Preparation technology for producing collagen through enzymolysis of fish scales

A preparation process and collagen technology, applied in the field of collagen extraction, can solve the problems of difficulty in obtaining high content of low-molecular-weight collagen peptides, difficulty in obtaining low-molecular-weight collagen, and difficulty in removing pigment substances, etc. Absorption, strong activity, small molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

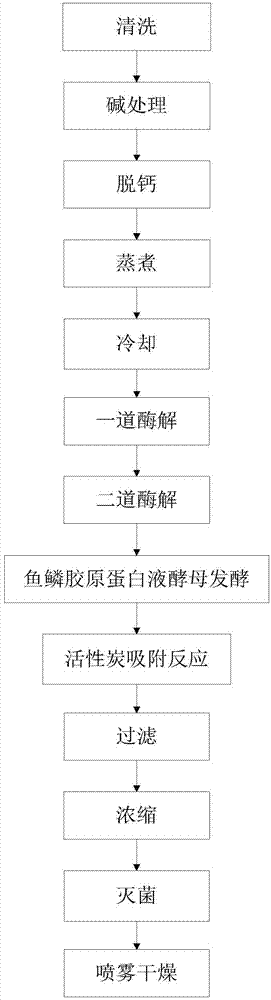

Method used

Image

Examples

preparation example Construction

[0053] A preparation process for enzymatic hydrolysis of fish scales to produce collagen, said method comprising the following steps:

[0054] (1) cleaning

[0055] Clean fish scales, remove sundries, and drain water;

[0056] (2) Alkali treatment

[0057] Pour fish scales into the enzymolysis tank, and add NaOH solution with a mass concentration percentage of 0.2%-0.5%, the mass volume concentration of fish scales and NaOH solution is 800-1500kg / m 3 ,

[0058] Add pure water to adjust the mass volume concentration of fish scales and NaOH solution to 300-440kg / m 3 , and adjust the temperature in the enzymolysis tank to 17-19°C, let it soak for 12-15 hours, filter out the NaOH solution, and wash the fish scales with pure water until neutral;

[0059] (3) Decalcification

[0060] Add an appropriate amount of acid solution into the enzymolysis tank, adjust the temperature in the enzymolysis tank to 17-19°C, soak the fish scales with the acid solution for 2-4 hours, filter ou...

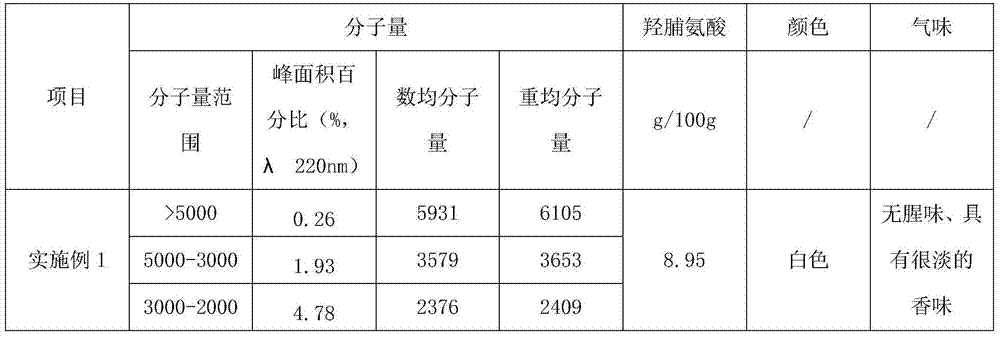

Embodiment 1

[0087] Embodiment 1 (best embodiment)

[0088] A preparation process for enzymatic hydrolysis of fish scales to produce collagen, said method comprising the following steps:

[0089] (1) cleaning

[0090] Clean fish scales, remove sundries, and drain water;

[0091] (2) Alkali treatment

[0092] Pour fish scales into the enzymolysis tank, and add NaOH solution with a mass concentration percentage of 0.3%, the mass volume concentration of fish scales and NaOH solution is 1200kg / m 3 ,

[0093] Add pure water to make the mass volume concentration of fish scales and NaOH solution 370kg / m 3 , and adjust the temperature in the enzymolysis tank to 18°C, let it soak for 14 hours, filter out the NaOH solution, and wash the fish scales with pure water until neutral;

[0094] (3) Decalcification

[0095] Add disodium EDTA and citric acid into pure water at a mass ratio of 6.8:78 to prepare a citric acid solution with a mass concentration of 16.8%, and pour it into an enzymatic hydr...

