Battery pole group welding device and method

A battery electrode group and electrode group technology, which is applied in the field of battery electrode group welding devices, can solve problems such as labor-intensive, low production efficiency, and cumbersome processes, so as to reduce product failure rate, improve production efficiency, and reduce production costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

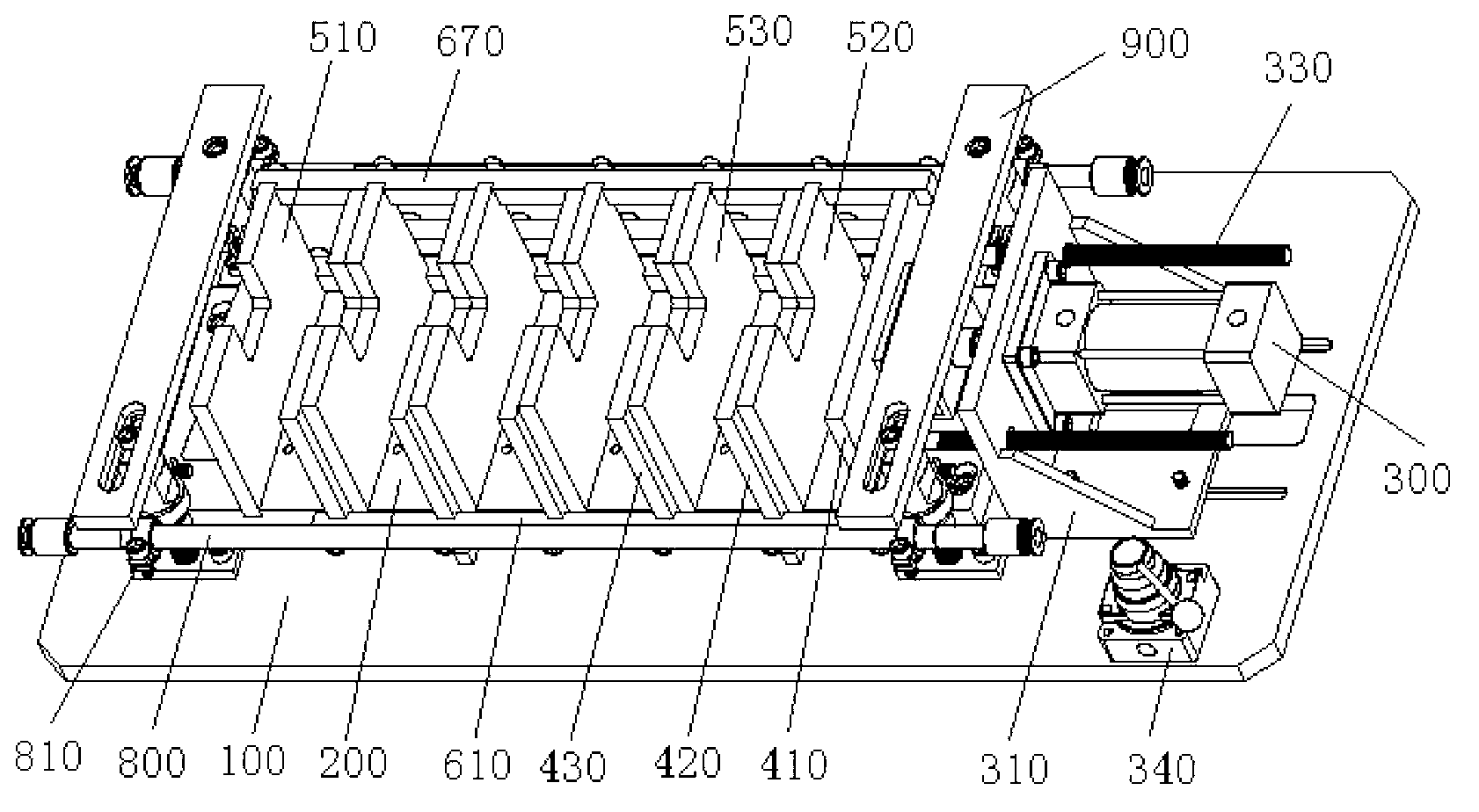

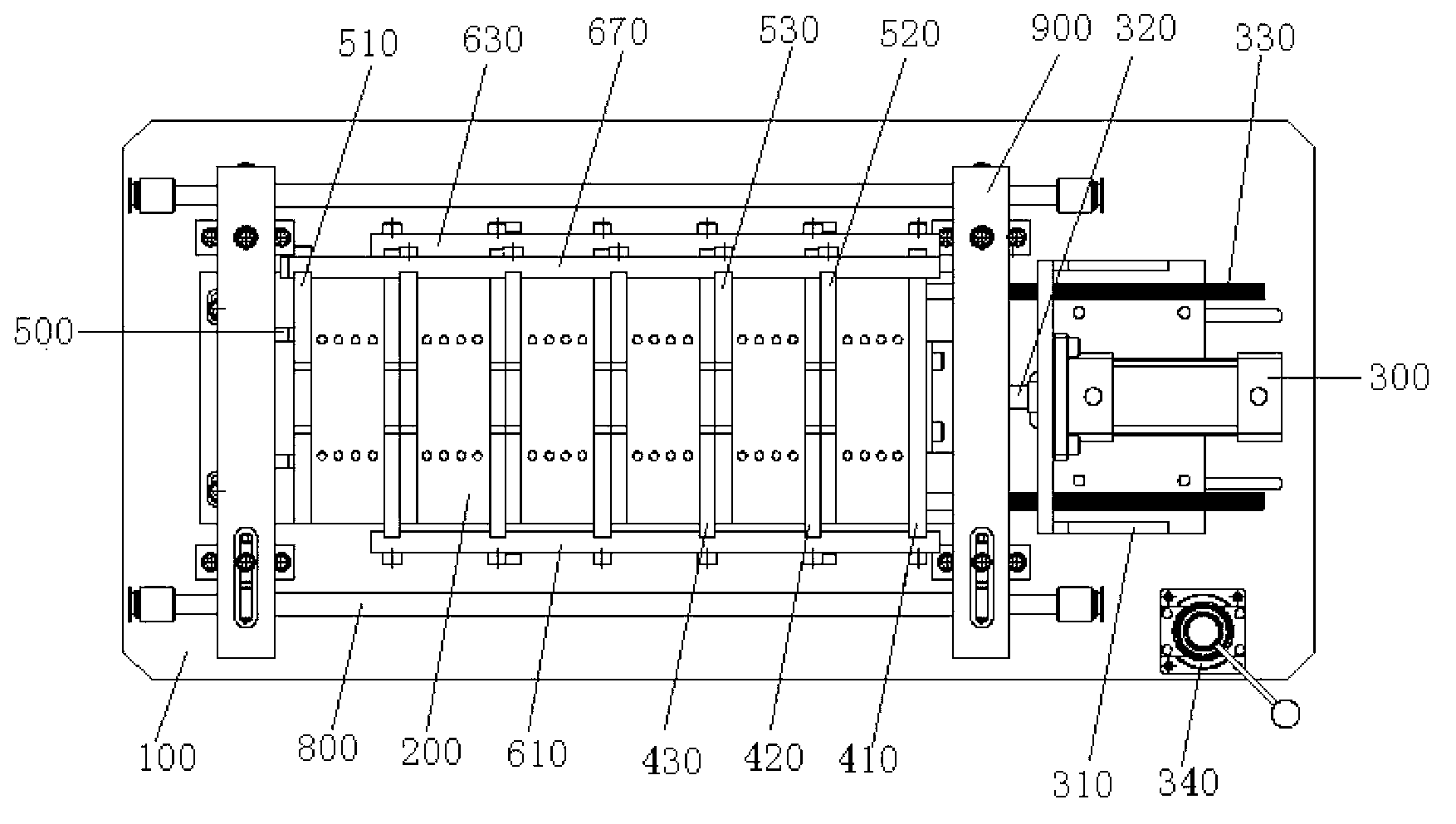

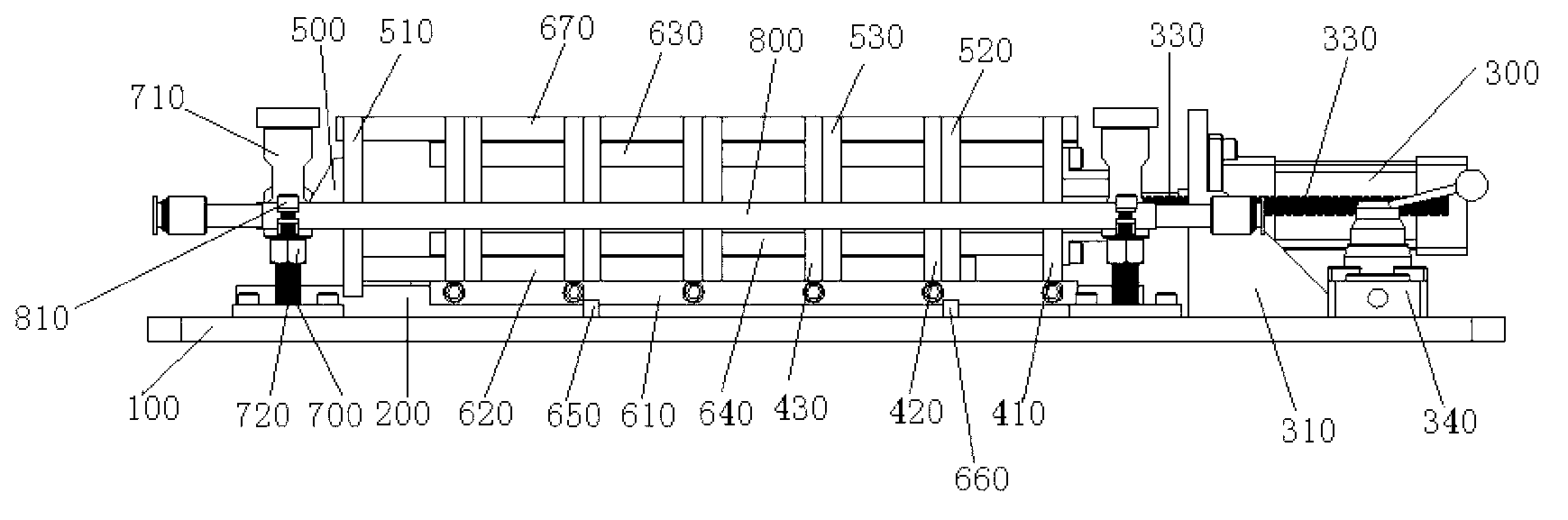

[0031] Please refer to figure 1 , figure 2 , the battery pole group welding device of the present application is suitable for the welding work of gravity casting pole plates and stretched mesh pole plates, including base 100 battery pole group clamping mechanism, pneumatic pressing mechanism, mold box bottom plate 