Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182results about How to "Simple daily maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

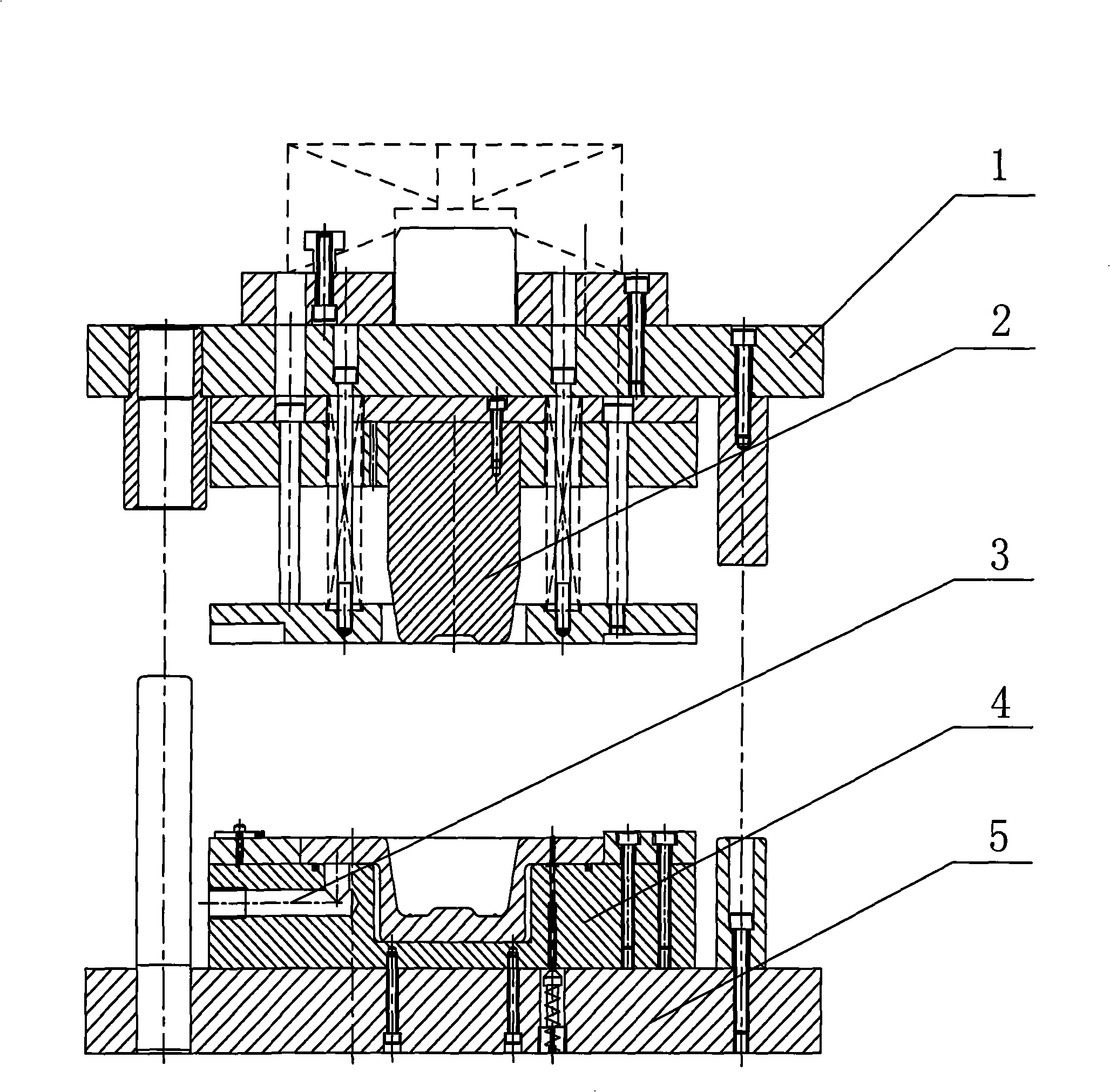

