Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Solve the development bottleneck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

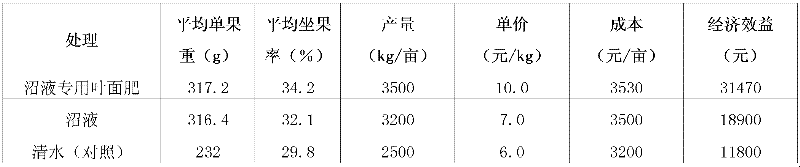

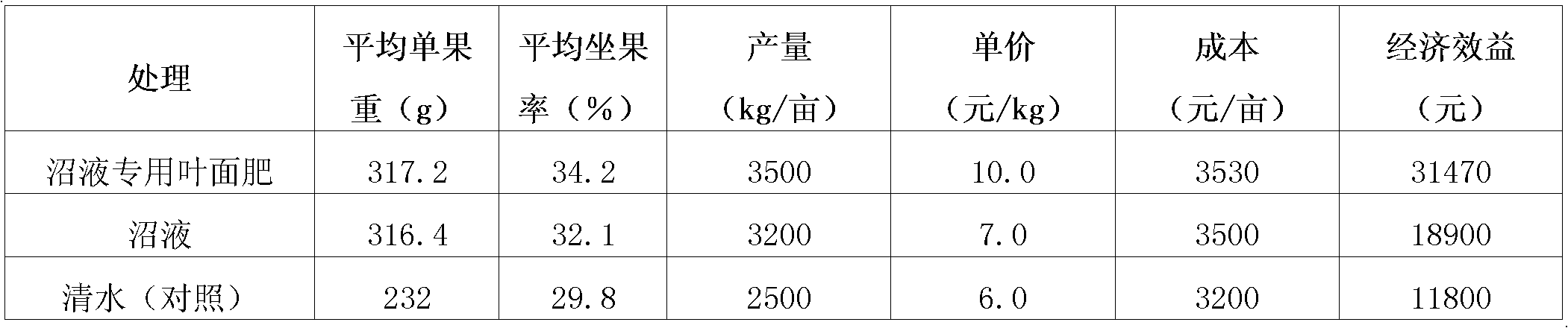

Foliage fertilizer based on marsh liquid in domestic marsh gas tank and preparation method thereof

InactiveCN102249775ASolve the development bottleneckPromote healthy developmentFertilizer mixturesNitrogenPotassium

The invention relates to a foliage fertilizer based on marsh liquid in a domestic marsh gas tank and a preparation method thereof. The foliage fertilizer based on marsh liquid in a domestic marsh gas tank is prepared from the following raw materials in parts by weight: 65-100 parts of marsh liquid and 1-3 parts of special nutrition bag for marsh liquid; and the special nutrition bag for marsh liquid is prepared from the following raw materials in parts by weight: 7-13 parts of nitrogen element, 2-5 parts of phosphorus element, 7-11 parts of potassium element, 2-6 parts of ferrum element, 3-6 parts of zinc element, 1-4 parts of manganese element, 0.5-1.5 parts of copper element, 1-2 parts of boron element and 1-2 parts of molybdenum element. The preparation method comprises the following steps: filtering the marsh liquid, preparing the special nutrition bag for marsh liquid, and mixing the marsh liquid with the special nutrition bag to obtain the marsh liquid foliage fertilizer. In theinvention, the marsh liquid stock solution is directly used as the main raw material of the foliage fertilizer without concentrating the marsh liquid; and the foliage fertilizer is especially applicable to domestic marsh gas tanks in scattered and separate households which prepare the marsh liquid when necessary.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

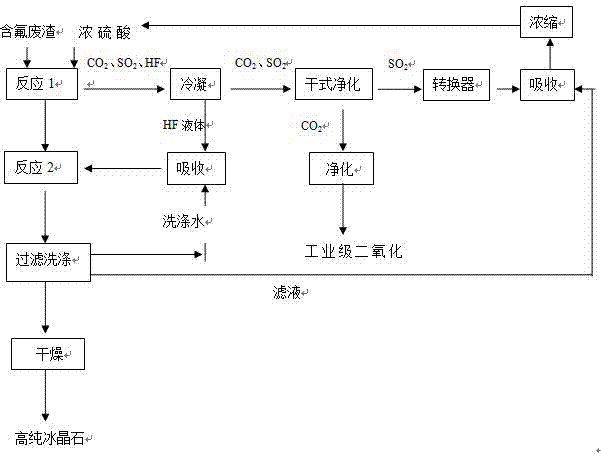

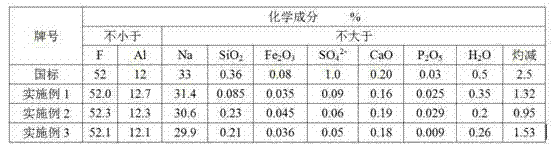

Method for producing cryolite by using fluorine-containing waste residues of electrolytic aluminium

ActiveCN102079534BQuality improvementReduce manufacturing costWaste processingSolid waste disposalPhysical chemistryEnvironmental engineering

Owner:BAIYIN ZHONGTIAN CHEM

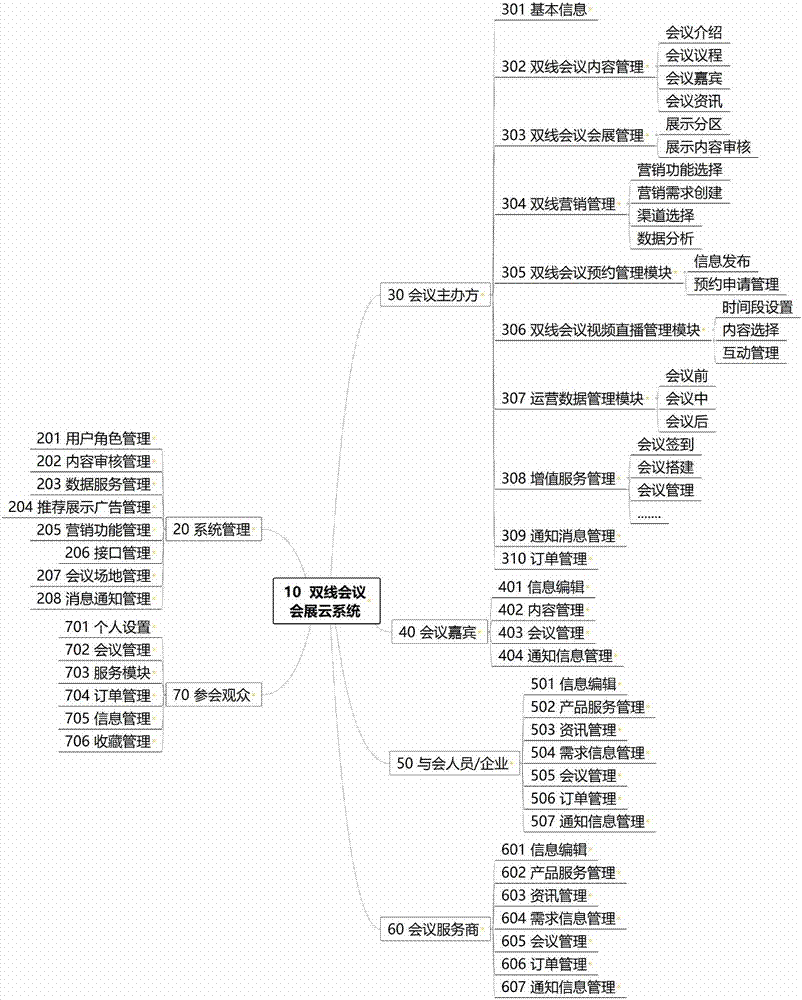

Double-line conference exhibition system

InactiveCN107480944AEasy to publishStrong compatibility and expansionOffice automationSystems managementHuman–computer interaction

The invention relates to online conference, in particular to a conference exhibition system. A double-line conference exhibition system includes system management, a conference organizer user role, a value-added service module, a conference guest user role, an enterprise user role, a conference service provider user role, and attendees. Online conference and online exhibition are integrated in one system, and an opportunity and platform is created for all parties to fully display themselves.

Owner:上海后博信息科技有限公司

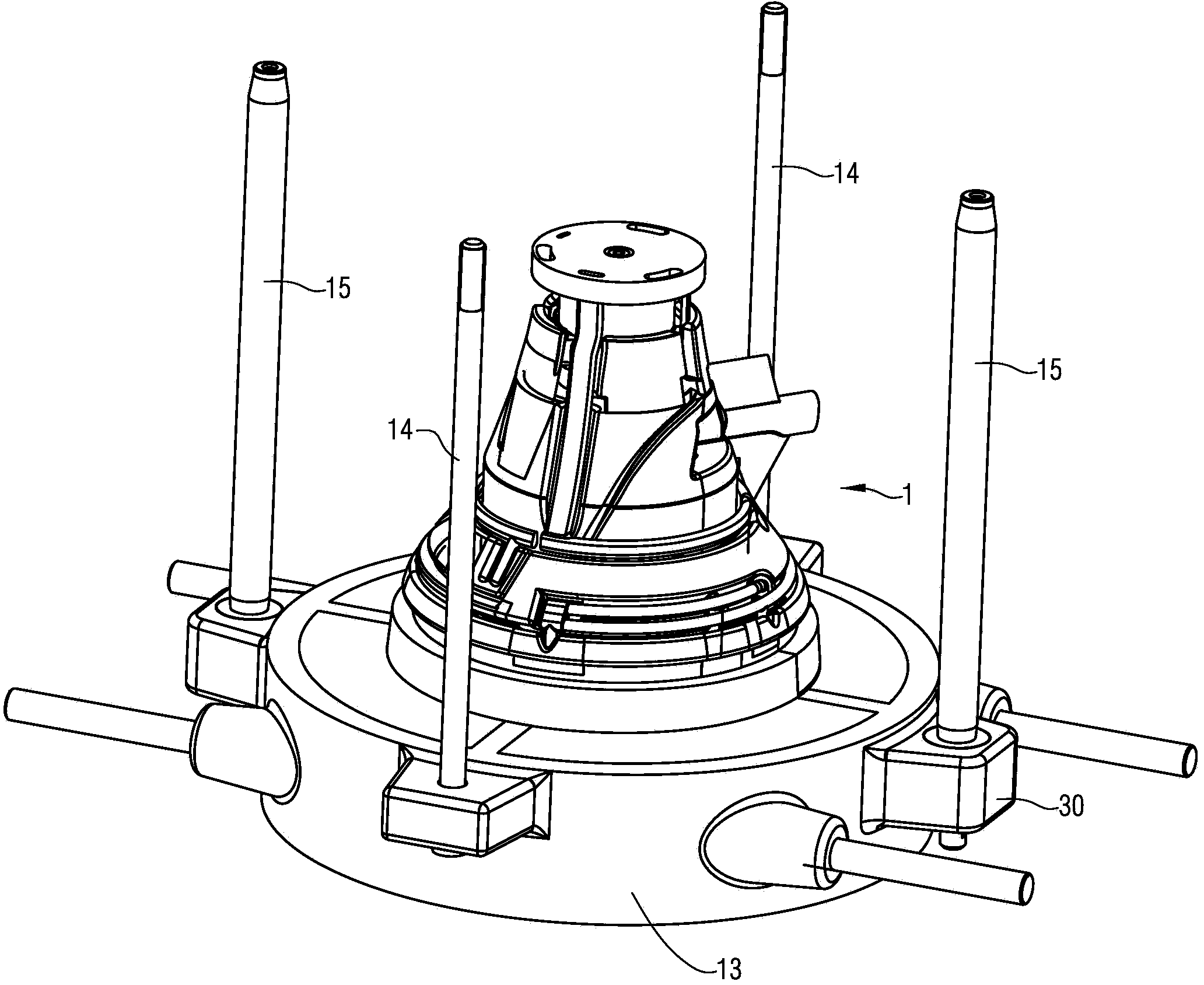

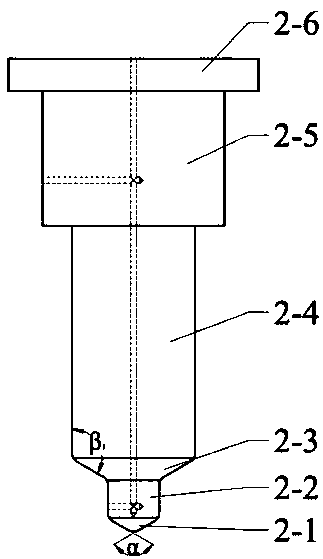

Laser cladding device capable of recycling and reusing reflected light

PendingCN110438492AAchieve reuseReduce harmMetallic material coating processesLight beamOptoelectronics

The invention provides a laser cladding device capable of recycling and reusing reflected light. The laser cladding device capable of recycling and reusing reflected light comprises a reflecting cover, a laser head inner wall and a laser head outer wall, wherein the inner wall of the laser head is arranged inside the outer wall of the laser head, a laser beam channel used for transmitting a laserbeam is formed inside the inner wall of the laser head, a powder beam used for transmitting a powder beam is formed between the out wall of the laser head and the inner wall of the laser head, the laser beam passes through the laser beam channel and then is focused on the surface of a to-be-machined workpiece, the powder beam is focused on the surface of the to-be-machined workpiece after passingthrough the powder beam channel, the laser beam and the powder beam are focused on the same point on the surface of the to-be-machined workpiece, and a reflecting cover can reflect the laser reflectedby the surface of the to-be-machined workpiece back to the joint focus point where the laser beam and the powder beam located on the surface of to-be-machined the workpiece. According to the laser cladding device, a reflected light recycling and reusing mechanism and related cooling mechanism are arranged, so that the damage of the reflected laser to equipment and a human body is reduced, the laser utilization efficiency is improved, and the development bottleneck of an existing laser cladding technology is solved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

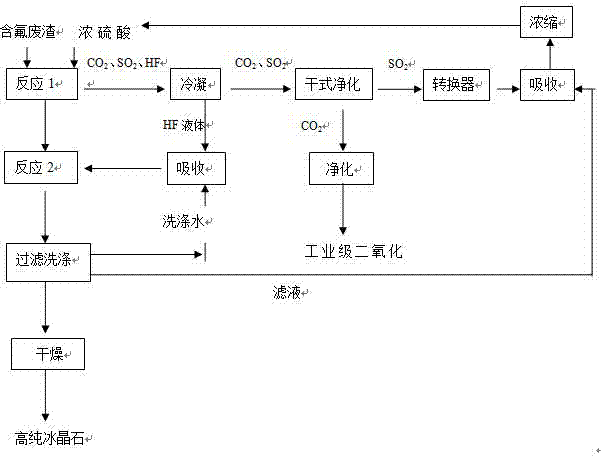

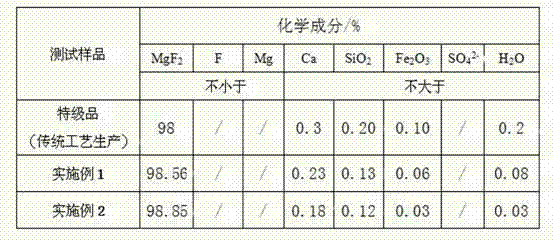

Production method for high-purity magnesium fluoride crystal

InactiveCN102674410AGuaranteed conversion rateQuality improvementMagnesium fluoridesEnvironmental resistanceCarbonization

The invention discloses a production method for a high-purity magnesium fluoride crystal. The production method for the high-purity magnesium fluoride crystal comprises the following steps: (1) mixing and stirring magnesium carbonate and water to prepare magnesium carbonate suspension, introducing CO2 gas into the magnesium carbonate suspension and performing carbonization to obtain reaction liquid A; (2) performing ammonolysis on fluosilicic acid to prepare ammonium fluoride solution or ammonium hydrogen fluoride solution; (3) mixing the reaction liquid A and the ammonium fluoride solution or ammonium hydrogen fluoride solution, reacting to obtain high-purity magnesium fluoride slurry, collecting the CO2 gas generated in the reaction process and returning the CO2 gas for carbonization reaction, and collecting ammonia generated in the reaction process for use; and (4) filtering the high-purity magnesium fluoride slurry, returning the filtrate for preparation of the magnesium carbonate suspension, and washing, drying and sintering the filer cake which is high-purity magnesium fluoride ointment to obtain the high-purity magnesium fluoride crystal. The production method for the high-purity magnesium fluoride crystal has good economic, social and environmental-protection benefits and is suitable for popularization and application.

