Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Suitable for production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of pearl milk tea

The invention relates to a processing method of pearl milk tea. The processing method comprises the steps of: pearl ball manufacture, tea water soaking, milk juice preparation, homogeneous operation, split charging: and the like. The processing method is characterized in that the pearl balls are made of cassava starch, konjac refined powder, sweet potato starch and glutinous rice flour through rolling rounding in the production process. The pearl balls manufactured by the method have the elastic outer sides and the tough inner sides, and the mouth feeling is unique. In addition, compared with the existing milk tea processing process, the processing method has the advantage that the consumption of creamer is greatly reduced on the premise of keeping the milk tea flavor unchanged. Compared with the boiler-shop operation mode in the prior art, the operation mode of the pearl milk tea is more suitable for large-scale production and processing.

Owner:安徽蒙记生物科技有限公司

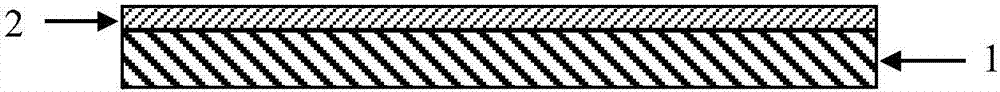

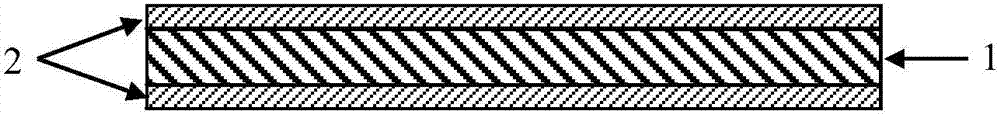

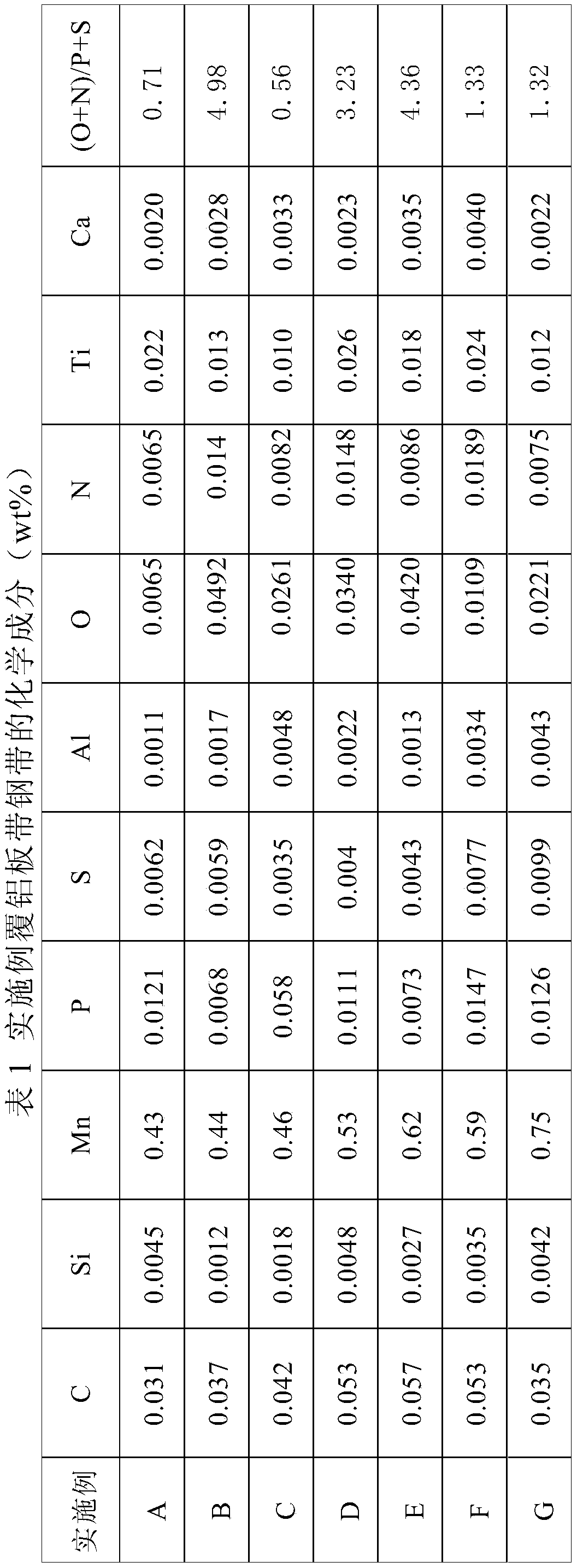

Aluminum-coated plate strip with excellent heat dissipating effect and production method thereof

ActiveCN107881410AImprove plasticityImproved interfacial bonding propertiesMetal rolling arrangementsSteel beltImpurity

The invention provides an aluminum-coated plate strip with an excellent heat dissipating effect and a production method thereof. The aluminum-coated plate strip is of a composite structure of an aluminum strip and a steel strip, and the steel strip comprises the components of, by weight, 0.005-0.03% of C, larger than 0 and smaller than or equal to 0.005% of Si, 0.2-0.6% of M, smaller than and equal to 0.015% of P, smaller than and equal to 0.005% of S, smaller than and equal to 0.005% of Al, 0.0062-0.02% of N, 0.006-0.05% of O and the balance Fe and inescapable impurities, wherein the conditions of O+N>=0.013% and 0.5<=(O+N) / (P+S)<=5 are met at the same time. The aluminum-coated plate strip has the strength of steel, is 200-320 MPa in yield strength and larger than or equal to 340 MPa in tensile strength, has the good plasticity and performance of cold bending, stamping machining and the like, has the characteristics of corrosion resistance, heat dissipation and beauty of aluminum, andcan be used for production of heat dissipating devices, heat dissipating pieces and wheels.

