Automatic and uniform painting device and method for laser transmission welding absorption layer

A technology of laser transmission welding and absorbing layer, which is applied to devices and coatings for coating liquid on the surface, which can solve the problems of low efficiency, human health impact, and inability to guarantee the thickness and uniformity of spray paint, so as to ensure the thickness and improve the The effect of painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

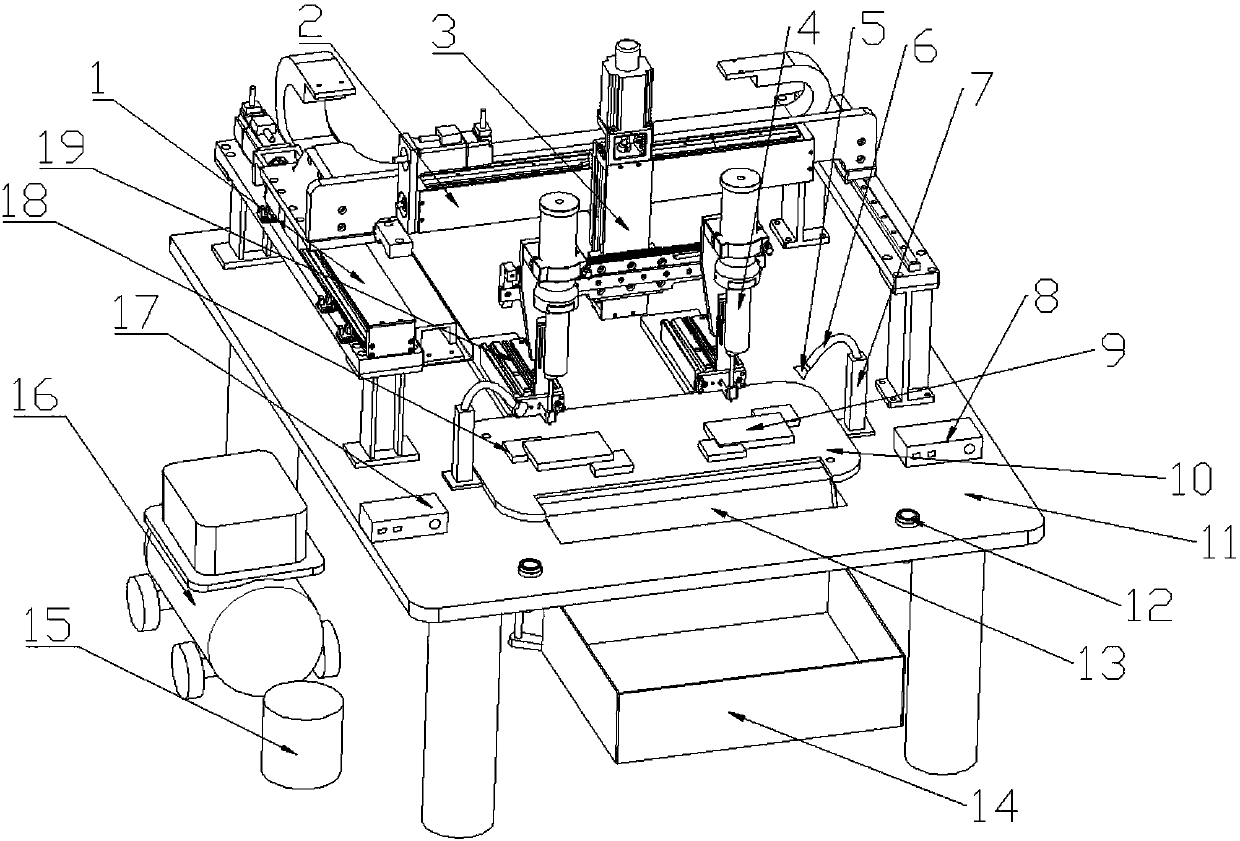

[0035] combined with figure 1 As shown, the automatic uniform painting device of the laser transmission welding absorbing layer according to the present invention includes a painting system, a drying system, a blanking system and a control system;