Owner:DO FLUORIDE CHEM CO LTD

Method for producing lamination-free anti-curl automatic labeling label

InactiveCN102717615AReduce manufacturing costDust consumption is reducedInksOther printing apparatusSurface finishMulti machine

The invention relates to a method for producing a lamination-free anti-curl automatic labeling label, belonging to the field of printing technologies. According to the method, a surface finishing process for printed products adopts printer online overprinting instead of the original laminating process, the printing is realized through material preparing, CTP (Computer to Plate) plate-making and plate-discharging, and multi-machine combination, and in particular, an all-in-one machine, which is formed in a manner that a six-color or seven-color printing machine is linked with an overprinting unit printer and a paper collecting and drying unit, is adopted to realize the completion of production by one-time paper skipping; and meanwhile, the consumption of spraying powder is reduced, the transparency of the printed products is improved, and the drying time is shortened. Various physical indicators of obtained products all reach or exceed the service properties of the original laminated labels, so that the green and the low consumption are achieved.

Owner:HUAXIN FOSHAN COLOR PRINTING

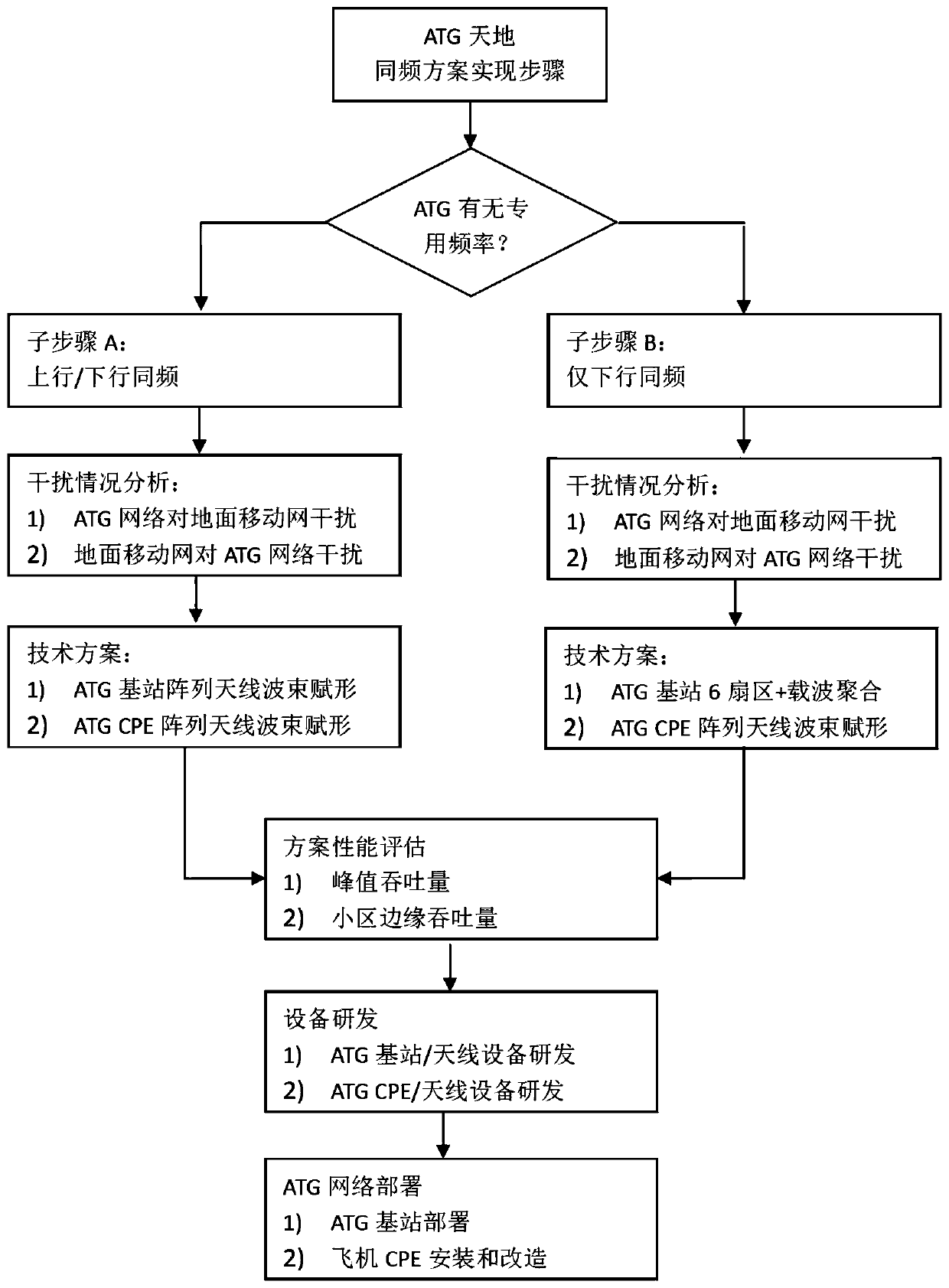

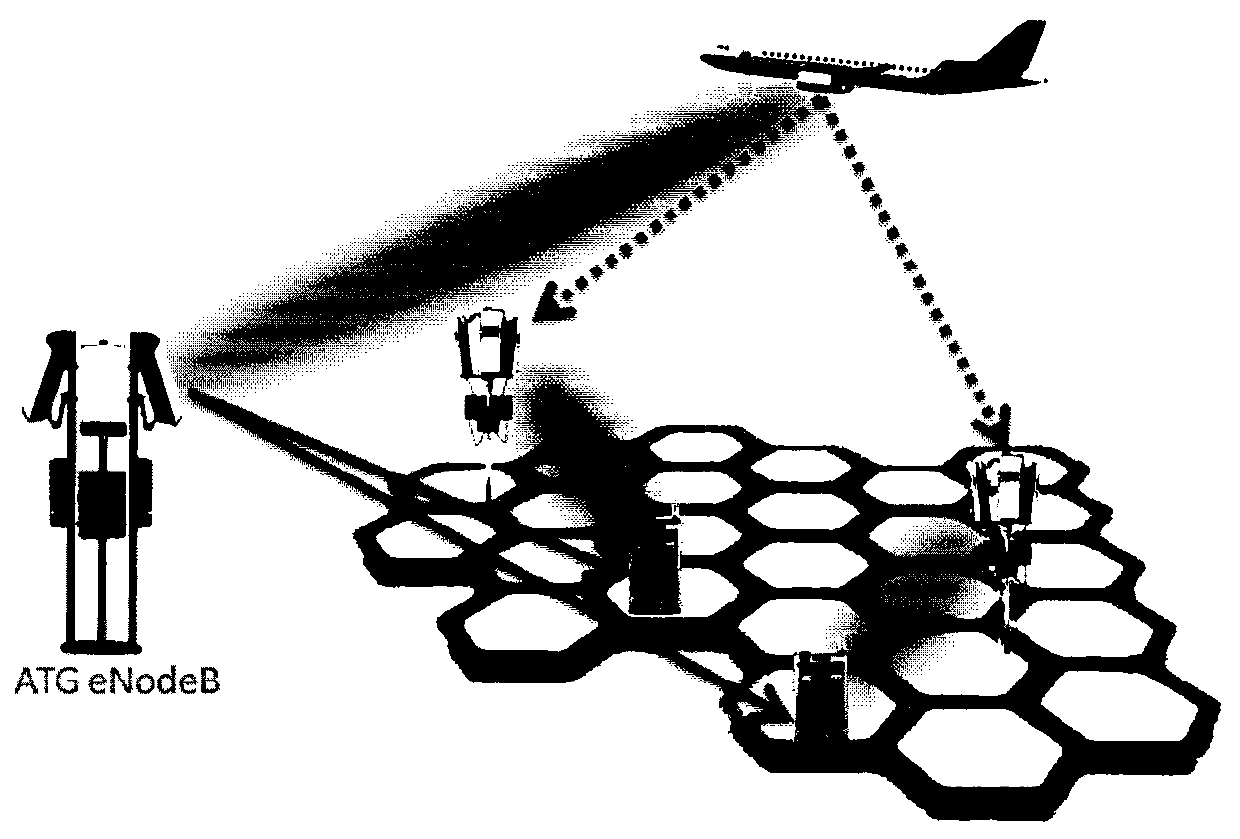

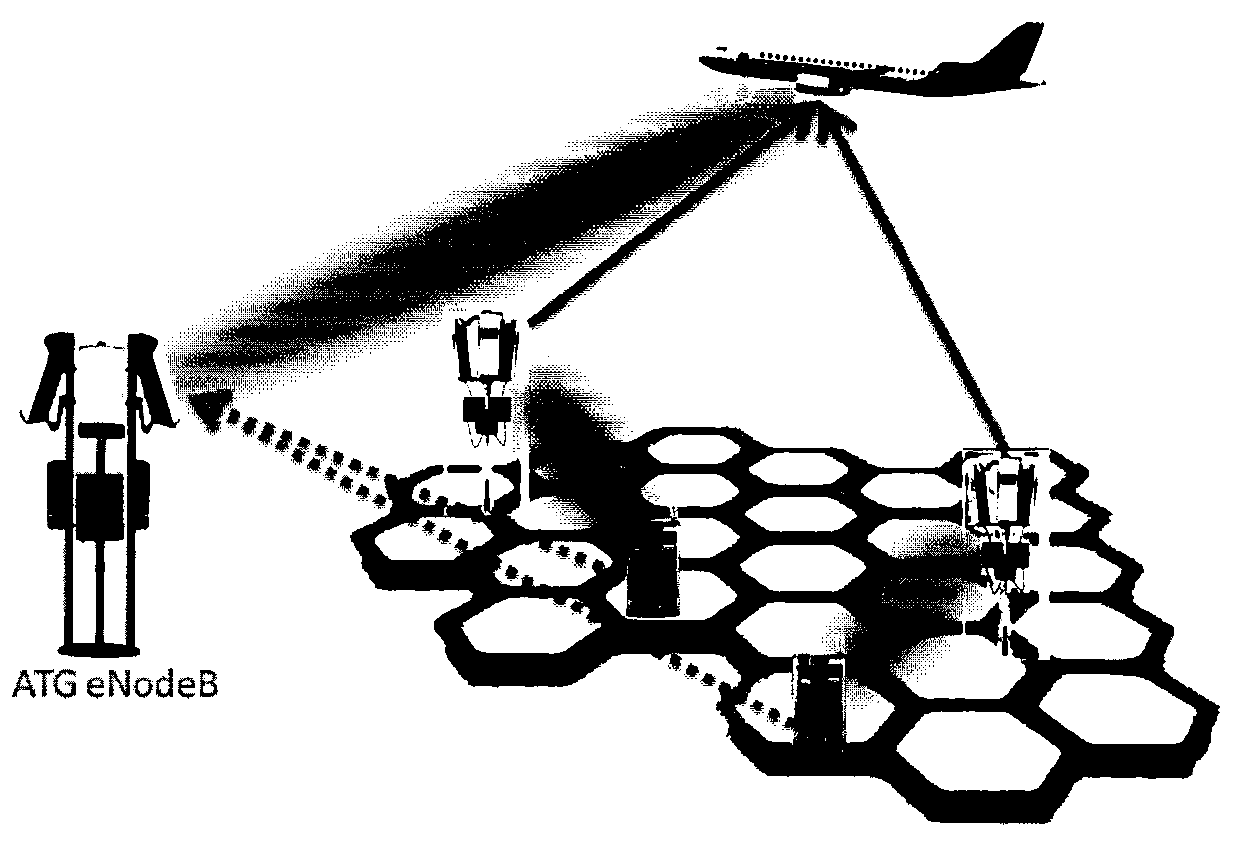

ATG networking solution based on space-ground co-frequency

ActiveCN110636509ASlight interferenceInterference is slight and can be avoidedNetwork planningHigh level techniquesNetwork deploymentComputer science

The invention discloses an ATG networking solution based on space-ground co-frequency, which solves the bottleneck of ATG network development by introducing special products and solutions and adoptingoperator frequency to perform space-ground co-frequency, solves the problem of frequency resources of air-ground communication (ATG), and removes obstacles of ATG deployment. Through the antenna co-frequency scheme of the invention, the problem of obtaining frequency resources in ATG network deployment can be solved, the use efficiency of operator frequency resources is improved, the operation ishelped in efficiency and income improvement, and the operation is improved. The method has a wide development prospect in the aspects of value-added services, advertisements and digital and intelligent services of big data.

Owner:北京长焜科技有限公司

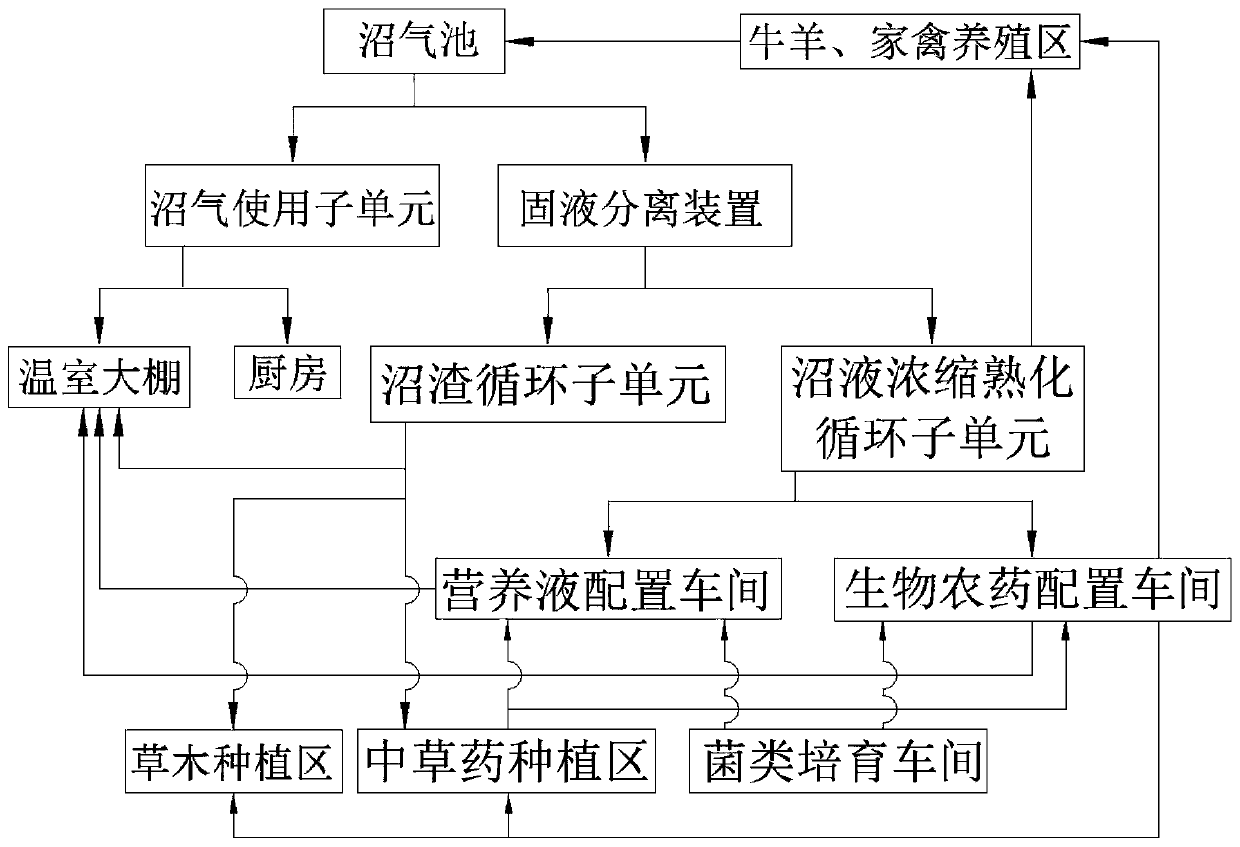

Ecological agriculture circulation system integrating agriculture, forestry, animal husbandry, biogas engineering and greenhouse

InactiveCN111149566ASolve bottlenecksSolve the use problemClimate change adaptationWaste water treatment from animal husbandryEnvironmental resource managementCrop livestock

The invention relates to an ecological agriculture circulation system integrating agriculture, forestry, animal husbandry, biogas engineering and a greenhouse. The ecological agriculture circulation system integrating agriculture, forestry, animal husbandry, biogas engineering and the greenhouse comprises a tree planting unit, a Chinese herbal medicine planting area, a forage grass planting unit,an animal husbandry unit, the greenhouse, a biogas engineering unit, a biological pesticide production workshop, an organic soilless cultivation nutrient solution production workshop and a microorganism breeding workshop. According to the ecological agriculture circulation system integrating agriculture, forestry, animal husbandry, biogas engineering and the greenhouse, grass and tree planting, animal husbandry and biogas engineering are organically combined, and depend on one another to form the organic ecological agriculture circulation system, so that the agriculture development bottlenecksof the land problems of a very small per capita share of cultivated land in China and large-area land polluted by chemical pesticides and chemical fertilizers and the problem of use of reeds, unusedgrassland and saline and alkaline land are completely overcome once and for all; the biogas industry development bottleneck of the problem of biogas slurry pollution is overcome; the forestry development bottlenecks of the problems of small land area, compensation of farmers and demolition are overcome; and the animal husbandry development bottlenecks of the problem of excrement pollution and theproblems of conflict between grass and livestock and conflict between large-scale breeding and protection of ecological environments are overcome.