Owner:BAOSHAN IRON & STEEL CO LTD

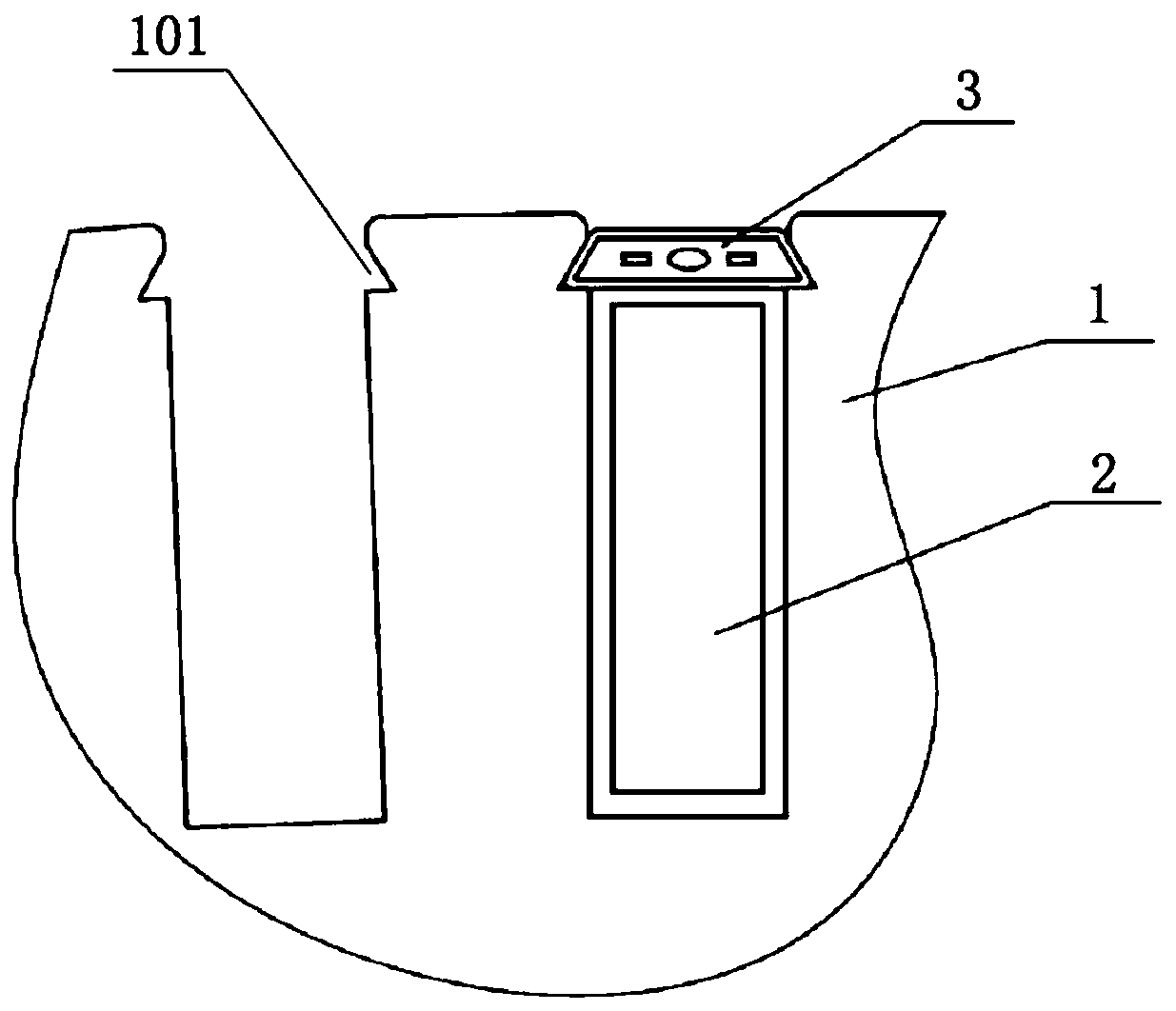

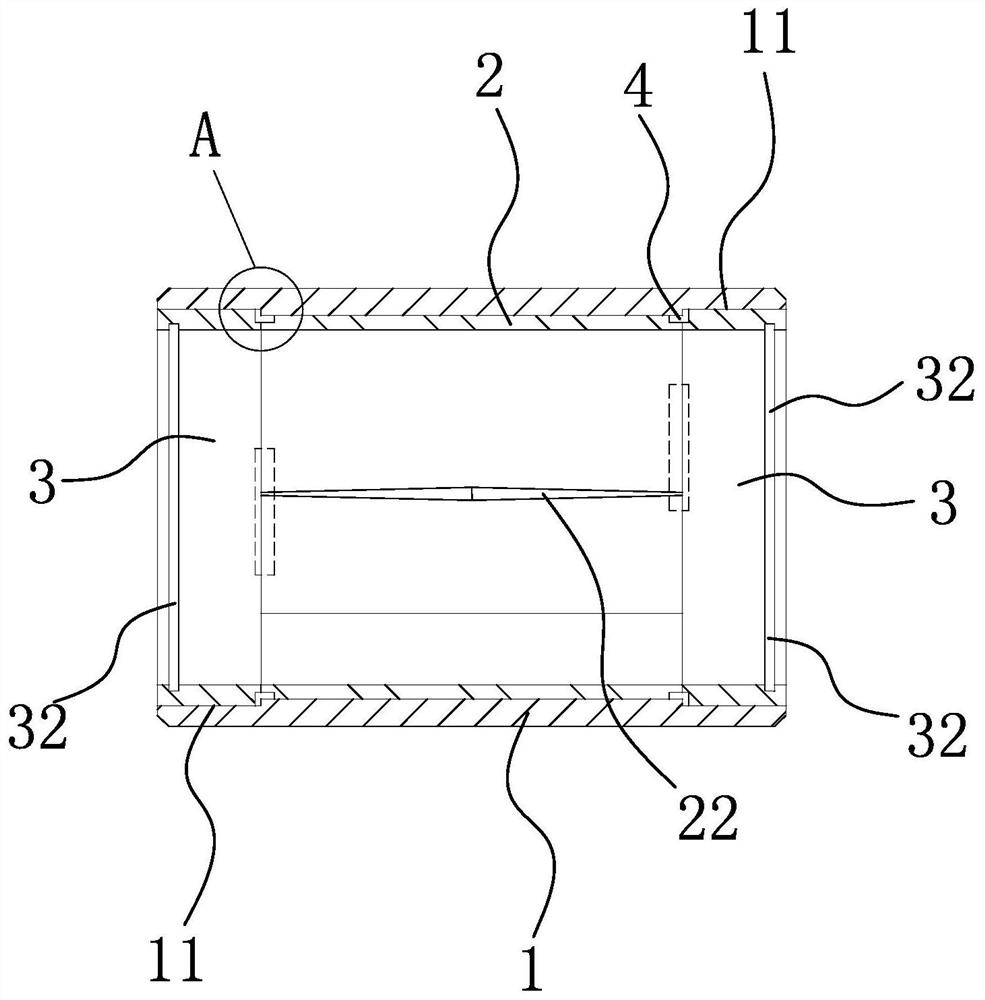

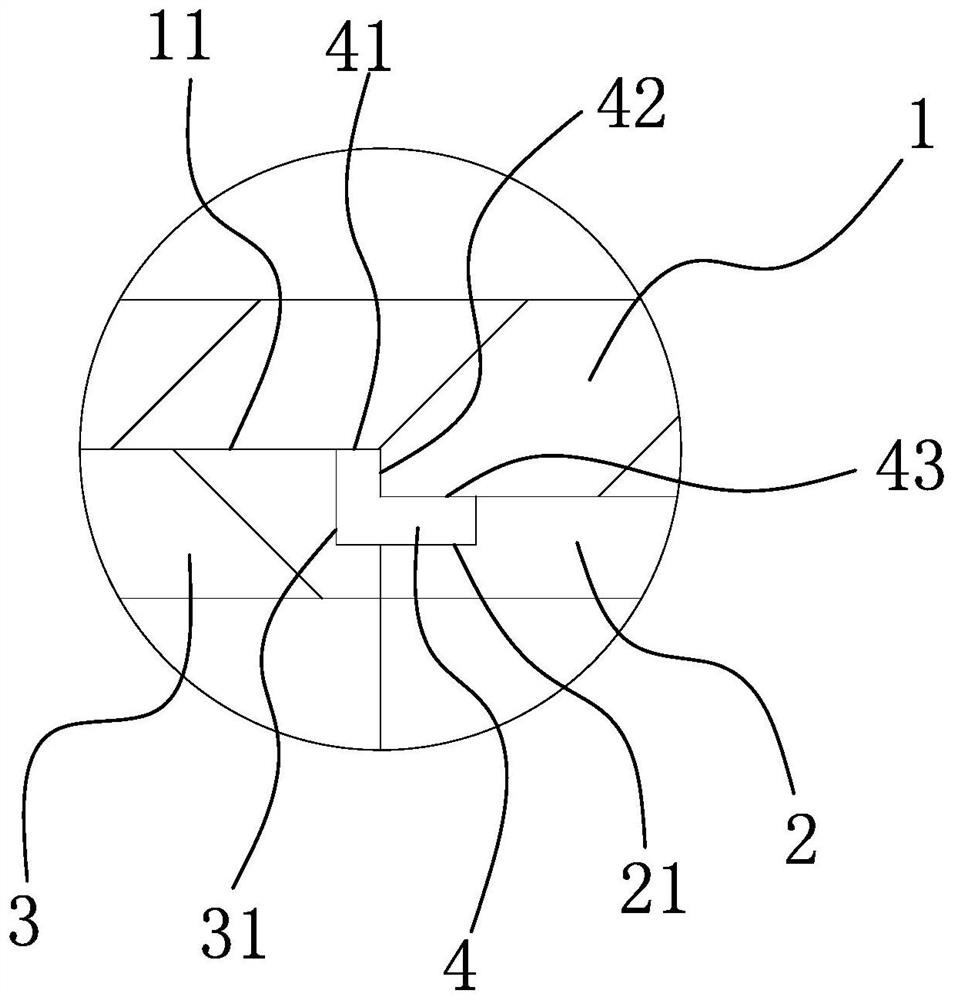

Mecanum electric wheel and omnibearing mobile platform

PendingCN106026504ASimple structureReduce in quantityMechanical energy handlingWheelsControl theoryVehicle engineering

The invention relates to the technical field of vehicle engineering, and provides a Mecanum electric wheel and an omnibearing mobile platform. The Mecanum electric wheel comprises a rotating mechanism and multiple Mecanum components. The rotating mechanism comprises a stator part and a rotor part which can coaxially rotate relative to the stator part. All the Mecanum components are equidistantly and circumferentially arranged outside the side wall of the rotor part in a surrounding way with the rotating shaft of the stator part acting as the center. All the Mecanum components are fixedly connected on the rotor part. According to the Mecanum electric wheel, the whole structure is simple and the conventional wheel hub structure is replaced by the rotating mechanism so that the number of parts of the whole electric wheel can be reduced, and the matching precision required for the stator part and the rotor part is low and thus the Mecanum electric wheel is more suitable for production and processing.