200 , support column 700 and blowing mechanism, etc., the pneumatic compression mechanism, mold box bottom plate 200 and support column 700 are arranged on the base 100, the battery pole group clamping mechanism is set on the mold box bottom plate 200, and the battery pole group clamping mechanism includes The movable side plate group and the fixed side plate group, the movable side plate group comprises the first movable side plate 410 and the second movable side plate 420, the fixed side plate group comprises the first fixed side plate 510 and the second fixed side plate 520, the first The movable side plate 410 is connected with the pneumatic pressing mechanism ...

Embodiment 2

[0040] A battery electrode group welding method, using the battery electrode group welding device in Embodiment 1 to weld the battery electrode group, comprising the following steps:

[0041] After the battery electrode group and the separator are made into a battery electrode group, put it into the battery electrode group welding device, and start the pneumatic pressing device to compress the electrode group;

[0042] Put the comb plate on the battery pole group, insert the tabs of the pole group into the comb plate, press the bead, put the welding parts and poles, and then weld the battery pole group;

[0043] After the welding is completed, clean the lead slag and ash on the comb board, remove the bead, lightly tap the lower comb board with a rubber hammer and other tools, loosen the pneumatic pressing device to retract the movable side plate, and take out the battery electrode that has been soldered. Group into the battery case. Clean up the lead ash and lead slag in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com