A kind of medical coconut fruit additive-free membrane and its production process

A production process and technology of coconut fruit film, which is applied in pharmaceutical formulations, pharmaceutical sciences, absorbent pads, etc., can solve problems such as complex and tedious processes, and achieve the effects of avoiding excessive damage, improving production efficiency, and saving key control points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] D1: Select the raw coconut film with a thickness of 0.3-0.5cm, add 1.8-2.2% NaOH solution of 1-1.2 times the volume, adjust the pH to 13-13.5 and heat it to 75°C, and keep the heat system for 20 -30min;

[0030] D2: Use deionized water to adjust the pH of the coheating system to 11-11.5, and at the same time heat the coheating system to boil and keep it for 1-1.5h;

[0031] D3: Use citric acid solution to adjust the pH of the co-heating system to 7.2-7.5, and at the same time lower the temperature of the co-heating system to 70-75°C and keep it for 20-30min to obtain semi-finished coconut membranes;

[0032] D4: Transfer semi-finished coconut membranes to deionized water for ultrasonic vibration cleaning, and use deionized water to circulate and filter out impurities;

[0033] D5: Pass ozone water into the cleaned coconut membrane to sterilize, and keep the ozone content in the water at 20-50ppm;

[0034] D6: After arranging the coconut membranes and pressing water to...

PUM

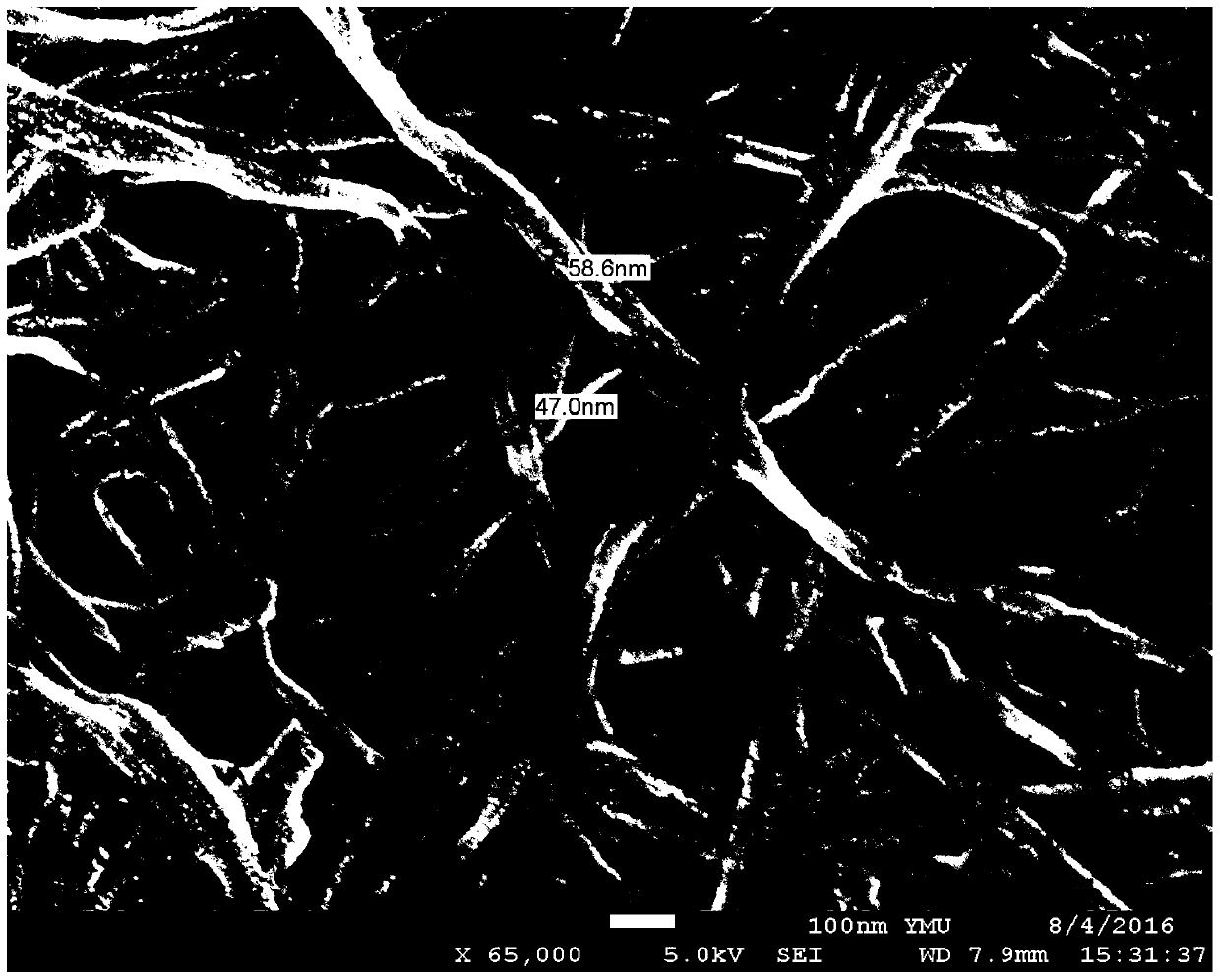

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com