Owner:SHENZHEN INST OF ADVANCED TECH

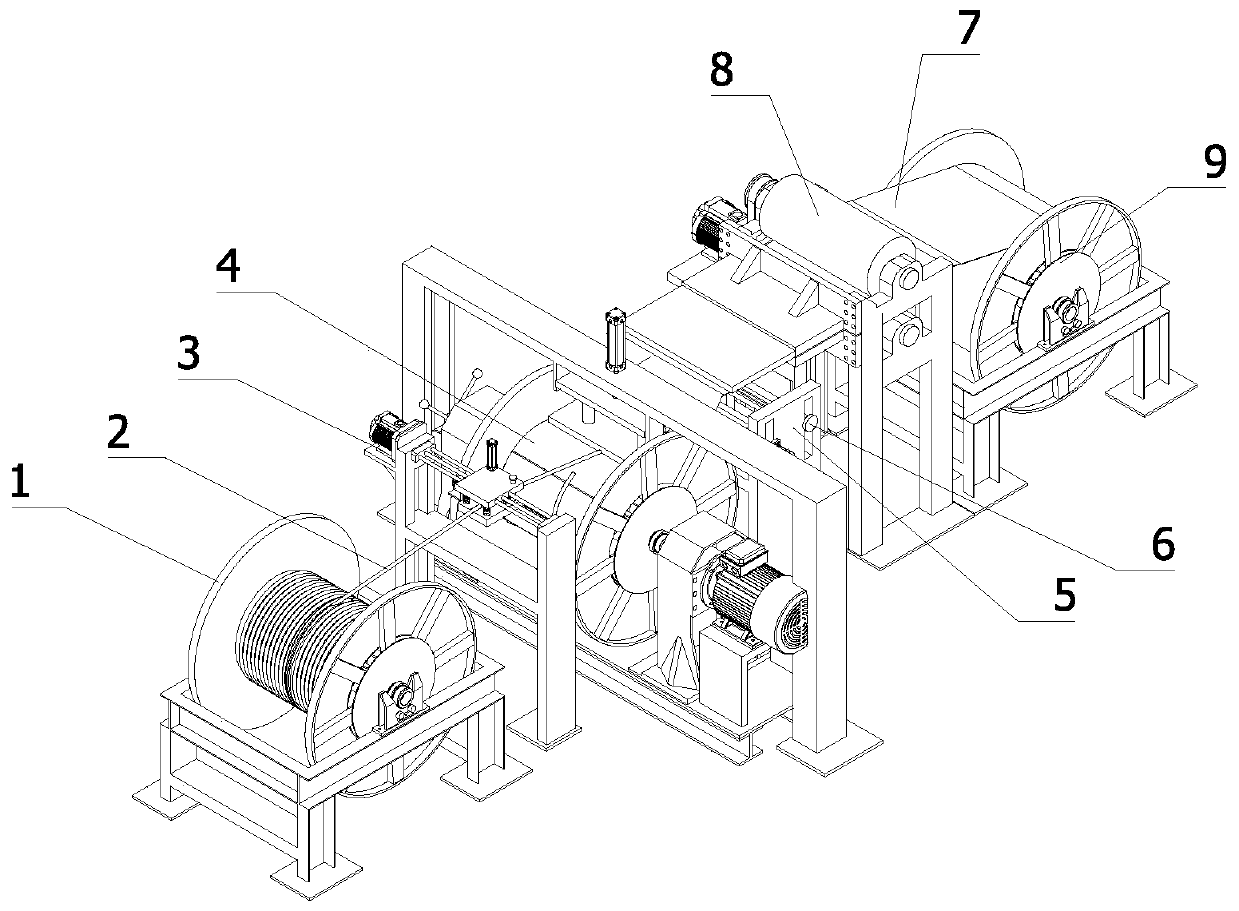

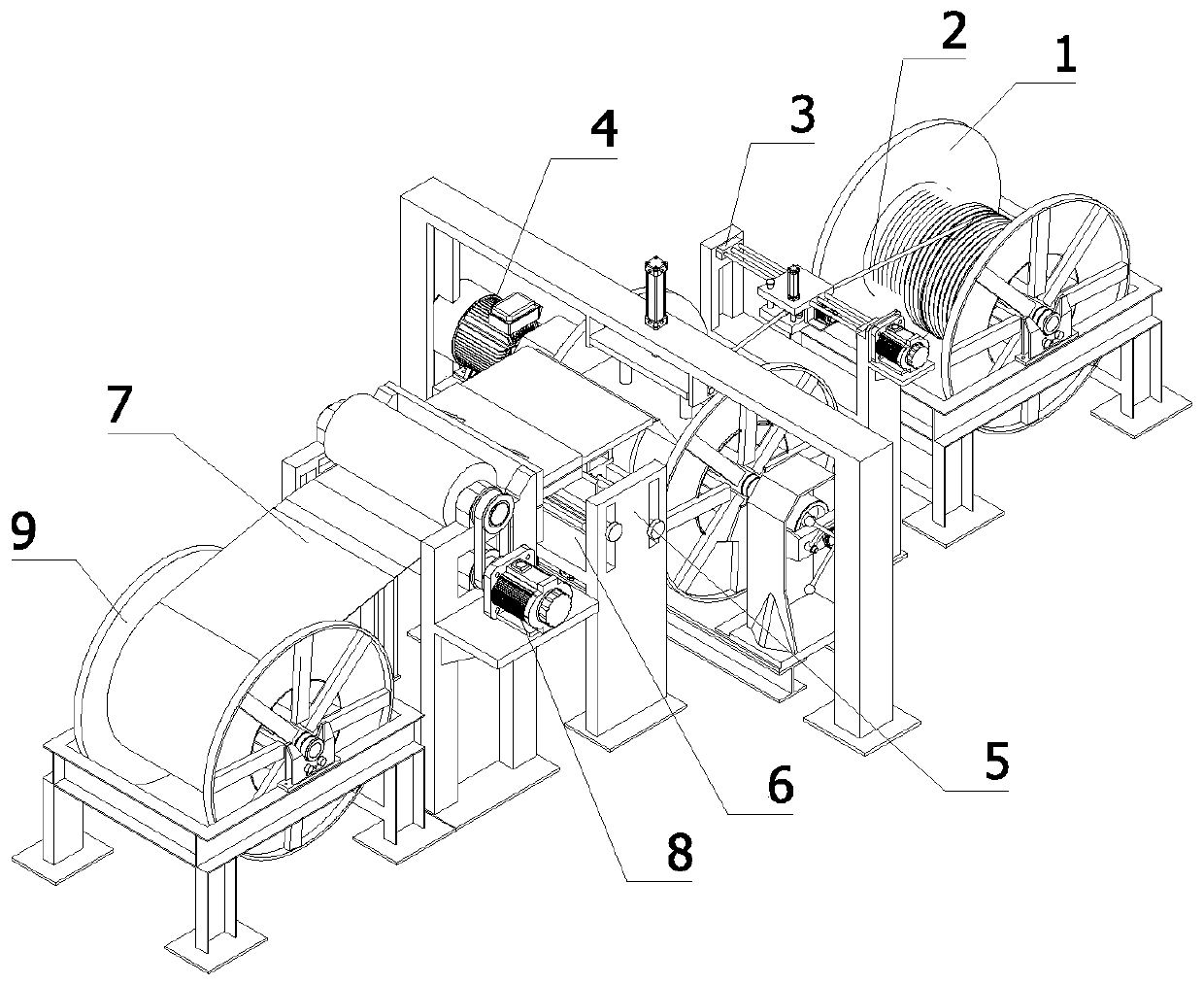

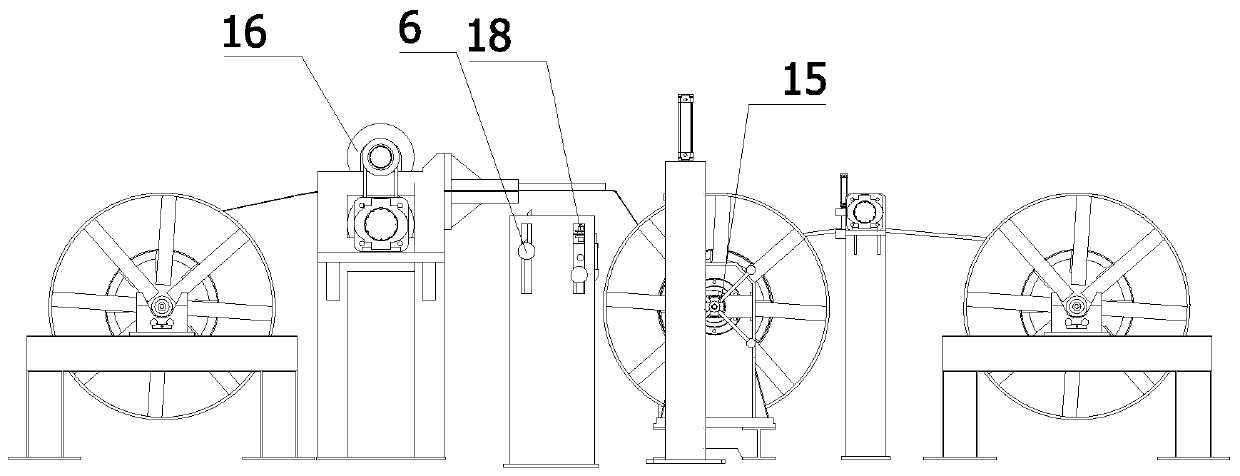

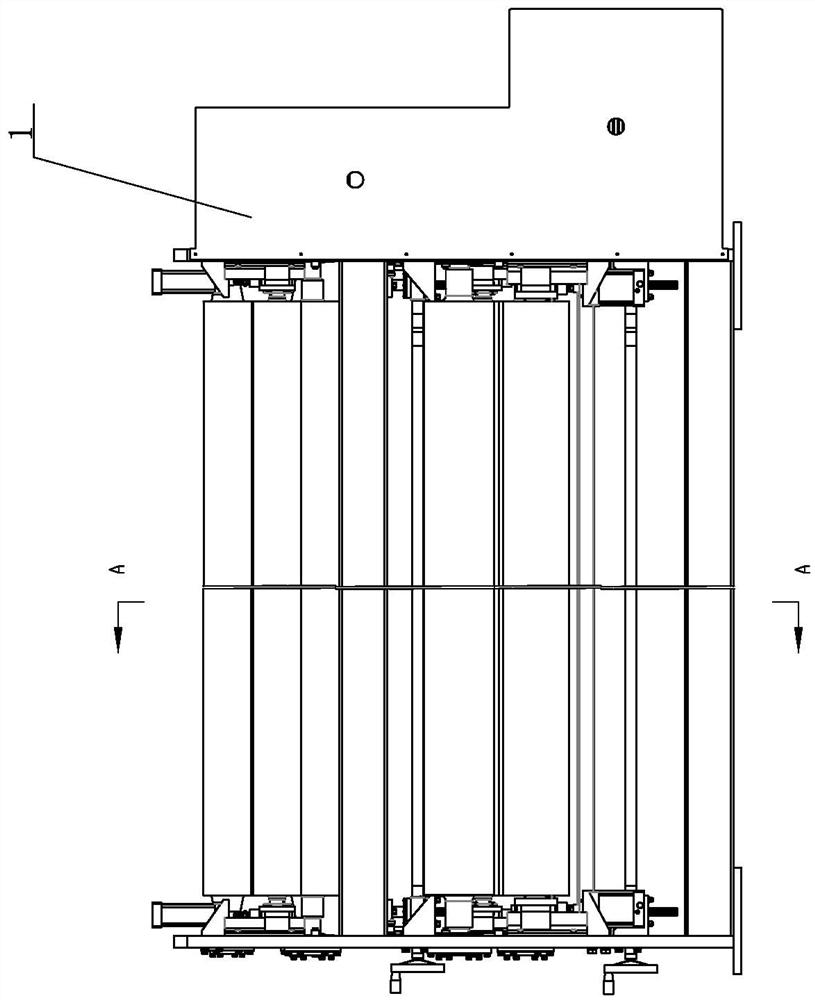

Automatic winding device of transformer

InactiveCN111599589AAutomatic deliveryImprove processing efficiencyCoils manufactureCardboardRolling paper

Owner:刘涛

Process for extracting dietary fibers from peony leaves by fermentation method

InactiveCN101999673AImprove water holding capacityHigh extraction rateFood preparationBiotechnologyMicrobiology

A process for extracting dietary fibers from peony leaves by a fermentation method belongs to the extraction process of dietary fibers for food processing. The method is characterized by adopting lactobacillus as the fermentation agent, carrying out inoculation, fermentation culture, drying, grinding and sieving on the peony leaf pulp prepared by grinding, seasoning, sterilizing and cooling the peony leaves and packaging the products with sealed bags, thus obtaining the dietary fibers. The method effectively solves the following problems: the natural ingredients are greatly damaged in the process of extracting the dietary fibers and the biological activity of the prepared products is low, and the dietary fibers obtained by the method have higher water holding capability and higher extraction ratio.

Owner:HENAN UNIV OF SCI & TECH

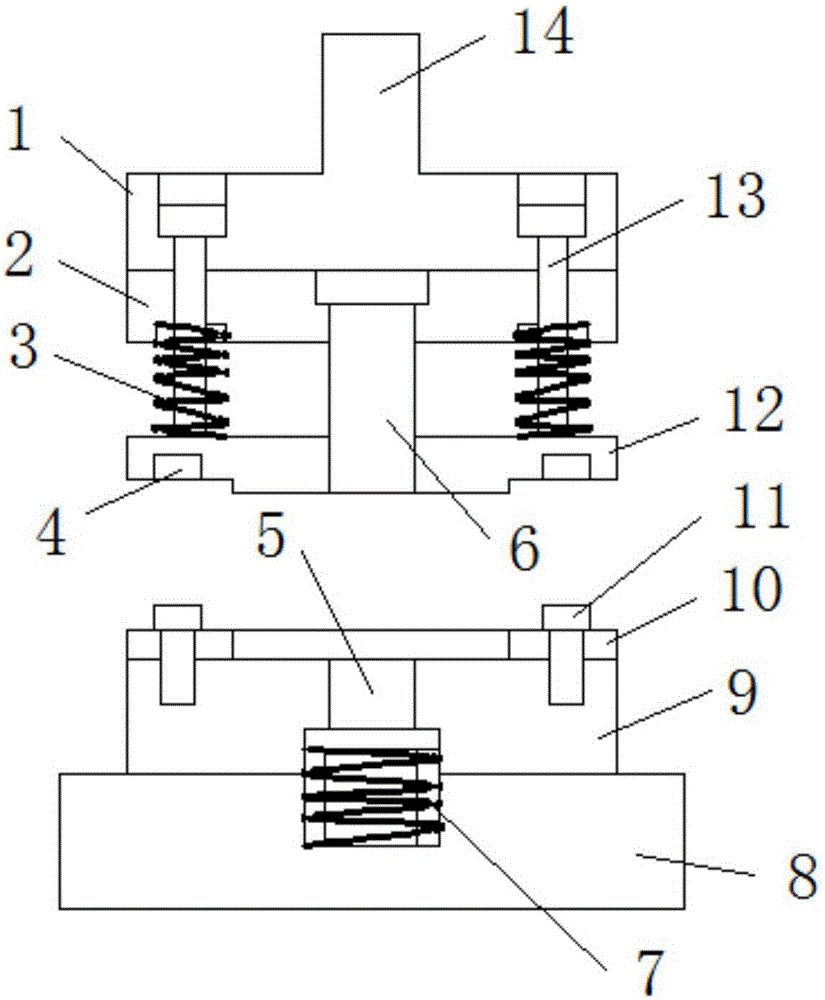

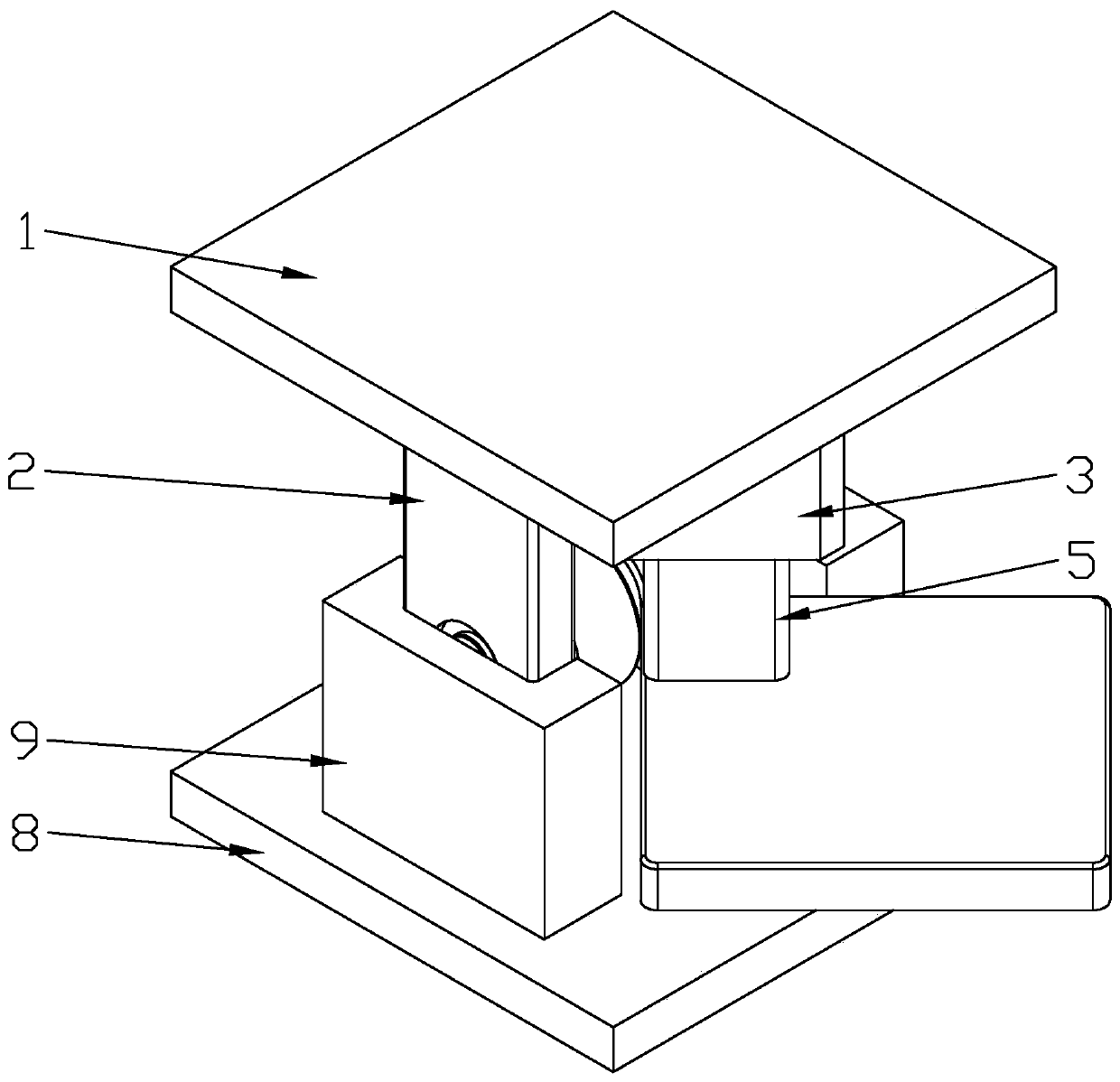

Stamping die facilitating discharging

InactiveCN106424357AImprove securityMaintain precisionShaping toolsMetal-working feeding devicesContinuous productionMechanical engineering

