Stamping die facilitating discharging

A stamping die and stripper plate technology, applied in the stamping die field, can solve the problems of poor consistency of formed products, unfavorable batch production, intermittent stamping die production, etc., to achieve high safety, maintain accuracy of whereabouts, and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

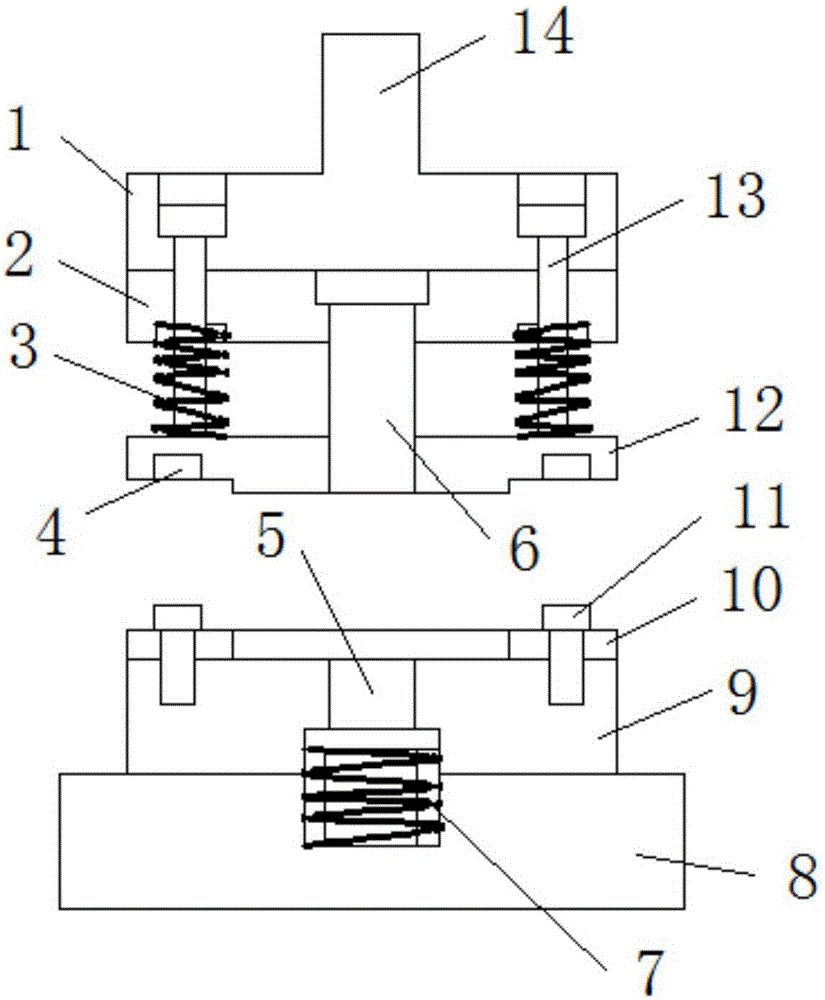

[0017] Such as Figure 1-2 Shown, a kind of stamping mold that is easy to unloading comprises upper mold base 1, punch 6, lower mold base 8 and die 9, and described upper mold base 1 upper end surface center is provided with mold handle 14, and described upper mold base The lower end surface of the seat 1 is provided with a fixed plate 2 through a bolt assembly, and the punch 6 is fixedly connected to the center of the fixed plate 2, and the lower end of the punch 6 is movably socketed with a discharge plate 12, and the discharge plate 12 is movable. The outer edge side of the plate 12 is vertically fixed with a discharge screw 13, the discharge screw 13 runs through the upper die base 1 and the fixed plate 2 and the upper end is located in the stepped hole inside the upper die base 1, and the lower part of the discharge screw 13 is provided with There is a discharge spring 3, the lower surface of the discharge plate 12 is provided with a guide hole 4, the die 9 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com