Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Solve easy yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

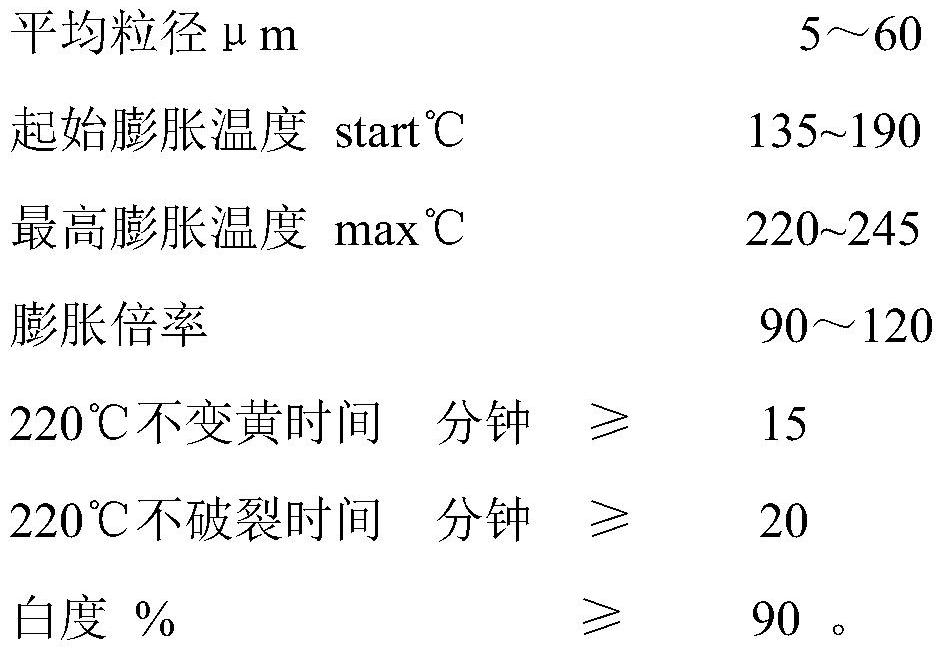

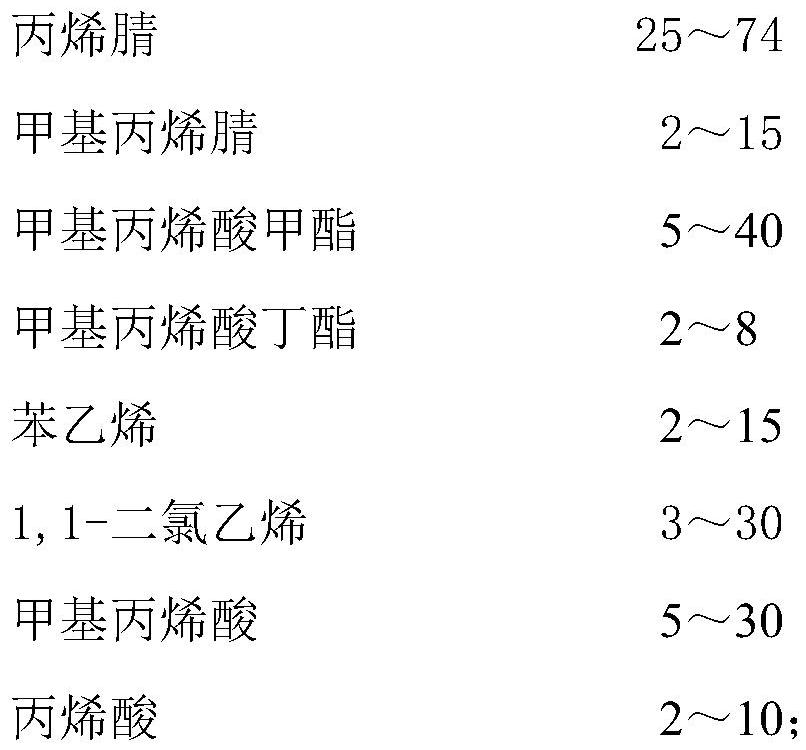

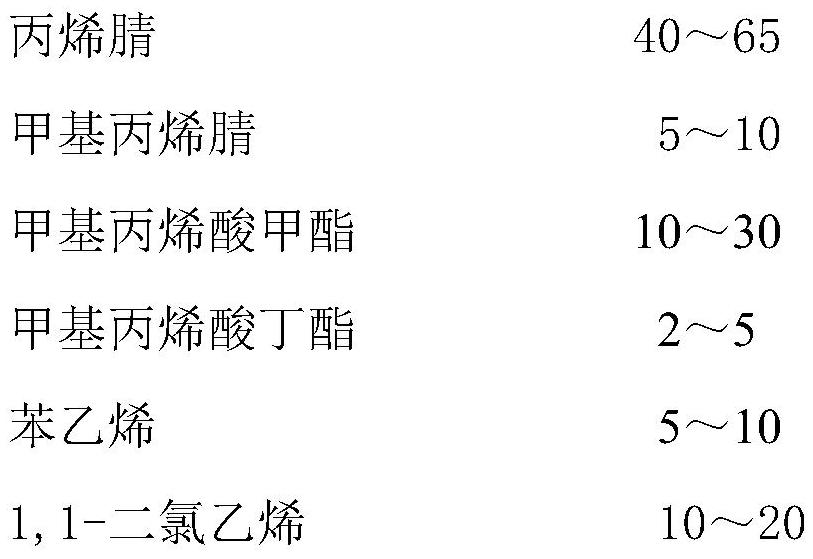

High-temperature expanded polymer microspheres and preparation method thereof

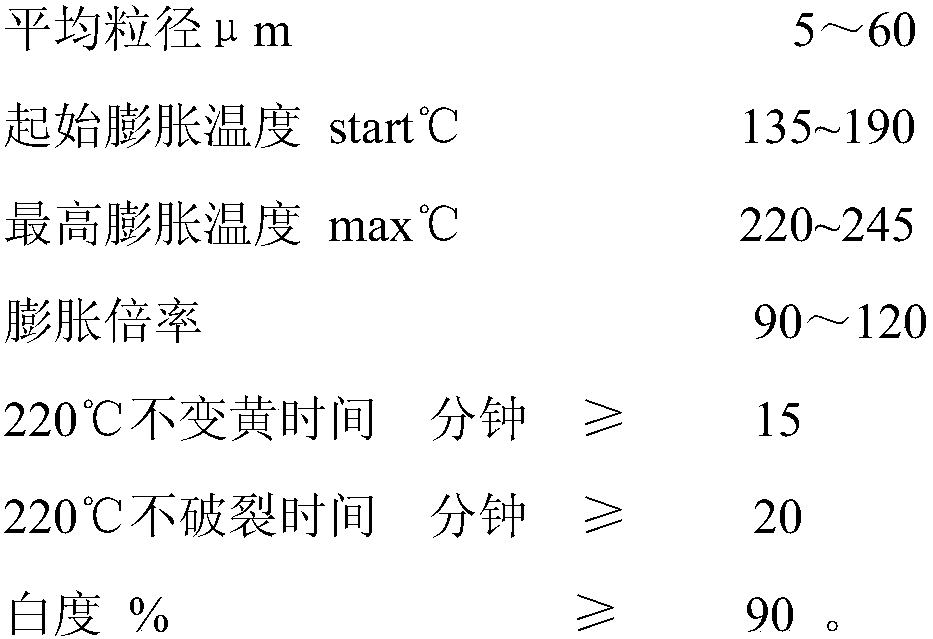

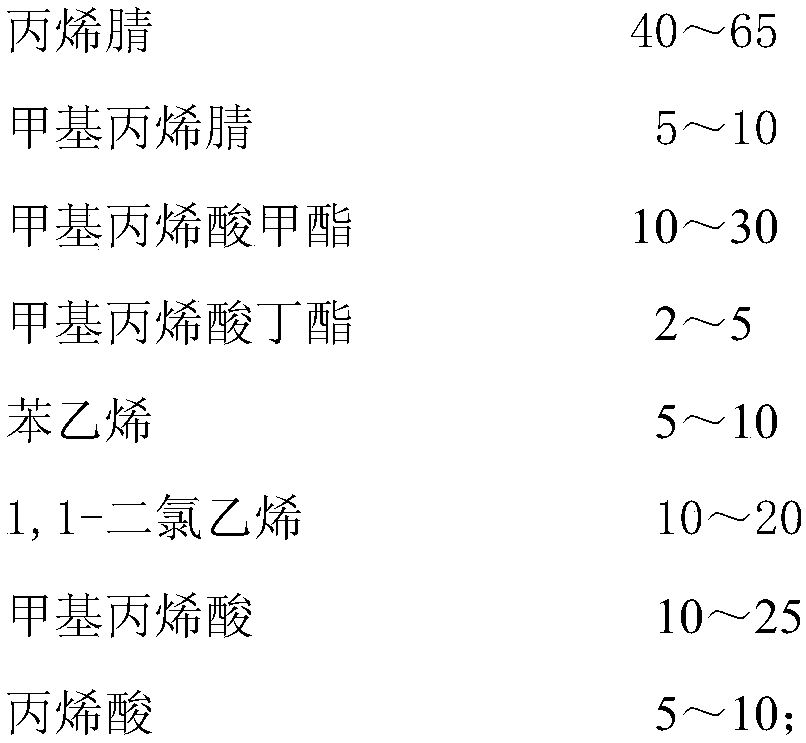

The invention provides high-temperature expanded polymer microspheres and a preparation method thereof and belongs to expandable particles. The high-temperature expanded polymer microspheres are prepared from a thermoplastic resin shell body and a foaming agent packaged in the shell body, wherein an oil-phase composition composed of a polymerizable monomer and a crosslinking agent can be dispersedinto a water-phase dispersed composition; in the presence of the foaming agent, the polymer microspheres coated with the foaming agent are directly prepared through carrying out suspension polymerization reaction and coating the foaming agent in situ; the high-temperature expanded polymer microspheres are characterized in that the oil-phase composition contains the polymerizable monomer and the crosslinking agent, and also comprises a silane coupling agent; the foaming agent is a mixture of isopentane, isooctane and n-octane; the high-temperature expanded polymer microspheres provided by theinvention have the advantages of complete core-shell structure, uniform grain diameter distribution, high foaming agent coating efficiency, good heat resistance of a shell-layer polymer, relatively high initial temperature in an expansion process, relatively high highest expansion temperature and high foaming ratio, have a relatively wide foam stabilizing temperature range, and are suitable for being applied to a thermoplastic resin, rubber or thermoplastic elastomer foaming and processing technology.