Owner:青岛大智大慧生态农业有限公司

Formula and production process for producing high-quality porcelain by using poor-quality raw materials

The invention belongs to the field of ceramic production, and particularly relates to a formula and a production process for producing a high-quality porcelain by using poor quality raw materials such as weathered feldspar, porcelain sand, red soil and other poor-quality raw materials. According to the formula, the weathered feldspar, the black clay, the kaolin, the black talc and the porcelain clay produced in the Dehua are subjected to the production process with characteristics of reasonable formula and right control so as to produce the daily-use porcelain meeting the export standard, such that the bottleneck problem constraining the Dehua exported ceramic enterprise development is solved, the production cost is substantially reduced, the raw material supply time is shortened, the economic efficiency is improved, the market competitiveness of the exported ceramic enterprise is enhanced, and the great promotional value and the great social and economic benefits are provided.

Owner:福建省德化县宏达陶瓷有限公司

Method for producing non-laminating anti-curling label capable of being labeled automatically

InactiveCN103770485AThe printed content is clearlyHigh degree of production automationOther printing apparatusPrinting after-treatmentColor printingHexachrome

The invention relates to a method for producing a non-laminating anti-curling label capable of being labeled automatically, and belongs to the technical field of printing. According to presswork, a printing machine is online for glazing in a surface finishing process to replace an original laminating process, printing is achieved through material preparation, CTP platemaking, plate discharging and multi-machine combination, especially an all-in-one machine composed of a six-color or seven-color printing machine online glazing unit printing machine and a collection drying unit is adopted for achieving one-shot paper feeding to complete production, meanwhile, the amount of sprayed powder is reduced, transparency of the presswork is improve and drying time is shortened. Various physical indexes of the presswork reach or exceed usability of an original laminated label and environment friendliness and low consumption are achieved.

Owner:HUAXIN FOSHAN COLOR PRINTING

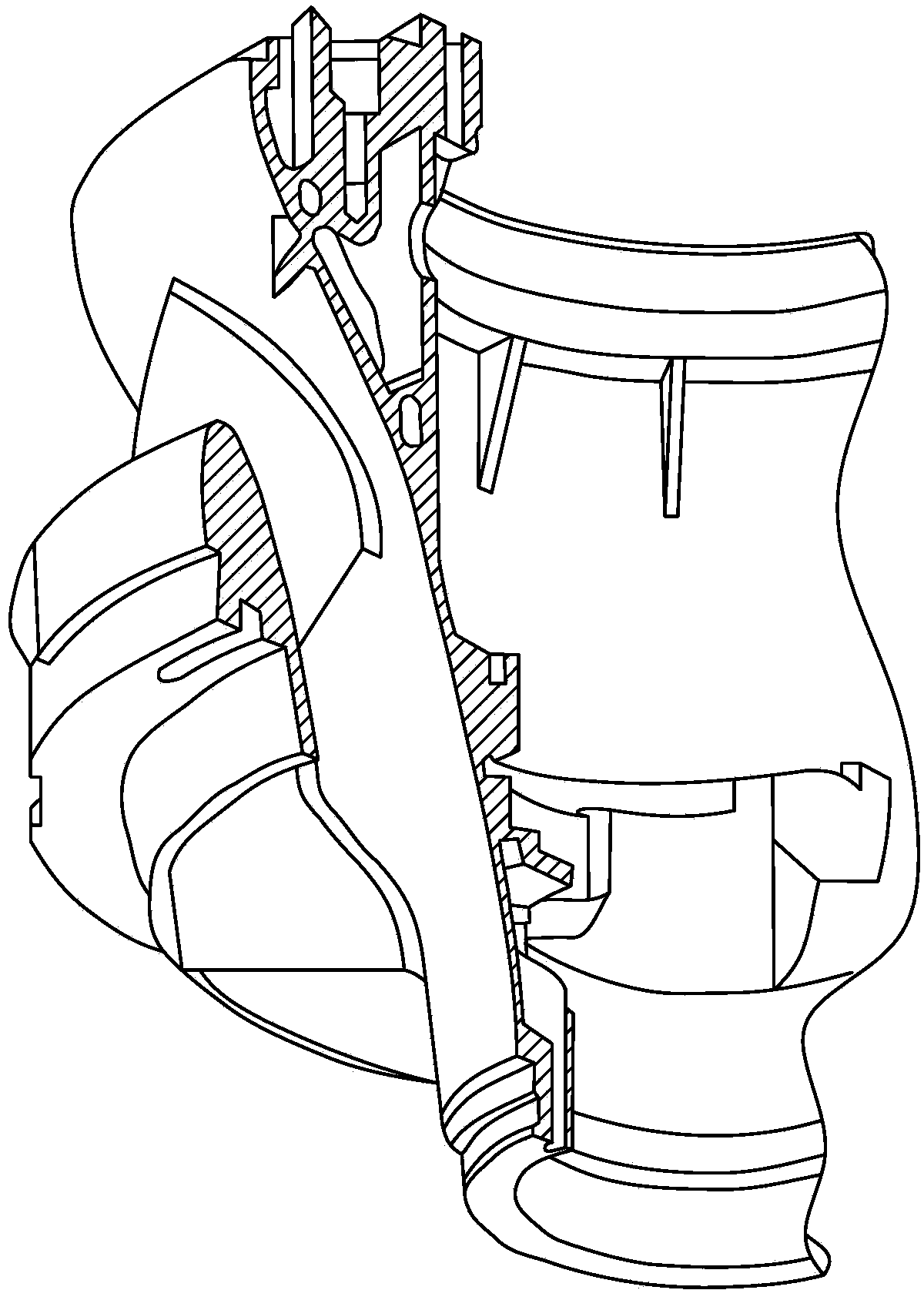

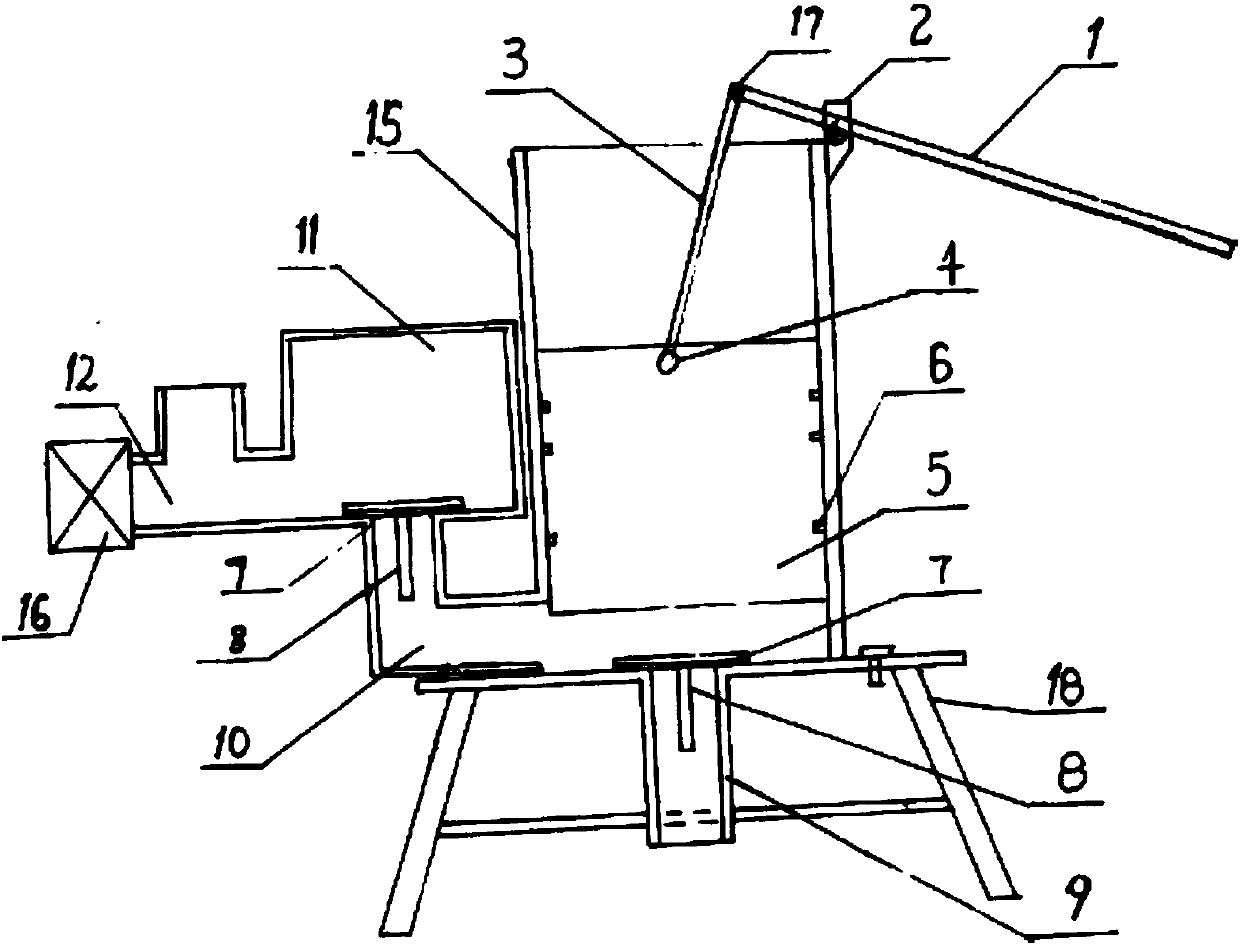

Method for casting aluminum-magnesium alloy aeroengine box

ActiveCN103406497ASolve the development bottleneckOvercome the flaw of being unable to castFoundry mouldsFoundry coresAero engineMagnesium alloy

The invention relates to a method for casting an aluminum-magnesium alloy aeroengine box. The aeroengine box is of a spiral cone shape and has a big head and a small head, wherein the diameter of the big-head end is 900-1,200 mm, the average wall thickness is about 2.5-3 mm, and the aeroengine box is formed through integral casting of aluminum-magnesium alloy. The method is used for solving the problem that the aeroengine box can not be cast by the traditional casting methods due to the structural features of the aeroengine box. According to the method, during the combination and assembly of a casting form, the casting form is combined in a manner that the big head is located at the downside, then, the small head is enabled to face downwards through inverting, and finally, aluminum-magnesium alloy is cast from a casting port of the small-head end from bottom to top. According to the method disclosed by the invention, a novel casting form combining and casting manner is provided, the defects that the existing casting methods can not be applied to casting are overcome, and the bottleneck in development of aeroengine box cast parts is solved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Flame-retardant and weather-resistant color masterbatch and production method thereof

The invention relates to the technical field of production of plastics and particularly relates to a flame-retardant and weather-resistant color masterbatch and a production method thereof. The production method comprises the following steps: firstly metering an antioxidant, a light stabilizer and a carrier, and mixing for 3 minutes via a stirrer at the temperature of 50 DEGC; extruding and pelleting via a two-screw extruder, then proportioning the carrier and a flame retardant, pigment and a dispersant, mixing for 10 minutes via the stirrer at the temperature of 70 DEG C, milling till the pigment, the additives and the carrier are uniformly bonded together, pulling the screws and cleaning a machine table, additionally arranging a 150-mesh sieve net on a machine head, producing by selecting screws with length-to-diameter ratio phi of 40 to 1, setting the revolutions of the screws to be 180rp, successively pelleting via the two-screw extruder under the condition that the temperature of a first zone of the machine table is 60 DEG C, the temperature of a second zone of the machine table is 140 DEG C, the temperature of a third zone of the machine table is 140 DEG C, temperature of a fourth zone of the machine table is 135 DEG C, the temperature of a fifth zone of the machine table is 130 DEG C, the temperature of a sixth zone of the machine table is 130 DEG C, the temperature of a seventh zone of the machine table is 130 DEG C, the temperature of an eighth zone is 140 DEG C, and the temperature of the machine head is 150 DEG C, stirring and mixing uniformly, drying water and then packing. The flame-retardant and weather-resistant color masterbatch produced by the method is capable of greatly improving the weather resistance of furniture products, prolonging the service life and the flame retardancy and reducing the product cost, can be used for solving the bottleneck problem of the development of the home furnishing material, and has great significance to the environmental protection.