The invention discloses a stamping die facilitating discharging. The stamping die comprises an upper die base, a male die, a lower die base and a female die. A die handle is arranged in the center of the upper end face of the upper die base. The lower end face of the upper die base is provided with a fixing plate through a bolt assembly. The male die is fixedly connected to the center of the fixing plate. A discharging plate is movably arranged at the lower end head of the male die in a sleeving manner, discharging threaded rods are perpendicularly and fixedly arranged on the outer edge sides of the discharging plate, the discharging threaded rods penetrate the upper die base and the fixing plate, the upper ends of the discharging threaded rods are located in step holes in the upper die base, discharging springs are arranged on the lower portions of the discharging threaded rods, and a guiding hole is formed in the lower surface of the discharging plate. The female die is fixedly connected to the lower die base through a bolt assembly, a positioning plate is fixedly connected to the female die through a guiding connection rod, a stamping hole corresponding to the male die is formed in the center of the female die, a material ejection platform is arranged in the female die and the lower die base, and a material ejection spring is arranged below the material ejection platform. According to the stamping die facilitating discharging, discharging is convenient, safety is high, and the stamping die is suitable for large-batch and long-term continuous production.

Owner:HUANGSHI DINGSHENG MOLD CO LTD

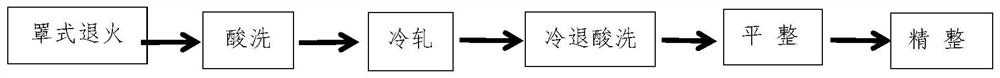

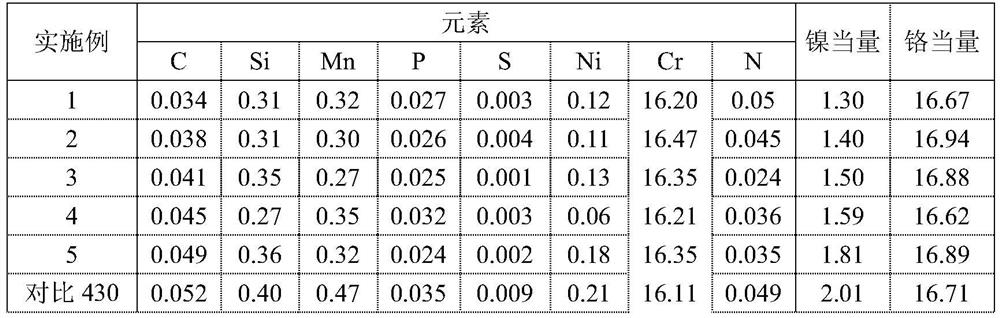

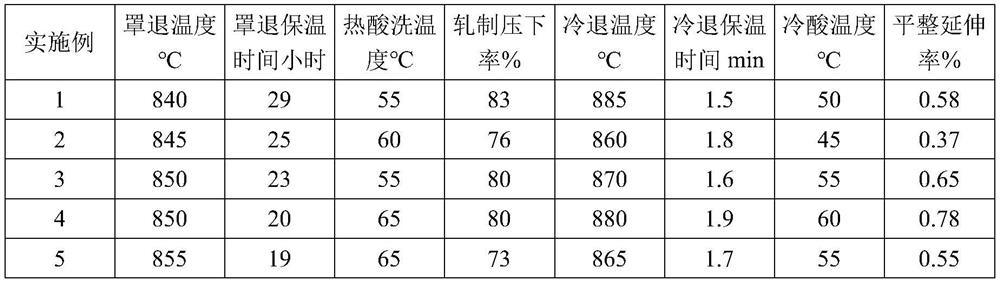

430 ferritic stainless steel for kitchen ware panels and preparation method thereof

InactiveCN113388780AHigh ferrite stabilityReduce work hardeningSS - Stainless steelUltimate tensile strength

The invention discloses 430 ferritic stainless steel for kitchen ware panels and a preparation method thereof. The 430 ferritic stainless steel comprises the following components in percentage by mass: 0.030-0.05% of C, 0.02-0.05% of N, 0.20-0.40% of Si, less than or equal to 0.20% of Ni, less than or equal to 0.35% of Mn, 16.00-16.50% of Cr, less than or equal to 0.035% of P, less than or equal to 0.010% of S, and the balance of Fe and inevitable impurity elements. The equivalent value of nickel is not greater than 2.00, and the equivalent value of chromium is not less than 16.50. During preparation, a hot-rolled black skin roll is subjected to cover annealing, acid pickling, cold rolling, cold annealing and acid pickling, leveling and other procedures to be prepared into a finished product with the required target thickness. The formula and the preparation process of the 430 ferritic stainless steel are scientific and reasonable, and the prepared stainless steel has higher ferritic stability and lower hardness and yield strength, so that the material is more suitable for stamping, can meet the requirement of cost control in the kitchen ware industry, and is suitable for production and processing of high-end kitchen ware.

Owner:NINGBO BAOXIN STAINLESS STEEL

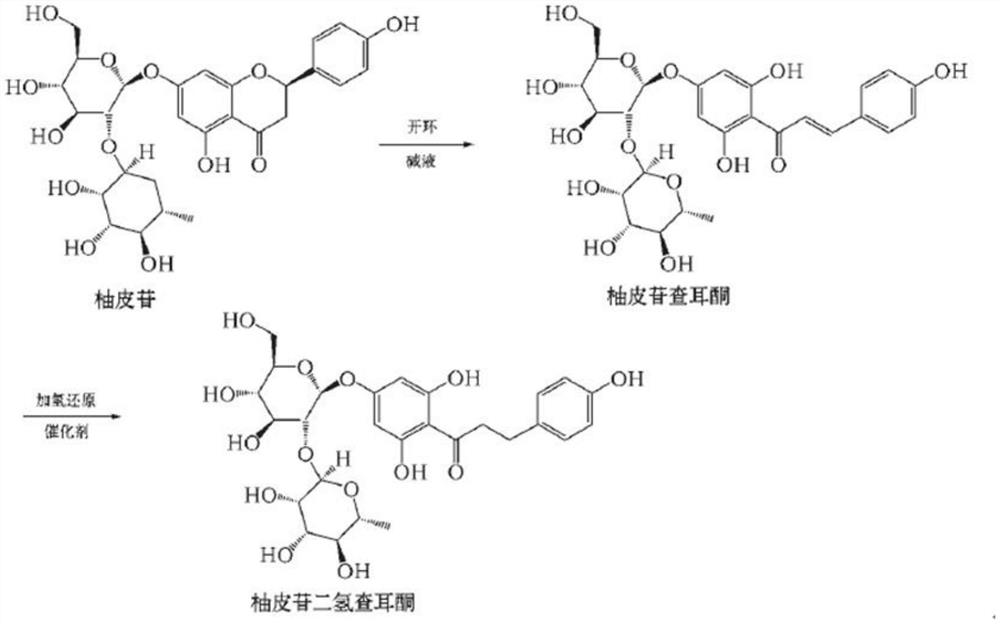

Synthesis method of hesperitin dihydrochalcone

InactiveCN110950747ARich sourcesEasy to getSugar derivativesOrganic compound preparationNeohesperidine dihydrochalconeHydrolysis

The invention provides a synthesis method of hesperitin dihydrochalcone, and gets rid of the dilemma that no literature records about the hesperitin dihydrochalcone synthesis process for reference ofmanufacturers exist at present. A one-pot method is adopted, neohesperidin is taken as an initial raw material, is placed in a sodium hydroxide solution to be subjected to ring opening and catalytic hydrogenation reduction to prepare neohesperidin dihydrochalcone, then an acid is added for neutralization, hydrolysis is performed under the acidic condition, and hesperitin dihydrochalcone is obtained.

Owner:SHAANXI JIAHE PHYTOCHEM

Pawpaw beverage

InactiveCN102132923ASuitable for production and processingSimple processing methodFood preparationCitric acidCarbohydrate

The invention discloses pawpaw beverage and a preparation method thereof. The pawpaw beverage is made from main components and auxiliary components, wherein the main components comprise pawpaw, water, citric acid and cane sugar; and the auxiliary components comprise pectin, xanthan gum, CMC-Na, lemon yellow and carmine. The preparation method comprises the steps: peeling fresh pawpaw, removing seeds, cleaning and crushing; weighing all the materials except the lemon yellow and the carmine according to production formulation and putting the weighed materials into a container; adding enough water and stirring evenly; homogenizing and boiling; and then coloring with the lemon and the carmine; and canning and sterilizing to obtain a finished product finally. The invention has the advantages that 1, the processing method is simple, and the materials are easy to get, therefore the pawpaw beverage is suitable for production and processing of small and medium enterprises; and 2, the pawpaw beverage contains the pawpaw which contains papain, carpaine, chymopapain, carbohydrate, protein, fat, various vitamins and various amino acids necessary for a human body. Therefore, the pawpaw beverage has the functions of reinforcing the stomach and promoting digestion, promoting lactation, effectively supplementing nutrients of a human body and enhancing the disease resisting capability of a human body, as well as insecticidal and antiphthisic functions,.

Owner:广西横县金山食品有限公司

Pellet units, pellet assemblies, building block mold and method for making heat preservation building blocks

InactiveCN105563625AEasy to prepareImprove efficiencyMould auxillary partsCeramic shaping mandrelsExpanded clay aggregateCompressive strength

The invention relates to pellet units, pellet assemblies, a building block mold and a method for making heat preservation building blocks. Each pellet assembly at least comprises two layers of pellet units, and every two adjacent pellet units are in mirror symmetry relative to the section between the two pellet units; each pellet unit is a cubic body and is provided with a concrete placement hole which is through along the vertical distance between two opposite-angle parallel sidelines in the cubic body; the building block mold comprises a pressing plate, a box frame with an opening in the top face and partition plates which are located in the box frame to equally divide the space inside the box frame; and the manufacturing method comprises the steps that the pellet assemblies are put into the equally-divided spaces, ceramsite concrete is poured into the box frame, after the ceramsite concrete solidifies, a ceramsite concrete blank body is taken out, each ceramsite concrete building block assembly with the corresponding pellet assembly is formed by cutting the ceramsite concrete blank body, then the section between two adjacent pellet units in each pellet assembly is cut, and heat preservation building blocks are formed. The manufacturing method is simple, high in efficiency, good in product stability and pressure resisting strength and suitable for production machining of the heat preservation building blocks in large batch.