Owner:SHANDONG RUIFENG CHEM

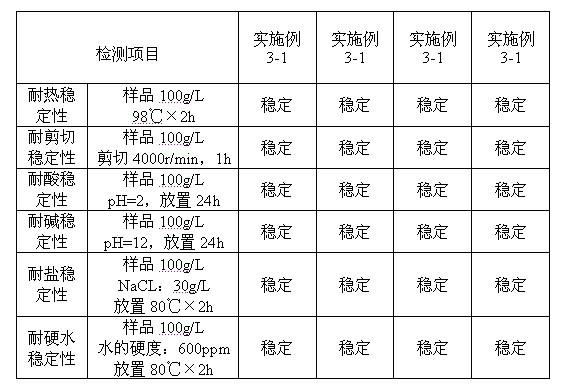

Supersoft hydrophilic block silicone oil compound and preparation method thereof

The invention relates to the field of textile finishing agent, in particular to supersoft hydrophilic block silicone oil compound and a preparation method thereof. The supersoft hydrophilic block silicone oil compound is composed of cations of the structural formula, wherein the n1 is the number of 5 to 10, the R is polyether group, and the degree of polymerization ranges from 3 to 50. The supersoft hydrophilic block silicone oil compound is applicable to handle finishing of fabric knitted by one or multiple fibers of cotton, dacron, chinlon and acrylic fibers and has softness, smoothness and looseness effects superior to those of amino-modified silicone oil, has excellent stability in acid and alkali resistance, electrolyte resistance, high temperature resistance, shearing resistance and the like and thoroughly solves the problems of easy demulsification, floating oil, roll banding, difficulty in refinishing and the like.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

Thermally-expandable polymer microsphere special for polyvinyl chloride resin foaming and preparation method thereof

The invention relates to a thermally-expandable polymer microsphere for polyvinyl chloride resin foaming and a preparation method thereof, and belongs to the field of expandable particles. The thermally-expandable polymer microsphere consists of a thermoplastic resin shell and a foaming agent encapsulated in the shell; an oil phase composition composed of a polymerizable monomer and a crosslinkingagent is dispersed in an aqueous phase dispersion composition; and in the presence of the foaming agent, the foaming agent is coated in situ through a suspension polymerization reaction to directly prepare the polymer microsphere coated with the foaming agent. The thermally-expandable polymer microsphere is characterized in that the oil phase composition comprises a silane coupling agent in addition to the polymerizable monomer and the crosslinking agent, and the foaming agent is a mixture of isopentane, isooctane and n-octane. The invention provides a thermally-expandable polymer microspherewhich has the advantages of complete core-shell structure, uniform particle size distribution, high foaming agent coating efficiency, good heat resistance of a shell polymer, high initial temperatureduring expansion, high maximum expansion temperature, high foaming ratio, and wide foam stabilizing temperature range, and is special for foaming polyvinyl chloride resin.

Owner:SHANDONG RUIFENG CHEM

Method for preparing super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer

ActiveCN104072783AGood self-emulsifying performanceImprove hydrophilicityVegetal fibresAcetic acidOrganic solvent

The invention relates to the field of a textile finishing agent, and particularly relates to a method for preparing a super-smooth hydrophilic quaternary ammonium salt-modified organic silicon copolymer. The method comprises the following steps: synthesizing a cationic modified polyether amine intermediate by using aliphatic polyether diamine and an alkylating agent under the action of an acid catalyst; carrying out addition polymerization of amino and an epoxy group on the cationic modified polyether amine intermediate and terminated epoxy polyether silicone oil in the presence of an organic solvent, then adding a glacial acetic acid, and synthesizing ternary block silicon oil. The super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer prepared by the method provides excellent hydrophilic performance to cotton fabric, and has an outstanding smooth effect, and the smoothness can achieve the level of common amino silicon oil, and is superior to that of most of ternary block silicon oil. The super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer has certain antibacterial and antistatic functions by improvement of the cationization degree, meanwhile, the problem that amino is easy to yellow in a high-temperature condition can be effectively solved, and the processed fabric is small in yellowing, and applicable to finishing of white or light fabric.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

Ice feeling finishing agent and preparation method thereof

The invention belongs to the technical field of printing and dyeing auxiliaries, particularly relates to an ice feeling finishing agent and a preparation method thereof. The ice feeling finishing agent mainly comprises raw silicone oil, an emulgator, a cosolvent, glacial acetic acid and water, wherein the raw silicone oil is prepared by adding 99-99.5% of silicone oil, 0.01-0.9% of a silane coupling agent and 0.01-0.1% of a catalyst into a reaction kettle for reaction. According to the ice feeling finishing agent and the preparation method thereof, provided by the invention, primary amine or / and secondary amine is / are introduced onto the molecular chain of silicone oil, therefore the hydrophilic performance of the overall molecular structure is improved, fabric subjected to finishing of the finishing agent has air-permeating, moisture permeating, moisture-absorbing and sweat releasing functions, at the same time can maintain a certain humidity, and enables people to have a feeling of comfortableness and coldness after wearing the clothes subjected to finishing; besides, the ice feeling finishing agent has excellent stability, thoroughly overcomes the defects that the conventional amino silicon oil is prone to demulsification, floating and roll sticking, can easily produce oil spots, and is not easy to repair.

Owner:珠海华大浩宏新材料有限公司

Preparation method of titanium dioxide for printing ink

InactiveCN104477989ASolve the effect of whitenessSolve easy yellowingTitanium dioxideChemistryTitanium dioxide

The invention discloses a preparation method of titanium dioxide for printing ink. The preparation method comprises the following steps of a, calcining metatitanic acid squeezed filter cake subjected to treatment at a temperature of more than 900 DEG C to obtain a titanium dioxide crude product, and preparing TiO2 slurry, b, feeding steam into the TiO2 slurry, and adding an aluminum-containing compound into the TiO2 slurry, c, adjusting slurry pH to 4-8 and keeping the pH, d, carrying out curing for 10-30min, e, carrying out filtration to remove soluble salt, carrying out drying and carrying out heat treatment, and f, carrying out air-flow crushing and simultaneously, adding an organic surface conditioning agent into the titanium dioxide to obtain a finished product. Compared with the prior art, the titanium dioxide obtained by the preparation method does not yellow easily, has good weatherability and heat resistance, and has high luster, high tinting strength, high masking performances, low wear resistance, excellent dispersibility and excellent granule size distribution in a solvent system and an aqueous system.

Owner:NINGBO XINFU TITANIUM DIOXIDE

High-covering black UV silkscreen printing ink

The invention discloses a high-covering black UV silkscreen printing ink. A preparation method for the high-covering black UV silkscreen printing ink comprises the following steps: preheating acrylate and then mixing the preheated acrylate with a part of active monomer; then adding a dispersant and carrying out primary dispersion; then successively adding pigment and a filling material and carrying out secondary dispersion; carrying out grinding to obtain color paste; mixing a phosphine oxide photoinitiator with residual active monomer; and adding the color paste, an organosilicon antifoaming agent and an organosilicon leveling agent and carrying out uniform dispersion so as to obtain the high-covering black UV silkscreen printing ink. The high-covering black UV silkscreen printing ink provided by the invention is reasonable in composition; all the components are in good compatibility; and the prepared printing ink has excellent comprehensive properties and good storage performance, and the viscosity of the printing ink is suitable for silkscreen printing. The printing ink does not need increase in the usage amounts of components like carbon black, prevents unfavorable influence of the components on the appearance and light shading performance of a product, and can meet light shading requirements of the product after only one printing and under the condition of a thickness of 7 to 8 micrometers, so unexpected technical effects are obtained.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

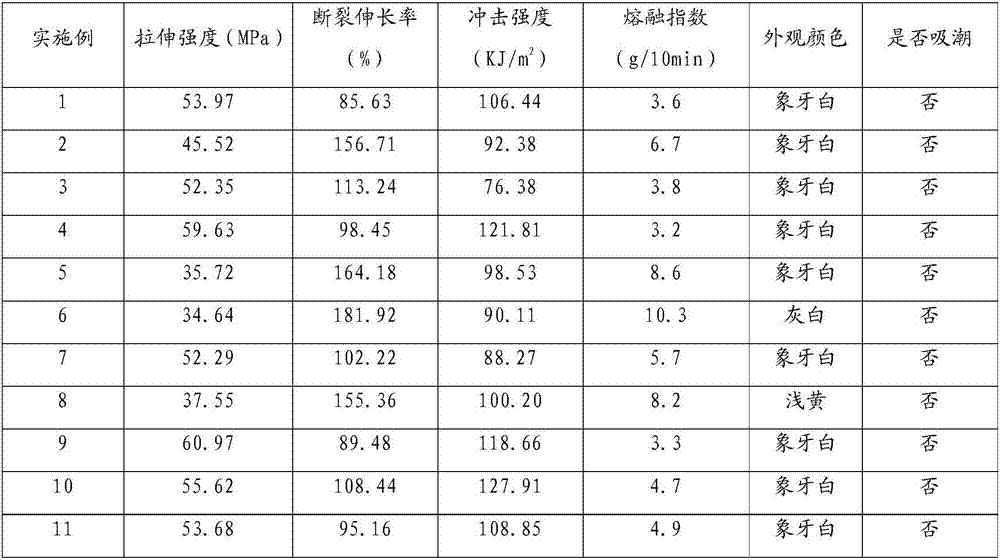

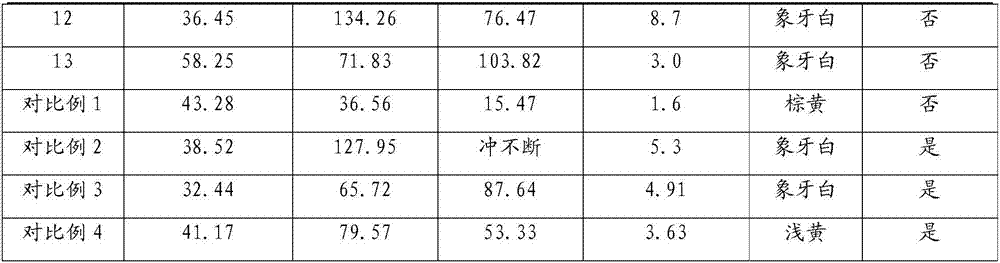

Highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition and preparation method thereof