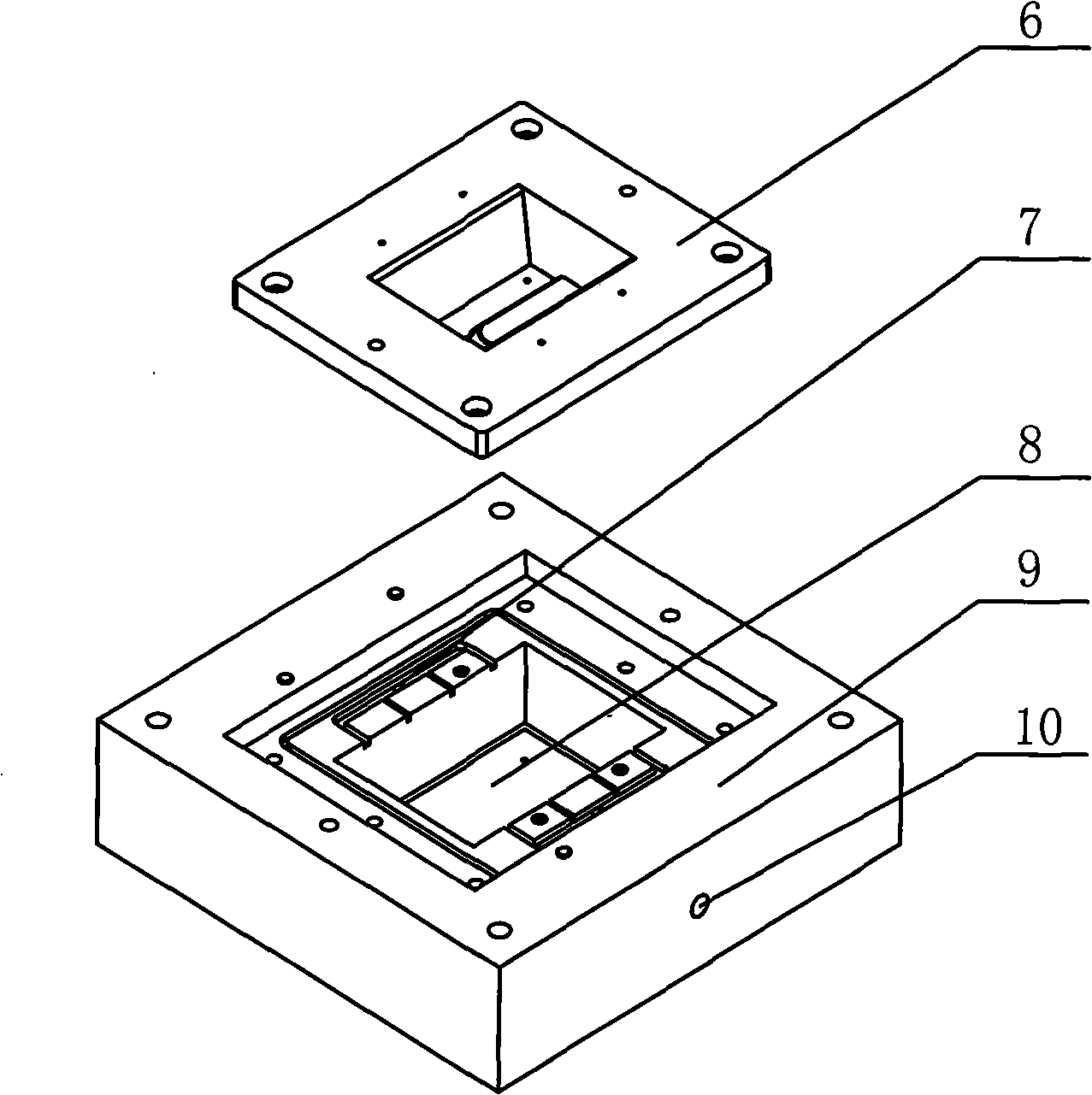

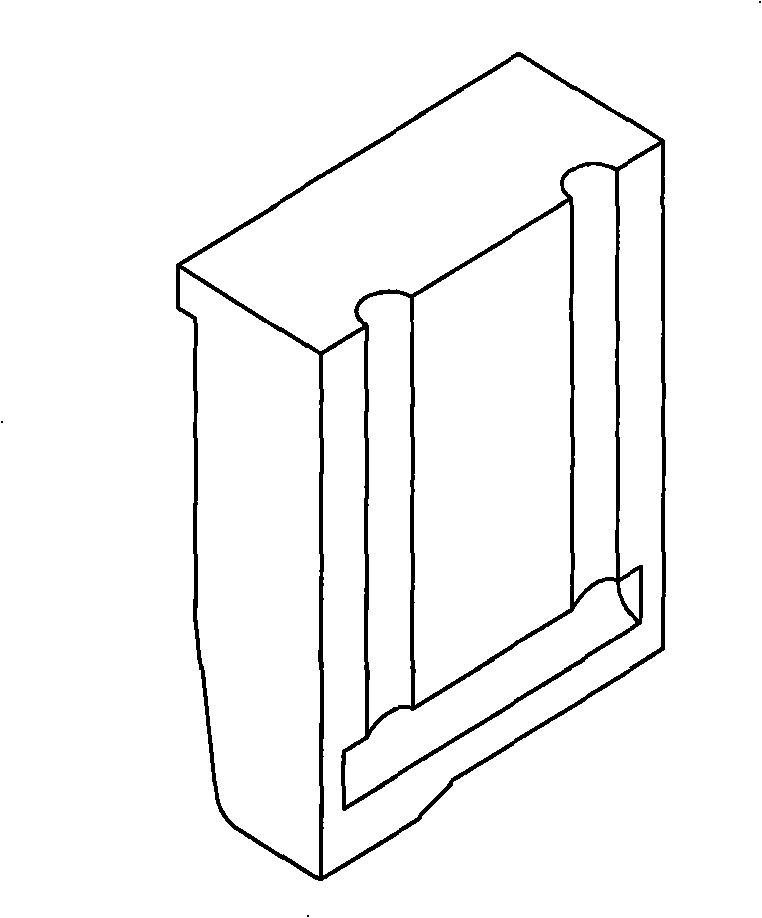

