3D printing polycaprolactone material and preparation method thereof

A polycaprolactone and inorganic filler technology, applied in the field of 3D printing modified polycaprolactone materials, can solve the problems of low strength of polylactic acid matrix and unsatisfactory strength improvement, achieve excellent modification effect, shorten molding time, The effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

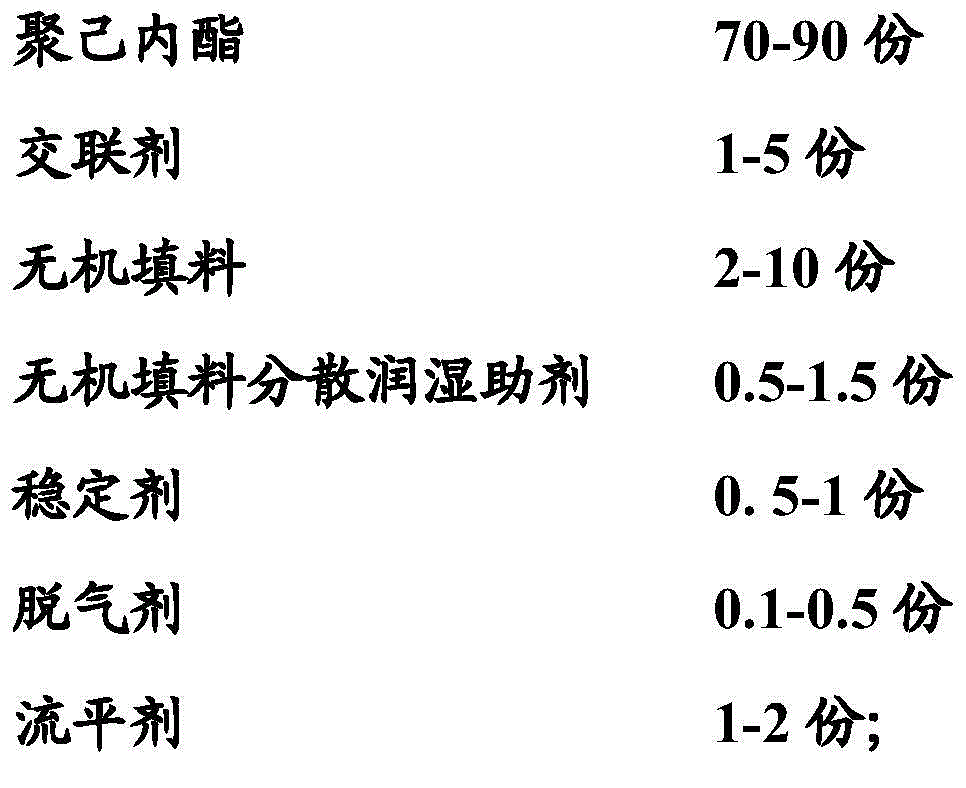

Method used

Image

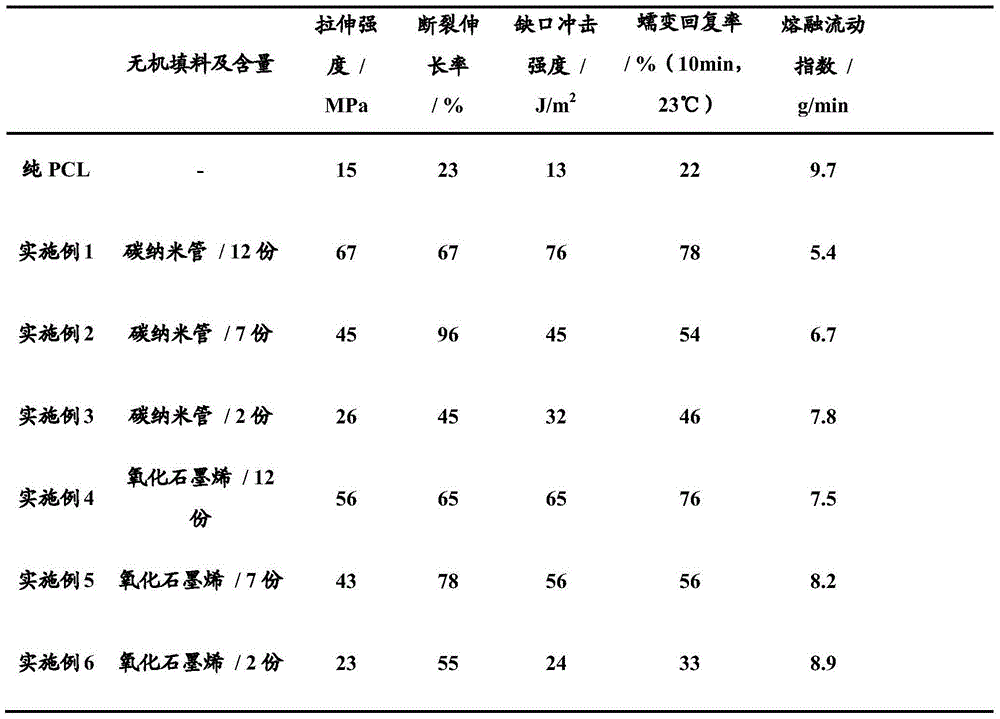

Examples

Embodiment 1

[0038] 1) 80 parts by weight of PCL (molecular weight: 420,000) obtained by ring-opening polymerization, 5 parts of BPO, 1 part of composite stabilizer, 0.5 part of benzoin degasser and 2 parts of epoxidized soybean oil fatty acid leveling agent are fully dried and manually well mixed;

[0039] 2) Disperse 10 parts of carbon nanotubes and 1.5 parts of oleic acid dispersion aid in chloroform, stir for a long time to facilitate the full effect of the two, then leave to stand and centrifuge, and vacuum dry the solid particles for later use;

[0040] 3) Add the mixture obtained in step 1) and the modified inorganic component obtained in 2) to a twin-screw extruder through a feed port for extrusion and granulation. The temperature of the twin-screw extruder is set as follows: 150°C-155°C, 155°C-160°C, 160°C-165°C, 165°C-170°C, 170°C-175°C, 175°C-180°C, 180°C- 185°C, 185°C-190°C. After the extrudate is air-cooled, use a granulator to granulate, and then dry at 40°C for 3 hours for...

Embodiment 2

[0043] 1) 83 parts by weight of PCL obtained by ring-opening polymerization (molecular weight: 420,000), 5 parts of BPO, 1 part of composite stabilizer, 0.5 parts of benzoin degasser and 2 parts of epoxidized soybean oil fatty acid leveling agent are fully dried and then manually well mixed;