ActiveCN109206829ASolve easy yellowingExcellent resistance to precipitationProcedure AgentsPolyolefin

The invention discloses a highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition and a preparation method thereof. The highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition comprises the following raw material components by mass percentage: 15-30% a styrene-based thermoplastic elastomer, 10 to 25% of polyolefin resin, 15 to 25% of a plasticizer, 10 to 20% of a char forming agent, 15 to 30% of a phosphorus-nitrogen flame retardant, 0.5 to 3% of a flame retardant synergist, 0.1 to 1% of an anti-oxygen agent, 0.1 to 1% of an anti-aging agent and 0.1 to 1% of a processing aid. Through high char forming property of crosslinked polystyrene powder, a triazine char forming agent is compounded, the triazine char forming agent replaces traditional polyphenylene ether to act as the char forming agent of the thermoplastic elastomer TPE, and the highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition has good flame retardant property and physical property, solves the problem that use of the polyphenylene ether is liable to cause yellowing, hasexcellent UV resistance, and can pass anti-precipitation tests with higher requirements.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

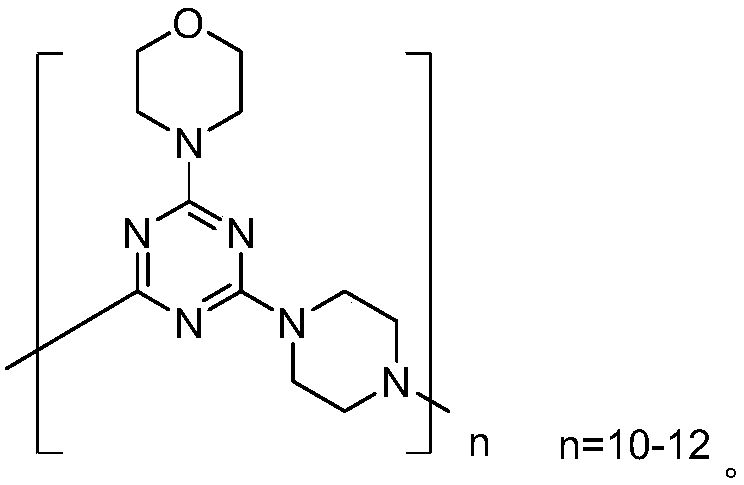

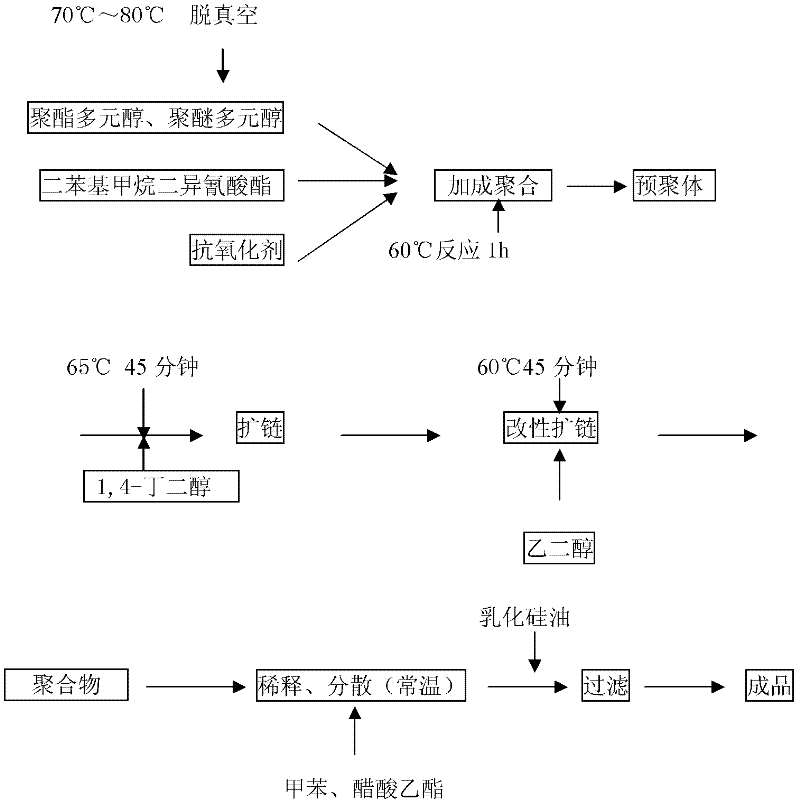

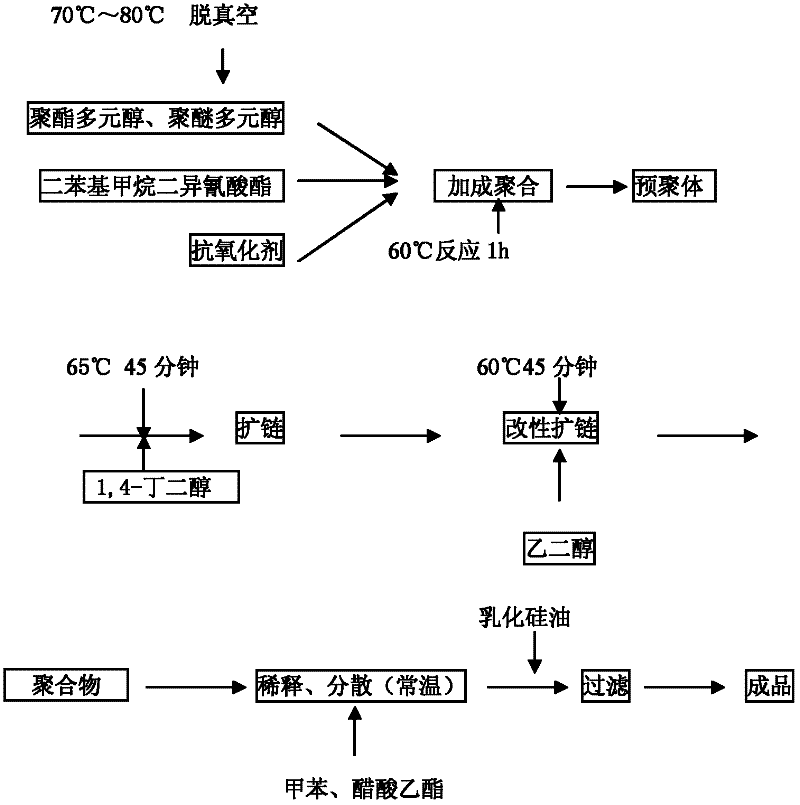

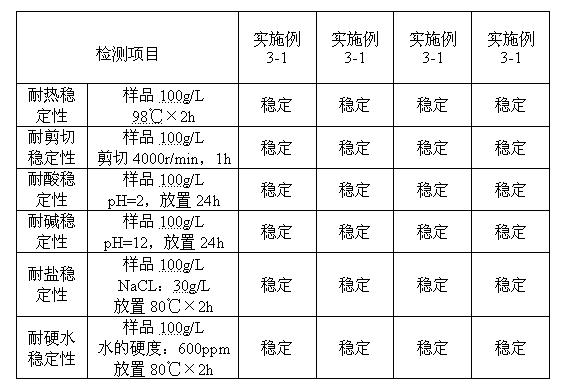

Crystal oil slippery resin used for synthetic leather and preparation method thereof

InactiveCN102604037AIncrease the relative molecular massImprove performanceFibre treatmentPolyesterAntioxidant

The invention relates to a crystal oil slippery resin used for synthetic leathers and a preparation method thereof. The crystal oil slippery resin is prepared from the following raw materials in parts by weight: 35-50 parts of dimethylformamide, 8-15 parts of polyether polyol, 4-8 parts of polyester polyol, 10-30 parts of methylene diphenyl diisocyanate, 0.5-1.8 parts of 1,4-butanediol, 3-6 parts of glycol, 10-20 parts of toluene, 10-20 parts of ethyl acetate, 3-5 parts of emulsified silicone oil and 0.01-0.03 part of antioxidant. Compared with the prior art, the crystal oil slippery resin disclosed by the invention has the beneficial effects that the crystal oil slippery resin can not only overcome the defects that oleoresin is tacky, poor in temperature resistance and the like, but also has the advantages of high temperature resistance, folding resistance, ageing resistance and the like. The crystal oil slippery resin used for the synthetic leathers is simple in process, convenient to produce and low in cost and can be directly applied to the posterior production procedure of the synthetic leathers; and third edition printing or spray coating can be adopted for the process.

