Portable welding device for communication coaxial cable joint

A portable communication and coaxial cable technology, applied in circuits, connections, electrical components, etc., can solve the problems of cumbersome maintenance work of welding heads, affecting communication effects, and common phenomenon of false welding, so as to ensure good contact, flexible operation, and easy operation. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

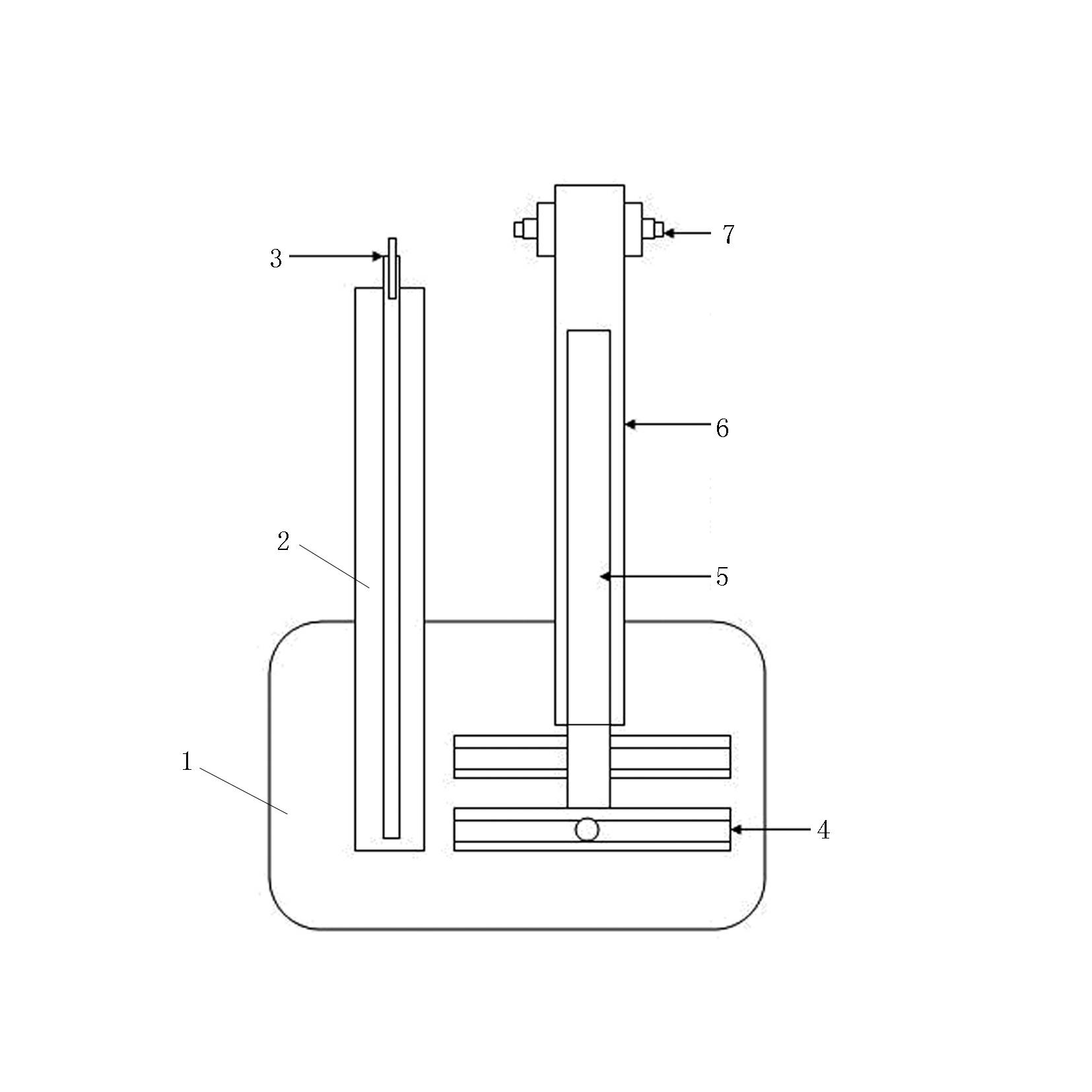

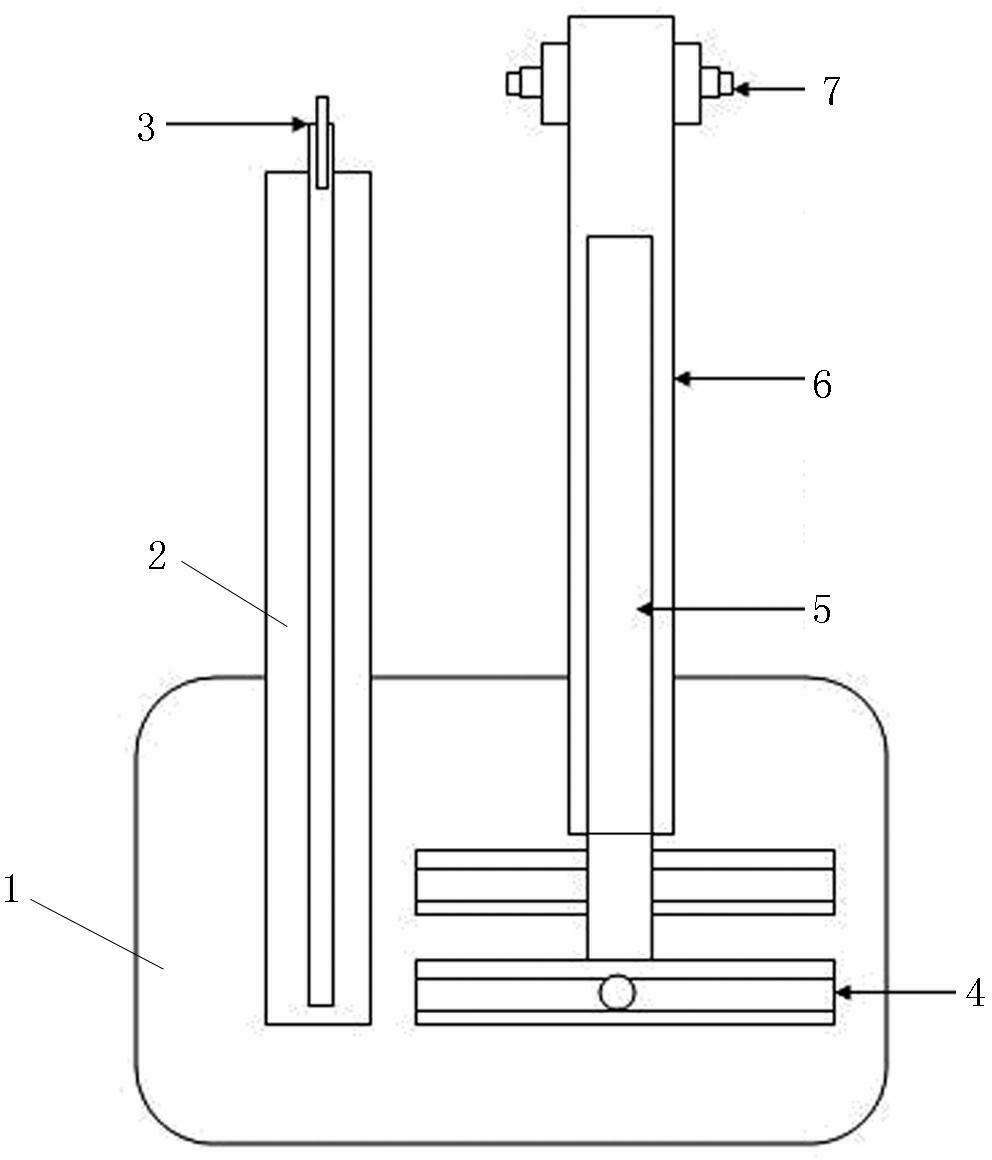

[0022] Such as figure 1 As shown, the base 1 is provided with a welding element 2, a transverse slideway 4, a tripod and a lighting lamp, the welding element 2 is connected to a power supply, a thermostatic controller and a welding heating element 3 are arranged on the welding element 2, and a horizontal slideway 4 is provided with Fixed rod 5, set sliding pipe 6 on the fixed rod 5, the top of sliding pipe 6 is respectively provided with BNC plug, socket and L9-J plug, socket.

[0023] Since the invention was put into trial use, it can complete the welding work of the communication dedicated line head in a short time with high quality and stability, and can reduce the maintenance workload in the future while completing the work efficiently. It is practical, easy to use, greatly improves the quality of welding, and takes up little space when it is portable. In terms of production and maintenance, this equipment improves the work efficiency of the members of the working class, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com