Pellet units, pellet assemblies, building block mold and method for making heat preservation building blocks

A core block and assembly technology, applied in the direction of mold auxiliary parts, manufacturing tools, ceramic molding machines, etc., can solve the problems of low compressive strength, poor quality stability of thermal insulation blocks, etc., to reduce labor costs, product stability and Good compressive strength and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with accompanying drawing, the present invention will be further described.

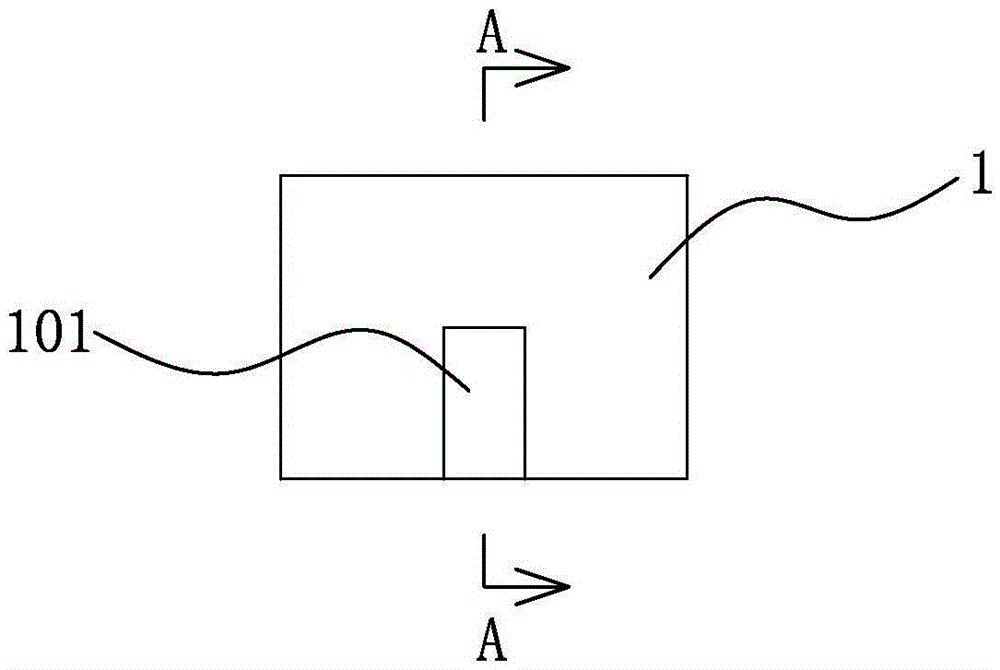

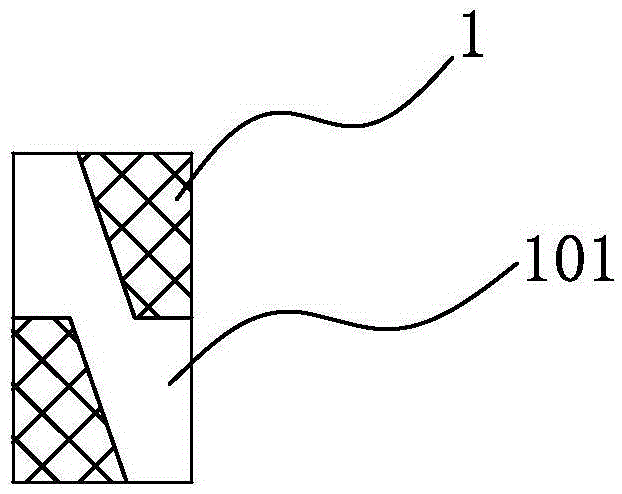

[0035] Such as Figure 1-3 As shown, it is the scheme of the first core block unit A1 of the present invention, the core block unit A is a cube, and the core block unit A is provided with a concrete that conducts along the vertical distance between two diagonal parallel sides in the cube. Pouring hole A101, the concrete pouring hole A is centrosymmetric with respect to the three-dimensional center point (geometric center of gravity or center of gravity) of the cube, and the concrete pouring hole A makes the side of the cube corresponding to the above two diagonal parallel sides in a "concave" shape.

[0036] Such as Figure 4-7 As shown, it is the second kind of core block unit B2 of the present invention. The key point of its structure is that the core block unit B is a cube. The core block unit B is provided with two concrete pouring holes B201. The vertical distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com