Owner:建德市顺发化工助剂有限公司

Preparation method of pollen-containing antioxidant softener

InactiveCN105714554ASimple preparation stepsGood flexibilityGrip property fibresWater bathsAntioxidant

The invention discloses a preparation method of pollen anti-oxidation softener, which belongs to the technical field of softener preparation. The invention collects fresh rapeseed flower pollen, grinds and sieves it, mixes it with ethanol solution, heats it in a water bath, and suction-filters it to obtain a filtrate, concentrates it and extracts it with petroleum ether, distills and concentrates it to obtain a pollen antioxidant liquid, mixes it with chloroacetic acid, etc., and heats it in a water bath, and filters The obtained filtrate is mixed with alkylphenol polyoxyethylene ether and deionized water, heated in a water bath, methanol is added dropwise, heated in an oil bath, cooled, and ultrasonically dispersed to prepare a pollen antioxidant softener. The beneficial effects of the present invention are: the preparation steps of the present invention are simple, the obtained product has good softness and biodegradability, and the durability is improved by more than 18.2%; the pollen anti-oxidation liquid prepared by using rape flower pollen can effectively solve the problem of easy yellowing after use The problem.

Owner:CHANGZHOU OPTICAL MATERIAL

Preparation method of high-temperature-resistant alkali type amino silicon oil emulsion

The invention belongs to the field of amino silicon oil, and discloses a preparation method of a high-temperature-resistant alkali type amino silicon oil emulsion, which comprises the following steps:S1, preparing 40-50 parts of amino silicon oil, 10-20 parts of an emulsifier, 35-40 parts of deionized water, 5-10 parts of a glycerol additive and 3-6 parts of trifluoromethyl maleic anhydride for later use; S2, adding an emulsifier into the high-shear emulsifying kettle, and starting to stir. According to the invention, trifluoromethyl maleic anhydride can be amidated with amino silicone oil, amino active hydrogen in the amino silicon oil structure is reduced and carboxyl is increased; therefore, the effect of reducing emulsion yellowing is achieved; the high temperature resistance and thealkali resistance of the amino silicon oil emulsion are improved; meanwhile, the emulsifier can improve the surface tension among various constituent phases in the emulsion, so that a uniform and stable dispersion system or emulsion substance is formed, the amino silicone oil emulsion has excellent stability, and the problems that the traditional amino silicone oil emulsion is easy to yellow and demulsify and poor in high-temperature resistance and alkali resistance are solved.

Owner:常州市宁河新材料科技有限公司

Glue capable of being used for bonding glass and metal and preparation method of glue

ActiveCN112831296ASolve easy yellowingImprove patienceNon-macromolecular adhesive additivesMacromolecular adhesive additivesIsocyanateAdhesive glue

The invention provides glue capable of being used for bonding glass and metal and a preparation method of the glue. The glue is prepared from main body resin, auxiliary resin, a dissolving medium and a functional auxiliary agent. Hydroxyl modified acrylic resin is taken as a main body, the polyester resin is taken as an auxiliary body, tackifying resin is added, and an isocyanate closed curing agent is combined for reaction, so that the prepared glue solves the defect that existing glue in the industry is easy to yellow under the condition of a heat transfer process, and the integrity, the material application range, the initial adhesion, the adhesion resistance and the like of the product are improved; and the glue has potential application value in the heat transfer printing industry.

Owner:东莞市迪奥顺水性涂料有限公司

A super soft silicone oil finishing agent

The invention relates to the textile finishing agent field, in particular to a super-soft finishing agent of silicone oil. The super soft finishing agent of the silicone oil comprises a silicone oil compound with the following cation structural formula as followed. The silicone oil compound occupies a weight percentage of 2%-60% in the finishing agent, the n1 is 5-10, the R is a polyether group, and a polymerization degree is 3-50. The super soft finishing agent of the silicone oil is suitable for feel finishing of one or more fiber constituted fabric such as cotton, Dacron, chinlon and acrylic fibers, and provided with better soft, smooth and fluffy effects than amino-modified silicone oil and excellent stability in resistance to acid and alkali, electrolyte, high temperature, shearing and the like; and problems of easy demulsification, floating oil, roll banding, difficult rework and the like in the existing amino-modified silicone oil are completely solved.

