Novel method of laser transmission welding connection

A new technology of laser transmission welding, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of destroying the quality of the weld seam, and the strength cannot meet the ideal requirements, so as to improve the connection strength and reliable connection strength , The effect of local connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

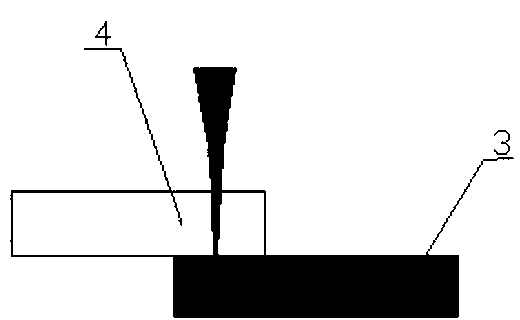

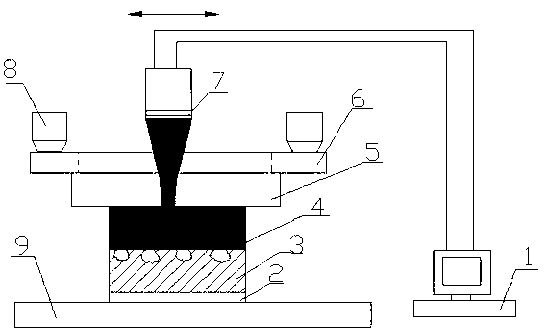

[0018] Below in conjunction with specific embodiment the present invention is further described, weld transparent nylon and 304 stainless steel metals with the present invention.

[0019] Welding preparation: The selected welding transparent light-transmitting material nylon (12) has a size of 10x10x2mm, and the light-absorbing material 304 stainless steel 14 has a size of 10x10x0.6mm. The laser uses a continuous energy semiconductor laser generator 7 with a maximum power of 130w and a wavelength of .

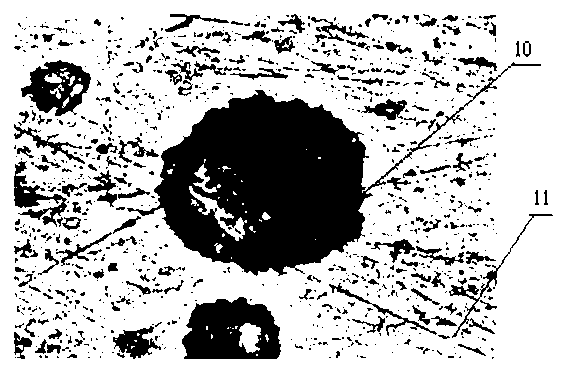

[0020] Surface treatment of the weldment: paste the sample 304 stainless steel 14 with an anti-corrosion mask on the area that does not need to be corroded, so that the contact area between the metal and the metal corrosive liquid is about 20mm 2 About, put it into the prepared 5%-15% ferric chloride solution, the temperature is about 26±1℃, take it out after 2-5 hours, it can form a diameter of about 46.60um-1103.53um, a depth of about For pits from 134.9um to 582.80um, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com