Owner:仇心金

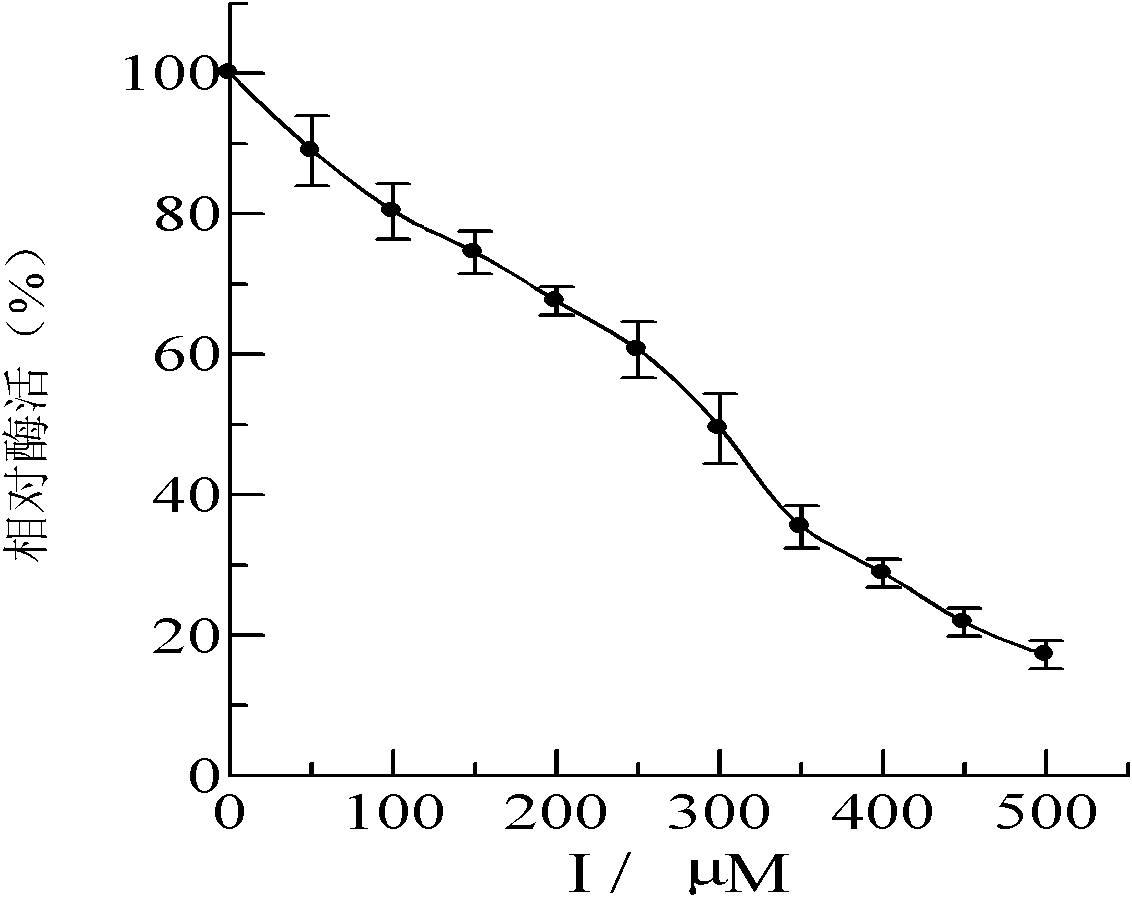

Tyrosinase inhibitor-based fruit and vegetable color fixative and preparation method thereof

ActiveCN101999638ALow priceSimple and efficient operationFood preparationSalicylic acidEnvironmentally friendly

Owner:XIAMEN UNIV

High-strength aluminum-coated plate strip and production method thereof

ActiveCN107881426AImprove plasticityImproved interfacial bonding propertiesUltimate tensile strengthImpurity

The invention discloses a high-strength aluminum-coated plate strip and a production method thereof. The high-strength aluminum-coated plate strip is of a structure composited by an aluminum strip anda steel strip. The steel strip comprises the chemical components of, by weight, 0.03%-0.06% of C, larger than 0% and smaller than or equal to 0.005% of Si, 0.4%-0.8% of Mn, no more than 0.015% of P,no more than 0.005% of S, no more than 0.005% of Al, 0.0062%-0.02% of N, 0.006%-0.05% of O, 0.002%-0.004% of Ca, 0.01%-0.03% of Ti and the balance Fe and inevitable impurities; and meanwhile, the sumof the contents of O and N is larger than or equal to 0.013%, and the relation of 0.5<=(O+N) / (P+S)<=5 is met. The aluminum-coated plate strip has high strength of steel; as for the aluminum-coated plate strip, the yield strength is 280-400 MPa, the tensile strength is 420 MPa or above, and the elongation rate is larger than 28%; and meanwhile the aluminum-coated plate strip has the characteristicsof good properties of plasticity, cold-bending, stamping and the like, corrosion resistance of aluminum, heat dissipation and attractiveness and can be used for production of heat dissipation devices, heat dissipation pieces, wheels and corrosion resistant boxes.

Owner:BAOSHAN IRON & STEEL CO LTD

Slotting and edge pressing device for luggage processing

PendingCN111621935AFacilitates hem sewingReduce labor intensityWork-feeding meansPressersAcute angleEngineering

The invention provides a slotting and edge pressing device for luggage processing, and relates to the technical field of luggage processing. The slotting and edge pressing device comprises a working platform and an edge dividing part located above the working platform; the bottom surface of the edge dividing part is parallel to the surface of the working platform, narrow and long spaces facilitating passing of pressure-dividing hems are reserved between the bottom surfaces of the pressure-dividing hems and the surface of the working platform, the feeding end of the edge dividing part is vertically provided with a tip for separating the two hems, and arc-shaped concave surfaces for guiding the hems to the two sides and separating the hems to be horizontal are arranged on the two sides of the tip; a flattening roller rotating around a horizontal shaft and a first rotary drive used for driving the flattening roller to rotate are further arranged on the two sides of the tip end and on thebottom plane of the edge dividing part; and an acute angle is formed between the axis of the flattening roller and the feeding direction, and when the flattening roller rotates, the flattening rolleris used for guiding the hems and pressing the hems to the two sides of the feeding direction. According to the slotting and edge pressing device, folded edges of the two hems are separated and flattened, subsequent edge pressing sewing is facilitated, manual work is replaced, and the production efficiency is improved.

Owner:湖南普利达箱包有限责任公司

Slimming health product and preparation method thereof

InactiveCN107432463APromote the breakdown of fatHigh activityFood ingredient functionsCarthamusHippophae rhamnoides

The invention discloses a slimming health product, which comprises, by weight part, 1-5 parts of ilex latifolia thumb, 2-8 parts of seabuckthorn fruits, 2-7 parts of ginkgo leaves, 2-5 parts of Chinese wolfberry fruits, 1-5 parts of hawthorn fruits, and 2-6 parts of flos carthami. The invention further discloses a preparation method of the slimming health product. The slimming health product has a slimming health-care effect, and can be administrated by people who suffer from primary hypertension and adiposis for a long time.

Owner:LIAONING YAOLIAN PHARMA

Motor, stator and stacked riveted magnetic slot wedge

The invention discloses a stacked riveted magnetic slot wedge. The slot wedge comprises a number of magnetically conductive sheets which are stacked in the axial direction into a whole body and arranged into the iron core slot of a stator iron core to compress a stator winding therein. Stacked riveting points which are used to form uneven riveting between two adjacent magnetically conductive sheets are arranged on the surfaces of the magnetically conductive sheets. Holes used for reducing tangential magnetic leakage are arranged in the middle of the surfaces of the magnetically conductive sheets. According to the invention, a number of stacked riveting points are arranged on the surfaces of the magnetically conductive sheets; two adjacent magnetically conductive sheets are unevenly overlapped through respective corresponding riveting points, and riveted and fixed; holes are arranged in the middle areas of the surfaces of the magnetically conductive sheets and mainly used to cut the tangential magnetic path; tangential magnetic leakage is effectively reduced; and the load capacity of a motor is improved. The invention further discloses a stator and the motor, which has the beneficial effects.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Preparation method of instant-dissolving soybean oligosaccharide peptide peanut product

The invention relates to a preparation method of an instant-dissolving soybean oligosaccharide peptide peanut product. The peanut product takes peanuts, bean pulp, sesame seed meal and white granulated sugar as raw materials. The preparation method comprises steps of eye selecting, curing, peanut skin removing, liquid soybean oligosaccharide peptide preparation, sugar melting, filtering, coarse grinding, primary refining, secondary refining, drying, checking, packaging and the like. By means of the preparation method, the obtained peanut product has good quality and fragrance, nutritive value and a health-care function. In addition, the preparation method is simple in process, fully takes the peanuts as the raw materials, and utilizes semi-finished liquid of soybean oligosaccharide peptide water to replace water to perform burdening and dense pulp mixing. Therefore, by means of the preparation method, the instant-dissolving soybean oligosaccharide peptide peanut product can be produced in a cost-optimal mode.

Owner:佳木斯冬梅大豆食品有限公司

Full-automatic production process research for double face character spray printing on flexible printed circuit boards

InactiveCN109605947AImprove work efficiencySuitable for production and processingTypewritersOther printing apparatusScreen printingEngineering

The invention discloses full-automatic production process research for double face character spray printing on flexible printed circuit boards. The technological process comprises horizontal board throwing, double face character spray printing, strengthened baking and board collecting; during horizontal board throwing, through a three-joint double-face suction cup type carrying hand board throwingmachine, the boards are horizontally held and are positioned and placed on the work table face of a character spray printer a; during double face character spray printing, the a work table face of the character spray printer performs pre-curing operation of character spray printing; and when manufacturing of a face A of the first piece of board ends, the device table face returns to the positionbefore operation, meanwhile, the board is sucked and held and fixed by an up-down rising and falling suction cup on the device side edge, and rising is performed to a set height for next operation. Through a hard board automatic screen printing ligature technological process, a printing manner changes, screen printing is changed into spray printing and UV baking so that an automatic ligature function can be achieved, the technological process is scientific and reasonable, using is safe and convenient, the work efficiency is improved when the flexible printed circuit boards are produced, and the full-automatic production process research for double face character spray printing on the flexible printed circuit boards is more applicable to producing and machining of the flexible printed circuit boards.