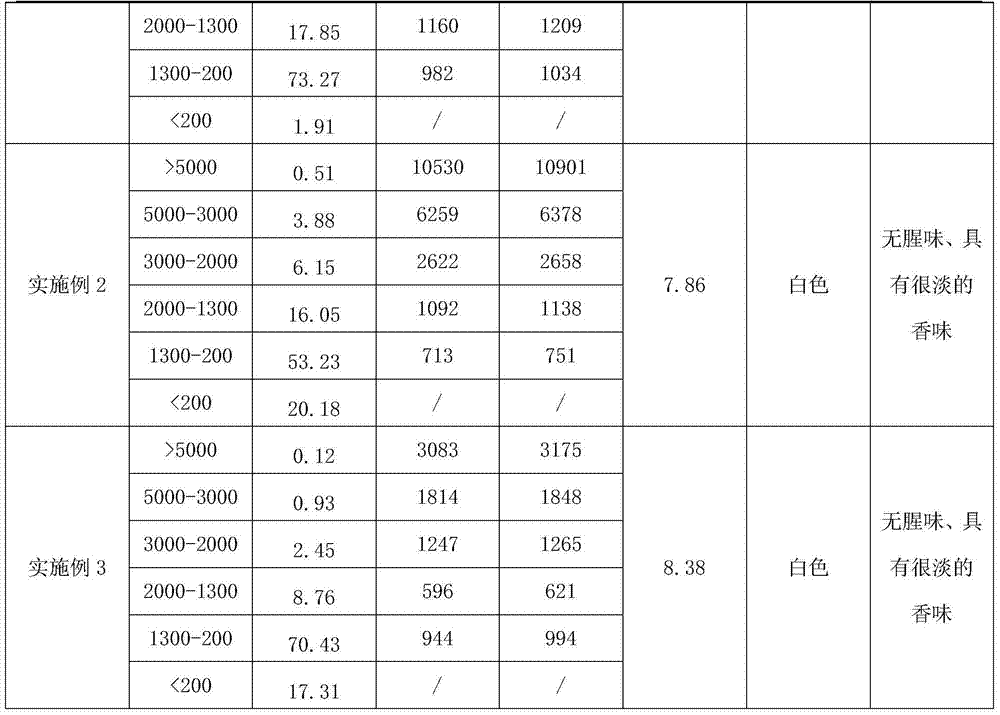

Embodiment 2

[0117] A preparation process for enzymatic hydrolysis of fish scales to produce collagen, said method comprising the following steps:

[0118] (1) cleaning

[0119] Clean fish scales, remove sundries, and drain water;

[0120] (2) Alkali treatment

[0121] Pour fish scales into the enzymolysis tank, and add NaOH solution with a mass concentration percentage of 0.2%, the mass volume concentration of fish scales and NaOH solution is 800kg / m 3 ,

[0122] Add pure water so that the mass volume concentration of fish scales and NaOH solution is 300kg / m 3 , and adjust the temperature in the enzymolysis tank to 17°C, let it soak for 12 hours, filter out the NaOH solution, and wash the fish scales with pure water until neutral;

[0123] (3) Decalcification

[0124] Add disodium EDTA and citric acid to pure water at a mass ratio of 1:17 to prepare a citric acid solution with a mass concentration of 15%, and pour it into an enzymatic hydrolysis tank. The mass volume concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com