A welding device and method for a fluoroplastic heat exchange tube and a tube sheet

A welding device and technology of fluoroplastics, which are applied in the field of welding devices for fluoroplastic heat exchange tubes and tube sheets, to achieve the effects of low energy consumption and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

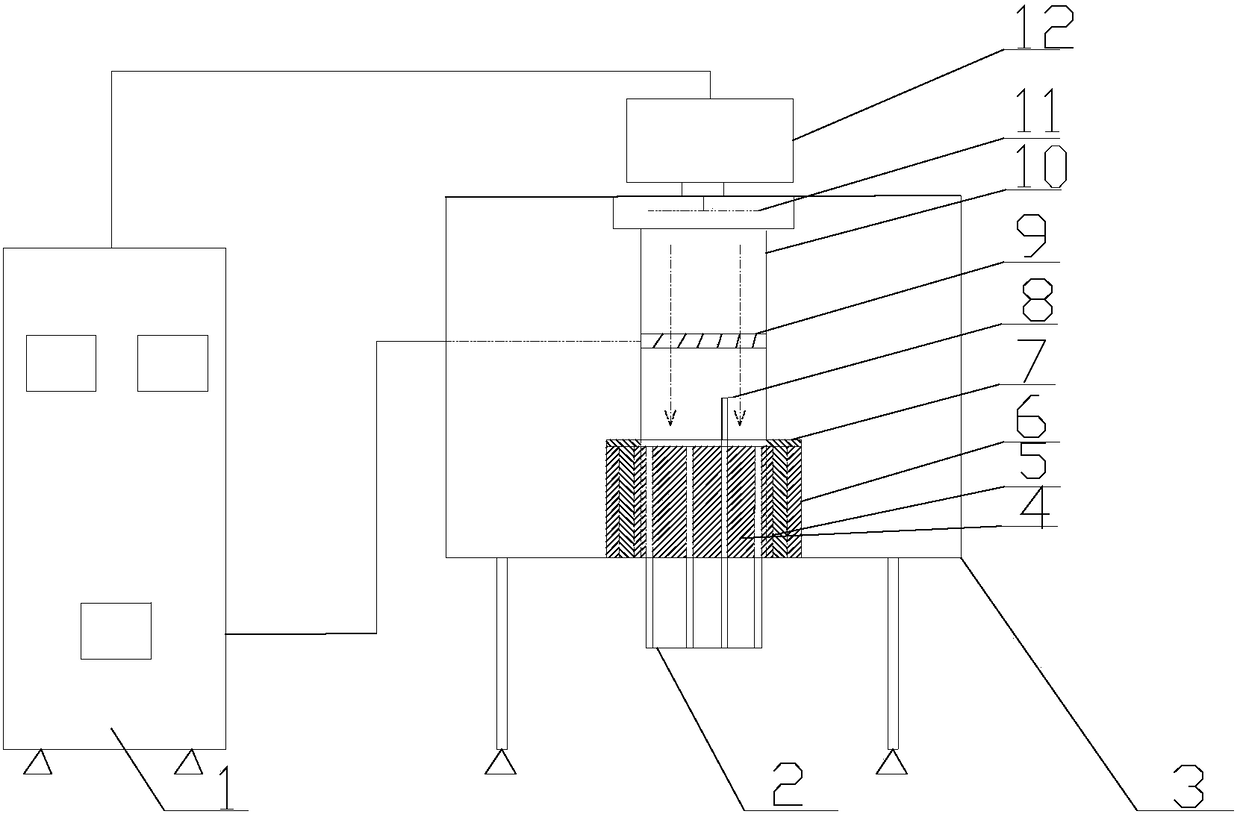

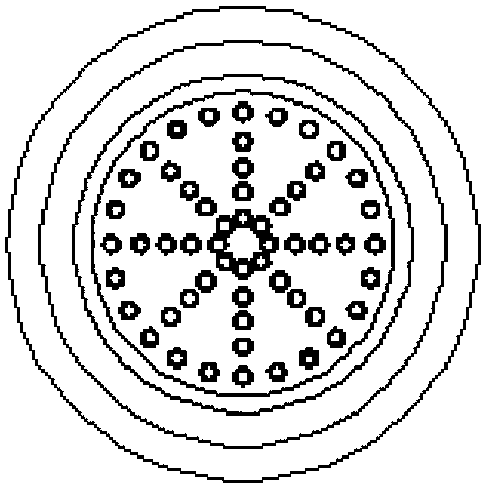

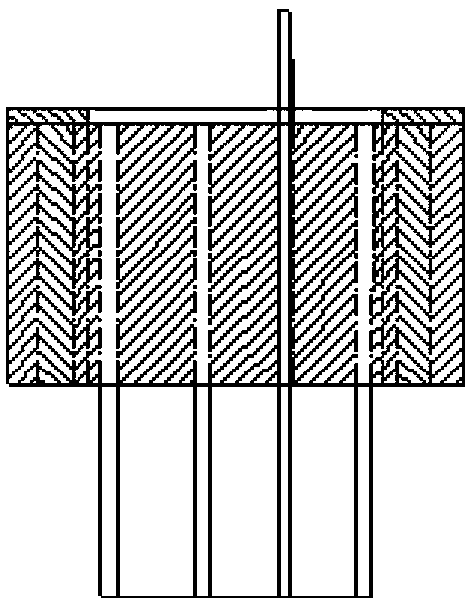

[0029] Such as figure 1 As shown, a welding device for a fluoroplastic heat exchange tube and a tube sheet includes a welding cabinet 3 and an electric control box 1. The welding cabinet 3 is vertically provided with an air blower 11 driven by a motor 12. Below the blower fan 11, a welding machine mold for positioning the fluoroplastic single tube 2 and the tube plate 4 is vertically arranged, and an air supply channel 10 is sealed and connected between the welding machine mold and the air outlet of the blower fan 11. An electric control heating plate 9 is arranged in the air supply passage 10 of the electric control heating plate 9, and the heat generated by the electric control heating plate 9 is transported to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com