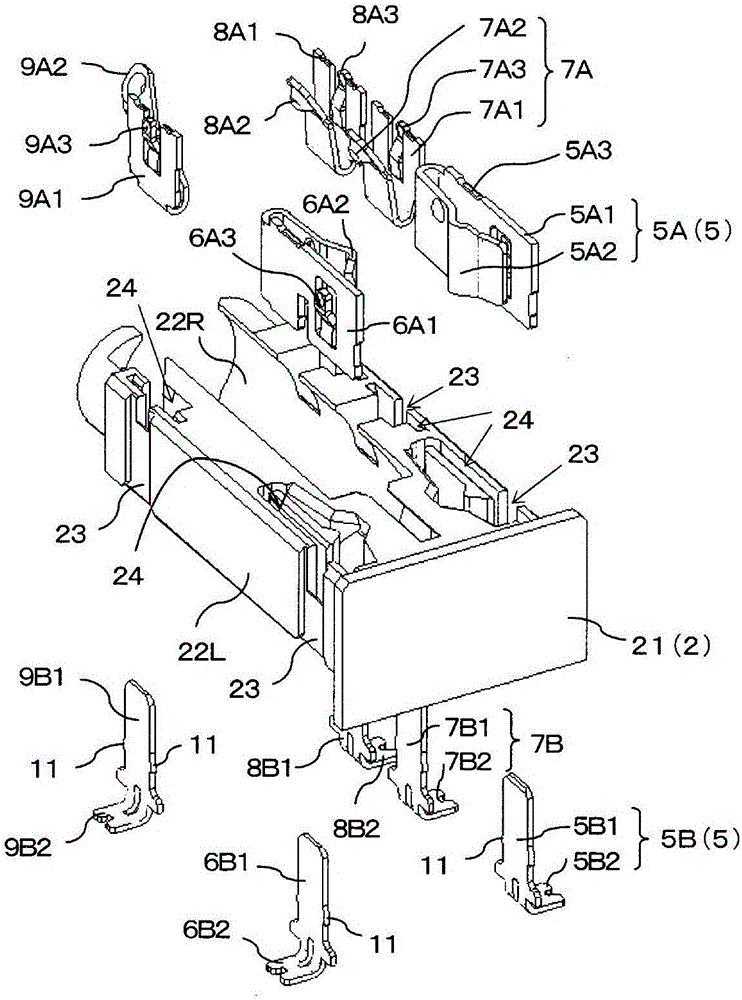

Socket

InactiveCN106469865AInhibit sheddingWith waterproof functionContact member assembly/disassemblyCoupling contact membersUltrasonic weldingEngineering

The invention provides a socket for sealing between a rear side opening portion of an outer housing and a lid body of an inner housing for covering rear side opening portion. A spring terminal is divided into a pair of spring piece portions attached to the inner housing and leg portions penetrating the outer housing and having tip end portions in contact with the spring piece portions which are inserted into the outer housing together with the inner housing. Since the leg portions are not attached into the inner housing inserted into the outer housing, it is unnecessary to form a clearance groove in the outer housing to avoid interference with the leg portions, and the rear side opening portion of the outer housing and the lid body of the inner housing for covering the rear side opening portion can be welded and sealed by laser transmission welding or ultrasonic welding.