Owner:DONGGUAN JINFULIANG PLASTIC & RUBBER TECH CO LTD

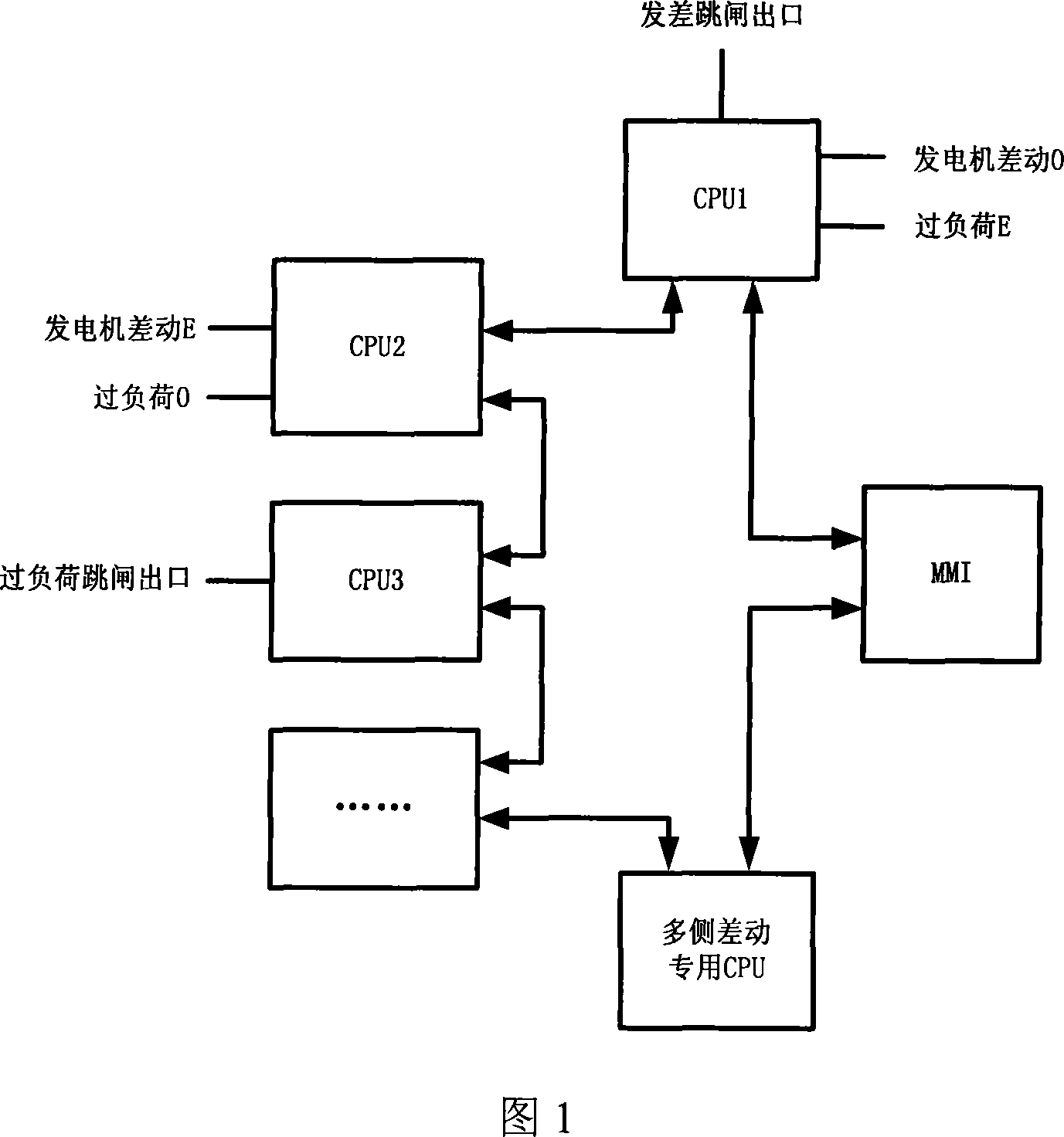

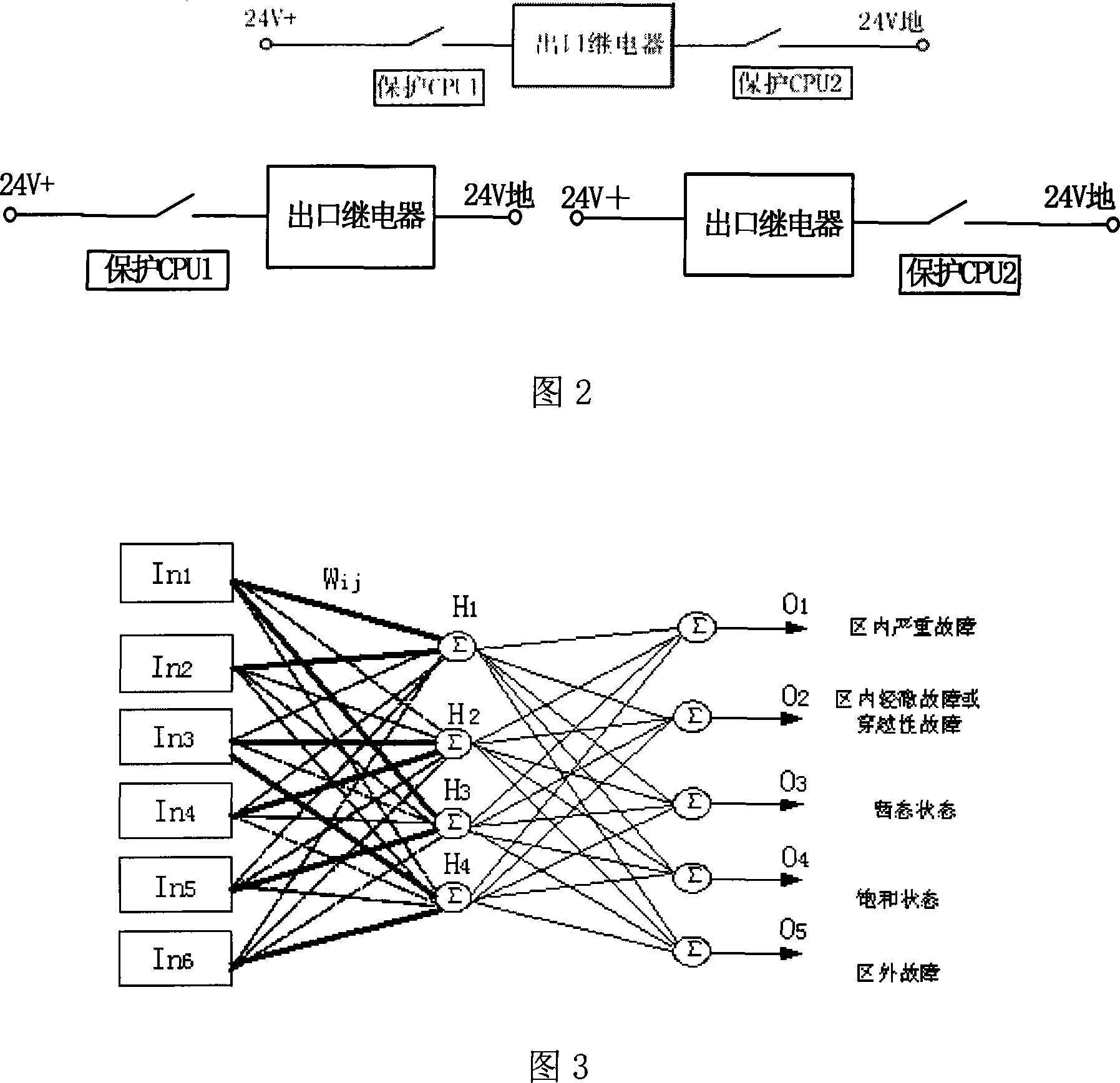

Digital type dispersed software/hardware fault-tolerant type protection technique

InactiveCN101183787ASolve the development bottleneckShare the riskEmergency protective circuit arrangementsTransient statePerformance index

The invention relates to a fault-tolerant protecting technology for digital discrete software and hardware, comprising the discrete technology and the fault-tolerant technology; wherein, the discrete technology realizes the discreteness of protecting software and hardware by distributed protection of CPU system based on double-loop network structure. The fault-tolerant technology comprises that: the hardware fault tolerance is realized by parallel processing of multi-CPU; protecting principle algorithm fault tolerance is realized by smart ANN technology; based on the different digital filters employed by power frequency parameter protecting principle and the wavelet filters employed by transient protection of transient signal; the filter is designed with a view to the dynamic fault-tolerant performance index, to improve the dynamic fault-tolerant performance of digital filtering algorithm; bad data in the data protection is detected and rejected which realizes information fault tolerance. The invention adopts the structure of discrete software and hardware, and the hardware employs fault-tolerant design, and the software allocates the functions of hardware; thus the invention has the advantages of algorithm fault tolerance and information fault tolerance, which respectively take the hardware adventure of the protection unit and the software adventure of the protection unit and the reliability of protection unit is improved.

Owner:GUODIAN NANJING AUTOMATION

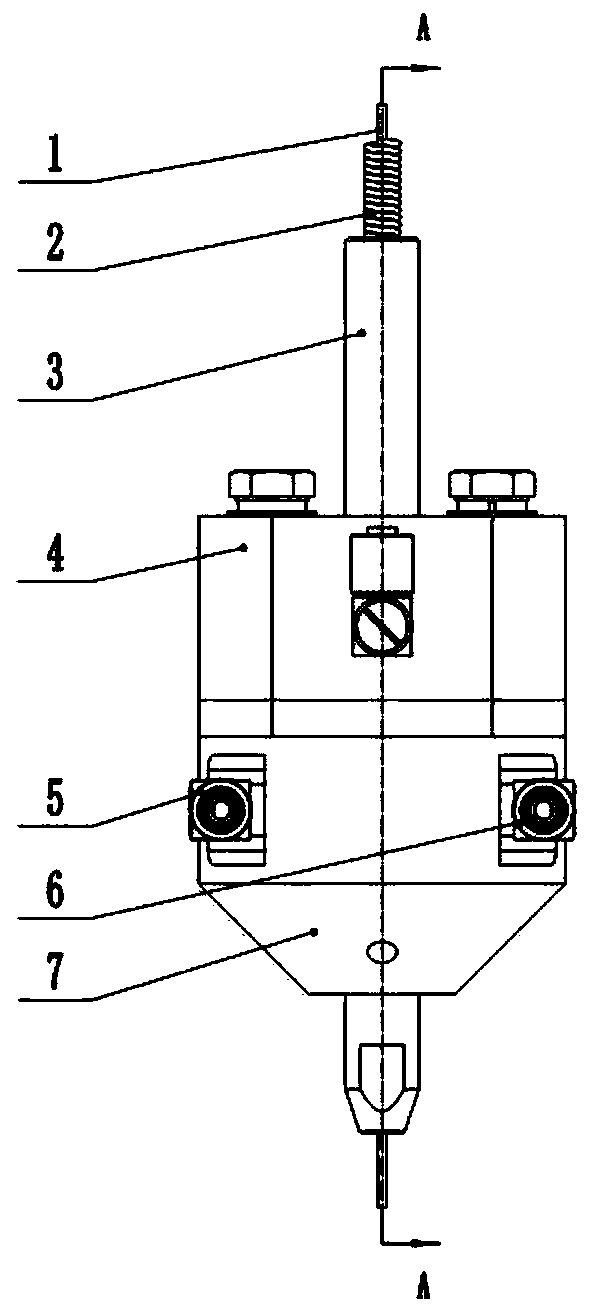

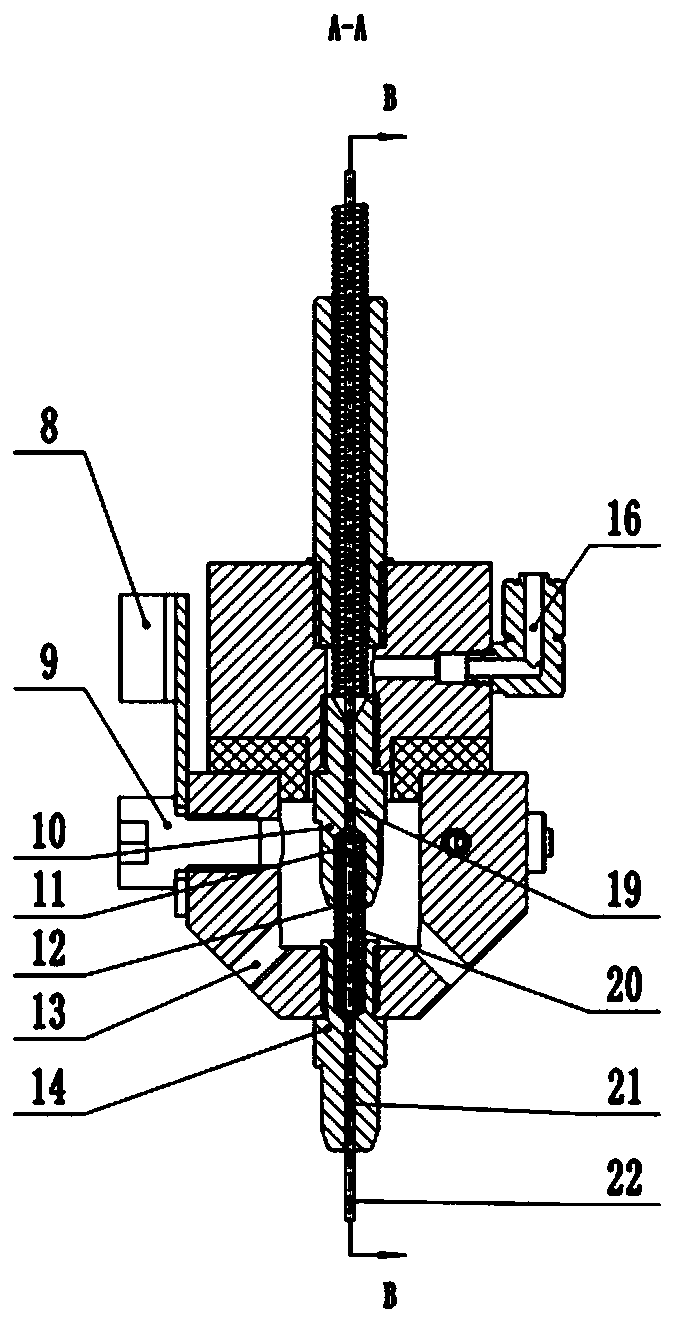

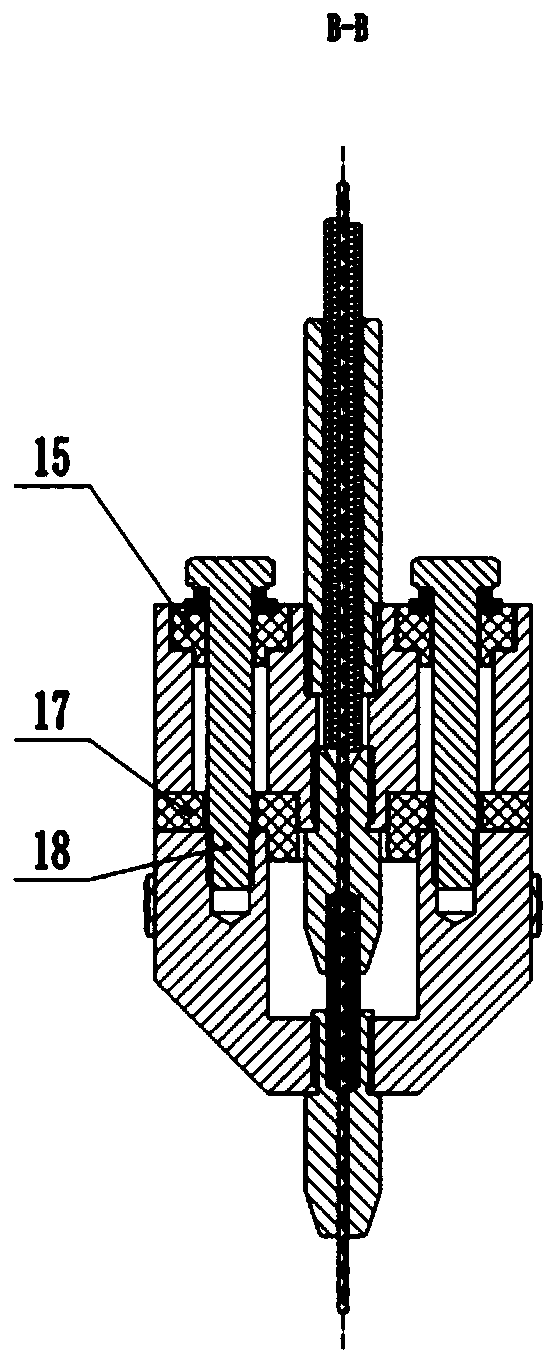

High-pressure biogas slurry discharger

InactiveCN108034577AImprove the efficiency of liquid materialSolve the development bottleneckBioreactor/fermenter combinationsBiological substance pretreatmentsPiston ringSolar water

The invention relates to a high-pressure biogas slurry discharger. The high-pressure biogas slurry discharger has the advantages that the biogas slurry can flow in a biogas digester, and the output ofthe biogas is increased. The high-pressure biogas slurry discharger consists of a handle, a piston, a piston ring, a flat sealing pad, a positioning pin, a water inlet pipe, a connecting pipe, a high-pressure tank, a cylinder sleeve, a water valve and the like; the water is sucked into the high-pressure tank by the vertical movement of the piston to produce the high-pressure water, and the lift can reach 20m or above. The high-pressure biogas slurry discharger has the characteristics that the structure is simple, and the convenience in use is realized; the biogas slurry discharging efficiencyin the biogas tank is greatly increased by five times or above, the output of the biogas is also obviously increased, the bottleneck problem restricting the development of biogas industry is effectively solved, and the biogas industry is promoted to develop; in the areas without running water, the high-pressure biogas slurry discharger can be used for filling a solar water heater with water, or watering a farmland.

