A kind of ice feeling finishing agent and preparation method thereof

A finishing agent and ice-feeling technology, which is applied in the field of ice-feeling finishing agents and their preparation, can solve the problems of high preparation cost, poor resilience, smoothness and moisture retention of knitted fabrics, and achieve various, easy to purchase, good Effects of Resilience and Smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

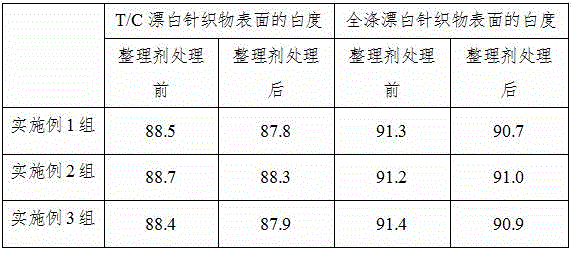

Examples

Embodiment 1

[0031] Example 1. The ice-like finishing agent of the present invention

[0032] The ice-feel finishing agent includes the following components and their weight percentages: 20 kg of crude silicone oil, 4 kg of fatty alcohol polyoxyethylene ether, 5 kg of methanol, 0.1 kg of glacial acetic acid and 70.9 kg of water; the crude silicone oil is obtained by mixing 99% linear Silicone oil, 0.9% 3-piperazinyl propyl methyl dimethoxy silane and 0.1% potassium hydroxide are put into the reaction kettle and prepared by reaction.

[0033] Preparation:

[0034] S1 Put 99% linear silicone oil, 0.9% 3-piperazinyl propyl methyl dimethoxy silane and 0.1% potassium hydroxide into the reaction kettle, heat up to 90°C, keep it for 30 minutes, until the viscosity reaches 1500 mpa.s , Turn on the vacuum system, reduce the pressure in the reactor to 7kpa, keep it warm for 3h, and have a viscosity of 20000mpa.s. Cool down to room temperature to obtain silicon oil crude oil;

[0035] S2 Add 4kg of fatty al...

Embodiment 2

[0036] Example 2. The ice-like finishing agent of the present invention

[0037] The ice-feel finishing agent includes the following components and their weight percentages: 30 kg of crude silicone oil, 6.5 kg of isotridecyl alcohol polyoxyethylene ether, 7 kg of ethanol, 0.3 kg of glacial acetic acid and 56.2 kg of water; 99.2% D4 silicone oil, 0.7% 3-cyclohexylaminopropyl trimethoxysilane and 0.1% tetramethyl ammonium hydroxide are put into the reaction kettle and prepared by reaction.

[0038] Preparation:

[0039] S1 Put 99.2% D4 silicone oil, 0.7% 3-cyclohexylaminopropyltrimethoxysilane and 0.1% tetramethylammonium hydroxide into the reaction kettle, heat up to 100℃, keep for 50min, until the viscosity reaches 2500mpa.s , Turn on the vacuum system, reduce the pressure in the reactor to 8kpa, keep the temperature for 3.5h, and have a viscosity of 40000mpa.s. Cool down to room temperature to obtain silicone oil crude oil;

[0040] S2 Add 6.5kg of isotridecyl alcohol polyoxyethylen...

Embodiment 3

[0041] Example 3. The ice-like finishing agent of the present invention

[0042] The ice-feel finishing agent includes the following components and their weight percentages: 45 kg of crude silicone oil, 10 kg of iso-deca polyoxyethylene ether, 12 kg of isopropanol, 0.8 kg of glacial acetic acid and 32.2 kg of water; the crude silicone oil is obtained by mixing 99.5 %DMC silicone oil, 0.42% diethylenetriaminopropyltrimethoxysilane and 0.08% sodium methoxide are put into the reactor and prepared by reaction.

[0043] Preparation:

[0044] S1 Put 99.5% DMC silicone oil, 0.42% diethylenetriaminopropyltrimethoxysilane and 0.08% sodium methoxide into the reaction kettle, raise the temperature to 110°C, keep it for 60 minutes, and turn on the vacuum system after the viscosity reaches 3000mpa.s. Decrease the pressure in the reactor to 10kpa, keep it warm for 4h, and have a viscosity of 90000mpa.s. Cool down to room temperature to obtain silicone oil crude oil;

[0045] S2 Add 10kg of isomeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com