Owner:SMK CO LTD

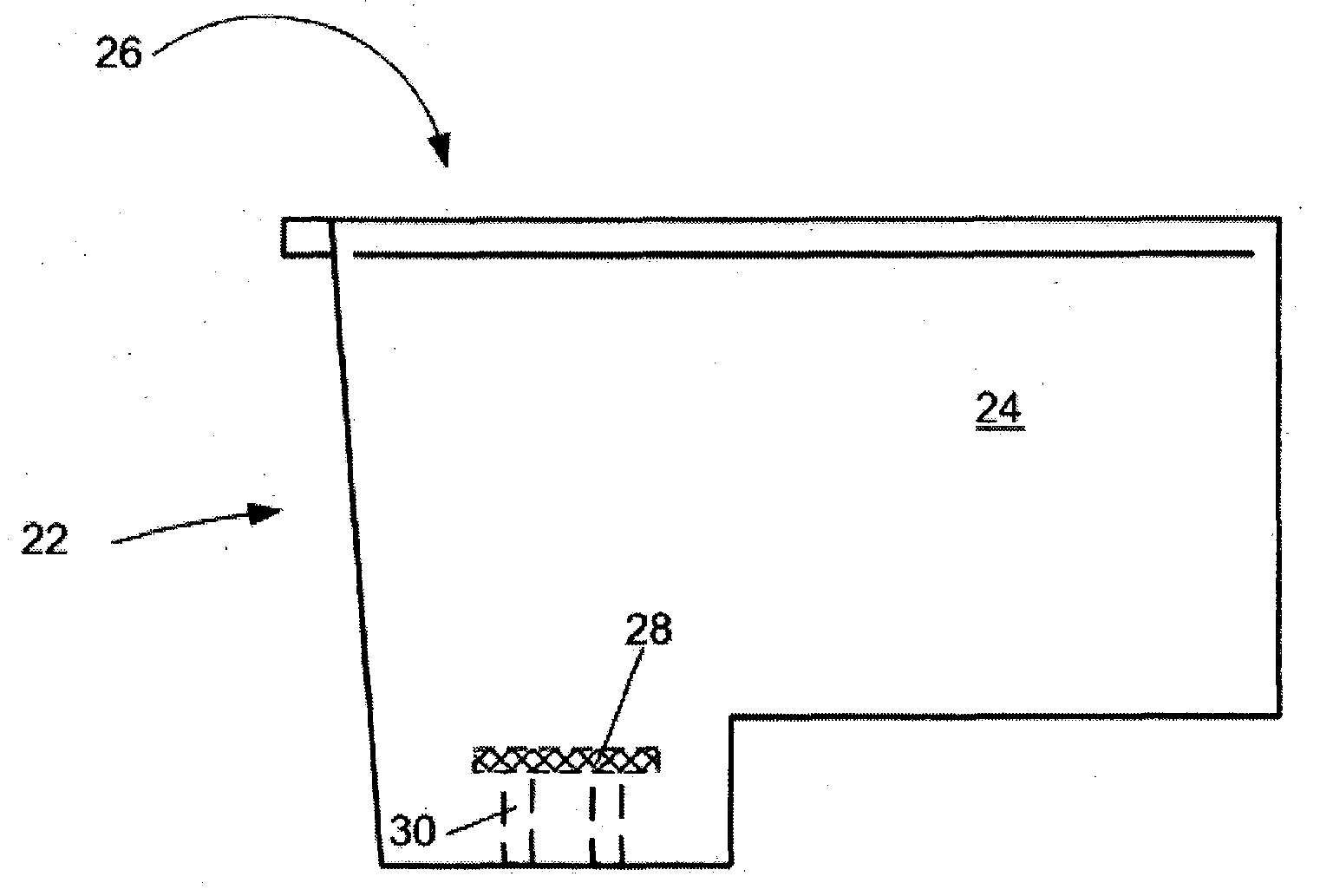

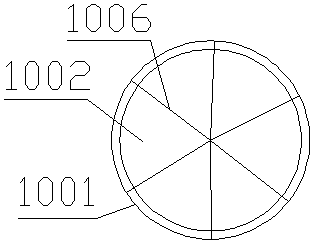

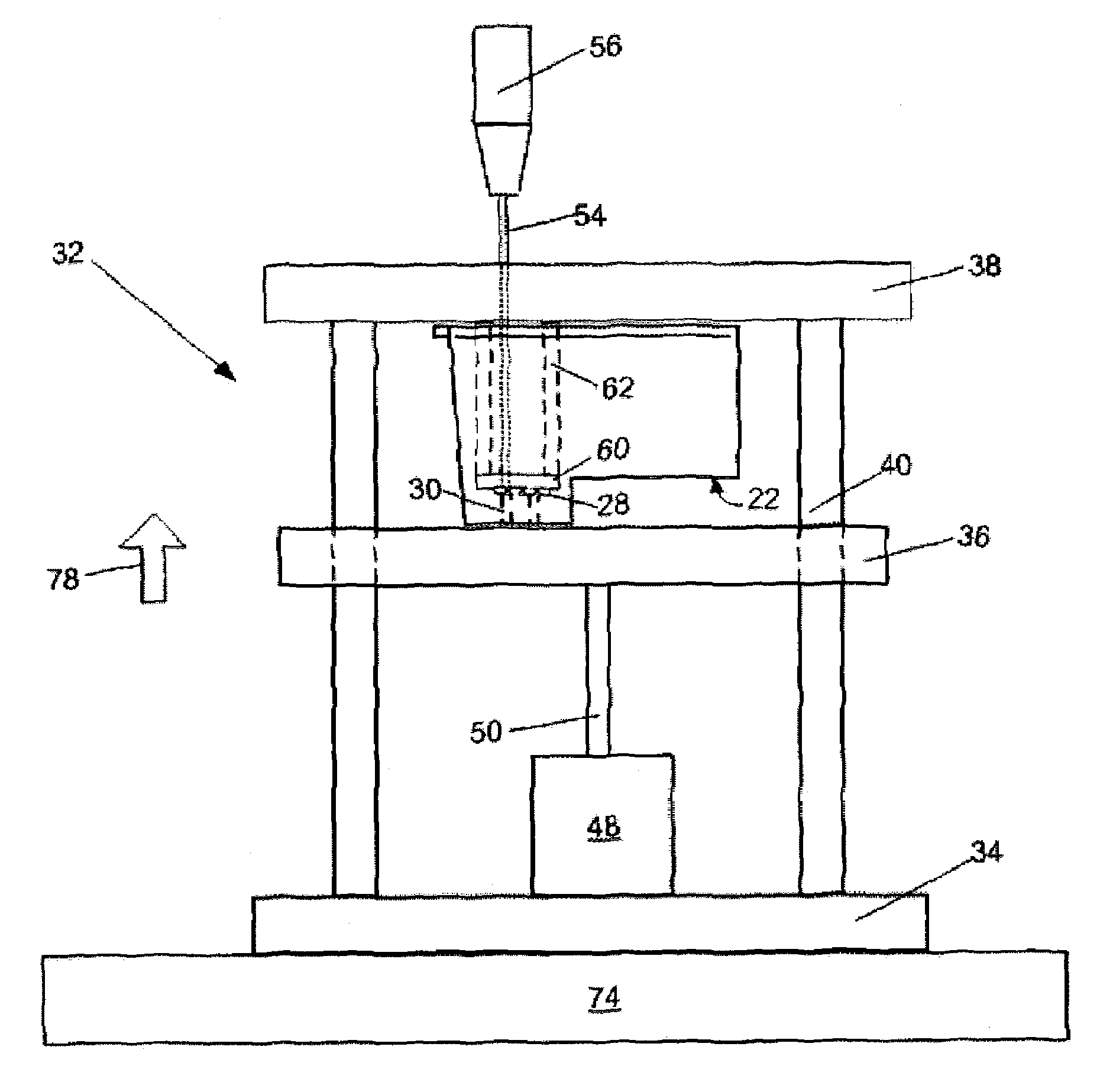

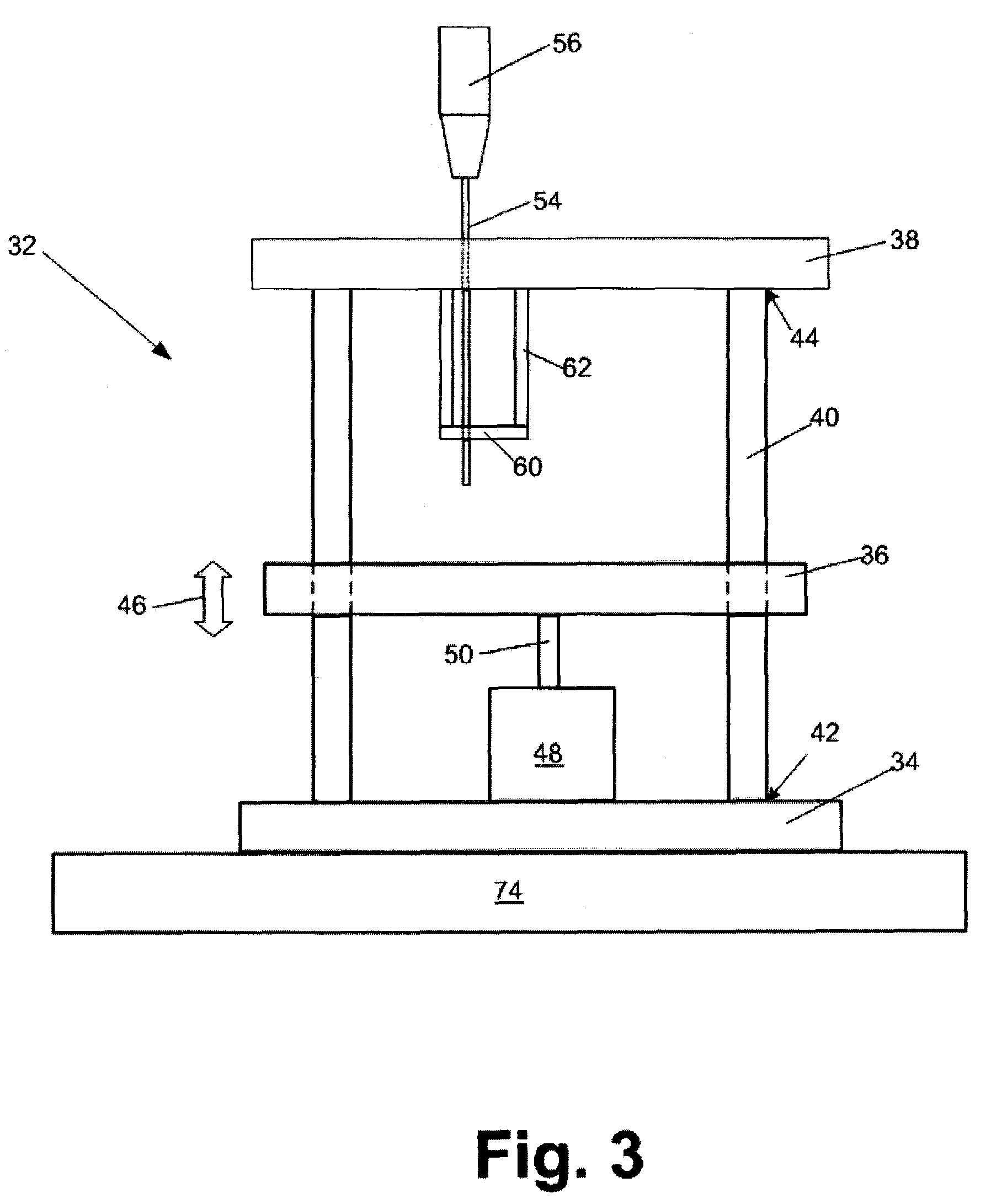

Method and apparatus for attaching an ink jet filter to an ink cartridge

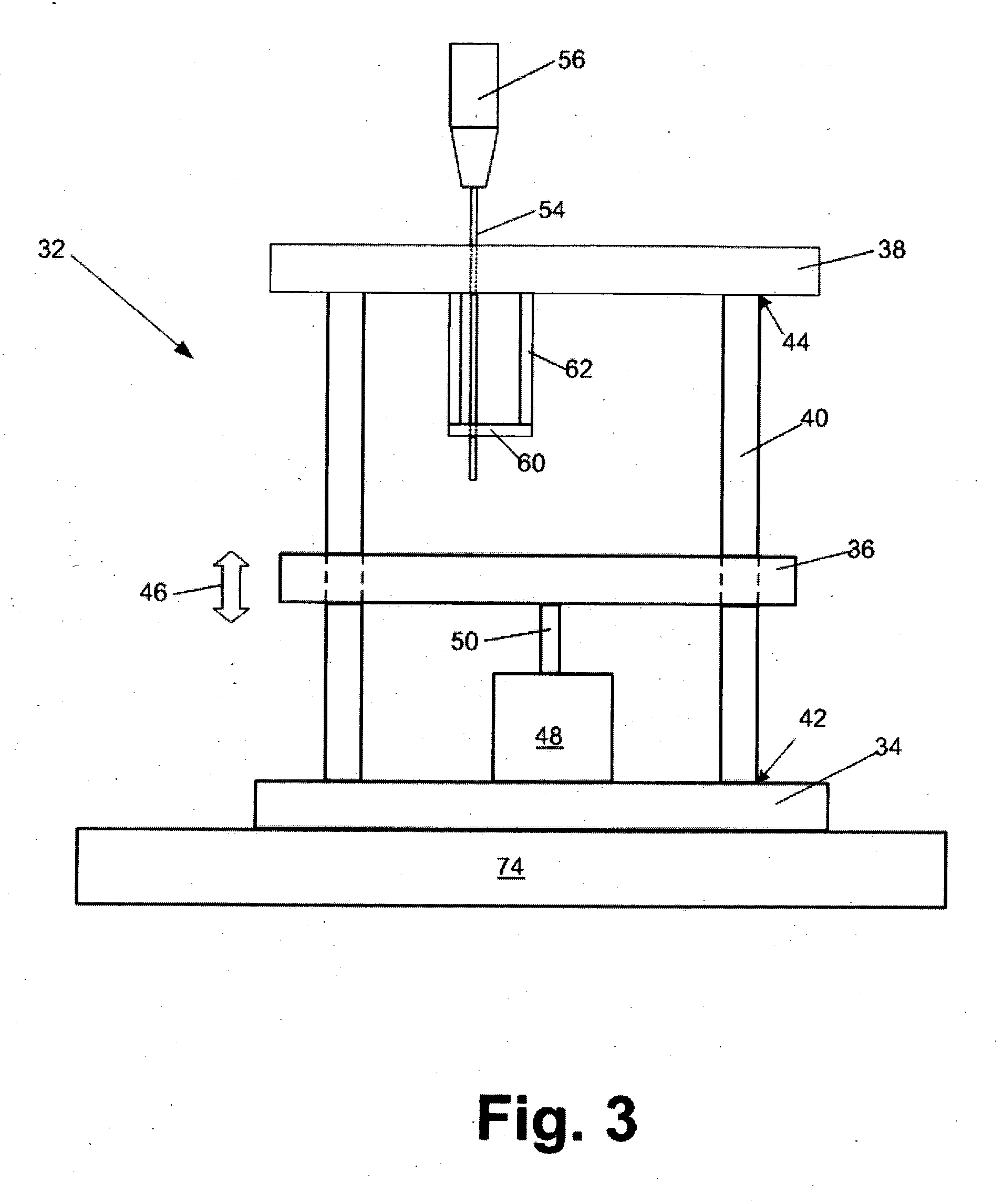

ActiveUS20050012793A1Avoid scratchesLess costlyMechanical working/deformationLamination ancillary operationsInk printerEngineering

An apparatus for a laser transmission welding process for attaching a synthetic filter material to a filter tower frame in an ink jet printer cartridge. The apparatus includes a laser beam source and a filter clamping fixture containing a base, slide rods attached on first ends thereof to the base, an optics support plate attached to second ends of the slide rods, a movable platform for