High power density laser sputtering ionization time-of-flight mass spectrometer and use thereof

A technology of time-of-flight mass spectrometry and high power density, applied in the field of mass spectrometers, can solve the problems that mass spectrometers cannot meet the adaptability requirements, reduce the resolving power of the instrument, and cannot effectively separate ions, etc. Less destructive, character-changing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

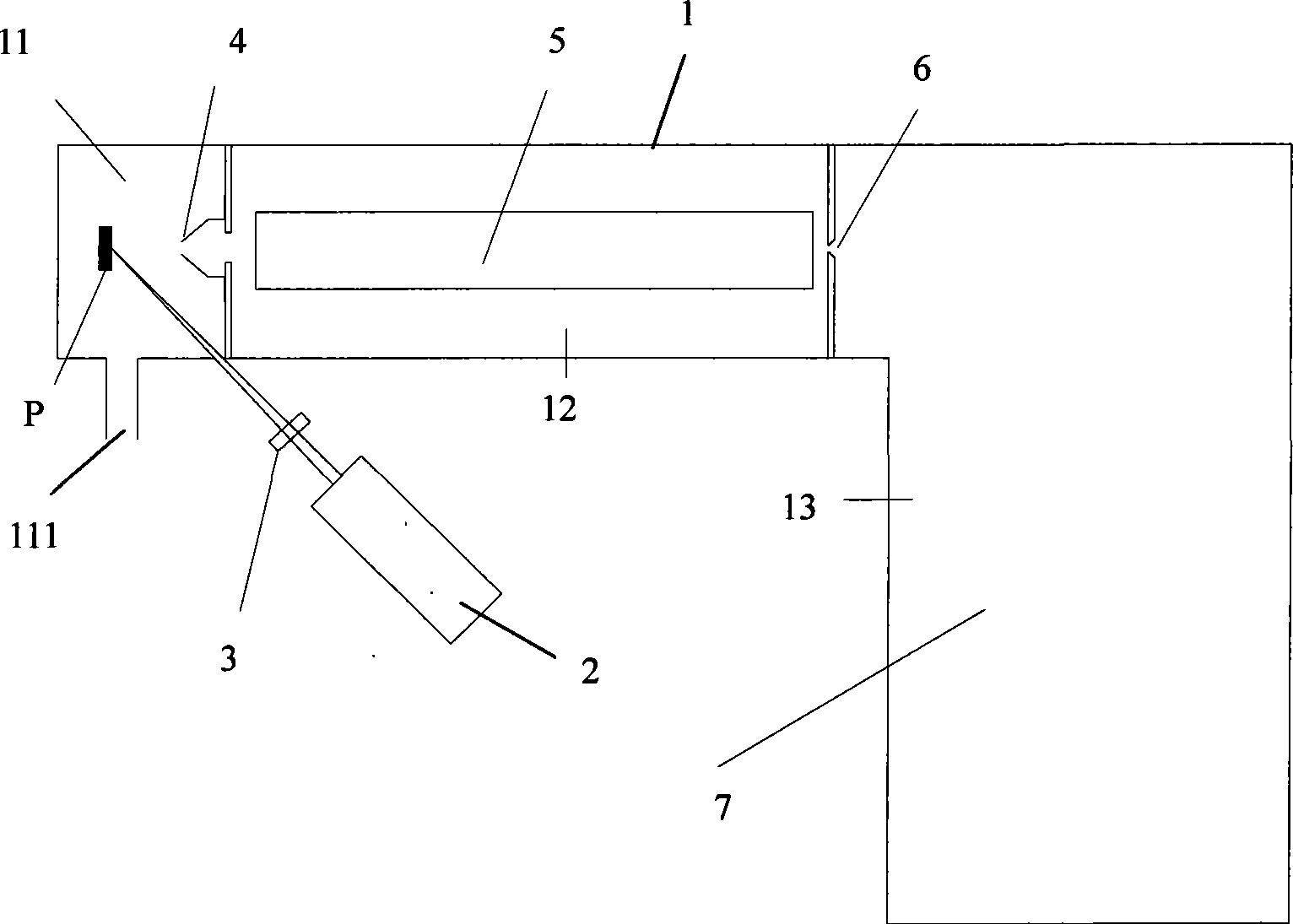

[0019] Such as figure 1 As shown, the present invention is provided with a vacuum cavity 1 , a laser 2 , a laser focusing lens 3 , a sampling cone 4 , an ion lens 5 (ie, an ion transmission device), a skimmer cone 6 and a time-of-flight mass analyzer 7 . The laser 2 and the laser focusing lens 3 are arranged outside the vacuum chamber 1 , and the sample P, the sampling cone 4 , the ion lens 5 , the skimmer cone 6 and the time-of-flight mass analyzer 7 are arranged in the vacuum chamber 1 in sequence.

[0020] The vacuum cavity 1 is provided with a three-stage vacuum chamber, the first-stage vacuum chamber 11 is before the sampling cone 4, the second-stage vacuum chamber 12 is between the sampling cone 4 and the skimmer cone 6, and the third-stage vacuum chamber 13 is behind the skimmer cone 6. The super-vacuum chamber 11 is provided with an auxiliary gas inlet 111 through which inert gases such as helium and argon are filled. The vacuum degree of the primary vacuum chamber 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com