Owner:HAIAN RUIHUA TEXTILE TECH CO LTD

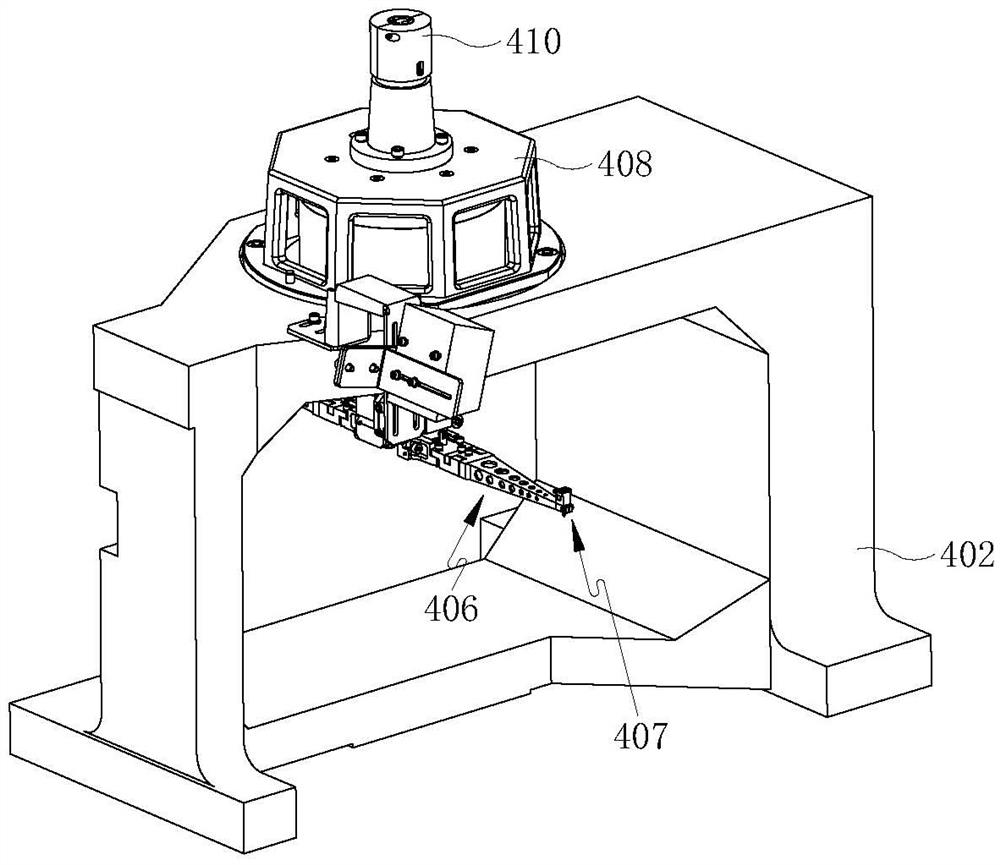

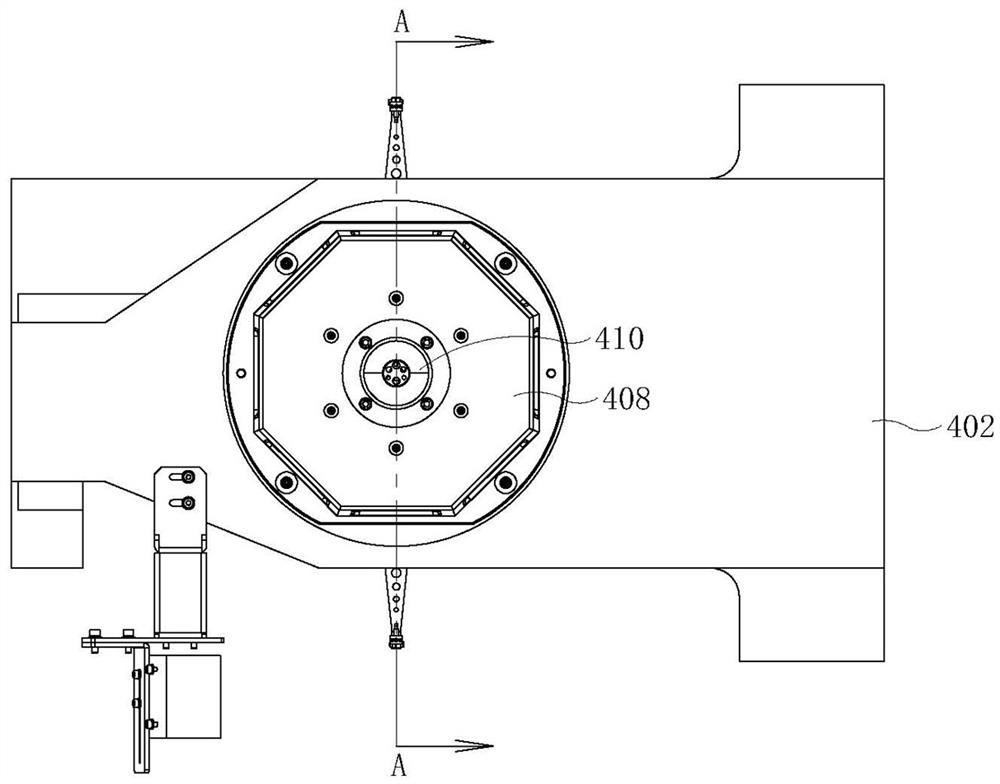

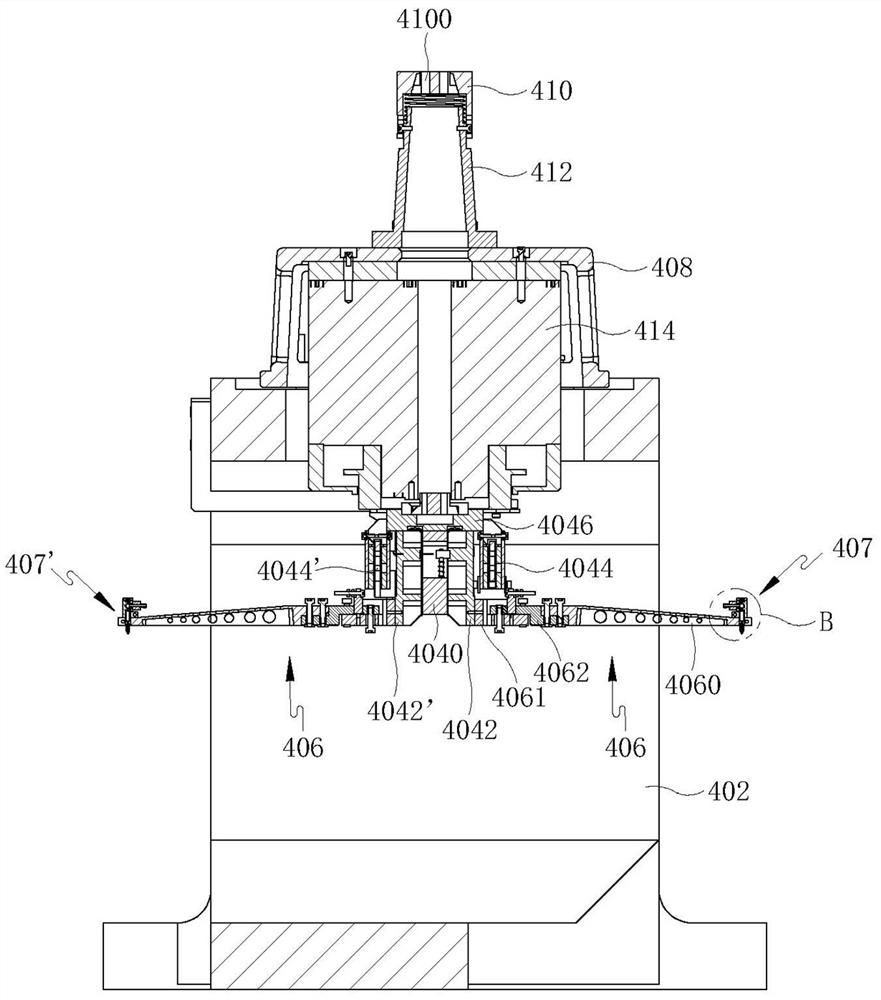

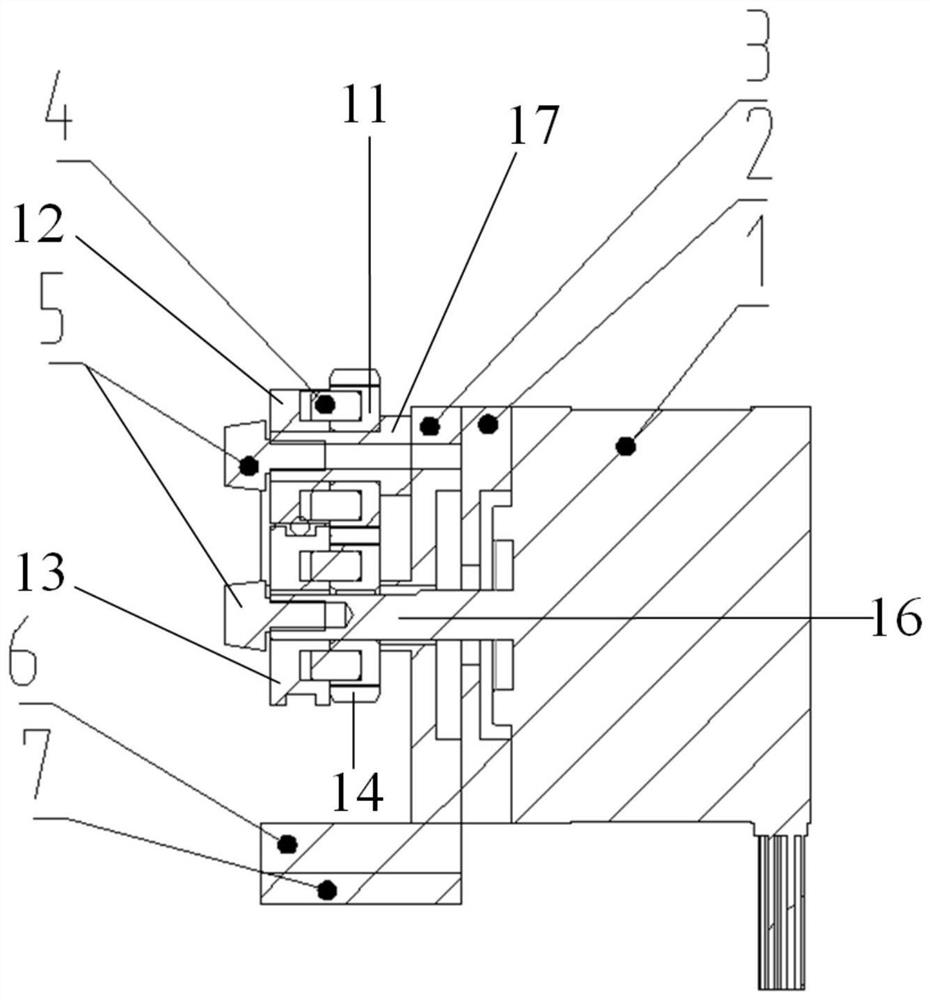

Wire laser cladding hot wire device

PendingCN110241417AInnovative power supply connection methodRealize linear conveying heatingMetallic material coating processesEngineeringHeating effect

The invention provides a wire laser cladding hot wire device. The device comprises a wire conveying pipe, a connecting rod, a flange, an insulating plate, an insulating pad, a water cooling head, a first conductive nozzle, a second conductive nozzle, an insulating pipe and a bolt; the connecting rod is connected to the flange, the wire conveying pipe is arranged in the connecting rod, the insulating plate is arranged between the flange and the water cooling head, the insulating pad is arranged between the flange and the bolt, the bolt sequentially penetrates through the insulating pad, the flange and the insulating plate and then is in threaded connection with the water cooling head, the first conductive nozzle is installed on the flange, the second conductive nozzle is installed on the water cooling head, and the insulating pipe is arranged between the first conductive nozzle and the second conductive nozzle. According to the wire laser cladding hot wire device, a heating structure of the hot wire device is innovatively arranged, so that the heating effect of the hot wire is improved, the highest temperature can reach 1000 DEG C, continuous and stable heating can be realized, the requirements of automatic continuous production are met, wire passing is smooth and wire blocking can be avoided, the structure is firm, deformation and shaking during long-time operation can be avoided, and the bottleneck problem of an existing wire laser cladding technology can be solved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

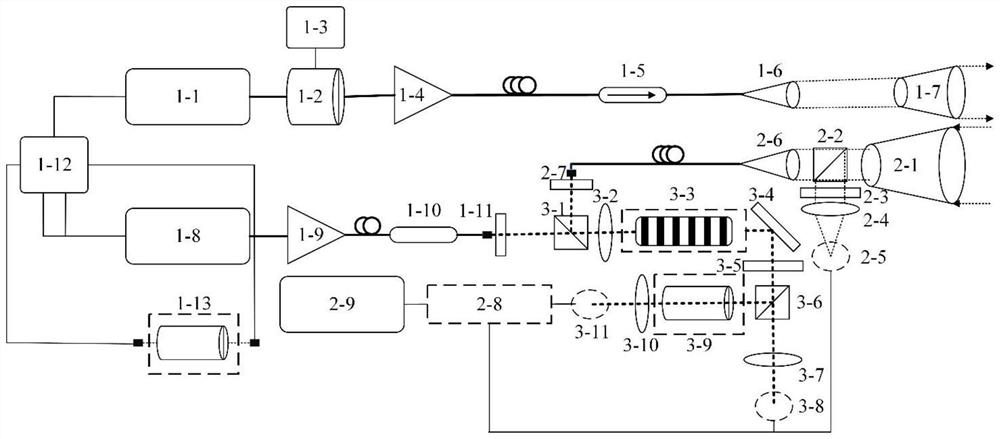

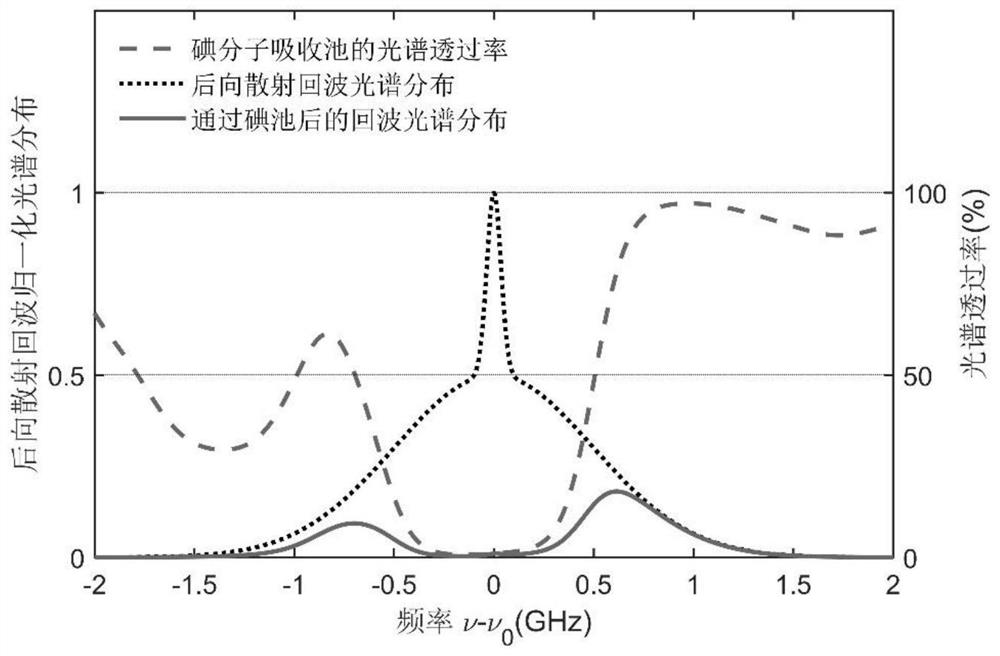

High spectral resolution laser radar based on up-conversion

PendingCN114488081ASolve difficult problems in developmentReduce development difficultyElectromagnetic wave reradiationICT adaptationMechanical engineeringNonlinear crystals

The invention discloses a high-spectral-resolution laser radar based on up-conversion. The high-spectral-resolution laser radar comprises a laser transmitting module, a telescope receiving module and a sum frequency and frequency discrimination module. The laser transmitting module generates a single-frequency laser pulse signal, the telescope receiving module receives and detects a laser radar echo signal, and the sum frequency and frequency discrimination module enables the received laser radar echo signal and a single-frequency pump light signal to be subjected to sum frequency through a nonlinear crystal to generate a photon matched with a certain absorption spectral line of the frequency discrimination molecular absorption cell. Spectrum frequency discrimination is carried out through a frequency discrimination molecule absorption cell, photons generated by mie scattering are absorbed, an extra laser radar equation is obtained, and accurate solving of the laser radar equation is achieved. According to the invention, the wavelength of the high-spectral-resolution laser radar can be converted to the absorption spectral line of the common frequency discrimination molecular absorption cell for spectrum frequency discrimination, and the development difficulty of the multi-wavelength high-spectral-resolution laser radar is reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

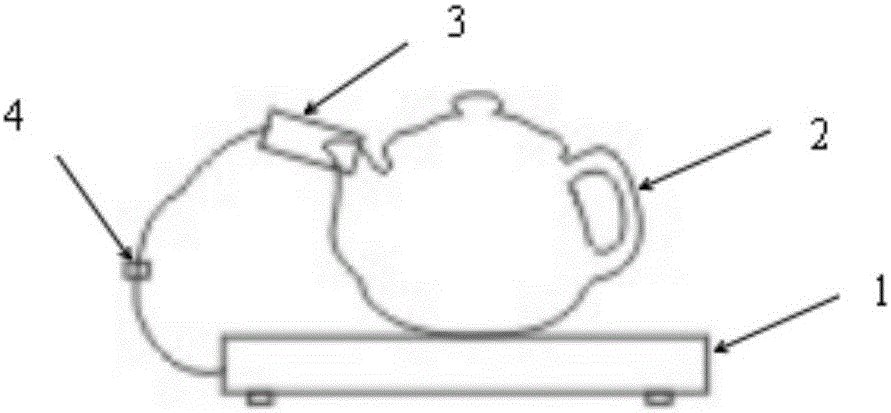

Intelligent stove with detection device

InactiveCN105674354AFacilitate communicationUseful for cookingDomestic stoves or rangesLiquid heating fuelHeating timeMicrowave oven

The invention discloses an intelligent stove with a detection device. The intelligent stove comprises a stove body (1), a pot (2) and the detection device (3); the detection device (3) is kept to be connected with the pot (2) when the stove body (1) is used for heating the pot (2), and the connection mode is that connection is conducted through a natural water outlet or a natural steam outlet of the pot (2), or connection is conducted by drilling a hole in the pot wall, or the detection device is directly put into the pot (2). According to the intelligent stove with the detection device, good communication between the stove body and the pot can be achieved, an intelligent system can be constructed, and all stoves except a microwave oven can monitor the temperature in an ordinary pot, conduct intelligent treatment according to the temperature in the pot, conduct corresponding adjustment on fire power or heating time or other functions, give out a prompt alarm and do subsequent treatment.

