A profile continuous processing production process

A production process and profile technology, which is applied in the field of continuous profile processing and production technology, can solve problems such as inability to automate processing of angle steel, and achieve the effects of improving feeding efficiency, ensuring accuracy and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

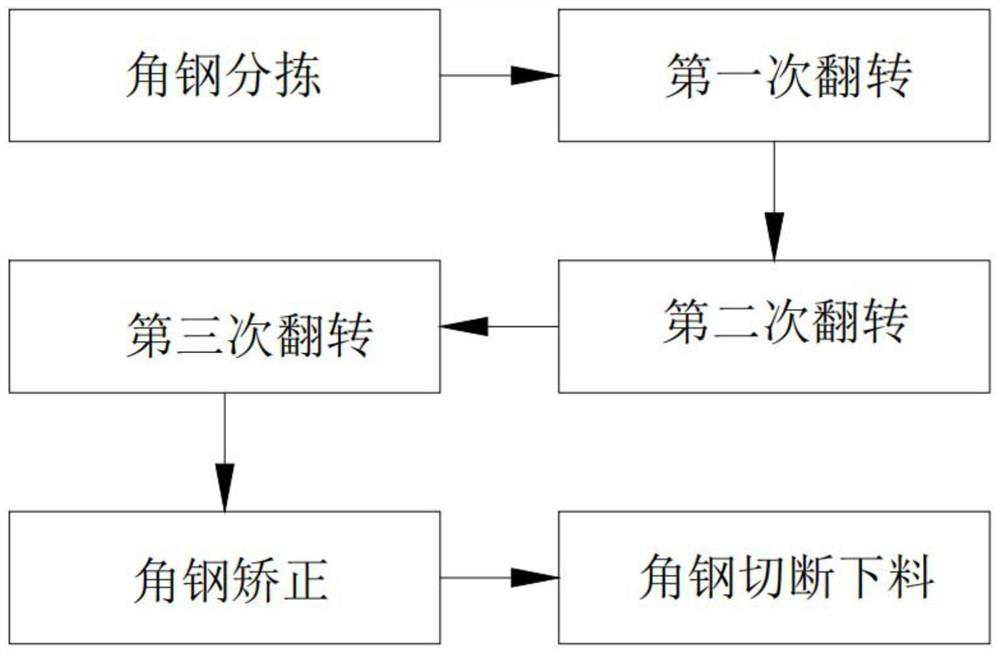

[0050] Such as figure 1 As shown, a profile continuous processing production process includes the following steps:

[0051] Step 1: Sorting the angle steel, when the conveyor belt assembly 311 rotates and passes through the storage rack 32, the right-angle block 312 sends the angle steel 10 to the conveying assembly 41 one by one, and the angle steel 10 falling on the conveying assembly 41 is L-shaped, inverted L Shaped and inverted V-shaped three states;

[0052] Step 2: Turn over for the first time. After step 1, the conveying component 41 drives the angle steel 10 to move one by one to the top of the jacking component 42, and the jacking component 42 only turns the inverted V-shaped angle steel 10 into L shape;

[0053] Step 3: Turn over for the second time. After step 2, the conveying component 41 sends the angle steels 10 one by one to cooperate with the moving component 53, and the moving component 53 drives the angle steels 10 to move forward, L-shaped and reverse-L-s...

Embodiment 2

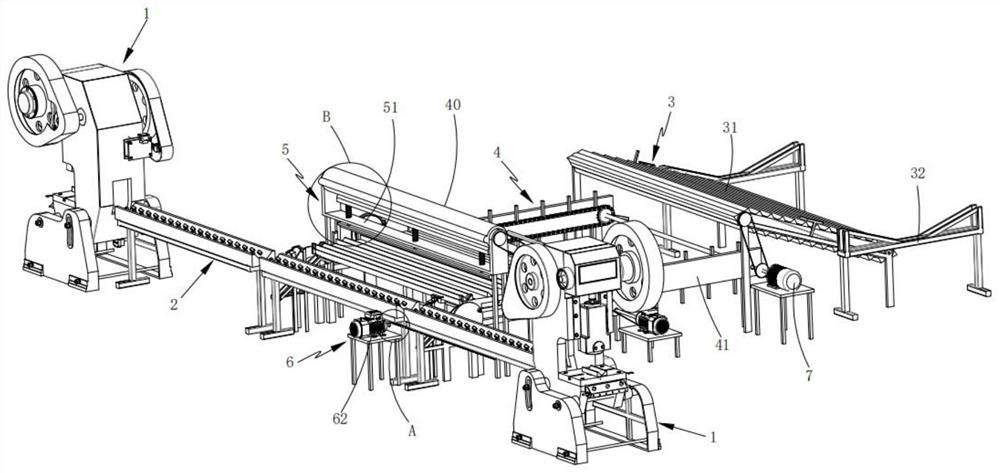

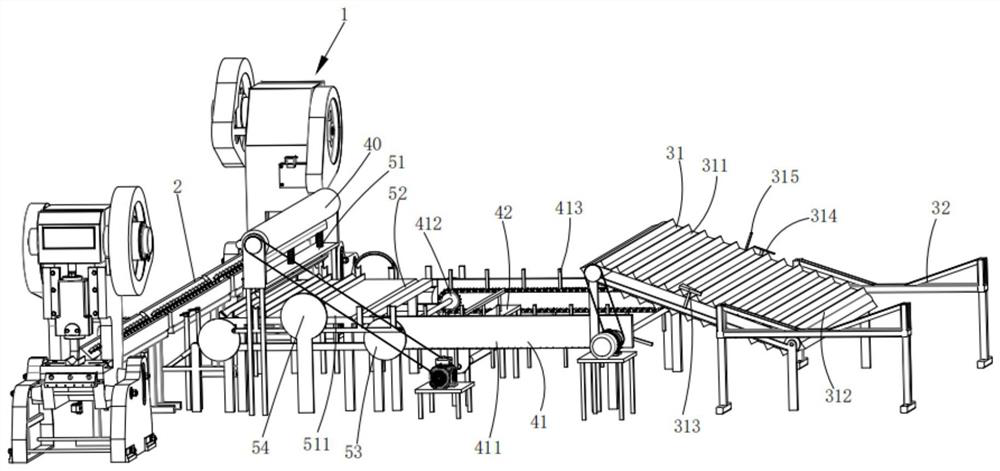

[0067] The present invention also provides a profile continuous processing production equipment:

[0068] Such as Figure 2 to Figure 4 As shown, a profile continuous processing production equipment includes two sets of shearing equipment 1, a feeding frame 2 arranged in the middle of the two groups of shearing devices 1, and is characterized in that it also includes a The feeding mechanism 3, the turning mechanism 4, the correction mechanism 5 and the feeding mechanism 6 are arranged in sequence along the direction toward the feeding frame 2 and are linked by the power assembly 7;

[0069] The feeding mechanism 3 includes a rotary assembly 31 and a rack 32 arranged at one end of the rotary assembly 31;

[0070] The turning mechanism 4 includes two sets of conveying assemblies 41 arranged at the other end of the rotating assembly 31 relative to the rack 32 and symmetrically arranged on both sides of the rotating assembly 31 , and a jacking assembly arranged at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com