Method for producing a composite part by transmission laser welding

A technology of laser transmission welding and composites, applied in the direction of chemical instruments and methods, layered products, layered product processing, etc., can solve the problem that welding is no longer sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

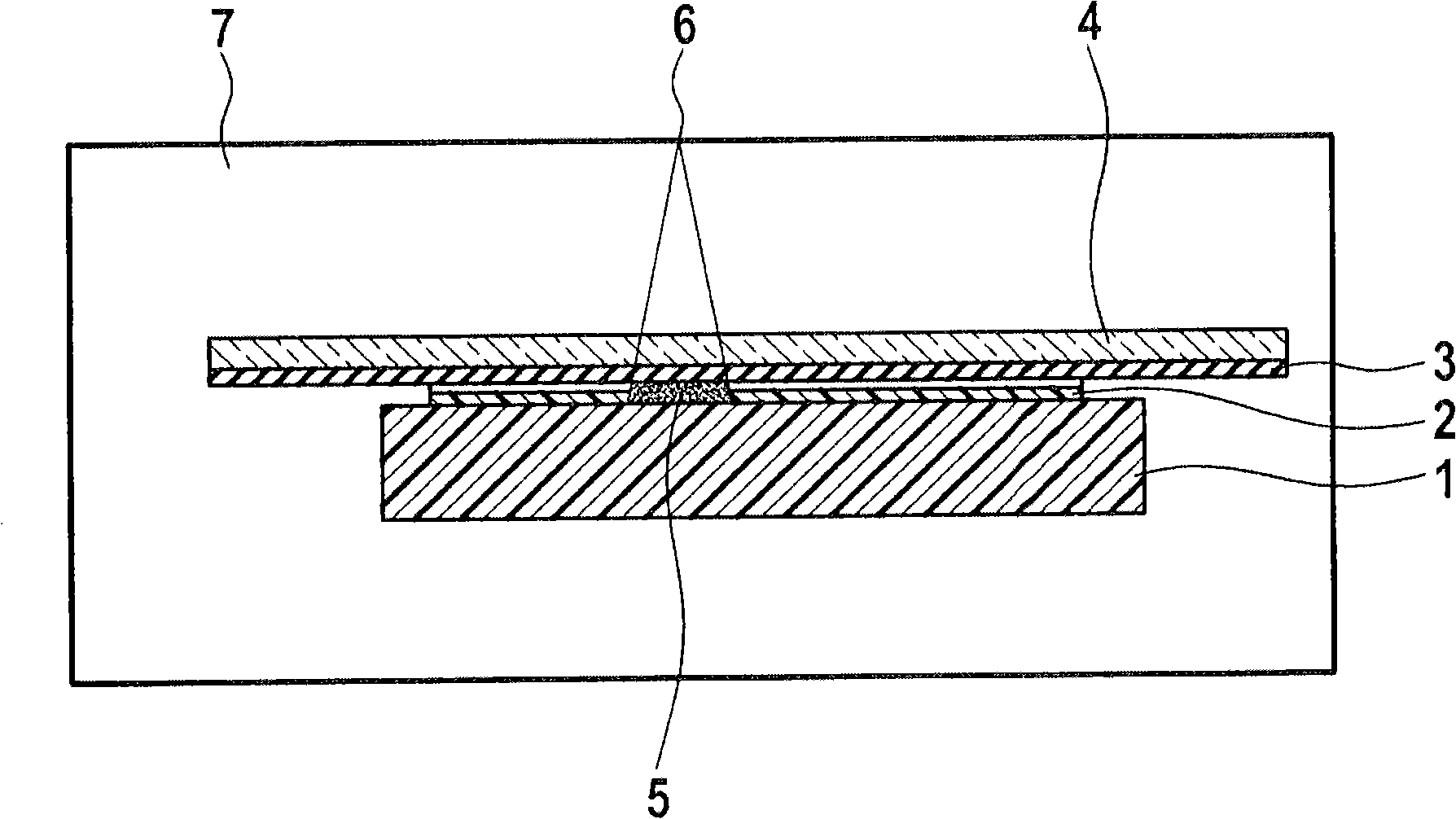

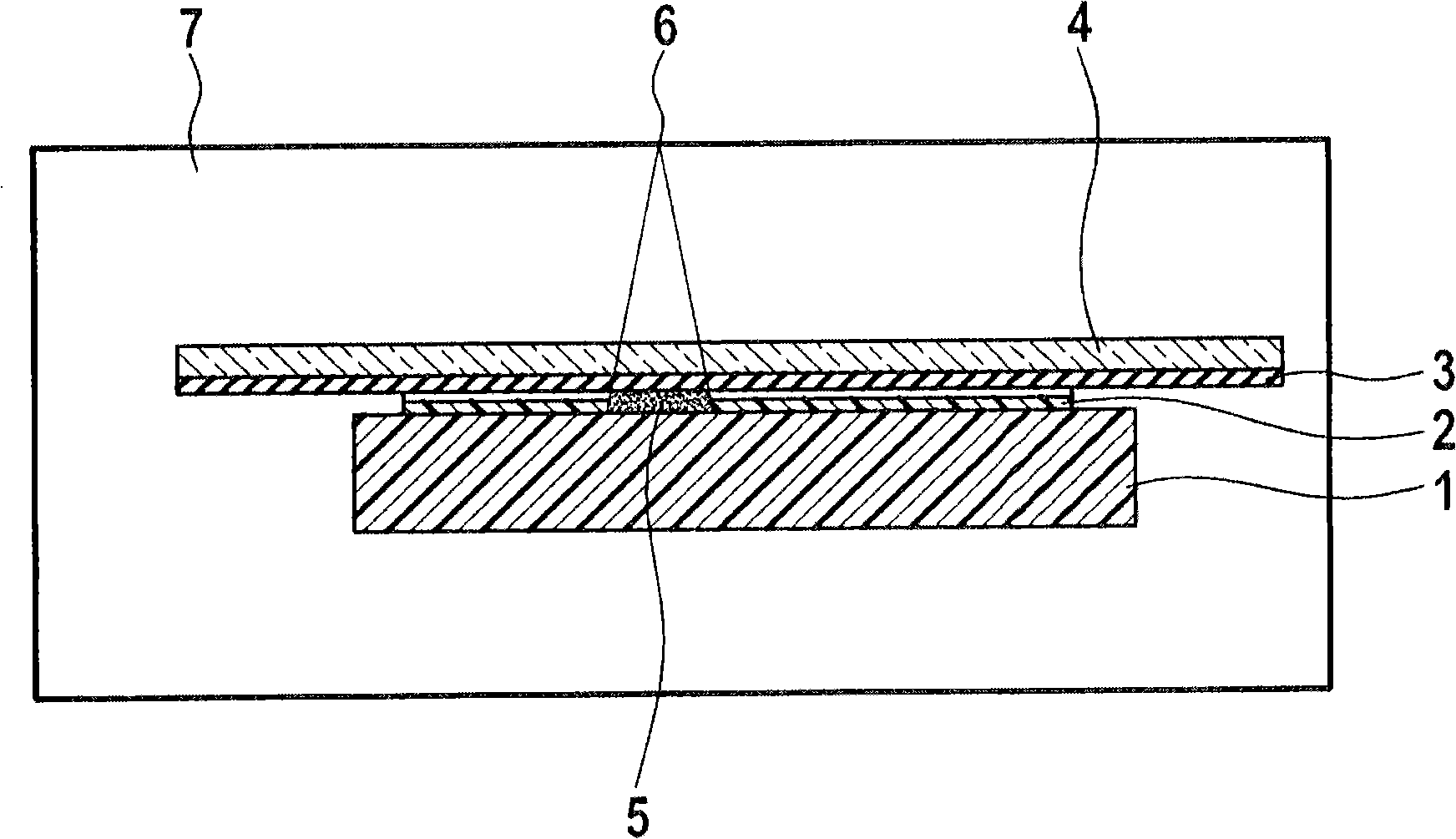

[0040] According to an embodiment of the method of the present invention, reference below figure 1 and 2 To explain the composite body obtainable by this method and the composite welded array device according to the present invention.

[0041] according to figure 1 , the composite welded array device is formed according to one embodiment of the present invention from a hard plastic part 1, a multilayer film 2 is flatly arranged on the hard plastic part 1, and a flexible plastic part 3 is flatly arranged on the multilayer film 2 And press tool 4 on.

[0042] Any weldable thermoplastic which is sufficiently thermodynamically compatible with the corresponding membrane during welding can be used as plastic for the rigid plastic part 1 . The rigid plastic part 1 is preferably formed from polypropylene. More suitable materials are, for example, polyethylene, polyisoprene, polyethylene terephthalate (PET), polycarbonate, their mixtures and their copolymers.

[0043] The multil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com