[0044] 2) Disperse 7 parts of carbon nanotubes and 1.5 parts of oleic acid dispersion aid in chloroform, stir for a long time to facilitate the full effect of the two, then leave to stand and centrifuge, and vacuum dry the solid particles for later use;

[0045] 3) Add the mixture obtained in step 1) and the modified inorganic component obtained in 2) to a twin-screw extruder through a feed port for extrusion and granulation. The temperature of the twin-screw extruder is set as follows: 150°C-155°C, 155°C-160°C, 160°C-165°C, 165°C-170°C, 170°C-175°C, 175°C-180°C, 180°C- 185°C, 185°C-190°C. After the extrudate is air-cooled, use a granulator to granulate, and then dry at 40°C for 3 hour...

Embodiment 3

[0048] 1) 88 parts by weight of PCL obtained by ring-opening polymerization (molecular weight: 420,000), 5 parts of BPO, 1 part of composite stabilizer, 0.5 part of benzoin degasser and 2 parts of epoxidized soybean oil fatty acid leveling agent are fully dried and manually well mixed;

[0049] 2) Disperse 2 parts of carbon nanotubes and 1.5 parts of oleic acid dispersion aid in chloroform, stir for a long time to facilitate the full effect of the two, then leave to stand and centrifuge, and vacuum dry the solid particles for later use;

[0050] 3) Add the mixture obtained in step 1) and the modified inorganic component obtained in 2) to a twin-screw extruder through a feed port for extrusion and granulation. The temperature of the twin-screw extruder is set as follows: 150°C-155°C, 155°C-160°C, 160°C-165°C, 165°C-170°C, 170°C-175°C, 175°C-180°C, 180°C- 185°C, 185°C-190°C. After the extrudate is air-cooled, use a granulator to granulate, and then dry at 40°C for 3 hours for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com