Owner:NINGBO RUNHE HIGH TECH MATERIAL CO LTD

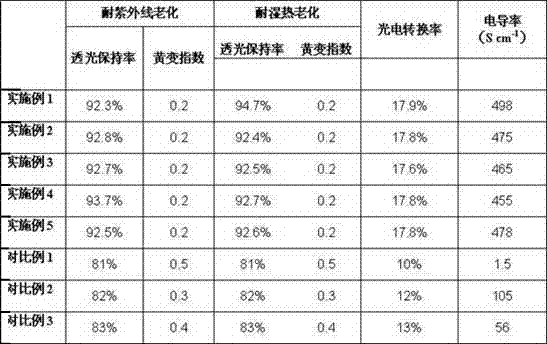

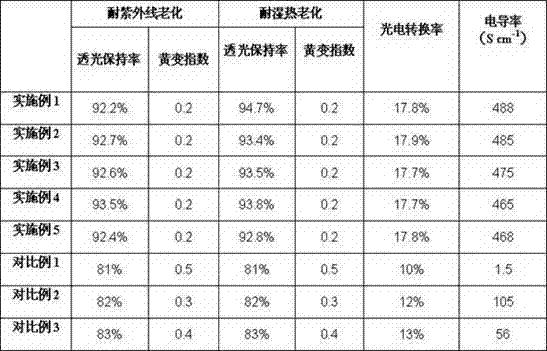

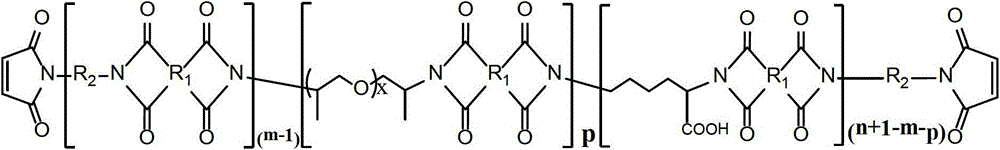

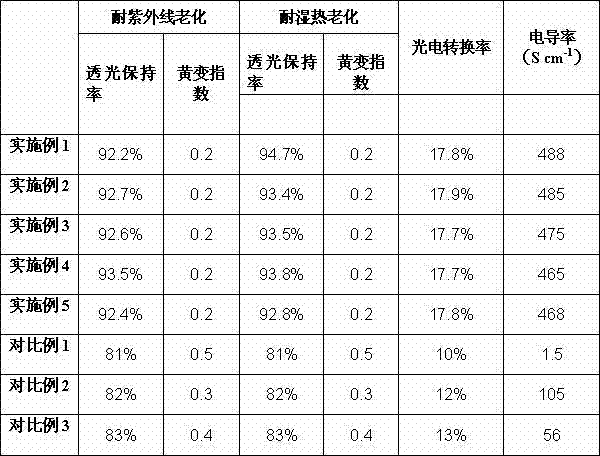

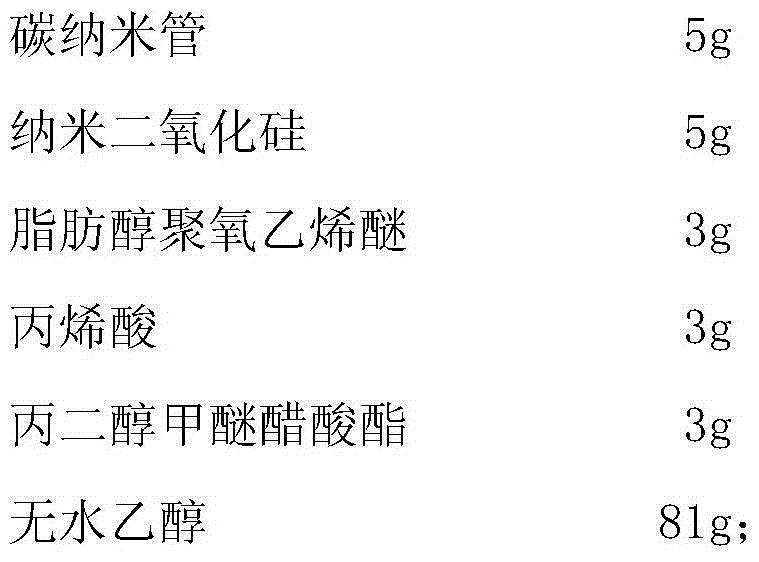

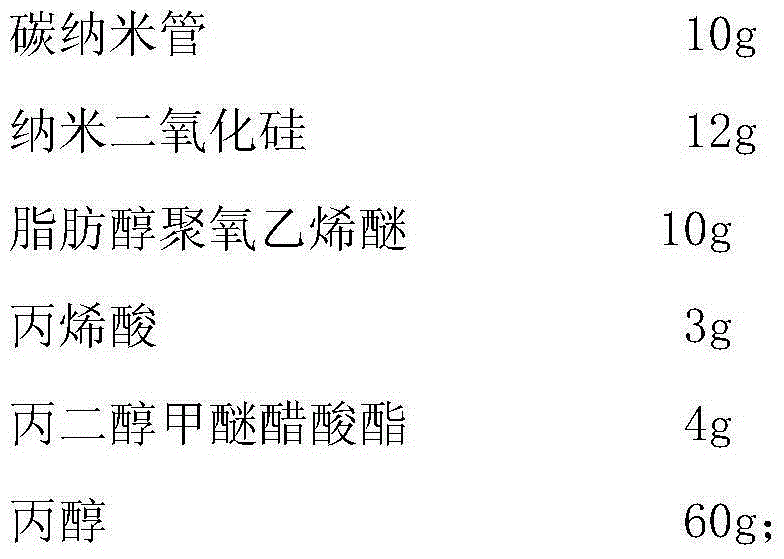

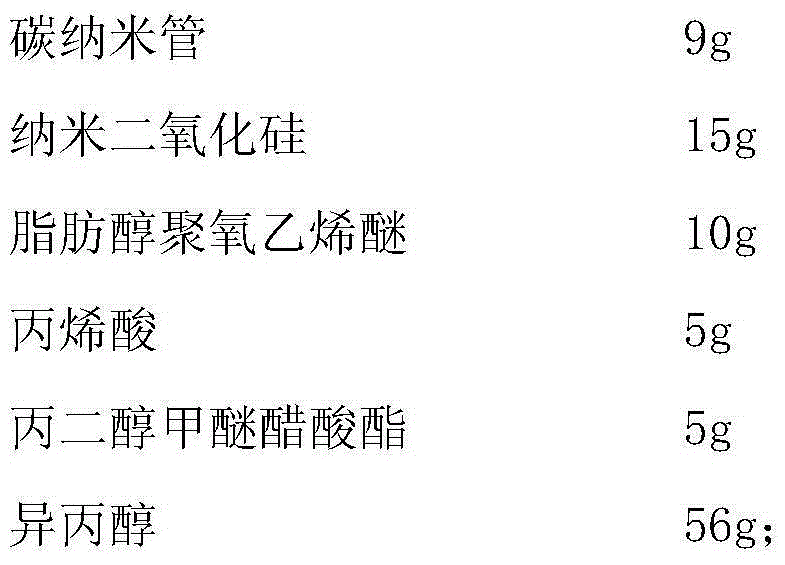

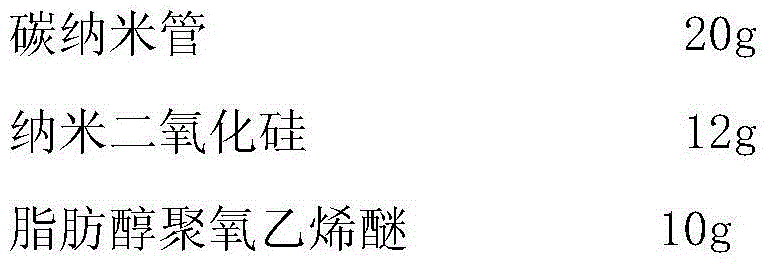

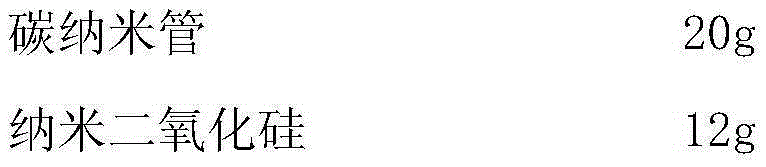

Preparation method of nano coating for EVA (ethylene-vinyl acetate copolymer) film surface

InactiveCN103571320ASimple processImprove conductivityPolyether coatingsElectrically-conductive paintsCarbon nanotubeFatty alcohol

The invention relates to a preparation method of a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol methyl ether acetate and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol methyl ether acetate serves as a film forming aid. A film covered by a coat formed by the nano coating has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. The preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:广东奥优涂料有限公司

Thermoplastic polyvinyl alcohol material and preparation method thereof

Owner:HUAIHUA UNIV

Preparation method of nano coating for EVA (ethylene-vinyl acetate copolymer) film surface of solar packaged cell

ActiveCN103571248ASimple processImprove conductivityElectrically-conductive paintsReflecting/signal paintsCarbon nanotubeSilicon dioxide

The invention relates to a preparation method of a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol butyl ether and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol butyl ether serves as a film forming aid. A film covered by a coat formed by the nano coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. The preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:浙江兆泽实业有限公司

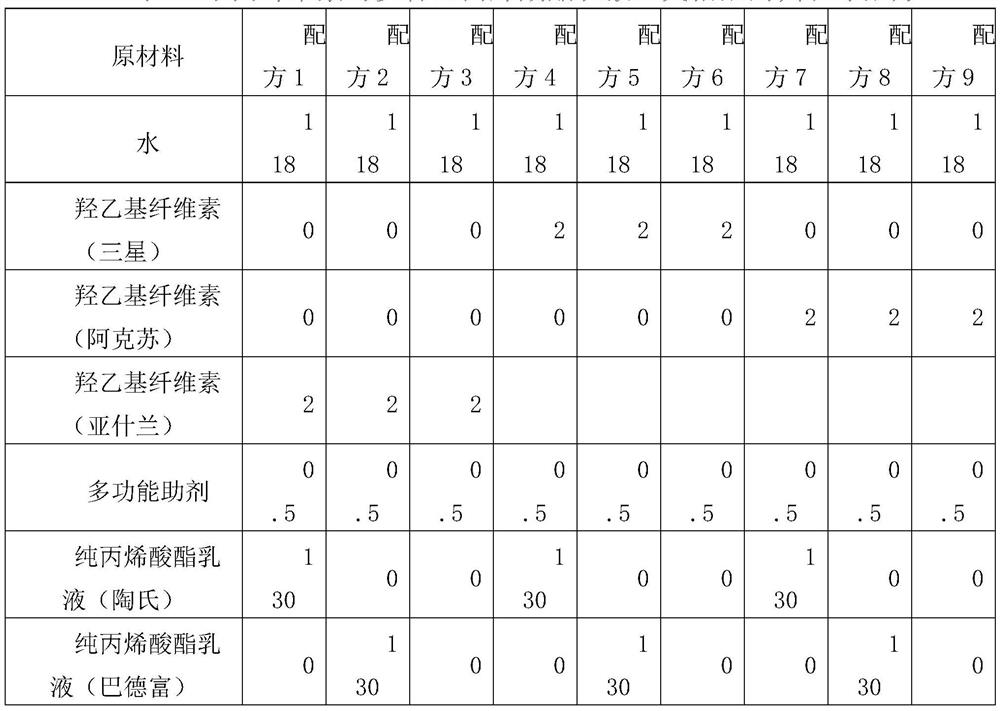

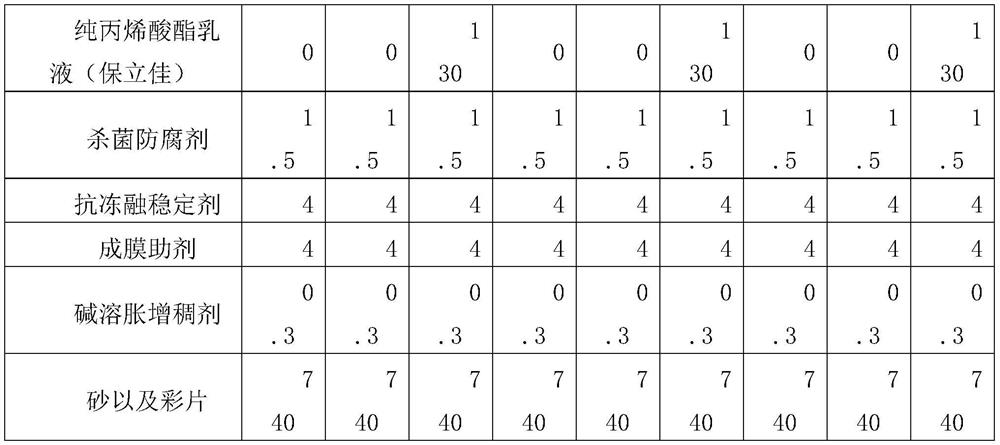

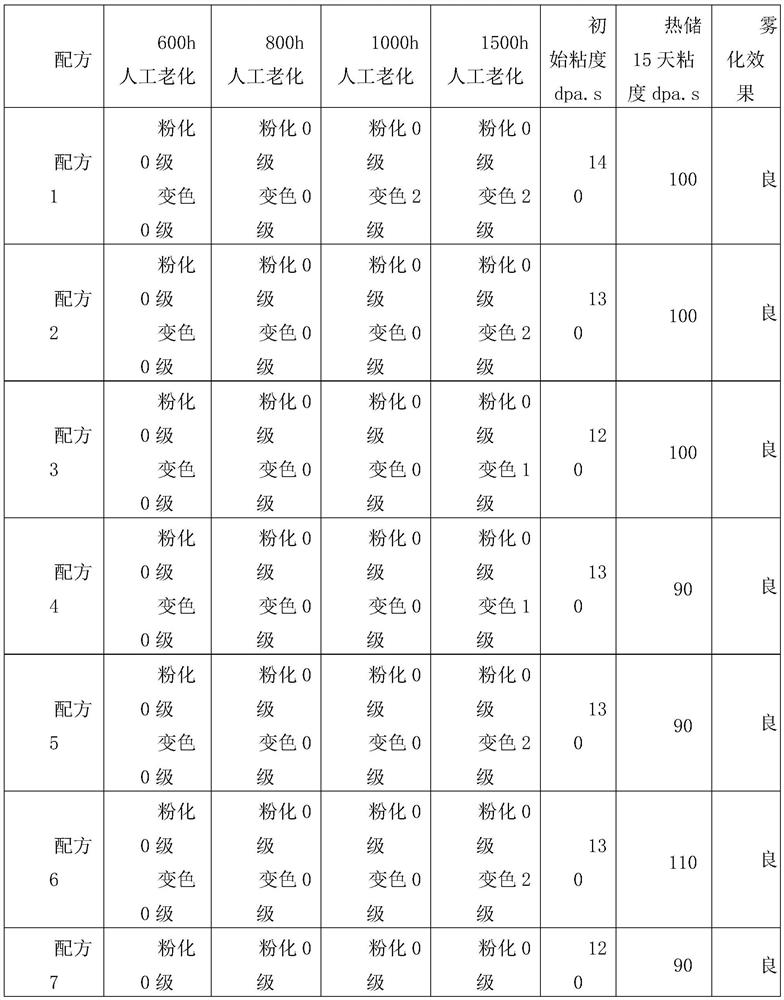

Low-consumption stone-like coating and preparation method thereof

PendingCN113912324ASolve easy yellowingSolve the serious problem of spray spatterCellulosePolymer science

The invention relates to a low-consumption stone-like coating and a preparation method thereof. The stone-like coating is prepared from the following raw materials in parts by mass: 100-120 parts of water, 1-3 parts of hydroxyethyl cellulose, 0.3-0.5 parts of a multi-functional additive, 120-140 parts of acrylate emulsion, 1-2 parts of a bactericidal preservative, 3.5-4.5 parts of a freeze-thaw resistant stabilizer, 3-4 parts of a coalescing agent, 0.2-0.5 parts of an alkali swelling thickene, 300-600 parts of sand, 100-300 parts of color sheets, 0.2-4.0 parts of a pH regulator, 10.0-40.0 parts of silica sol, 20.0-90.0 parts of styrene-acrylic emulsion, 40-60 parts of a slipping agent, 1-2 parts of an anti-freezing agent and 1-2 parts of a water-based defoaming agent. According to the invention, proper cellulose is screened out from different celluloses and is reasonably matched with the emulsion, so that the stability and constructability of a product are improved, and the water retention property and thixotropic property of the system are improved; the acrylic ester emulsion is selected, so that the problem that a stone-like coating using common styrene-acrylic emulsion is easy to yellow is effectively solved; and the problem that color difference between batches is difficult to control can be effectively solved through application of the color sheets.