holding an ink cartridge slidably disposed on the slide rods between the base and the optics support plate, a platform moving device for translating the platform to and from a laser welding position, a laser beam transparent plate suspended by support legs from the optics support plate to a position between the movable platform and the optics support plate. The apparatus greatly improves synthetic filter attachment to a filter tower frame in an ink cartridge.

Owner:FUNAI ELECTRIC CO LTD

Laser transmission welding system and method

ActiveCN108637470AImprove permeabilityReduce lossLaser beam welding apparatusThermoplasticLaser transmitter

The invention discloses a laser transmission welding system and method, and relates to the field of laser welding. The system comprises a laser emitter, a vacuum clamping system and a control system.The vacuum clamping system comprises a coordinate platform, a clamping device and a workpiece system. According to the laser transmission welding system and method, lasers are adopted as energy, and the sealing performance of an inner cavity of the vacuum clamping device is guaranteed through a sealing ring, a sealing gasket and a sealant; a sealing cavity of a box body is vacuumized to generate negative pressure in the clamping device, a piston rod is driven through the inner and outer pressure difference of the box body to apply clamping force to the workpiece system, and accuracy of the clamping force is controlled through a sensor-computer-relay; and laser transmission welding between similar or dissimilar thermoplastic plastic and metal is achieved, and welding quality is improved.