Owner:韩戟

Magnetism gravity wind energy and solar energy comprehensive green energy resource self-generating electricity device

InactiveCN108999746ASolve the development bottleneckSimple structureWind motor with solar radiationWind energy with electric storageHigh energyFan blade

Owner:梅格菲

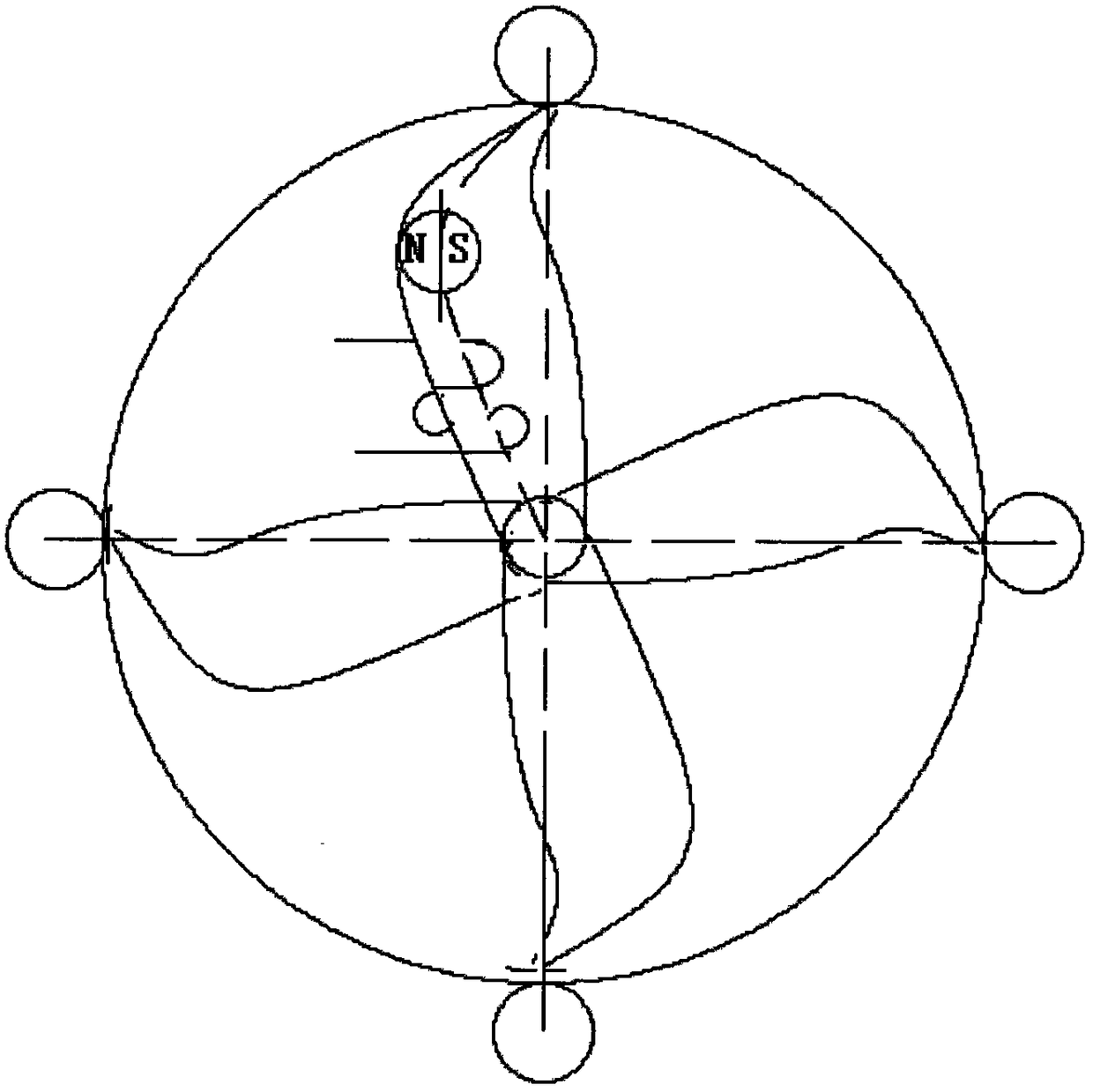

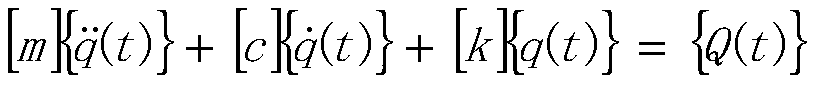

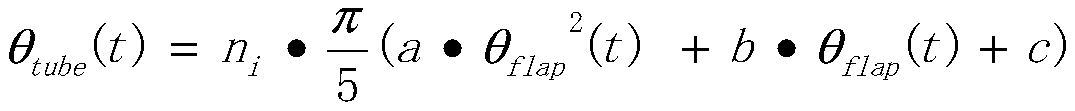

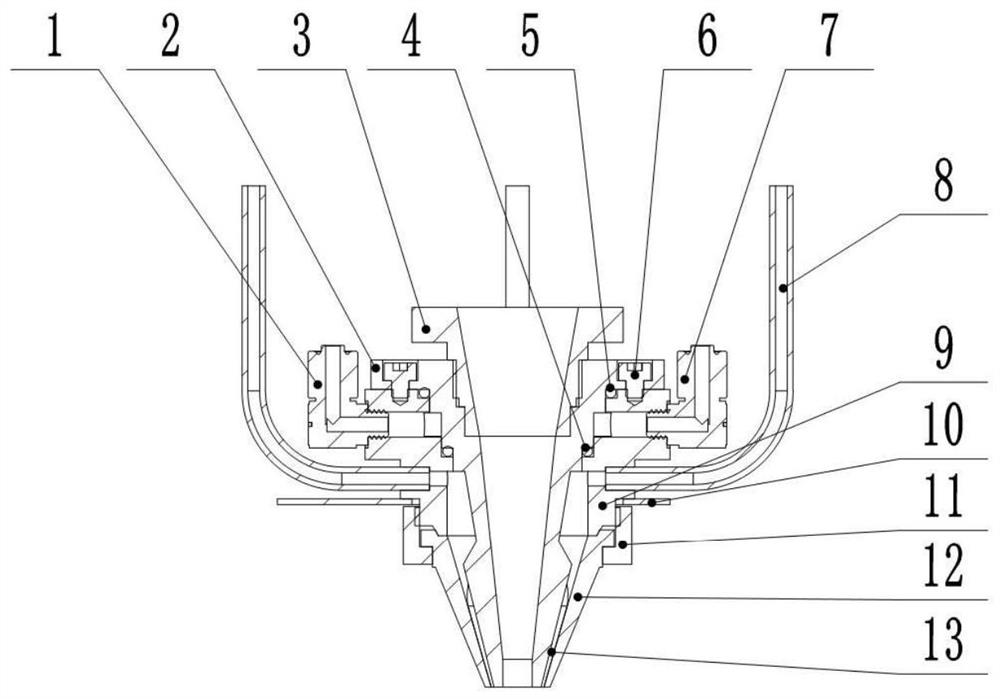

Dynamic modeling method for aircraft high-lift system

ActiveCN111143987ASolving Dynamics ProblemsLow costGeometric CADSustainable transportationDynamic modelsMathematical model

The invention discloses a dynamic modeling method for an aircraft high-lift system. The dynamic modeling method comprises the steps of: 1, calculating rigidity keq of all torque tubes between actuators; 2, establishing a mathematical model of a speed reducer in the transmission line system; 3, establishing a combined mathematical model of a composite mechanism between the transmission line systemand the high lift device; 4, calculating the rotational inertia of each composite mechanism and flap; and step 5, carrying out dynamic analysis by using a Lagrange method and the like. The dynamic model of the high-lift system is established, the dynamics problem in the development of the aircraft high-lift system is solved, an accurate fault mechanism can be provided for faults in an iron bird test, in the design of the high-lift system, the key problems of speed reducer protection threshold design, system fault load calculation and the like are solved, the development efficiency is improved,the cost of the high-lift system is greatly reduced, and the development bottleneck problem is solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Method for lowering parcel postage based on friendship

InactiveCN107742197ASolve the development bottleneckIncrease salesBuying/selling/leasing transactionsLogisticsViscosityComputer science

The invention discloses a method for lowering the parcel postage based friendship. On the basis of the current situation that the larger the weight of the cross-border parcel is, the lower the postageof unit weight on average is, obviously, the purpose of lowering the postage can be achieved by combining parcels, in order to encourage parcel combination, the service fee for paying collection parcels is extracted proportionally from the saved postage, if a member A knows the intention of a member B for parcel collection, while the member A shops, the member B can be appointed as a parcel receiver, if the member B wants to increase the income of the service fee of parcel collection, order capable of performing parcel combination can be collected by means of the friend group relations of themember B, finally, a friend group with the member B as the center is finally formed for parcel combination to lower the postage, the member B is responsible for receiving the parcels and distributingthe parcels to friends, the postage can be lowered, the development bottleneck existing for a long time on a cross-border distribution platform is solved, and shopping invitations can be sent to thefriends through the member B so as to increase the sales volume of the platform, improve commodity marketing and improve the viscosity among the members.

Owner:陈明烟

Foliage fertilizer based on marsh liquid in domestic marsh gas tank and preparation method thereof

InactiveCN102249775BSolve the development bottleneckPromote healthy developmentFertilizer mixturesMarshPotassium

The invention relates to a foliage fertilizer based on marsh liquid in a domestic marsh gas tank and a preparation method thereof. The foliage fertilizer based on marsh liquid in a domestic marsh gas tank is prepared from the following raw materials in parts by weight: 65-100 parts of marsh liquid and 1-3 parts of special nutrition bag for marsh liquid; and the special nutrition bag for marsh liquid is prepared from the following raw materials in parts by weight: 7-13 parts of nitrogen element, 2-5 parts of phosphorus element, 7-11 parts of potassium element, 2-6 parts of ferrum element, 3-6 parts of zinc element, 1-4 parts of manganese element, 0.5-1.5 parts of copper element, 1-2 parts of boron element and 1-2 parts of molybdenum element. The preparation method comprises the following steps: filtering the marsh liquid, preparing the special nutrition bag for marsh liquid, and mixing the marsh liquid with the special nutrition bag to obtain the marsh liquid foliage fertilizer. In theinvention, the marsh liquid stock solution is directly used as the main raw material of the foliage fertilizer without concentrating the marsh liquid; and the foliage fertilizer is especially applicable to domestic marsh gas tanks in scattered and separate households which prepare the marsh liquid when necessary.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

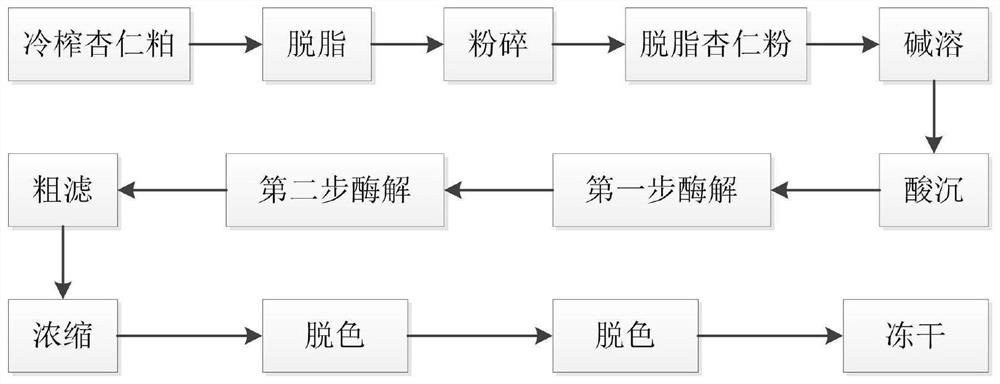

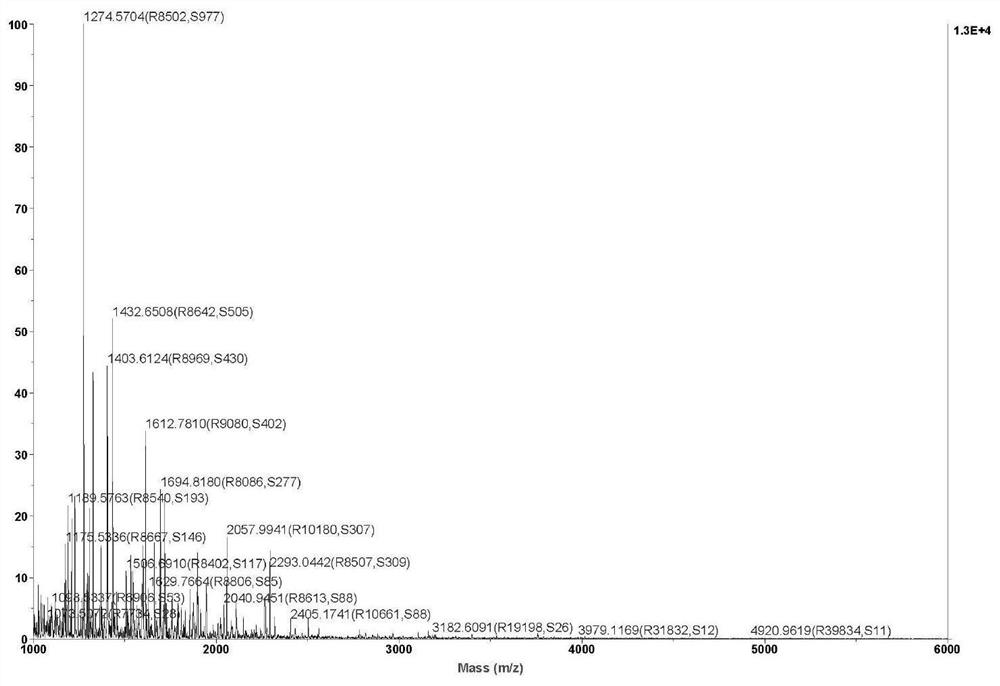

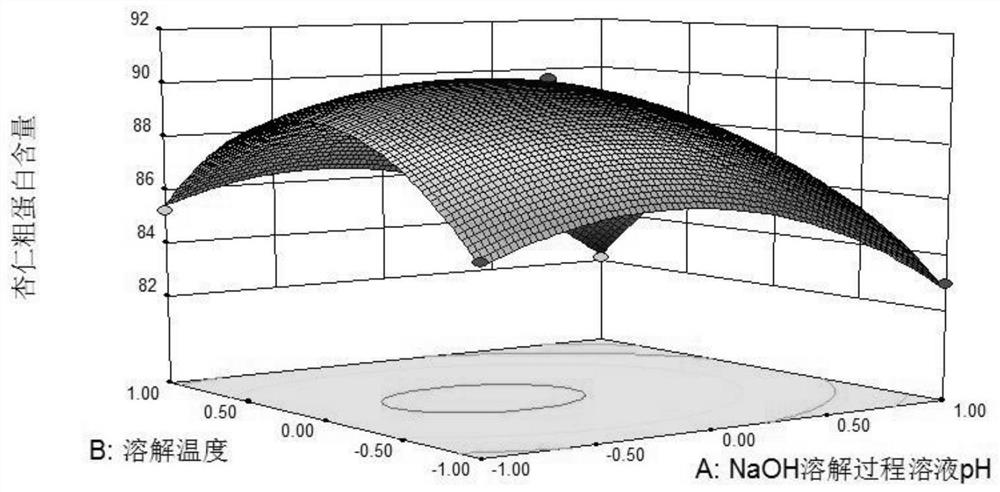

A method for preparing almond peptide from cold-pressed almond meal

InactiveCN110079574BImprove solubilityImprove functional propertiesPeptide preparation methodsFermentationEngineeringProtein processing

Owner:XINJIANG AGRI UNIV

LED and semiconductor laser chip suction and release device control method and device

InactiveCN114496892AIncrease delivery speedSorting speed is fastSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses an LED and semiconductor laser chip suction and release device control method and device, and relates to the technical field of mechanical equipment control, and the method comprises the following steps: S11, sucking a chip by a suction nozzle located at a suction position; s12, the suction nozzles located at the placement positions place the chips; and S13, the two suction nozzles swing by 180 degrees to exchange positions. According to the control method and device for the LED and semiconductor laser chip sucking and releasing device, the technical problem that in the prior art, the conveying speed of the LED and semiconductor laser chip is low is solved, and the sucking and releasing task of the chip can be rapidly completed; the sorting speed of the LED and the semiconductor laser chip can be effectively improved; and the device is simple in structure, compact and reasonable in layout and low in manufacturing cost, and is favorable for promoting the technical level and batch production capacity of the LED and semiconductor laser chip industry.