Owner:河南三棵树新材料科技有限公司

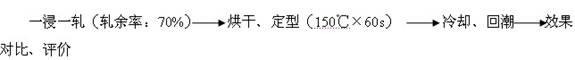

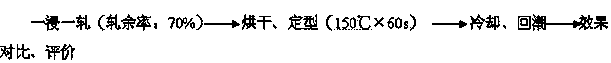

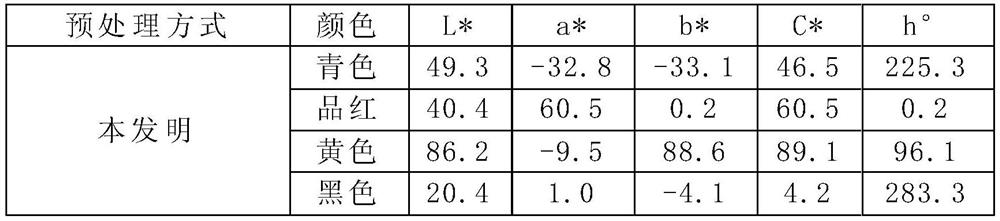

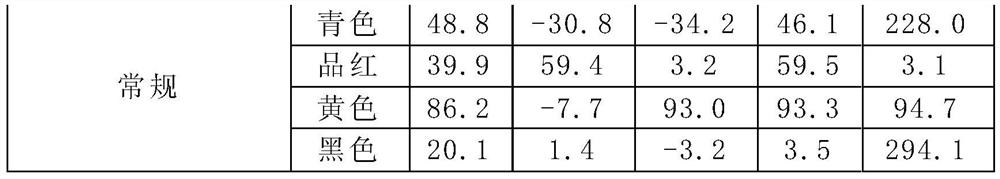

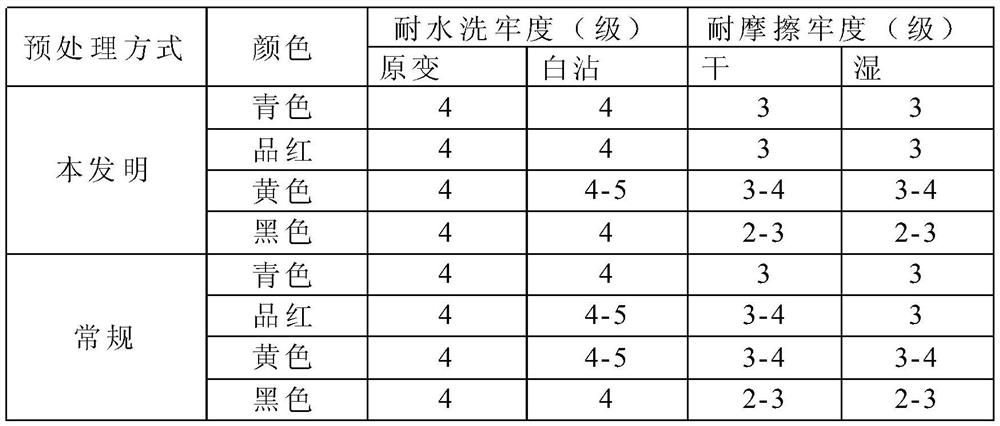

Method for digital textile printing in wet state

InactiveCN111607989AAvoid skewAvoid problems such as yellowingDyeing processTextile printerProcess engineering

The invention belongs to the technical field of textile digital printing, and in particular relates to a method for digital textile printing in a wet state. The method comprises the following processsteps of preparation of a pretreatment working fluid; squeegee treatment of uniformly squeegeeing the pretreatment working fluid on the dry textile; and a printing treatment of directly digitally printing, drying, steaming and washing the wet textiles after the squeegee treatment without the operation of drying. The method for digital textile printing in the wet state can solve the problems of weft skew, yellowing, pretreatment liquid and energy waste caused by pretreatment using a tentering setting machine in the prior art, and the digital printing products using the method are full and bright in colors.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