Owner:JIANGSU UNIV

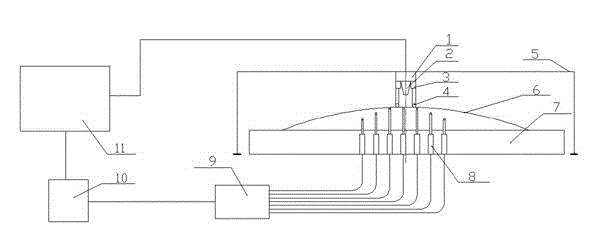

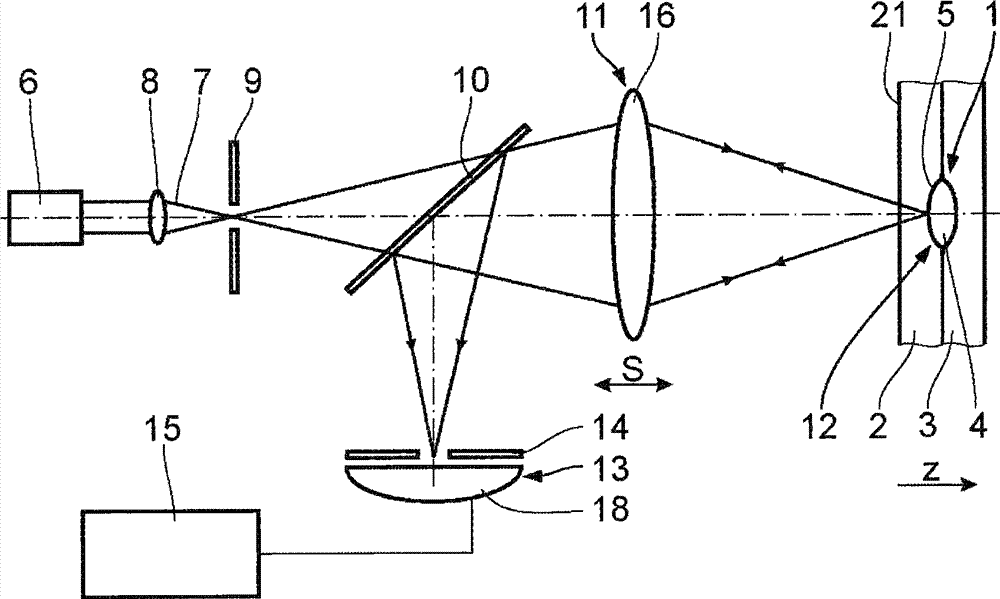

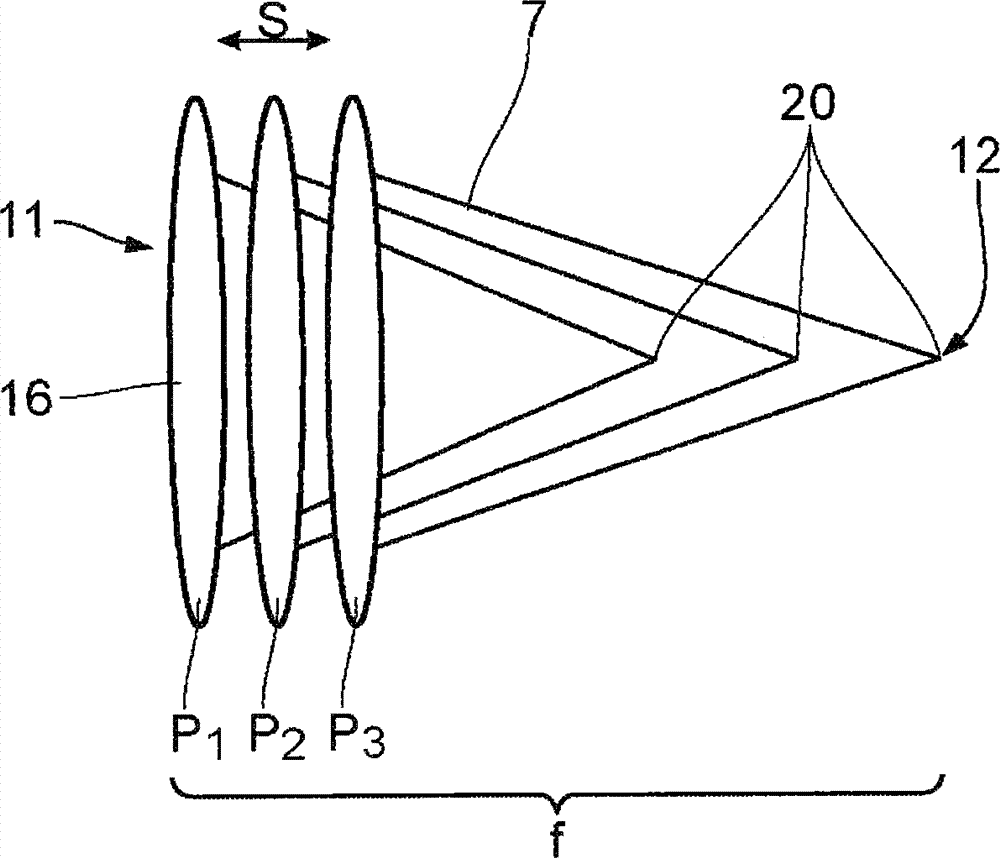

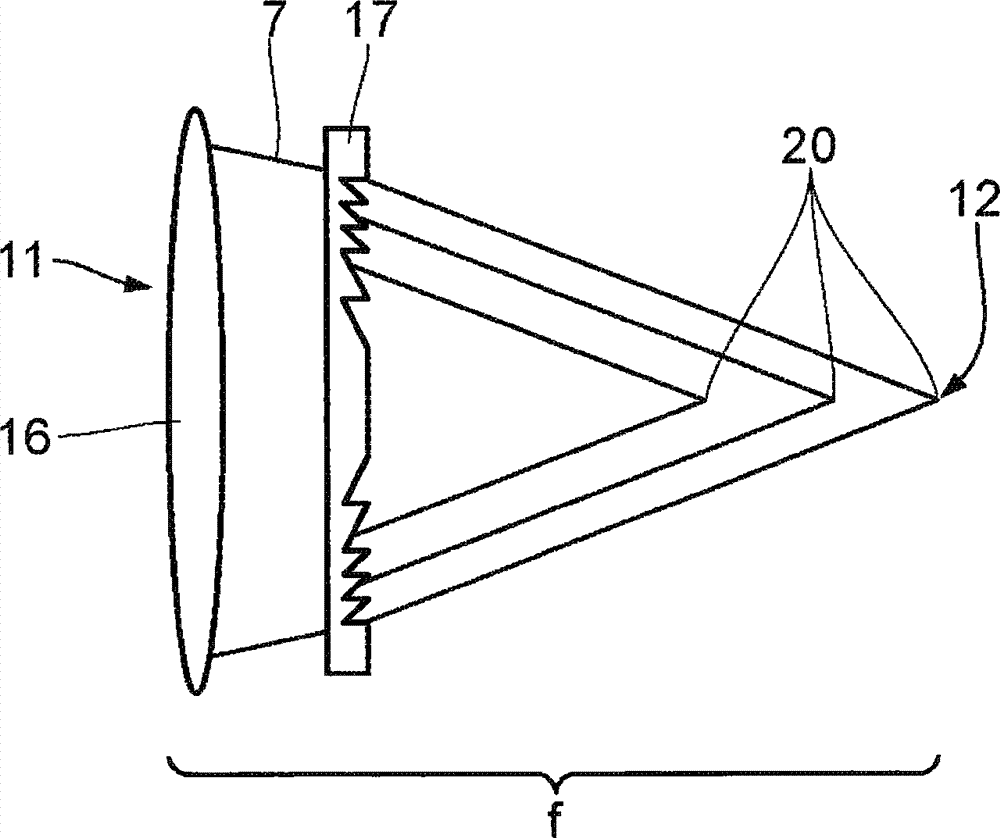

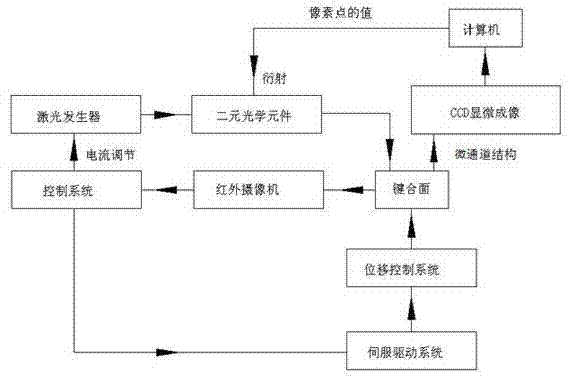

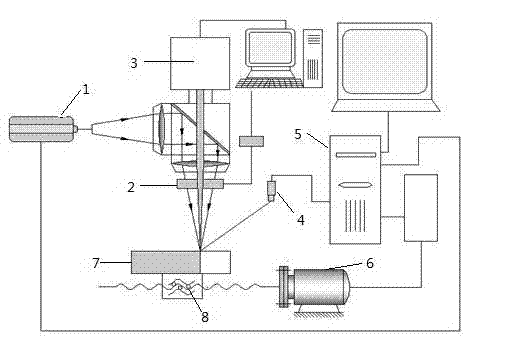

Bonding device for polymer microfluidic chip

InactiveCN102756474ARealize dynamic control technologyRealize online control technologyHeat-affected zoneDisplacement control

The invention discloses a bonding device for a polymer microfluidic chip, comprising a laser generator, a controllable optical system, an image identification and image processing system, a control system, and a displacement control platform. The bonding device is characterized in that a binary optical element is arranged in the controllable optical system, a laser beam is diffracted at a to-be-bonded chip on the displacement control platform via the binary optical element, and the formed optical spots are controllable in size and intensity; and the image identification and image processing system is arranged, the image identification and image processing system comprises a CCD (charge coupled device) and a computer, and the sizes and intensities of the optical spots are controlled via the processing of the computer on the acquisition of the CCD for the diffracted images. According to the invention, a binary optical technology, a polymer laser transmission welding technology, and a real-time online temperature and image measurement technology are combined together; and welding seams which are narrower in bonding width, smaller in a heat affected zone, and higher in intensity compared with a laser mask can be obtained by virtue of the diffraction action of the binary optical element on laser.

Owner:SUZHOU UNIV

Water vapor permeable, waterproof textile laminate and method for the production thereof

InactiveUS20170043567A1Easy to pullEasy to handleLamination ancillary operationsLayered product treatmentFiberWater vapor

A water vapor permeable, waterproof textile laminate, comprising at least two layers made of planar web material, which are disposed on top of each other and bonded to each other, wherein an open fabric web comprising polymer fiber threads forms a top tier and a film-like, water vapor permeable, waterproof thermoplastic membrane web forms a bottom tier. The polymer fiber threads of the fabric web comprise raised thread regions, which are held bearing against the membrane web and / or are partially fused into the membrane web, wherein the membrane web comprises integral fusion areas with the raised thread regions, which are generated according to the invention by way of laser light in a laser transmission welding method.

Owner:LEISTER TECHNOLOGIES