Owner:BRAIN POWER (QING YUAN) CO LTD

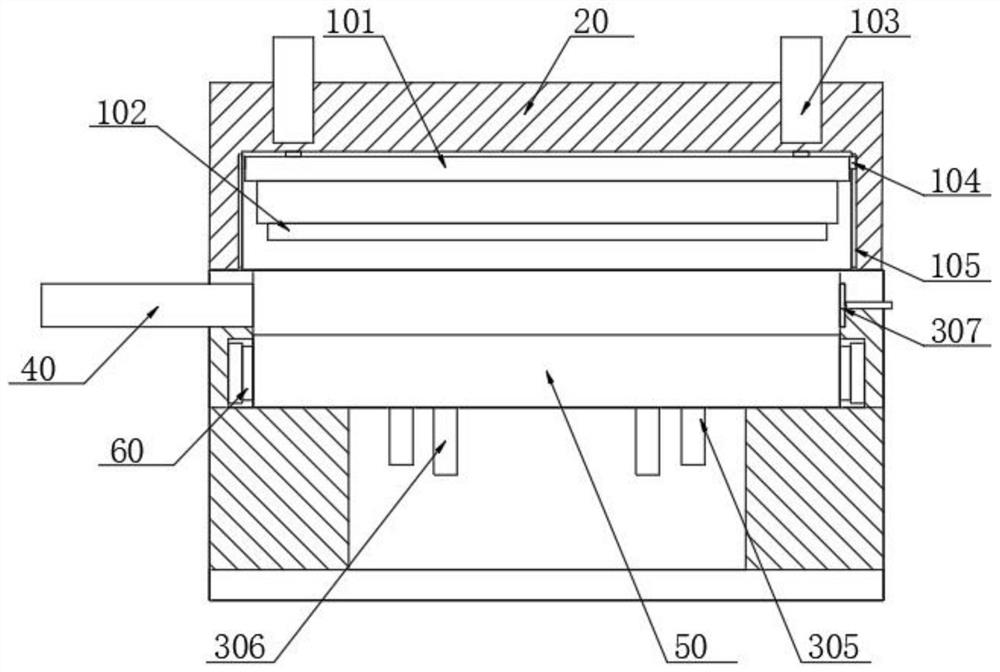

Baking tray four-corner integrated forming device

PendingCN110695198AImprove work efficiencySimple structureShaping toolsMetal-working feeding devicesMechanical engineeringIndustrial engineering

The invention belongs to the technical field of baking tray forming equipment and relates to a forming device, in particular to a baking tray four-corner integrated forming device. The device comprises an upper die assembly and a lower die assembly which are correspondingly arranged up and down. The upper die assembly comprises an upper die plate, a material pressing fixing plate, a material pressing plate, a spring, a roller wheel shaft and a forming pressing roller, wherein the pressing fixing plate is fixedly connected to the lower end of the upper die plate, the upper part of the materialpressing plate is slidably connected into an inner cavity of the material pressing fixing plate, and the lower part of the material pressing plate stretches out of an inner cavity of the material pressing fixing plate; a pressing roller assembly is arranged at the lower end of the upper die plate; and the lower die assembly comprises a lower die plate and a forming block, the forming block is fixed to the lower die plate, and a forming corner of a fillet structure is formed on the formed block. The device is simple, compact and reasonable in structure, the working efficiency of four-corner forming of a baking tray is improved, and the device is suitable for production and processing of large-batch products; the product quality is greatly improved; the production cost is reduced; and the device can be suitable for forming of baking trays of different product specifications.

Owner:SAN NENG BAKE WARE WUXI

Production method of medical fine-grain titanium/titanium alloy bar

The invention discloses a production method of a medical fine-grain titanium / titanium alloy bar. The production method comprises the following steps of: performing combined multidirectional upsetting and stretching deformation on a forging blank above and below a phase transformation point T(beta); and after the last upsetting and stretching deformation, directly stretching the upset blank into a finished product of bar. The production method disclosed by the invention is simple and convenient, the technology is standard, little cracking occurs in a production process, large-specification ingot and large forging equipment are not required, and the cost is low. The production method disclosed by the invention has no limit to the alloy type, the ingot specification and the processing means, and is suitable for the production and processing of a small number of medical titanium / titanium alloy bars of multiple varieties and multiple specifications. According to the medical fine-grain titanium / titanium alloy bar disclosed by the invention, the microscopic structure and mechanical property of the product are stable, and the two ends are consistent with the middle part in performance.

Owner:西安赛特新材料科技股份有限公司

Multifunctional textile machine

InactiveCN108149368AAvoid damageImprove responsivenessLoomsContinuous wound-up machinesEngineeringBrake pad

The invention discloses a multifunctional textile machine, comprising a support; a pressure-bearing platform is fixedly connected to the lower end of the support; an electrohydraulic bar is fixedly mounted at the inner top end of a limiting channel, a photoelectric protector is fixedly mounted at the upper end of a pillar, an electric telescopic bar is fixedly mounted on the rear surface of a limiting plate, a brake ring is fixedly connected to the rear end of the electric telescopic bar, and a brake pad is fixedly mounted on the rear surface of the brake ring. The photoelectric protector canprotect limbs of an operator from being injured by rotation of a driving device when the textile machine operates; the electric telescopic bar, the brake ring and the brake pad can provide braking fora roller when the photoelectric protector stops and a motor rotates, so that responding capacity of the roller is enhanced; the multifunctional textile machine has scientific and reasonable structureand good application safety and convenience, has improved practicality and may better adapt to the production and processing in textile workshops.

Owner:响水县嘉亿纺织有限公司

Synthesis method of hesperetin dihydrochalcone

InactiveCN110551011ARich sourcesEasy to getSugar derivativesOrganic compound preparationSynthesis methodsPotassium hydroxide

The invention provides a synthesis method of hesperetin dihydrochalcone. The synthesis method gets rid of the dilemma that no document records a hesperetin dihydrochalcone synthesis related process which can be used for reference by manufacturers. A one-pot method is adopted, hesperidin is taken as a starting raw material to be placed into a sodium hydroxide solution or a potassium hydroxide solution for catalytic hydrogenation to prepare hesperidin dihydrochalcone, then acid is added for neutralization, and hydrolysis is conducted under the acid condition to obtain the hesperetin dihydrochalcone.

Owner:SHAANXI JIAHE PHYTOCHEM

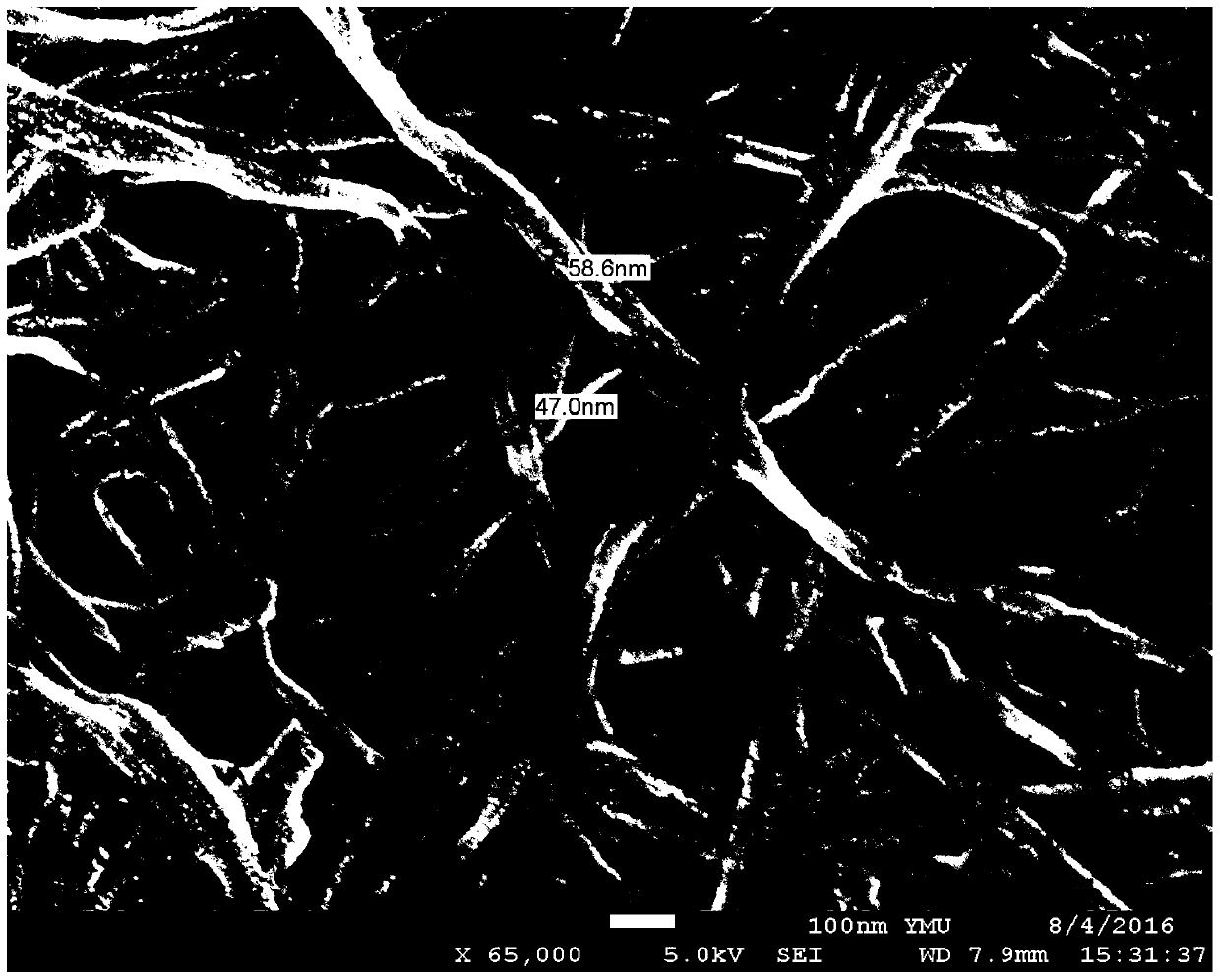

A kind of medical coconut fruit additive-free membrane and its production process

ActiveCN106924802BLess destructiveIncrease productivityPharmaceutical delivery mechanismAbsorbent padsAntiseptic sterilizationEngineering

The invention relates to the field of medical dressings and in particular relates to a medical coconut fruit additive-free membrane and a production process thereof. A raw material coconut fruit membrane is treated with strong alkali NaOH by sections and weak acid, namely citric acid, is used for neutralizing; an obtained semi-finished coconut fruit membrane is washed through ultrasonic oscillation and sterilized through ozone water; the membrane is packaged in a reasonable manner and is subjected to sterilization and disinfection treatment in high-temperature and high-pressure, and irradiation manners, so as to obtain a wound covering membrane which has a clean appearance, wherein a microcosmic reticular fiber structure and a membrane overall appearance texture of the wound covering membrane meet medical-grade requirements; the microcosmic reticular fiber structure forms small pores and can effectively prevent external bacteria from invasion; in a utilization process, medical liquid can be effectively locked and water and the medical liquid are prevented from being lost so that acting time of effective components on skins is prolonged; a drug administration effect is gentle and the irritation on wounds can be effectively reduced; the membrane has a certain absorption effect on tissue liquid of the wounds and has an excellent skin-friendly property; the production process is further simplified, is easy to operate and is suitable for large-batch rapid production.

Owner:海南奈雅生物技术有限公司

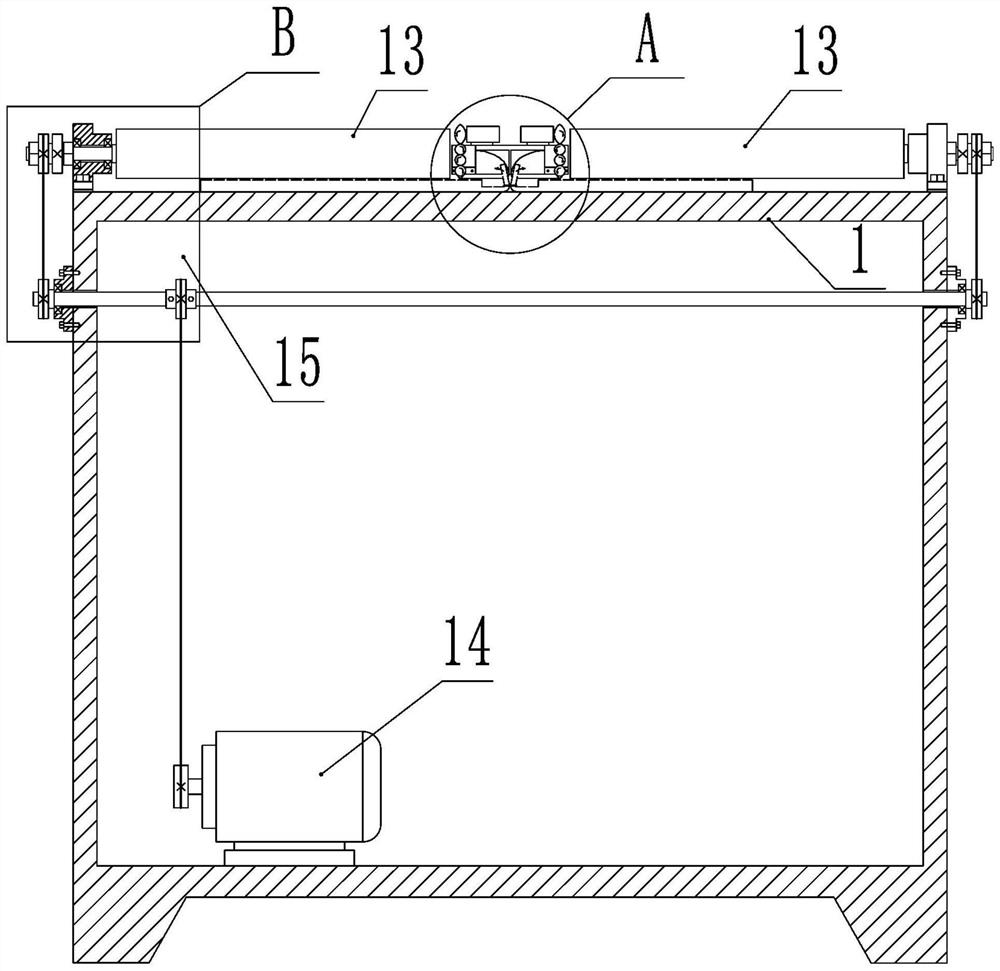

Double-sided liquid feeding device

ActiveCN112252079ASuitable for production and processingIncrease productivityPaper recyclingPaper/cardboardProcess engineeringMechanical equipment