A kind of ice feeling finishing agent and preparation method thereof

Owner:珠海华大浩宏新材料有限公司

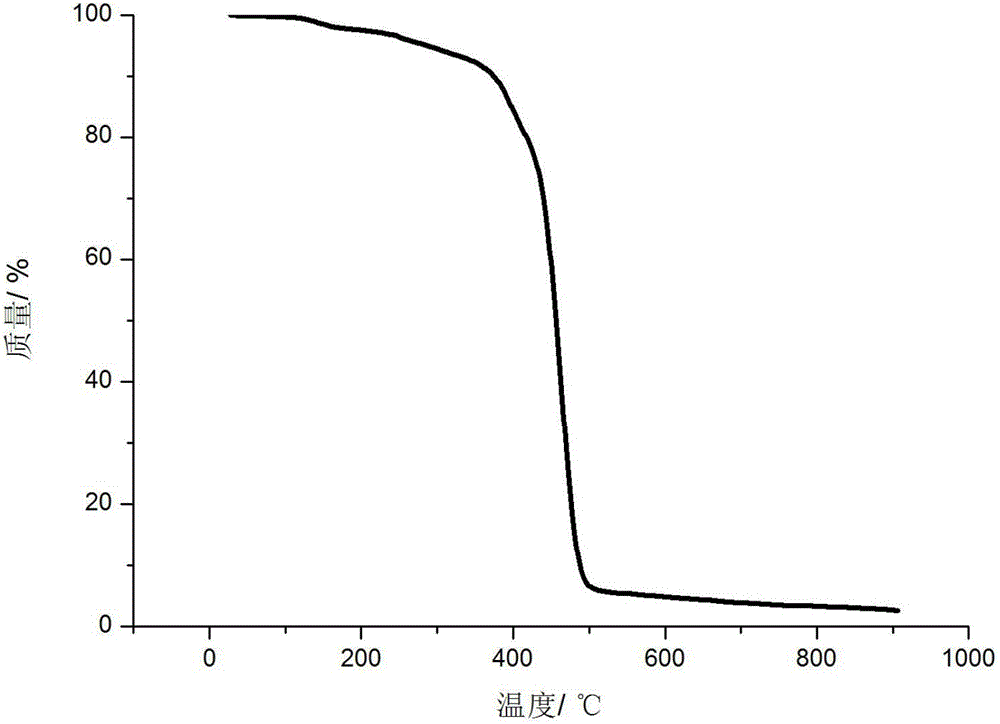

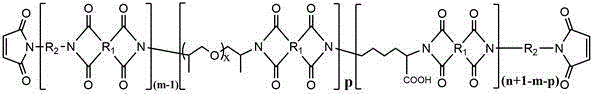

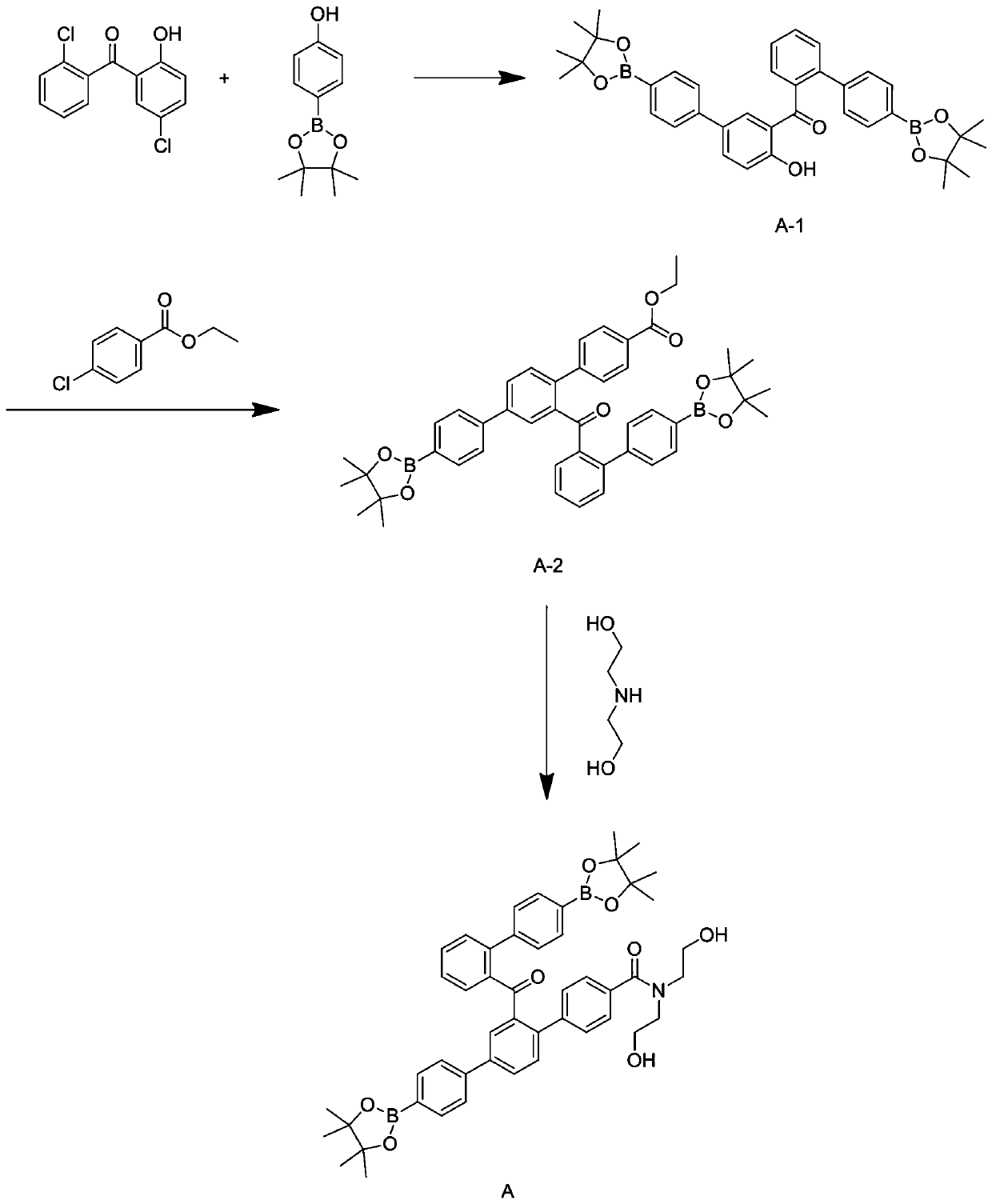

Polyimide oligomer and liquid photoimagable solder resist ink

ActiveCN103145988BImprove heat resistanceImprove solder resistanceOrganic chemistryInksResistOligomer

The invention discloses a polyimide oligomer and a liquid photoimagable solder resist ink. A structural formula of the polyimide oligomer is as follows: R1 is alicyclic, R2 is alkyl with at least one carbon ring structure, n is not less than 1 and not more than 30, m is not less than 1 and not more than 30, p is not less than 1 and not more than 30, and (n+1-m-p) is more than 0, x is not less than 5 and not more than 50. The photoimagable polyimide oligomer has the advantages of excellent heat resistance, soldering resistance, golden resistance, chemical resistance, and yellowing resistance. The liquid photoimagable solder resist ink prepared from the oligomer has excellent heat resistance, soldering resistance, golden resistance, chemical resistance, yellowing resistance, insulativity, high resolution, high flexibility and high adhesion, can be used for effectively solving the problem that the liquid photoimagable solder resist ink is easy to yellow at high temperature under the processes of thermocuring, solder coating and reflow soldering, and is especially suitable for preparing white solder resist ink so as to achieve high reflecting whiteness.

Owner:东莞德芳油墨科技有限公司

Nano coating for EVA (ethylene-vinyl acetate copolymer) film surface of solar packaged cell

ActiveCN103571236ASimple processImprove conductivityPhotovoltaic energy generationElectrically-conductive paintsCarbon nanotubeFatty alcohol

The invention relates to a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol butyl ether and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol butyl ether serves as a film forming aid. A film covered by a coat formed by the nano coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. A preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

A kind of preparation method of eva thin film surface coating

ActiveCN103555025BSimple processImprove conductivityElectrically-conductive paintsAdhesiveCarbon nanotube

The invention relates to a preparation method of an EVA (ethylene-vinyl acetate) film surface paint. The EVA film surface paint is composed of the following components in percentage by mass: 5-10% of carbon nanotube, 5-15% of nano silicon dioxide, 3-15% of fatty alcohol polyethenoxy ether, 3-5% of acrylic acid, 3-5% of propylene glycol monomethyl ether acetate and the balance of organic solvent. The mass ratio of the fatty alcohol polyethenoxy ether to the acrylic acid is 1:1-3:1; and the fatty alcohol polyethenoxy ether is used as a dispersant, the acrylic acid is used as an adhesive, and the propylene glycol monomethyl ether acetate is used as a film-forming assistant. The coating film formed by the EVA film surface paint has electric conductivity and low yellowing rate, and enhances the photoelectric conversion rate of the battery pack; and the preparation method is simple in technique and convenient to operate, and can efficiently enable the carbon nanotubes and silicon dioxide nanotubes to be uniformly dispersed and fixed to the EVA film surface.

Owner:广东绿树环保涂料科技有限公司

A kind of eva adhesive film surface nano-coating

ActiveCN103555040BSimple processImprove conductivityElectrically-conductive paintsAdhesiveCarbon nanotube

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

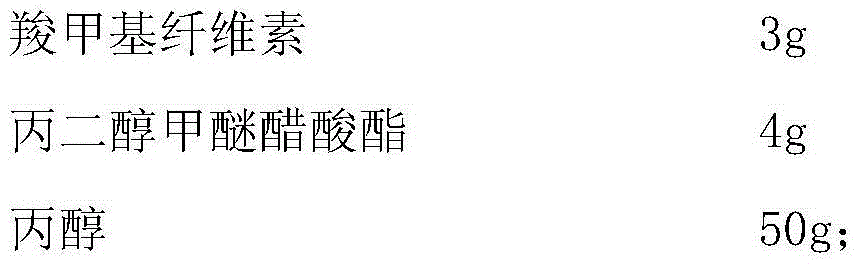

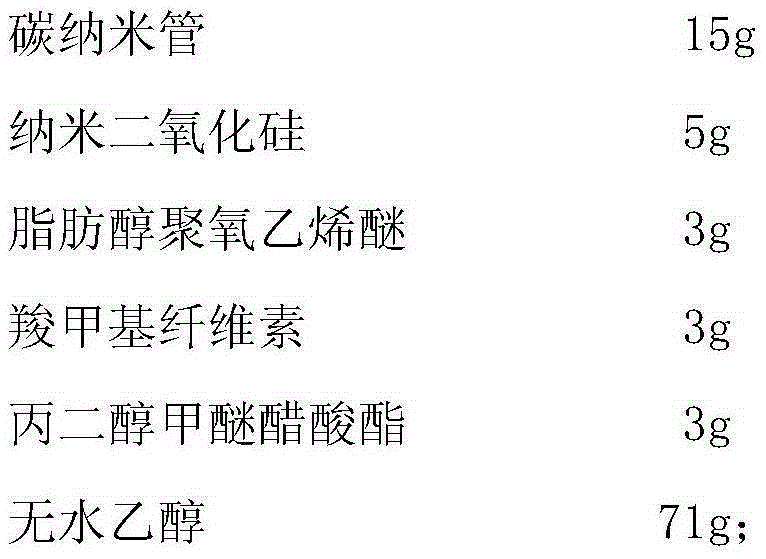

Polyether polyol, preparation method thereof, preparation method of polyether amine and prepared polyether amine

ActiveCN108395528AIncrease profitReduce pollutionOrganic compound preparationEther preparation from oxiranesHydroxylaminePolyol

The invention discloses a polyether polyol, a preparation method thereof, a preparation method of polyether amine and the prepared polyether amine. By-products (including propylene glycol, dipropyleneglycol and dipropylene glycol) of polypropylene glycol rectification are used as raw materials to prepare the anti-yellowing polyether polyol, and the preparation process is carried out in the presence of N,N-dialkyl hydroxylamine. The anti-yellowing polyether polyol reacts under the action of a reductive amination catalyst for preparing the polyether amine, wherein the reductive amination catalyst comprises an NbAlO4 carrier and active components of NiO, Au2O3 and SeO2 supported on the carrier. According to the invention, wastes are turned into values, the invention solves the problem that the polyether polyol synthesized by the recycled and reused rectification by-products of polypropylene glycol rectification is yellowed easily, and finally the polyether amine product with a Pt-Co colour number of 10 or below is obtained.

Owner:WANHUA CHEM GRP CO LTD

A kind of anti-yellowing reinforced nylon 66 material and preparation method thereof

The invention provides an anti-yellowing reinforced nylon 66 material and a preparation method thereof. The preparation method comprises steps as follows: functional monomers and phosphate heat stabilizers are dispersed in coupling agents, ethanol is added for dilution and alcoholysis, and PH value of a slurry is adjusted to be 3.2-3.8; glass fiber is soaked in the prepared slurry and dried, and processed glass fiber is obtained; nylon 66, long-carbon-chain nylon and antioxidants are evenly mixed by a high-speed mixer and added from a main feeding port of a twin-screw extruder, the processed glass fiber is added from a side feeding port and subjected to extrusion, bracing and pelletizing, and the anti-yellowing reinforced nylon 66 material is obtained. The anti-yellowing performance of the prepared material is far higher than that of other ordinary reinforced materials.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