Ultra-large plastic inspection well seat laser welding combined forming device and method

InactiveCN108454116AFlexible and convenient operationReduce welding distortionMiniaturizationEngineering

The invention relates to a ultra-large plastic inspection well seat laser welding combined forming device and method. The device comprises a base and a laser control robot. The upper end of the left side of the base is fixedly connected with the laser control robot, the top end of the laser control robot is movably connected to a mechanical arm, the front end of the mechanical arm is movably connected to a laser beam output device, a laser is arranged on the left side of the base, the laser is connected to the laser beam output device through an optical fiber, the center of the upper end of the base is movably connected to a rotary worktable, the left side of the upper end of the rotary worktable is fixedly connected to a positioning block, the right side of the positioning block is provided with a ultra-large plastic inspection well seat, and an assembly robot is fixedly connected with the right side of the upper end of the base. The device adopts a modular multi-layer annular ring block and a combined well seat bottom plate connection structure, adopts a laser transmission welding method, is convenient and flexible to operate, has high welding efficiency, reduces the design and manufacturing cost of a injection mold and the difficulty of the injection molding process, and achieves the miniaturization of the injection mold and injection molding equipment and flexible and modular production of ultra-large plastic inspection well seats.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Method and apparatus for attaching an ink jet filter to an ink cartridge

ActiveUS6998008B2Avoid scratchesLess costlyMechanical working/deformationLamination ancillary operationsLight beamEngineering

An apparatus for a laser transmission welding process for attaching a synthetic filter material to a filter tower frame in an ink jet printer cartridge. The apparatus includes a laser beam source and a filter clamping fixture containing a base, slide rods attached on first ends thereof to the base, an optics support plate attached to second ends of the slide rods, a movable platform for holding an ink cartridge slidably disposed on the slide rods between the base and the optics support plate, a platform moving device for translating the platform to and from a laser welding position, a laser beam transparent plate suspended by support legs from the optics support plate to a position between the movable platform and the optics support plate. The apparatus greatly improves synthetic filter attachment to a filter tower frame in an ink cartridge.