The invention relates to a double-sided liquid feeding device, and belongs to the technical field of papermaking mechanical equipment. The paper feeding device is characterized by comprising a rack, and a paper inlet and a paper outlet are formed in the rack; a paper feeding guide roller, an A surface liquid feeding device, a B surface liquid feeding device and a tussah device are arranged in therack, paper enters the rack through a paper inlet, and sizing operation is conducted on the two faces of the paper through the A surface liquid feeding device and the B surface liquid feeding device under guide conveying of the paper feeding guide roller; and the sized paper penetrates out of the rack from the paper outlet after being subjected to dewatering and calendaring treatment by the tussahdevice. The double-sided sizing operation of paper can be efficiently achieved, the production efficiency is high, the equipment design is simple and reasonable, the sizing action is flexible and adjustable, and the device is suitable for production and processing of high-quality paper products.

Owner:山东北方造纸机械有限公司

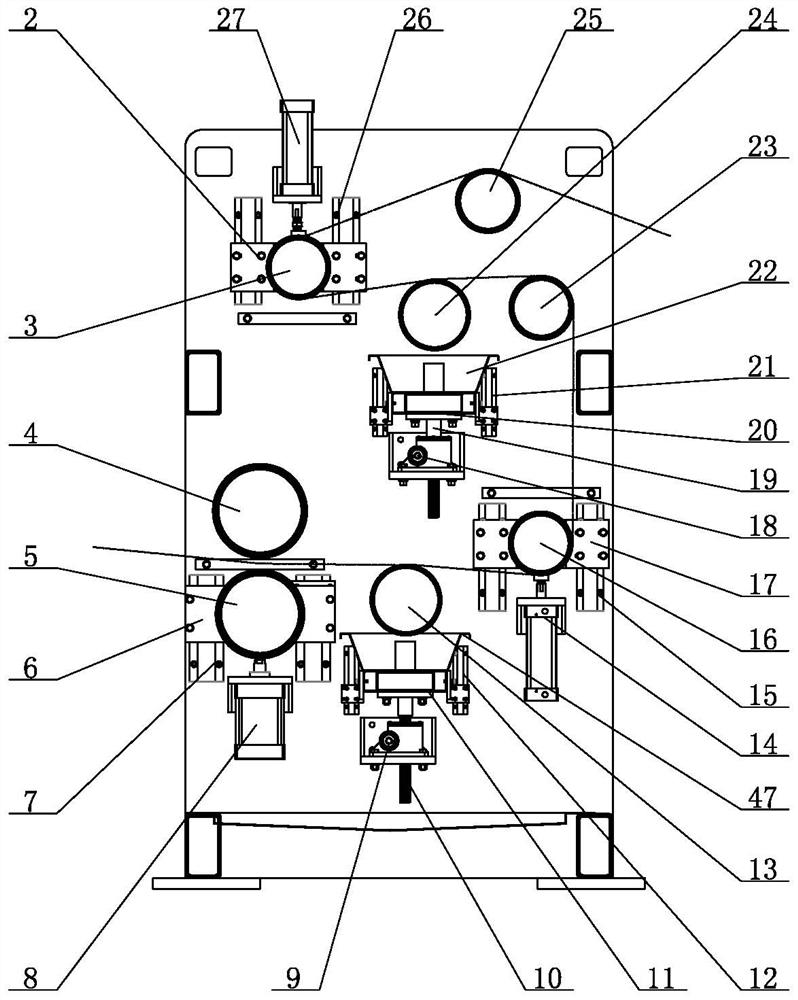

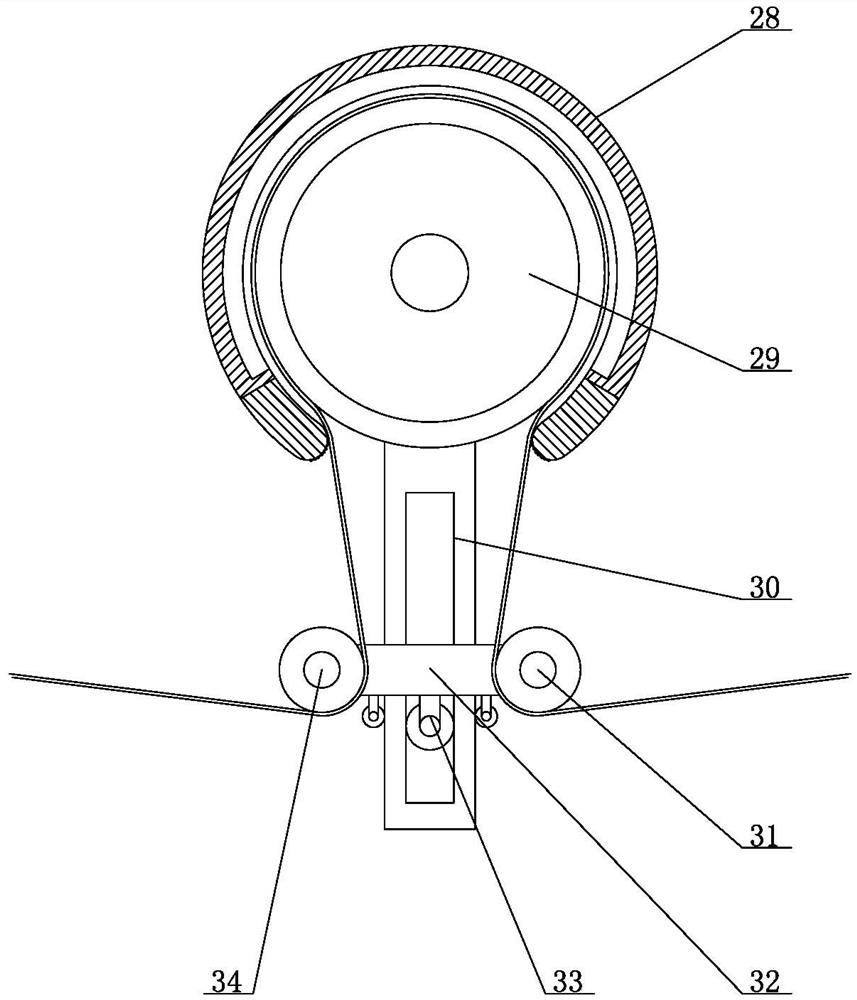

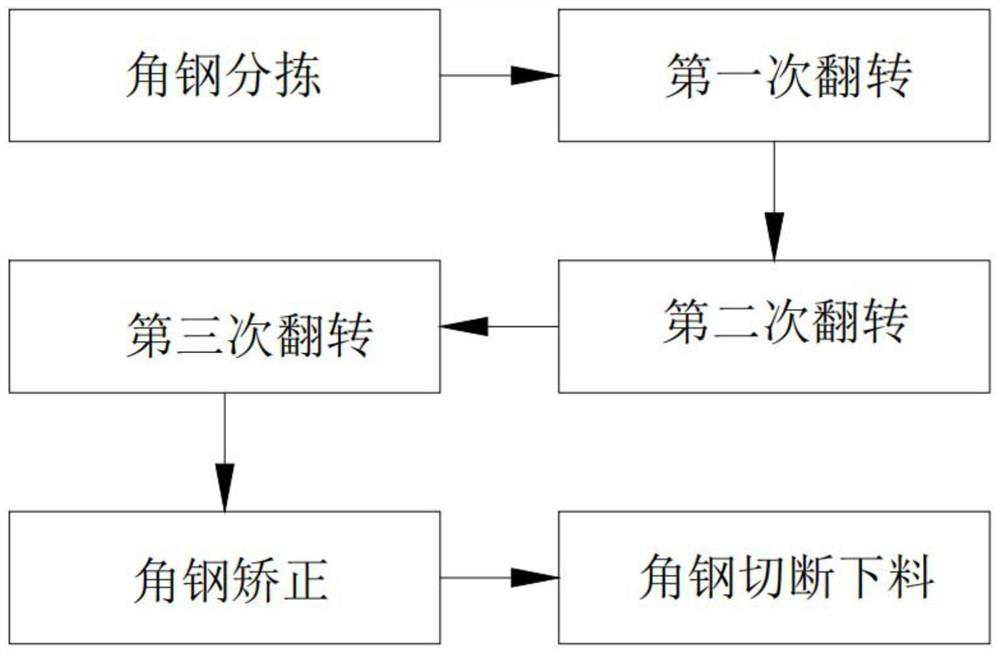

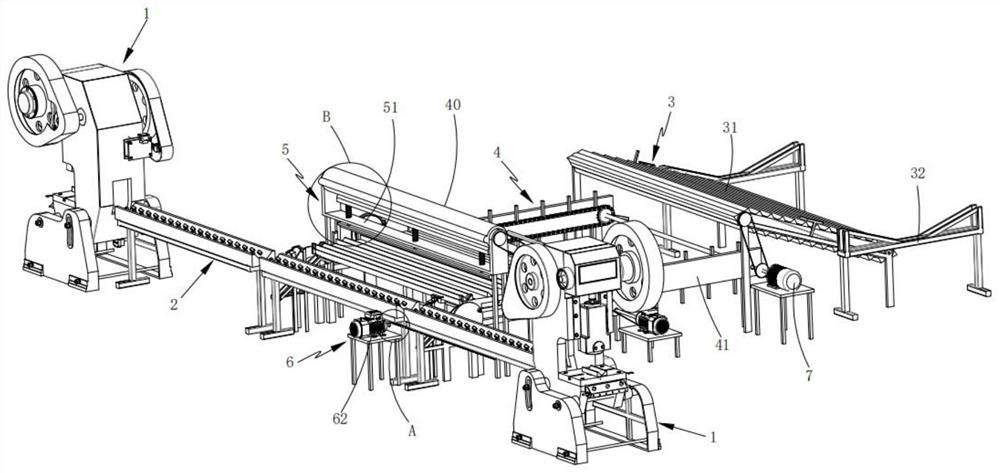

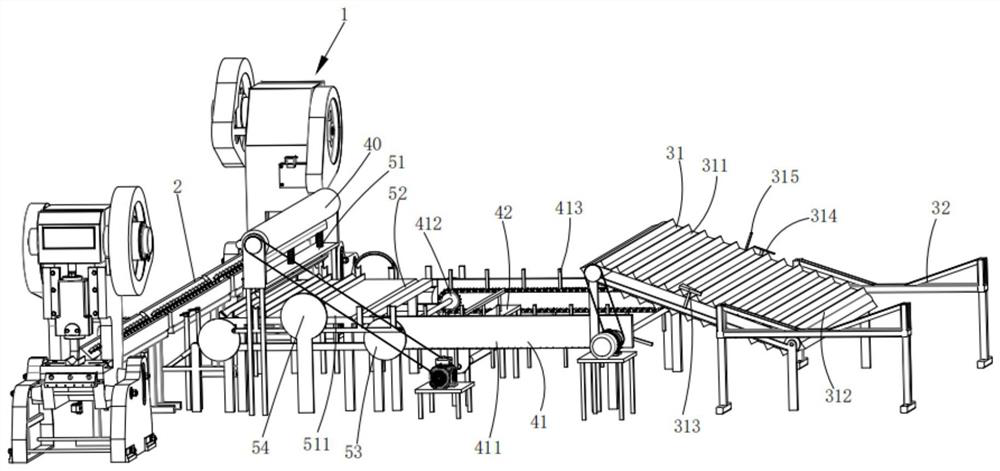

A profile continuous processing production process

ActiveCN112872719BImprove feeding efficiencyGuaranteed accuracyMetal working apparatusStructural engineeringMechanical engineering