Owner:山东泓瑞光电科技有限公司

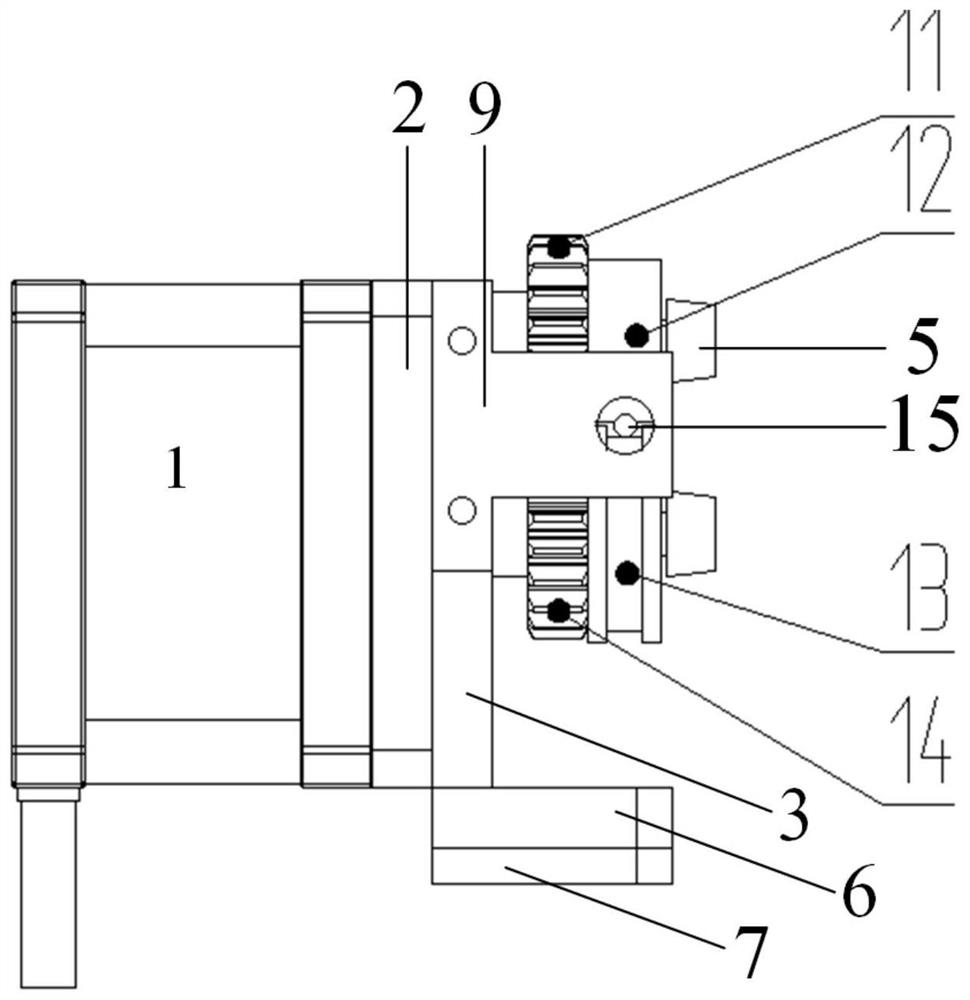

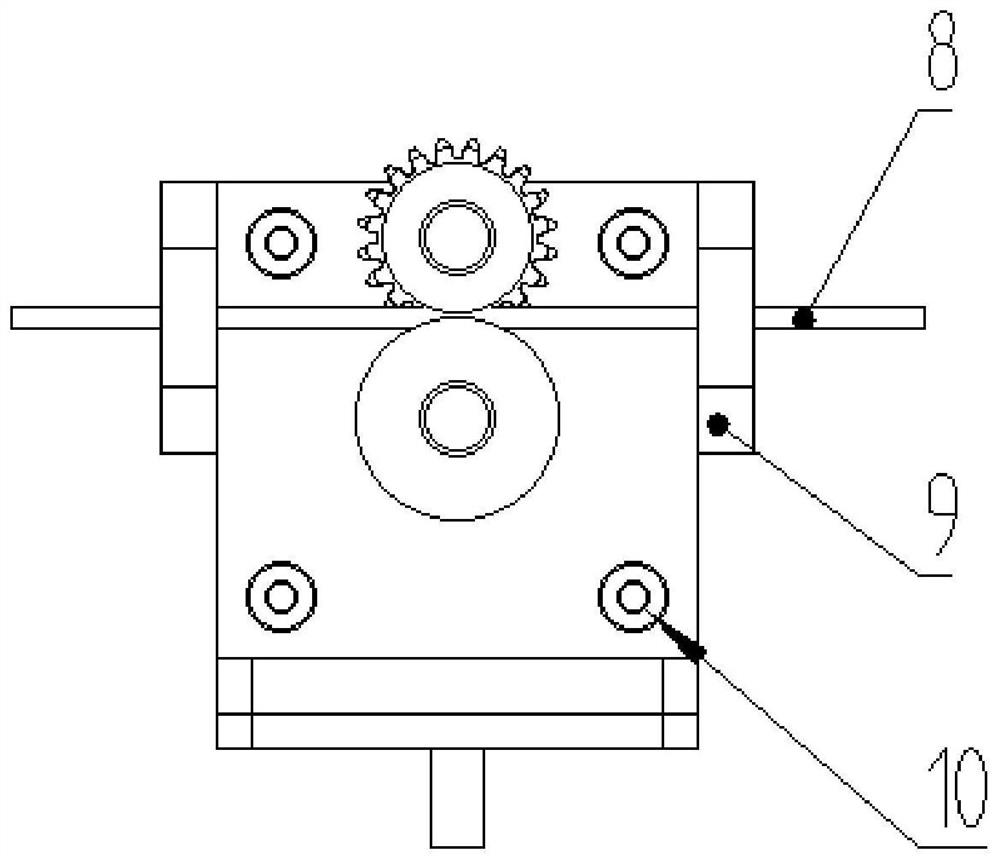

Laser cladding wire feeding device

InactiveCN112064009AReduce the probability of interferenceReduce volumeMetallic material coating processesDrive wheelGear wheel

The invention provides a laser cladding wire feeding device. The laser cladding wire feeding device comprises a motor, a motor installation flange, a driven wheel, a wire pressing wheel, a wire feeding wheel and a driving wheel, wherein the motor installation flange is installed on the motor; a motor shaft of the motor penetrates through the motor installation flange; a protruding shaft column isarranged on the motor installation flange; the driving wheel and the wire feeding wheel are coaxially installed on the motor shaft side by side and are driven by the motor shaft so as to rotate synchronously; the driven wheel and the wire pressing wheel are coaxially installed on the protruding shaft column side by side and rotate synchronously; the driven wheel and the driving wheel are in meshing transmission connection through a gear; and the driving wheel transmits rotation of the motor shaft to the driven wheel. The device provided by the invention is simple and clear in structure and easy to disassemble and assemble, the addition of the load of other mechanisms does not need to be considered during installation, the installation space of the whole mechanism is saved, the risks of metal wire bending and unsmooth wire feeding can be reduced, the wire feeding stability is improved, the wire replacement time is shortened, the production efficiency is improved, and the development ofthe laser cladding technology is promoted.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

A kind of processing method of banana leaf sheath

ActiveCN104842422BImprove toughnessGood colorReed/straw treatmentPlant material mechanical workingDried bananaPolyamide

The invention discloses a processing method for banana leaf sheaths. The method specifically includes the steps of: 1) raw material treatment: after banana harvesting, stripping banana leaf sheaths one by one, removing rotten and deteriorated leaf sheaths and other impurities; 2) water removal: remove water from the banana leaf sheaths obtained in step 1); 3) modification treatment: spraying a layer of modifier to the surfaces of the banana leaf sheaths obtained in step 2), with the modifier being a mixed water solution of urea formaldehyde resin and polyamide in a mass ratio of 1:1-2 and having a mass concentration of 0.1-0.5%, and performing standing; 4) drying: drying the banana leaf sheaths obtained in step 3); 5) bundling and warehousing: collecting the dry banana leaf sheath products obtained in step 4), stacking them neatly and bundling them together, concentrating the banana leaf sheaths, and then carrying out warehousing dry storage. The method provided by the invention employs the modifier composed of urea formaldehyde resin and polyamide to treat banana leaf sheaths and can increase the toughness and color of the banana leaf sheaths.

Owner:GUANGXI JIANMEILE FOOD

The formula and production process of making high-quality porcelain from inferior raw materials

ActiveCN104387020BShorten supply timeSolve the development bottleneckClaywaresKaolin clayPhysical chemistry