Owner:FUNAI ELECTRIC CO LTD

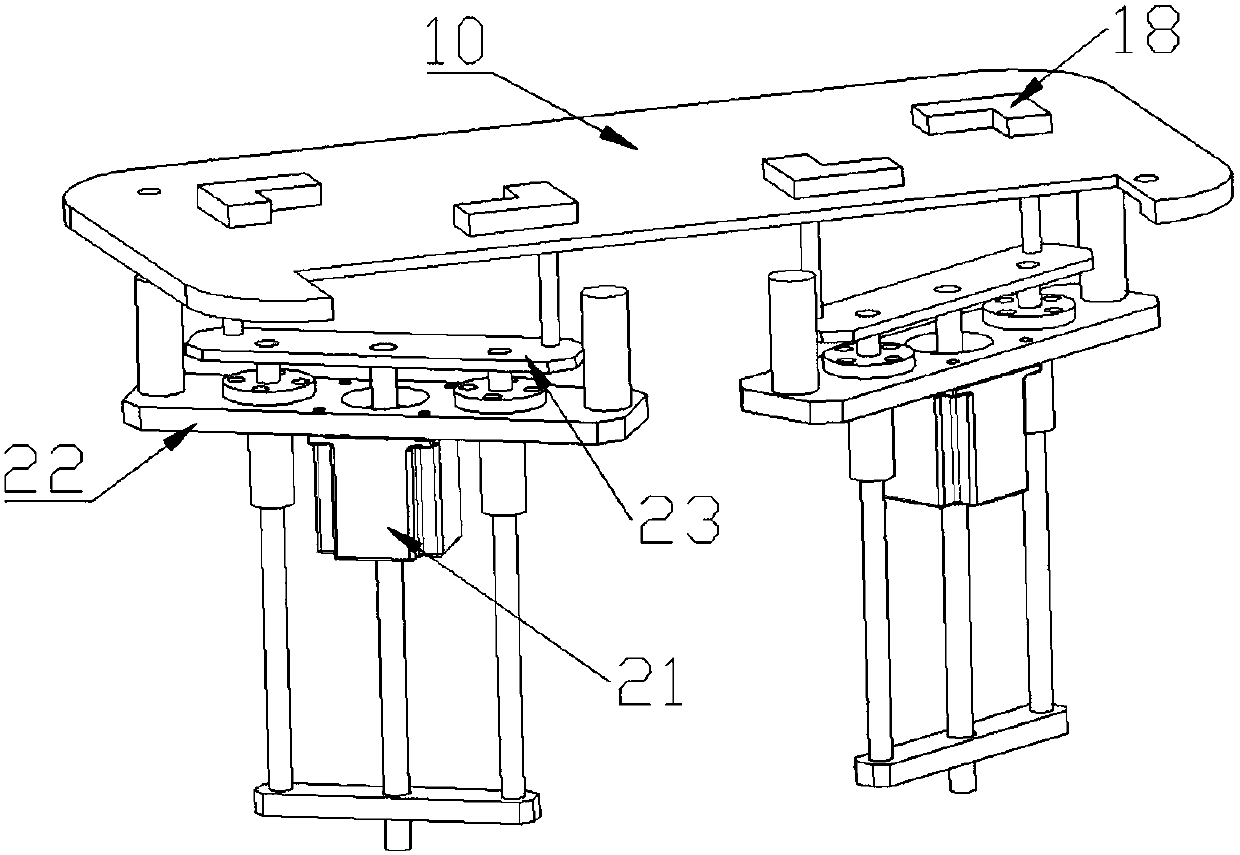

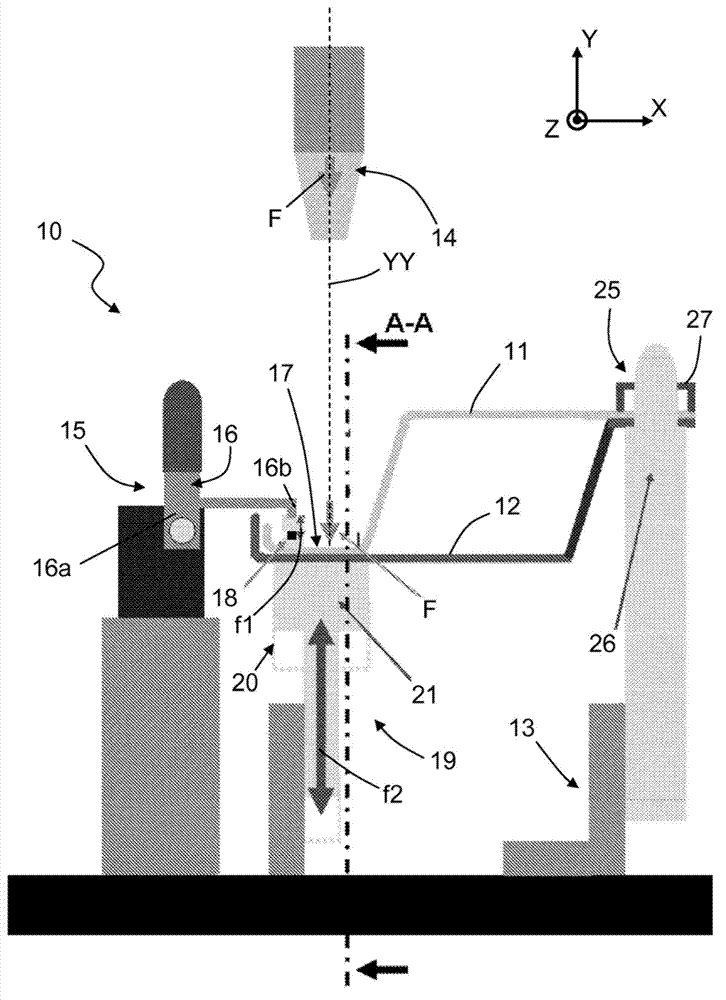

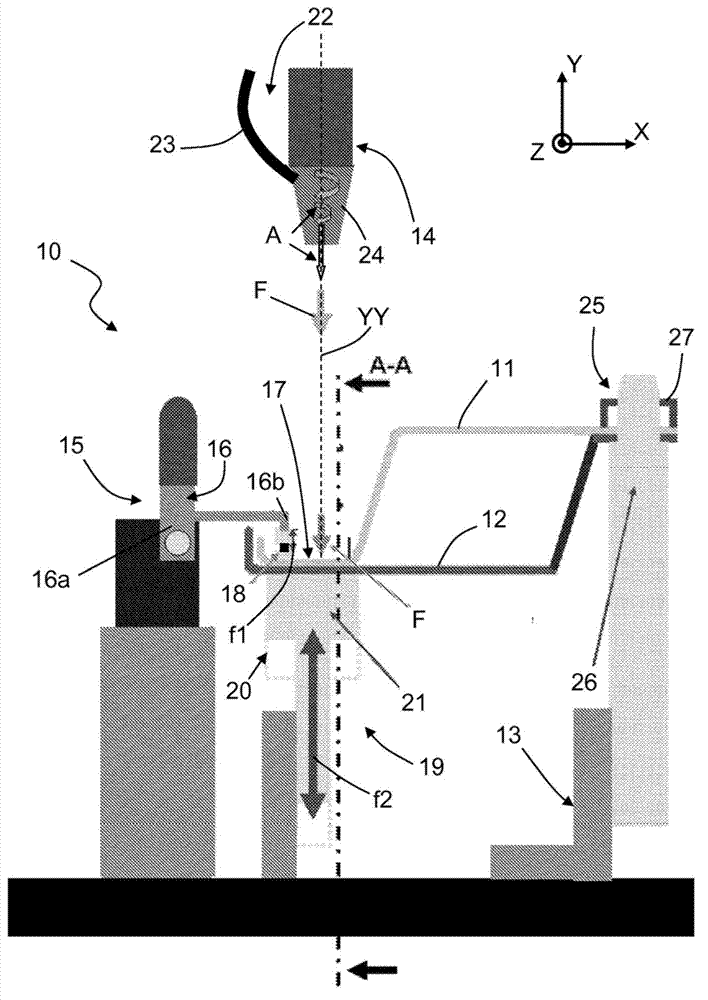

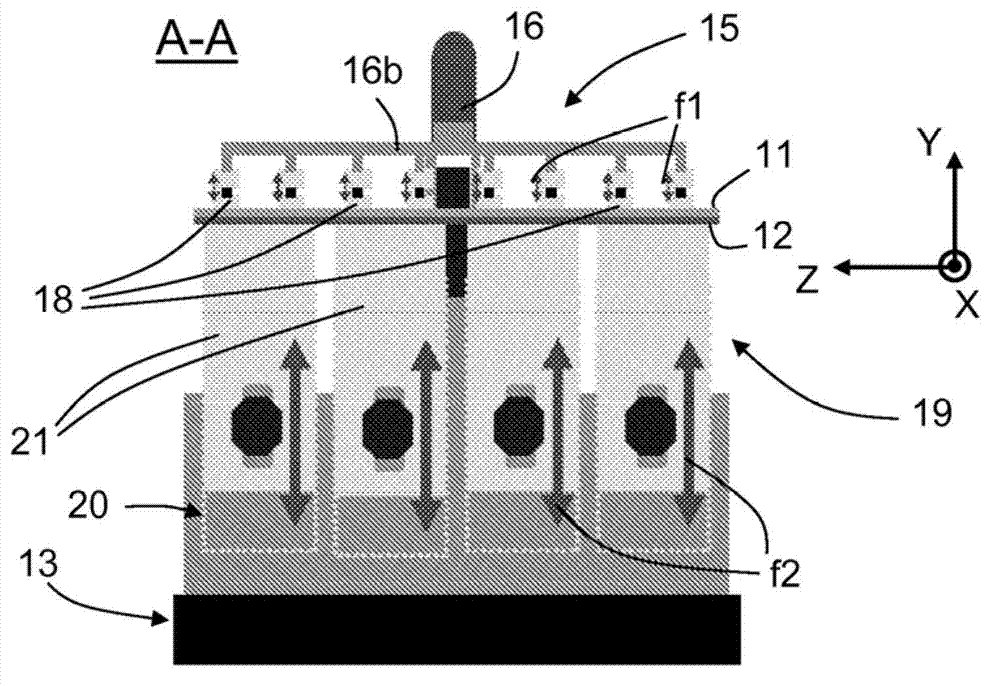

Device for assembling two parts made from thermoplastic materials by means of laser-transparent welding and associated assembly method

ActiveCN102958676AEasy to weldFast and efficient weldingDomestic articlesDoorsEngineeringLaser transmission welding

The invention relates to a device (10) for the laser welding assembly of a first upper transparent part (11) to a second lower absorbent part (12), comprising a means (14) for projecting a laser beam (F) onto the upper part (11), first clamping means (15) for geometrically referencing the two parts (11, 12), second clamping means (19) and first adjustment means (20) associated with the second flanging means (19). The first adjustment means (20) comprise a plurality of mobile members (21) which can be actuated independently of one another at a pre-determined welding interface (17) between the two parts (11, 12) and which are used to adjust a pre-determined stress (f2) at said welding interface (17). The assembly method of the invention is intended for the laser-transparent welding of two parts (11, 12) assembled using one such assembly device (10).

Owner:RENAULT SA

Straight-through type plastic inspection well chamber forming processing device and processing method thereof

The invention discloses a straight-through type plastic inspection well chamber forming processing device and a processing method thereof. The device comprises a plastic extruding device, a plate plastic extruding mold, a plate conveyor, a circle rolling mold, a robot, a laser output system and an automatic control system for controlling the whole device to operate; the plate plastic extruding mold is arranged at the outlet of the plastic extruding device, by taking the conveying direction of the plate as a benchmark, the plastic extruding device is positioned behind the plate conveyor, a plate cutting machine is arranged between the plastic extruding device and the plate conveyor, the circle rolling mold is arranged in front of the plate conveyor, a circumferential body conveyor is arranged at the front end of the circle rolling mold, and the robot is located in front of the circumferential body conveyor. The method comprises the steps that the plate undergoes plastic extruding, pressing is carried out, and laser transmission is adopted for welding, and manufacturing of a well chamber is completed. According to the device and the method, the laser transmission welding method is adopted, the welding deformation is small, the welding efficiency is high, the design and manufacturing cost of the mold is reduced, the automation degree is high, and the device and the method are beneficial to large-scale flexible production of the plastic inspection well chambers of various specifications.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com