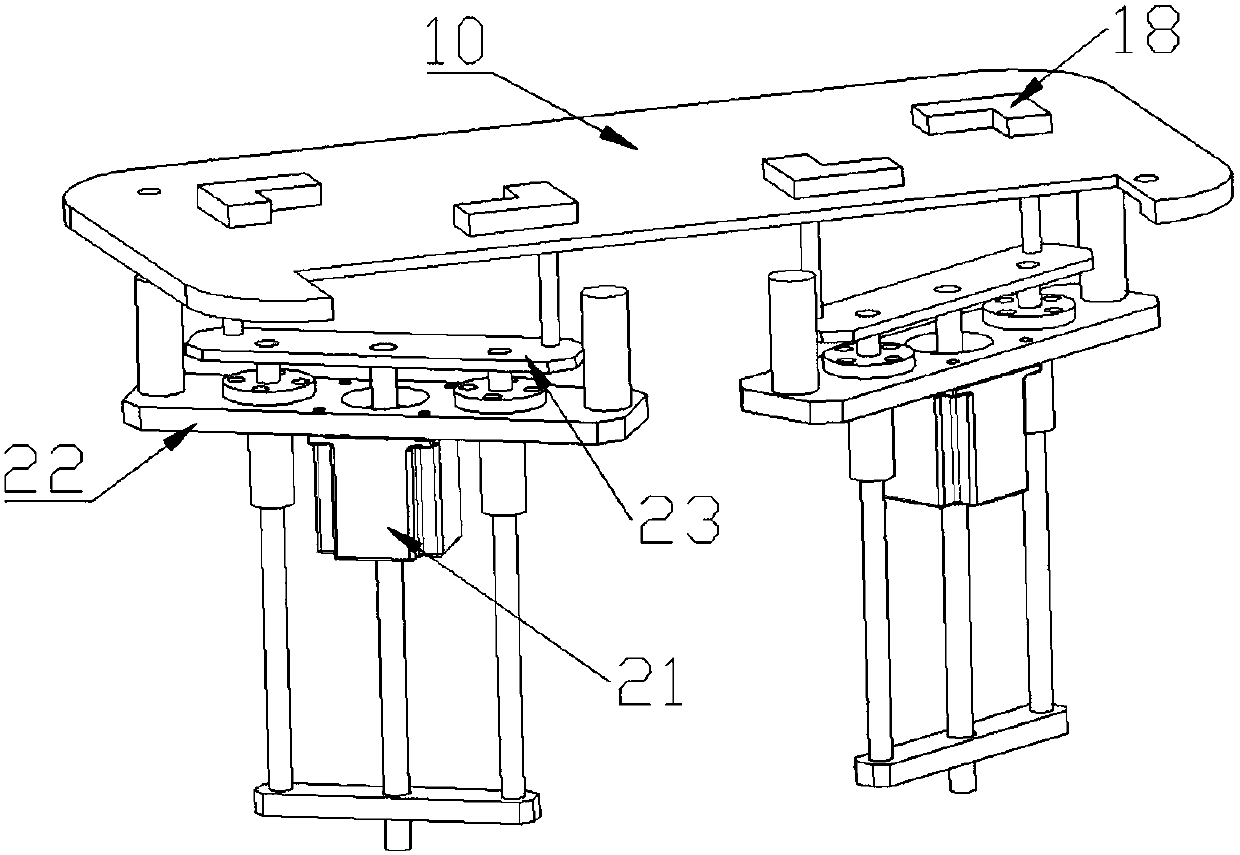

[0036] Described painting system comprises working platform 11, double start button 12, support plate 10, limit block 18, screw motor 21, motor mounting plate 22, support imitation block 23, painting device; Described double start button 12 is installed on the working platform 11;

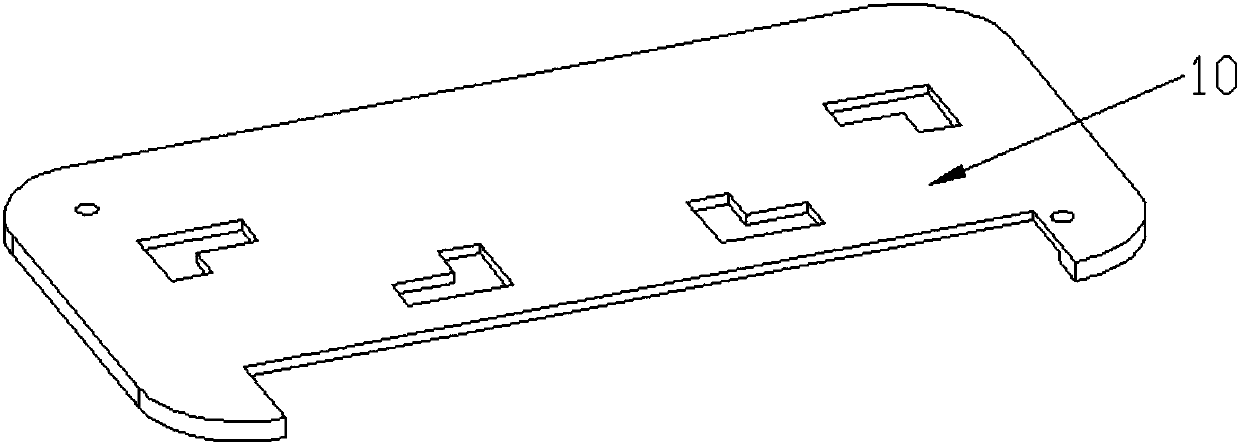

[0037] Such as figure 2 As shown, there are five through grooves on the support plate 10, wherein four L-shaped through grooves are used to ensure that the limit block 18 can move up and down, and the other large through groove is used as the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com