Owner:福建省德化县宏达陶瓷有限公司

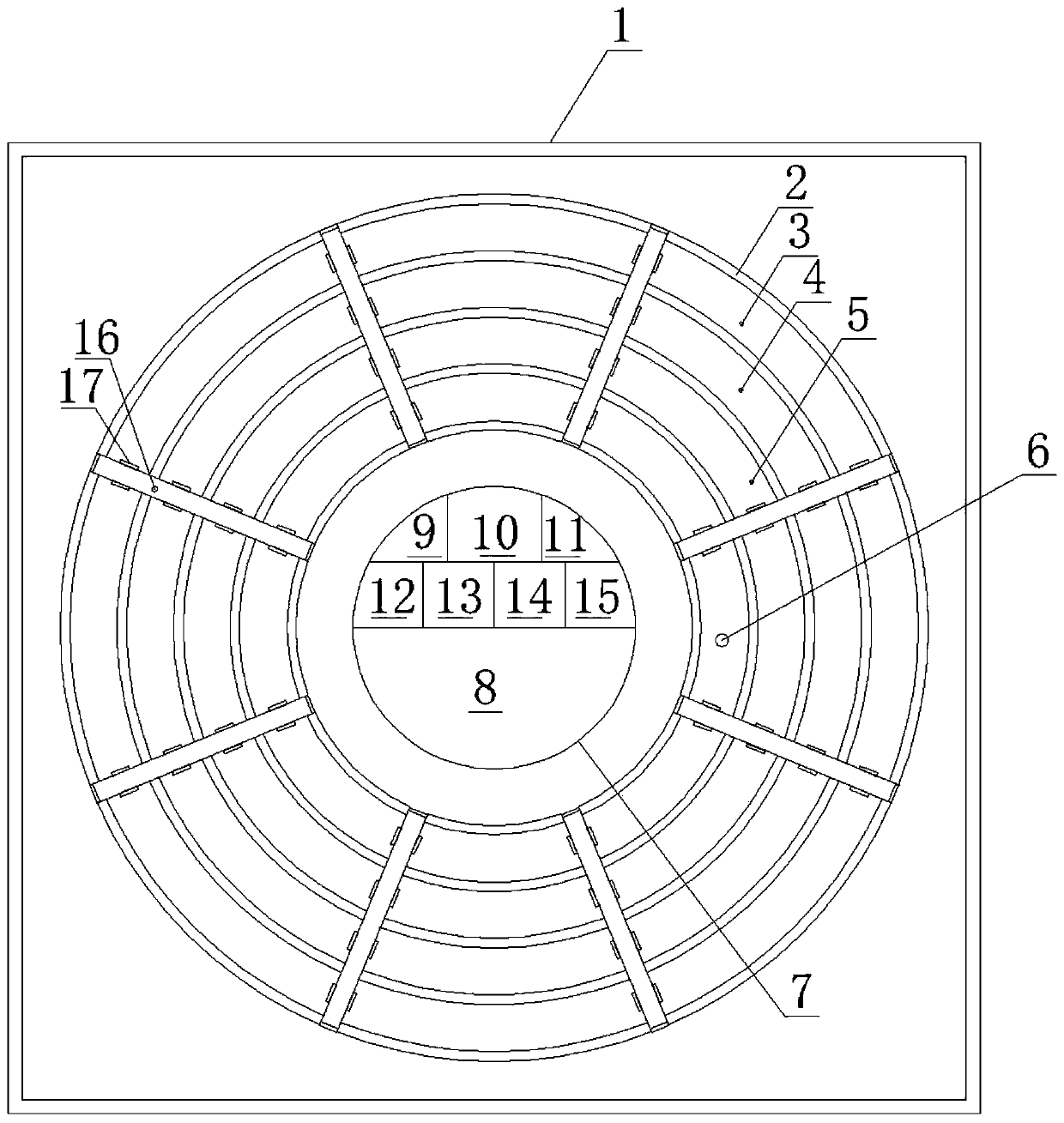

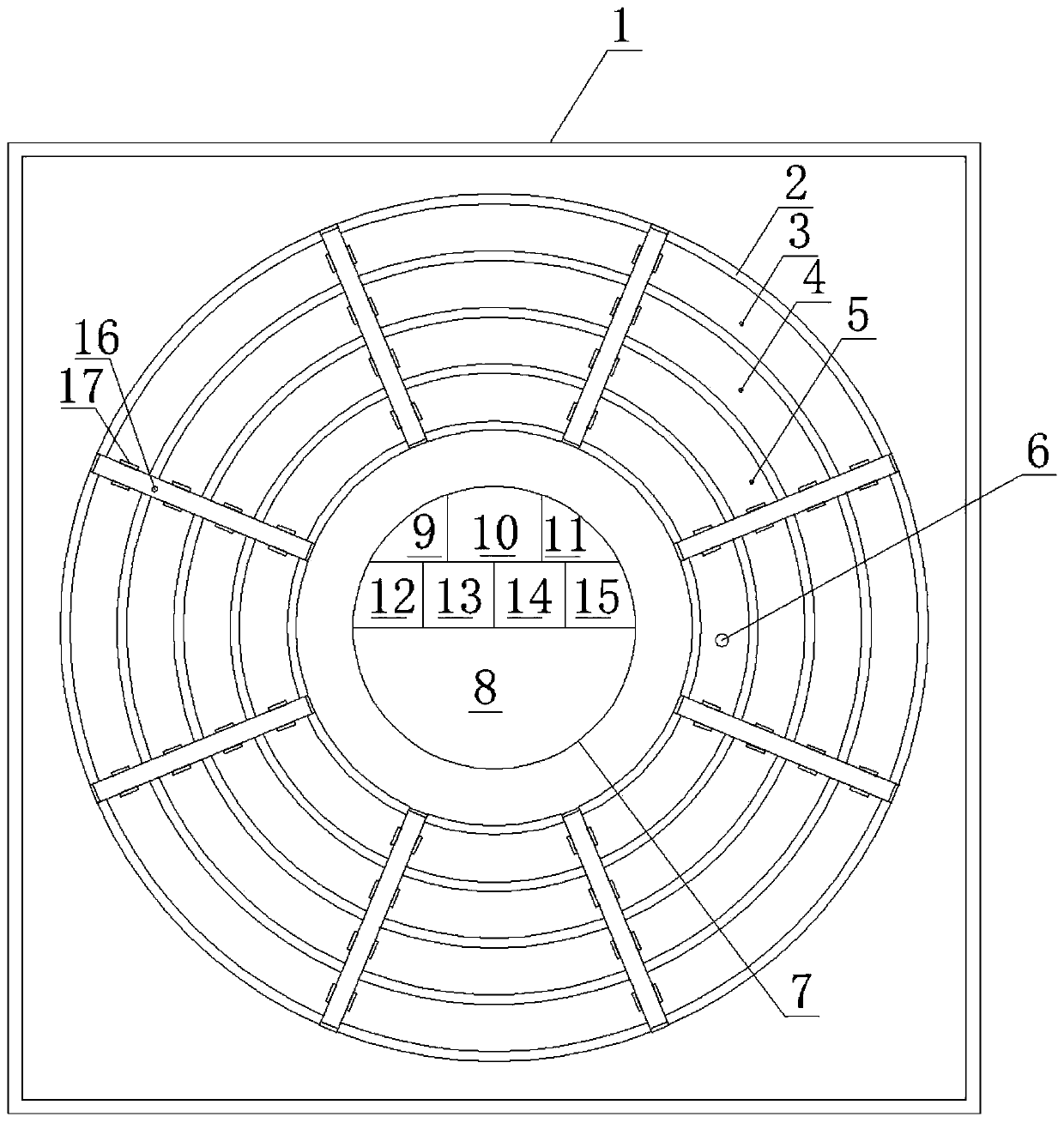

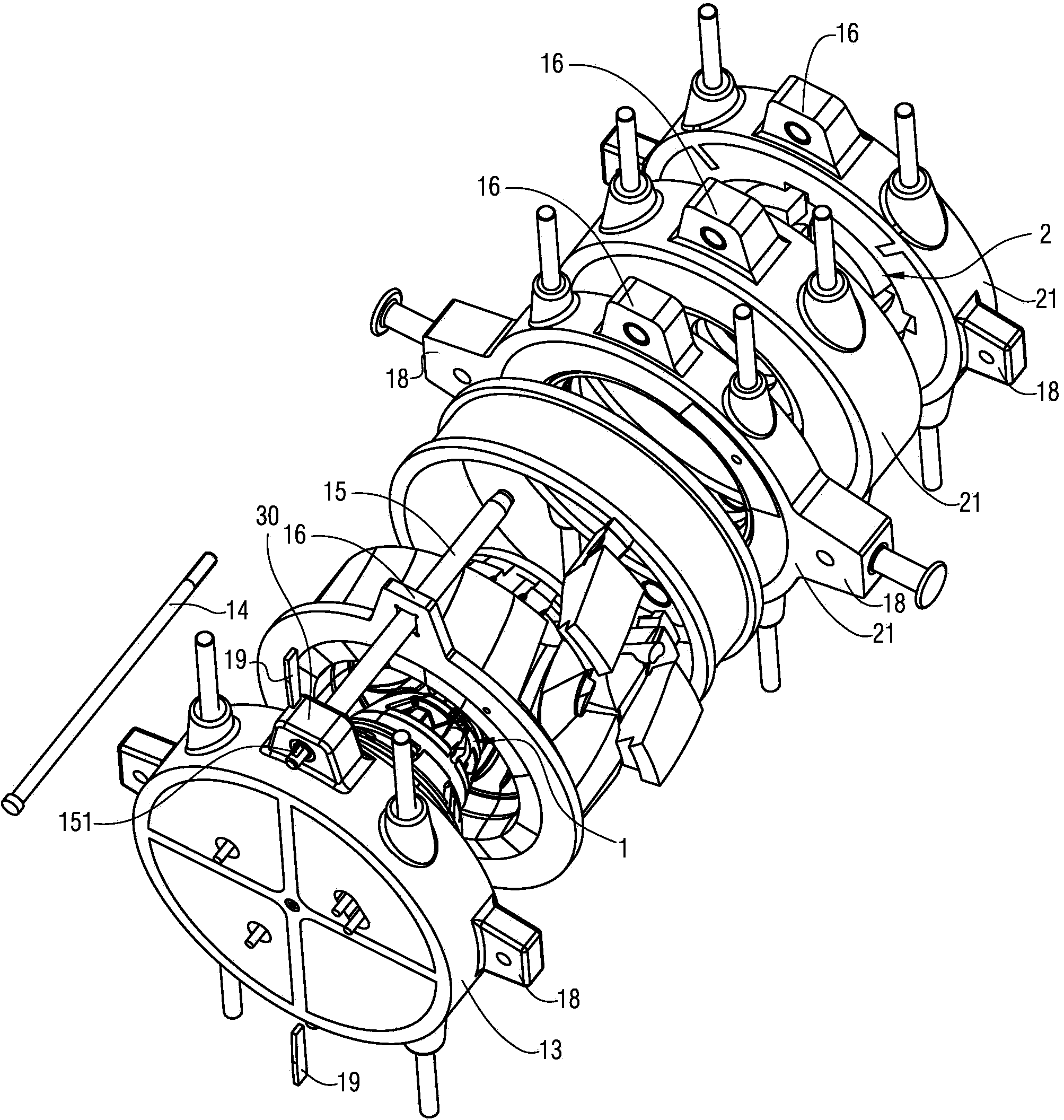

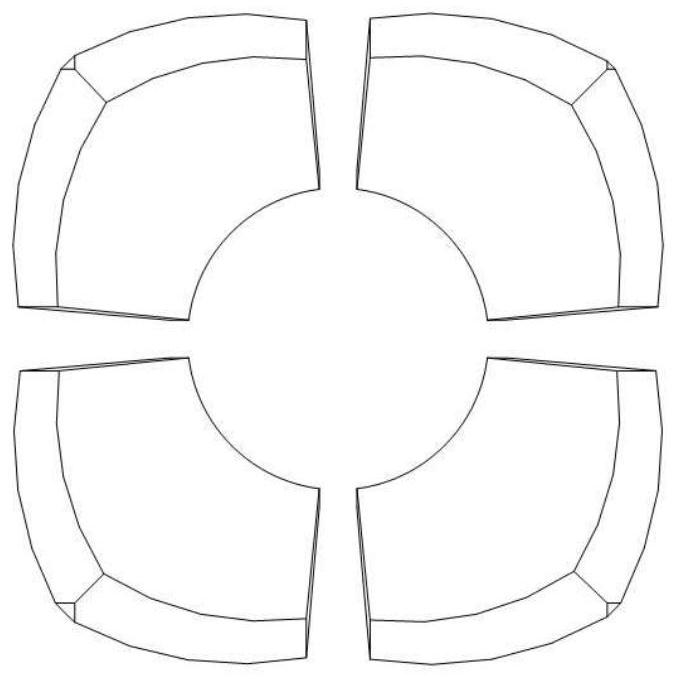

Coaxial annular multi-beam powder feeding nozzle

InactiveCN112030155AImprove fluencyIncrease profitMetallic material coating processesMixed flowStructural engineering

The invention provides a coaxial annular multi-beam powder feeding nozzle. The coaxial annular multi-beam powder feeding nozzle comprises a water filling connector, an inner core, a water dischargingconnector, a powder feeding pipe, a main body and a shell; the inner core is installed in the main body, the water filling connector and the water discharging connector are connected to the main body,and an annular water channel communicating with the water filling connector and the water discharging connector is formed between the main body and the inner core; the powder feeding pipe is connected to the main body, and an annular powder-gas mixed flow cavity communicating with the powder feeding pipe is formed between the main body and the inner core; and the shell is installed on the main body, and a powder spraying cavity communicating with the annular powder-gas mixed flow cavity is formed between the shell and the main body. According to the coaxial annular multi-beam powder feeding nozzle, by innovatively arranging a powder feeding nozzle structure, the utilization rate of powder and laser is increased, the powder feeding smoothness is improved, the powder blocking rate is reduced, the nozzle structure is simple and reliable, and the problem of the development bottleneck of existing coaxial laser cladding technology is solved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

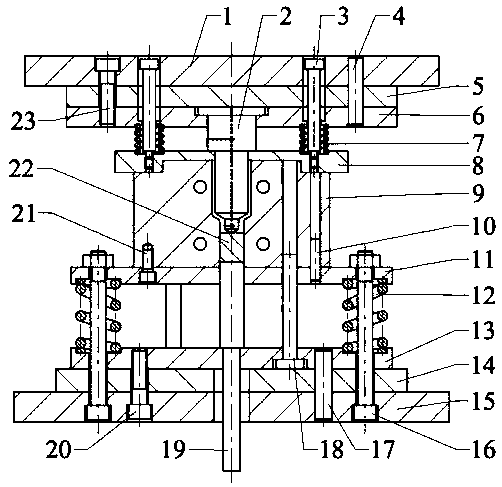

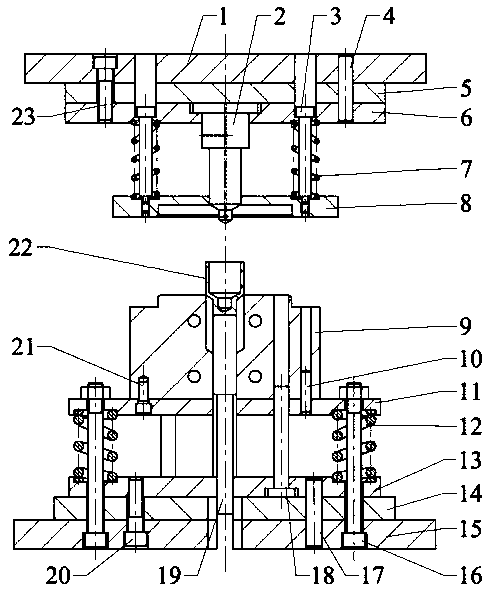

A kind of extruding die and method of corner expanding diameter by using bar material to prepare pipe

The invention discloses a corner diameter expanding extrusion die and method for preparing a tubular product by adopting a bar and belongs to the technical field of metal plastic working. The corner diameter expanding extrusion die comprises an upper mold plate, an extrusion core rod, an upper base plate, a core rod fixing plate, an unloading plate, a concave mold, a concave mold supporting plate,a spring, a convex mold supporting plate, a lower base plate, a lower mold plate, an inner guide pillar and an extrusion convex mold. The mold adopts the floating convex mold, and the front end of the extrusion core rod is of a cone-shaped structure, so that a material flows favorably and the extrusion force is reduced; axial extrusion, secondary corner extrusion and diameter expanding extrusiondeformation of the tubular product can be achieved by means of an extrusion channel formed by the extrusion core rod and the concave mold. The mold can achieve extruding, unloading and ejecting operations of the tubular product sequentially in one stroke, so that the extrusion die is high in production efficiency and suitable for batch preparation of superfine crystal tubular products, and can achieve industrial applications of a severe plastic deformation technique.

Owner:常熟市锡顺模具厂

A kind of processing method of banana leaf sheath for knitting handicraft

Owner:GUANGXI JIANMEILE FOOD

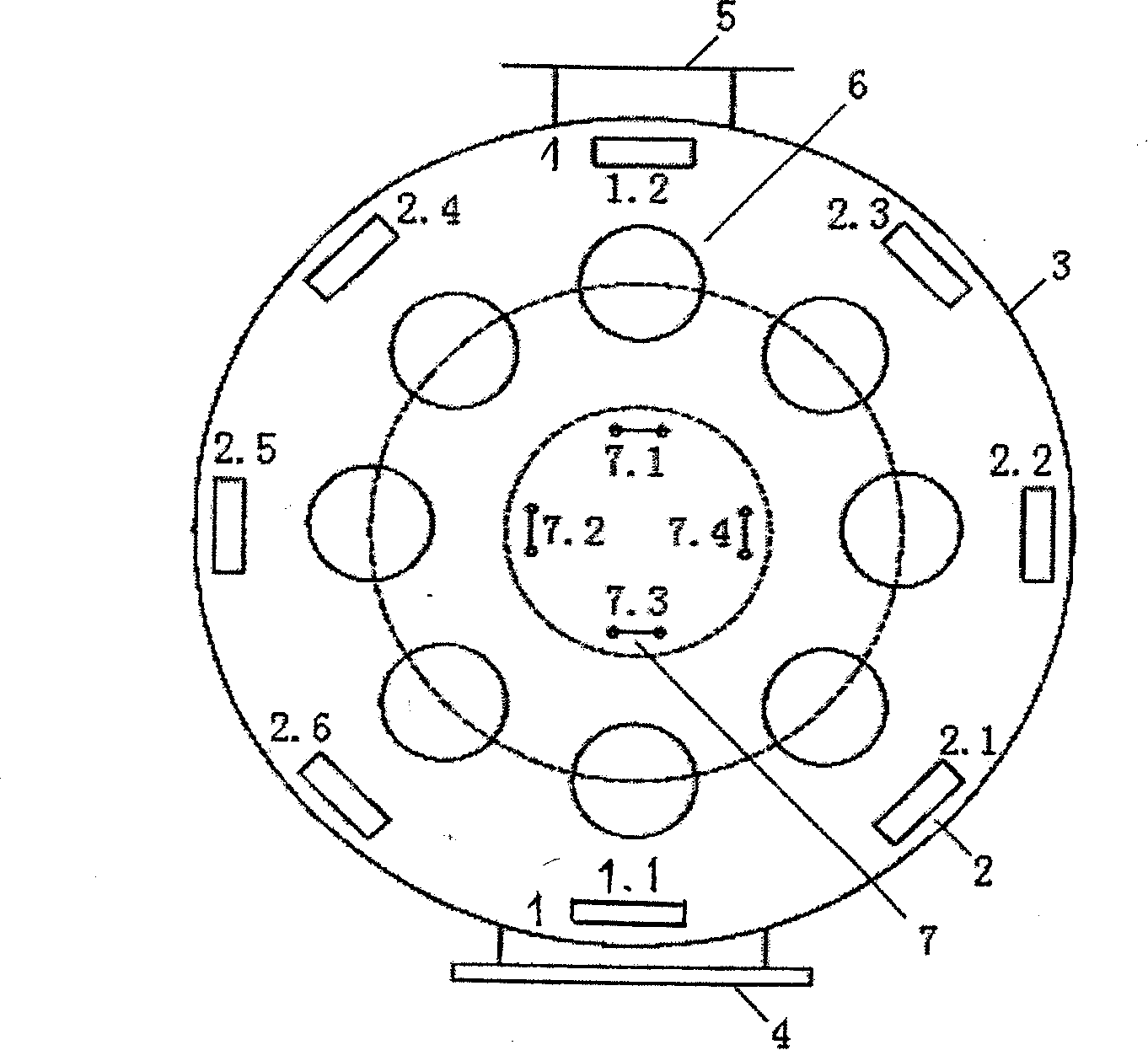

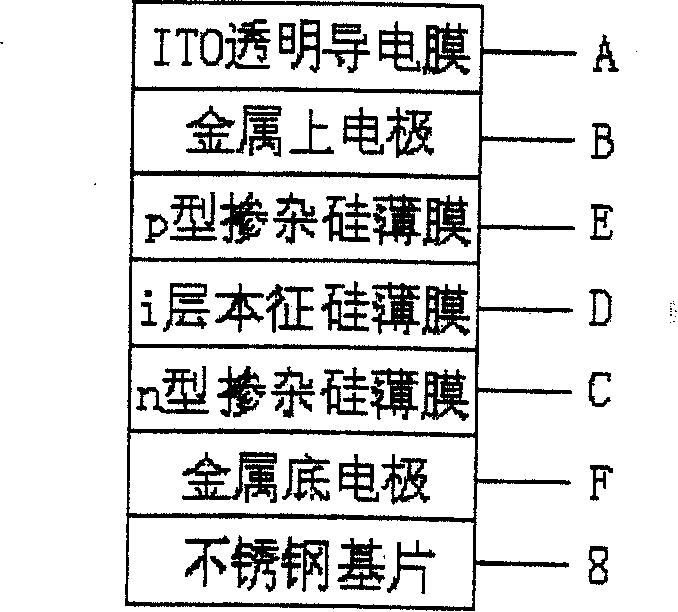

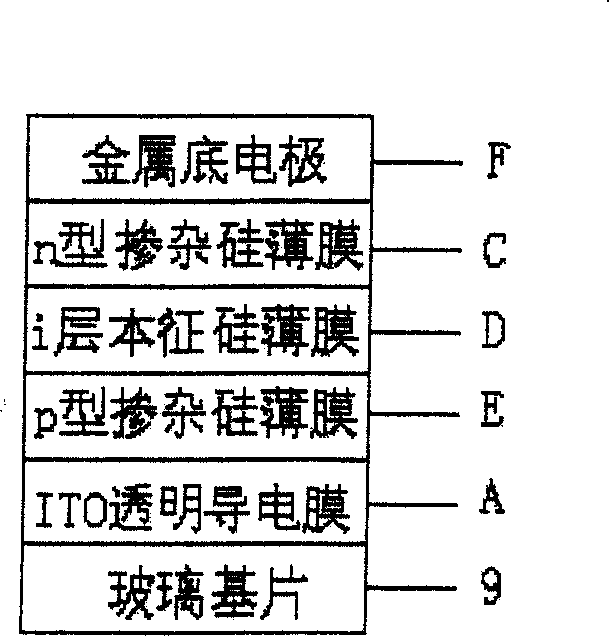

Physical vapor deposition device and method for Nano silicon-crystal thin film of solar battery

InactiveCN100385036CEliminate light decayHigh energy stateVacuum evaporation coatingSputtering coatingGas phaseSilicon solar cell

A physical evaporation deposition apparatus for preparing the nano-crystal silicon film of solar cell is based on the vacuum evaporation coating machine but has the physical evaporation deposit function. It method includes such steps as designing the figuration of vacuum evaporation coating machine, using ion beam method to deposit nano-crystal silicon film, and gas-phase doping to prepare the PIN structure of solar cell. Its advantage is high photoelectric conversion efficiency.

Owner:吴大维

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com