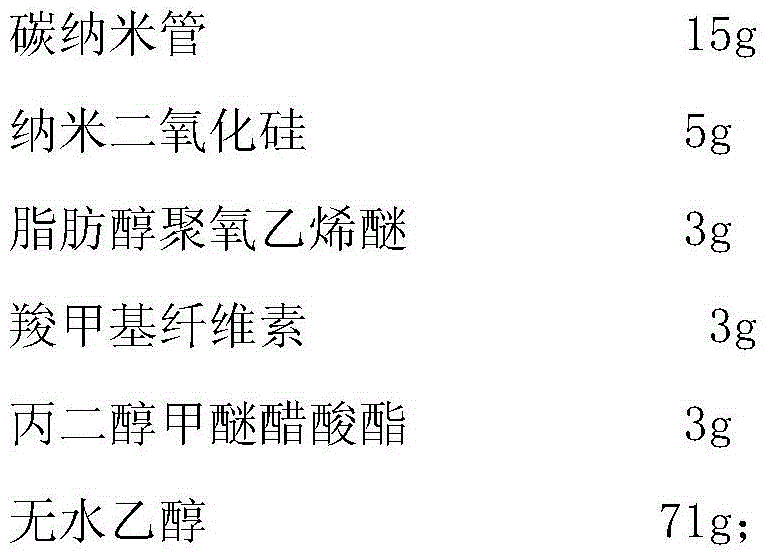

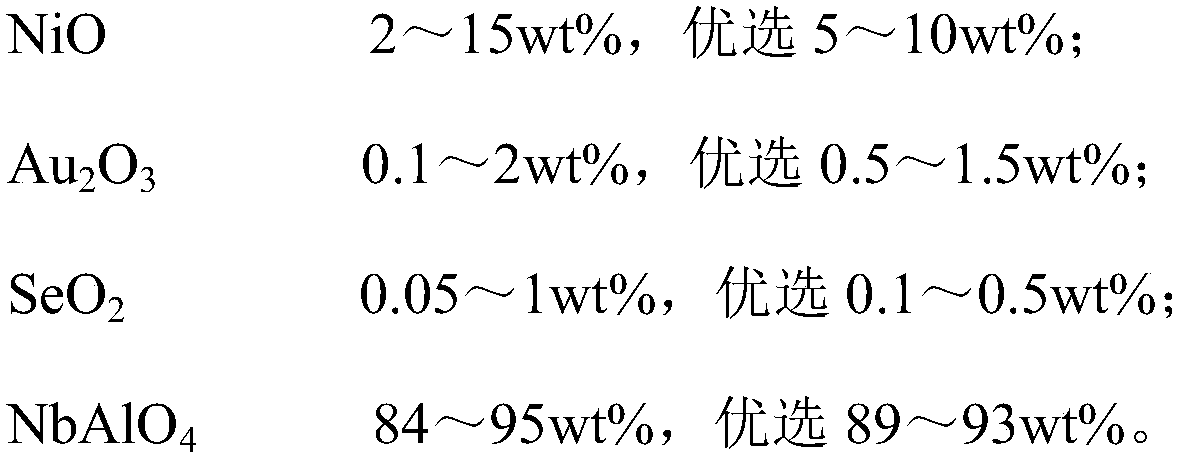

A kind of preparation method of EVA adhesive film surface nano-coating

ActiveCN103555015BSimple processImprove conductivityPolyether coatingsElectrically-conductive paintsPolymer scienceAdhesive

The invention relates to a preparation method of an EVA (ethylene-vinyl acetate) adhesive film surface nano paint. The EVA adhesive film surface nano paint is composed of the following components in percentage by mass: 10-20% of carbon nanotube, 5-15% of nano silicon dioxide, 3-15% of fatty alcohol polyethenoxy ether, 3-5% of carboxymethyl cellulose, 3-5% of propylene glycol monomethyl ether acetate and the balance (10-30%) of organic solvent. The mass ratio of the fatty alcohol polyethenoxy ether to the carboxymethyl cellulose is 1:1-3:1; and the fatty alcohol polyethenoxy ether is used as a dispersant, the carboxymethyl cellulose is used as an adhesive, and the propylene glycol monomethyl ether acetate is used as a film-forming assistant. The coating film formed by the EVA adhesive film surface nano paint has electric conductivity and low yellowing rate, and enhances the photoelectric conversion rate of the battery pack; and the preparation method is simple in technique and convenient to operate, and can efficiently enable the carbon nanotubes and silicon dioxide nanotubes to be uniformly dispersed and fixed to the EVA adhesive film surface.

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

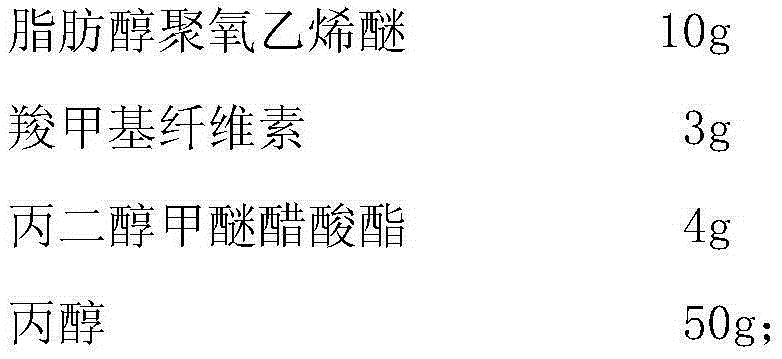

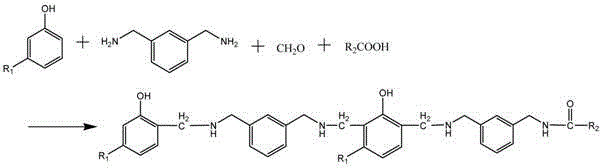

A kind of alkylphenol modified phenolic amide curing agent and preparation method thereof

ActiveCN102633991BStrong resistance to salt spray corrosionHigh impact strengthOrganic compound preparationCarboxylic acid amides preparationPolyamideAlkylphenol

The invention discloses an alkylphenol-modified phenolic amide curing agent and a preparation method thereof. The raw material components contain phenol or phenol derivatives, formaldehyde or paraformaldehyde, polyamines, fatty acids or fatty acid polymers. The preparation method includes: Mix fatty acid or fatty acid polymer, polyamine, heat up reaction, cool down, add phenol or phenol derivative, formaldehyde or paraformaldehyde, mix, heat up reaction, dehydrate to obtain product; or mix phenol or phenol derivative, polyamine, Formaldehyde or paraformaldehyde is mixed evenly, the reaction is heated up, fatty acid or fatty acid polymer is added, the reaction is heated up and dehydrated to obtain the product. The curing agent of the invention has strong resistance to salt spray corrosion, and its performance is better than that of polyamide curing agents, modified phenalkamine resins and their mixtures. The curing agent of the invention has good impact strength, flexibility and excellent performance. water resistance.

Owner:CARDOLITE CHEM ZHUHAI

High temperature expanded polymer microspheres and preparation method thereof

Owner:SHANDONG RUIFENG CHEM

A kind of preparation method of super smooth hydrophilic quaternary ammonium salt modified organosilicon copolymer

ActiveCN104072783BGood self-emulsifying performanceImprove hydrophilicityVegetal fibresAcetic acidOrganic solvent

The invention relates to the field of textile finishing agents, in particular to a method for preparing a super-slippery hydrophilic quaternary ammonium salt-modified organosilicon copolymer, which comprises the following steps: Synthesize cationic modified polyether amine intermediate under the following conditions; add glacial acetic acid to the cationic modified polyether amine intermediate and epoxy-terminated polyether silicone oil for addition polymerization of amino and epoxy groups in the presence of an organic solvent , Synthetic ternary block silicone oil. The super-slippery hydrophilic quaternary ammonium salt modified silicone copolymer prepared by the present invention endows cotton fabrics with excellent hydrophilic properties and outstanding silky effect, and its smoothness can reach the level of ordinary amino silicone oil, which is better than most ternary silicone oils. Block silicone oil; the improvement of the degree of cationization endows the super-smooth hydrophilic quaternary ammonium salt modified silicone copolymer with certain antibacterial and antistatic functions, and at the same time can effectively solve the problem of easy yellowing of amino under high temperature conditions. Smaller, suitable for finishing white or light colored fabrics.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

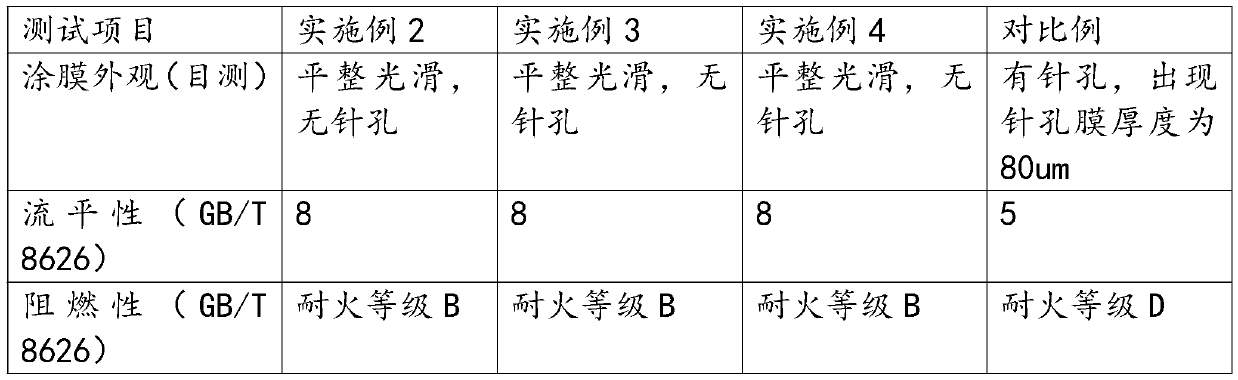

Powder coating with high-temperature-yellowing-resistant function

InactiveCN110746866ASolving the problem of pinholesReduce curing reactivityFireproof paintsPowdery paintsPolymer scienceFirming agent

The invention discloses powder coating with a high-temperature-yellowing-resistant function. The powder coating is prepared from the following raw materials in parts by weight: 58-66 parts of polyester resin, 2.5-5 parts of a curing agent, 1-2 parts of a smoothing degassing agent, 1-2 parts of a flatting agent, and 25-40 parts of pigments and fillers. The polyester resin is taken as a substrate, amixture of a four-degree-of-functionality hydroxyalkyl amide curing agent and a modified dihydroxyalkyl amide curing agent with the mass ratio being (14 to 17):(20 to 22) is taken as the curing agent, the hydroxyalkyl amide curing agent is modified, boron ester bonds, benzene rings and benzophenone structures are introduced in the form of firm chemical bonds, ultraviolet absorbents and anti-yellowing agents do not need to be added, the modified dihydroxyalkyl amide curing agent is applied to the coating, the activity of a curing reaction can be lowered, the pinhole phenomenon of a film is relieved, the high-temperature-resistant stability of the powder coating is further improved, thus the problem that the film is prone to being yellowed at the high temperature is solved, and the anti-aging property of the film can be maintained permanently.

Owner:六安捷通达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com