The invention relates to a production process for continuous processing of profiles, comprising the following steps: sorting the angle steels, moving the right-angle blocks to send the angle steels one by one to the conveying assembly; turning over for the first time, the conveying assembly drives the angle steels to move one by one to the top of the jacking assembly, and lifting The component only flips the inverted V-shaped angle steel into an L-shaped; the second flip, the moving component drives the angle steel to move forward, and the L-shaped and reverse-L-shaped angle steels are all turned into an L-shape after passing through the turning chute; the third flip, moving The L-shaped plate in the assembly receives the angle steel and conveys it to the base. The L-shaped plate makes the angle steel sent to the base form a V-shaped arrangement; the angle steel is corrected, and the moving rod transfers the angle steel to the right below the die unit, and then the die unit The angle steel is corrected; the angle steel is cut and blanked, and the angle steel is matched with the cleaning assembly. The cleaning assembly rotates and the angle steel is turned over to the feeding rack, and the distribution assembly pushes the angle steel to the shearing equipment for cutting and blanking; the invention can realize the angle steel continuous production and processing.

Owner:西安恒为测量技术有限公司

A kind of synthetic method of naringin dihydrochalcone

The invention provides a method for synthesizing naringin dihydrochalcone, which is safer, simpler and non-toxic. The present invention uses naringin as a starting material, puts it in lye for ring-opening catalytic hydrogenation, and purifies it to prepare the refined naringin dihydrochalcone.

Owner:SHAANXI JIAHE PHYTOCHEM

A high-strength aluminum-clad strip and its production method

ActiveCN107881426BImprove plasticityImproved interfacial bonding propertiesChemical compositionHigh intensity

The invention discloses a high-strength aluminum-coated plate strip and a production method thereof. The high-strength aluminum-coated plate strip is of a structure composited by an aluminum strip anda steel strip. The steel strip comprises the chemical components of, by weight, 0.03%-0.06% of C, larger than 0% and smaller than or equal to 0.005% of Si, 0.4%-0.8% of Mn, no more than 0.015% of P,no more than 0.005% of S, no more than 0.005% of Al, 0.0062%-0.02% of N, 0.006%-0.05% of O, 0.002%-0.004% of Ca, 0.01%-0.03% of Ti and the balance Fe and inevitable impurities; and meanwhile, the sumof the contents of O and N is larger than or equal to 0.013%, and the relation of 0.5<=(O+N) / (P+S)<=5 is met. The aluminum-coated plate strip has high strength of steel; as for the aluminum-coated plate strip, the yield strength is 280-400 MPa, the tensile strength is 420 MPa or above, and the elongation rate is larger than 28%; and meanwhile the aluminum-coated plate strip has the characteristicsof good properties of plasticity, cold-bending, stamping and the like, corrosion resistance of aluminum, heat dissipation and attractiveness and can be used for production of heat dissipation devices, heat dissipation pieces, wheels and corrosion resistant boxes.

Owner:BAOSHAN IRON & STEEL CO LTD

Serger pay-off mechanism used for automobile seat cushion production

InactiveCN108821024ARising costsScientific and reasonable structureFilament handlingAutomobile seat cushionEngineering

The invention discloses a serger pay-off mechanism used for automobile seat cushion production. The serger pay-off mechanism comprises a mounting fixation seat. A first groove is fixedly formed in theupper surface of the mounting fixation seat, a second groove is fixedly formed in the side, close to the first groove, of the upper surface of the mounting fixation seat, and a third groove is fixedly formed in the side, close to the second groove, of the upper surface of the mounting fixation seat. According to the serger pay-off mechanism, through a thread combing assembly, the problem that sewing thread on various bobbins is mutually intertwined in the pay-off process of the serger pay-off mechanism is fundamentally solved; when the sewing thread on the bobbins is used thoroughly, a limitplate can be taken off the mounting fixation seat through a limit assembly, and accordingly, the bobbins and sewing thread can be replaced with new bobbins and sewing thread conveniently; and throughheight adjusting assemblies, the distance between the thread combing assembly and the bobbins can be adjusted, accordingly, the pulling angle of the sewing thread can be adjusted, and the sewing thread is not abraded in the pay-off process.

Owner:李天意

Copper sleeve structure for precision self-lubricating bearings

ActiveCN111059150BSuitable for production and processingReduce the difficulty of composite processingBearing componentsEngineeringMechanical engineering

A copper sleeve structure for a precision self-lubricating bearing comprises an outer iron-based cylinder body, two ends of the inner wall of the outer iron-based cylinder body are respectively provided with an expanded hole, an inner copper-based middle cylinder and two inner copper-based end cylinders are included, the inner copper-based middle cylinder is inserted into the outer iron-based cylinder body, two ends of the inner copper-based middle cylinder are respectively flush with the hole bottoms of the expanded holes, one inner copper-based end cylinder is inserted into one expanded hole, the other inner copper-based end cylinder is inserted into the other expanded hole, a plurality of first arc-shaped notches circumferentially distributed are formed in two ends of the inner copper-based middle cylinder, the first arc-shaped notches arranged at one end of the inner copper-based middle cylinder are distributed in a staggered manner with the first arc-shaped notches arranged at theother end of the inner copper-based middle cylinder, the inner end of each inner copper-based end cylinder is respectively provided with second arc-shaped notches corresponding to the corresponding first arc-shaped notches one by one, a plurality of arc-shaped locking blocks with L-shaped transverse sections are further included, one end of each arc-shaped locking block is clamped in the corresponding first arc-shaped notch, and the other end of each arc-shaped locking block is clamped in the corresponding second arc-shaped notch.

Owner:嘉兴政欣信息技术有限公司

Polyester chip for producing automotive interior fiber and preparation method thereof

The invention discloses a polyester chip for producing automobile interior decoration fibers and a preparation method thereof. Firstly, the polyester chip that meets the technical requirements is synthesized: using a two-pot process semi-continuous polymerization reaction device, by introducing isocyanate in the esterification reaction Construct and replace carboxylic acid to reduce the melting point of the product to the target range, and then add reactive catalyst, stabilizer, auxiliary materials, etc. in the polycondensation reaction to control the reaction temperature and vacuum degree, and the final synthetic intrinsic viscosity is 0.730‑0.740dl / g The target polyester chip base material; the synthesized product is passed through the solid phase drum device water steam crystallization process to complete the pre-crystallization of the polyester chip; the pre-crystallized polyester chip is obtained by temperature control without cooling down. The continuous negative pressure processing technology completes the drying of polyester chips. After drying, the water content of polyester chips is not higher than 0.05%, and the intrinsic viscosity is not lower than 0.715dl / g. Through the above three steps, the special polyester chips for automotive interior fibers that meet the requirements of industrial production can be prepared.

Owner:TIANJIN HUAXIN YINGJU POLYESTER MATERIAL SCI & TECH

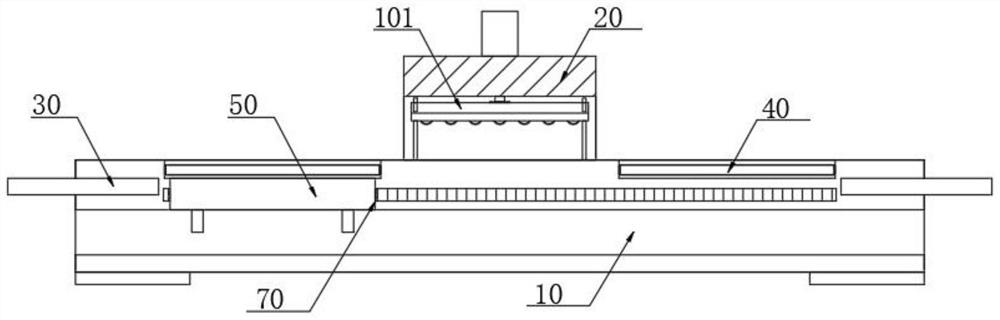

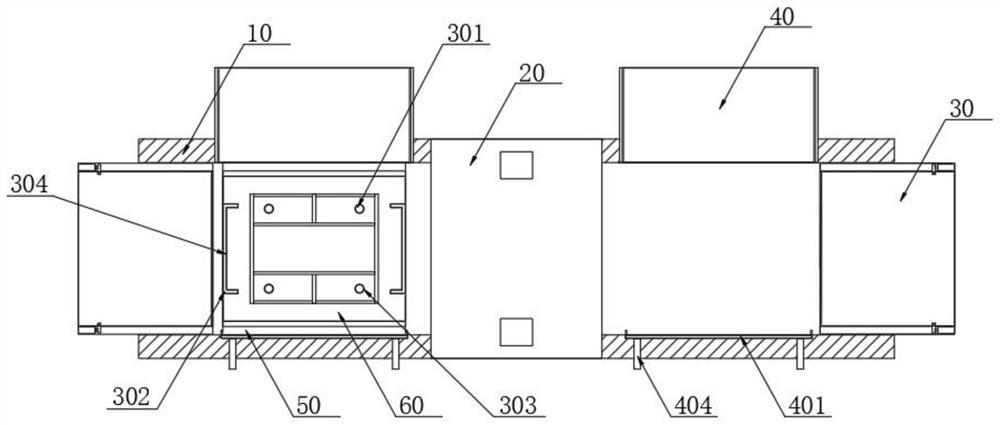

Indentation die cutting equipment for food paper packaging box

InactiveCN114407428AImprove production and processing efficiencyReduce consumptionPaper-makingBox making operationsPaperboardMachining process

The invention relates to the technical field of packaging box production, in particular to food paper packaging box indentation die-cutting equipment which comprises a rack, a die-cutting frame, a feeding frame and a discharging frame. A paper board and a die-cutting base plate are conveyed to the position above a die-cutting plate, die-cutting treatment is completed through a die-cutting assembly, at the moment, the die-cutting plate moves to the right side, and the die-cutting plate moves to the left side; the die-cutting waste, the die-cutting base plate and the die-cutting piece are sequentially conveyed to the discharging frame, manual auxiliary operation is not needed in the machining process, automatic indentation die-cutting machining treatment of a packaging box is achieved, after machining of a packaging box paperboard is completed, the feeding frame located on the right side continues to convey the paperboard and the die-cutting base plate to the die-cutting plate, and the die-cutting waste is discharged through the discharging frame. According to the continuous indentation die-cutting machine, continuous indentation die-cutting machining of one packaging box paperboard is completed again, continuous indentation die-cutting machining of the packaging box paperboard is achieved, the production and machining efficiency of packaging boxes is greatly improved, meanwhile, consumption of human resource cost is effectively reduced, and the continuous indentation die-cutting machine is suitable for production and machining of large-batch products.

Owner:连云港民奥环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com