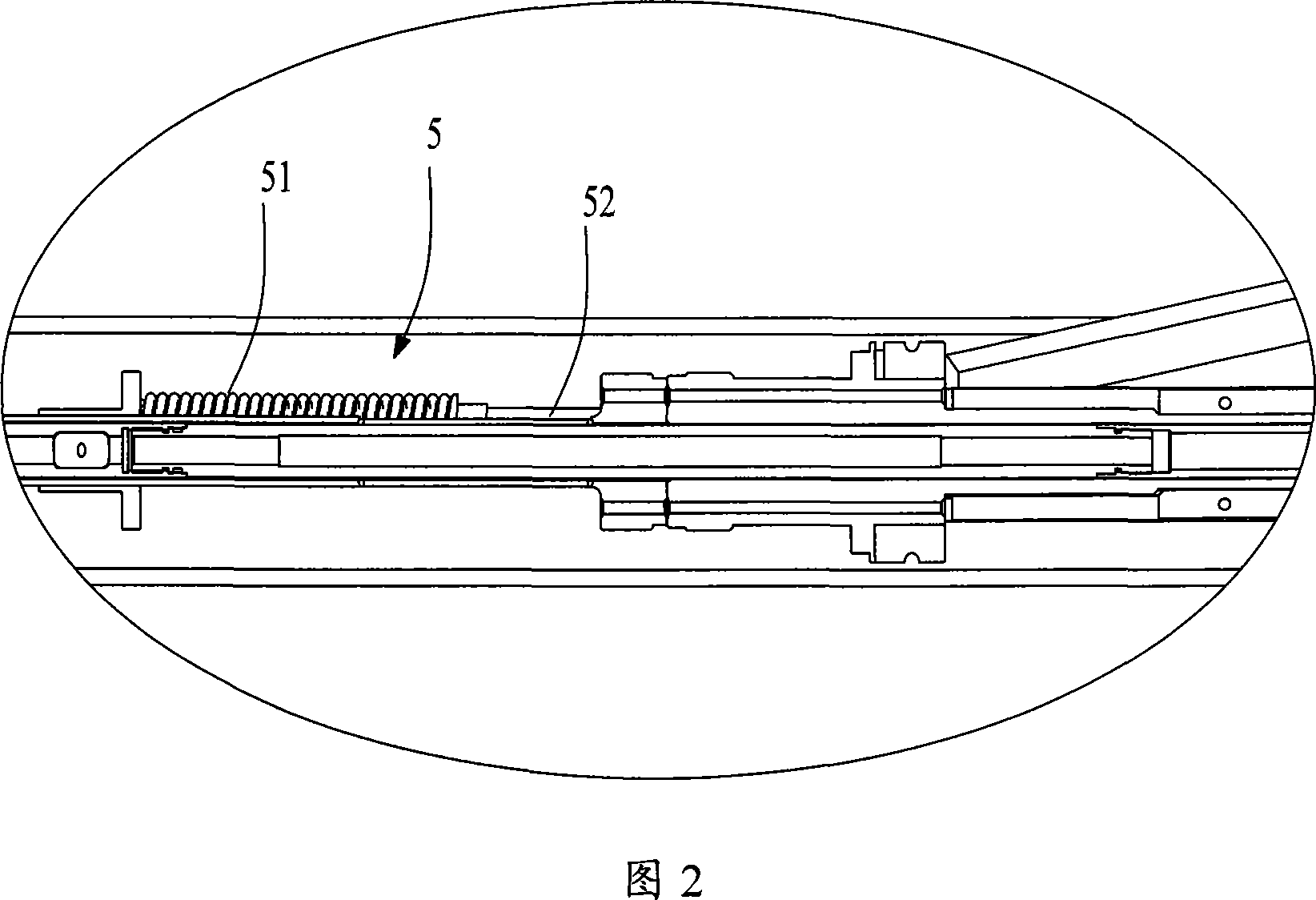

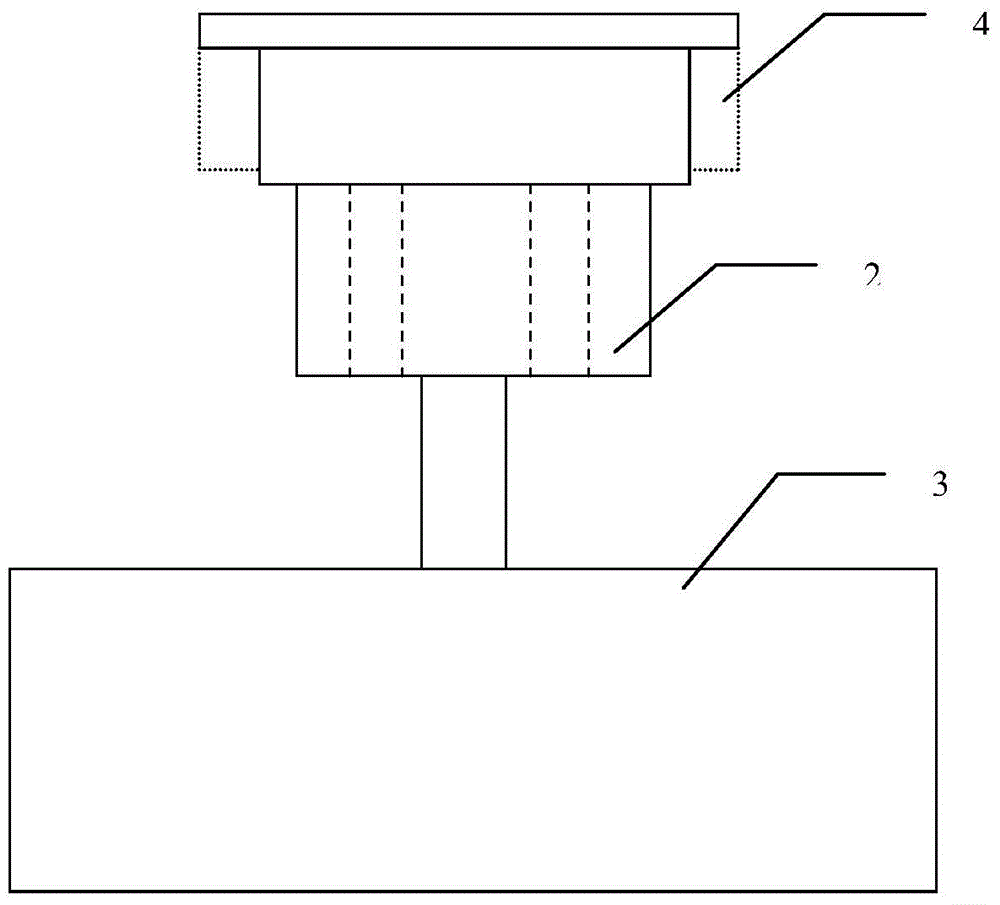

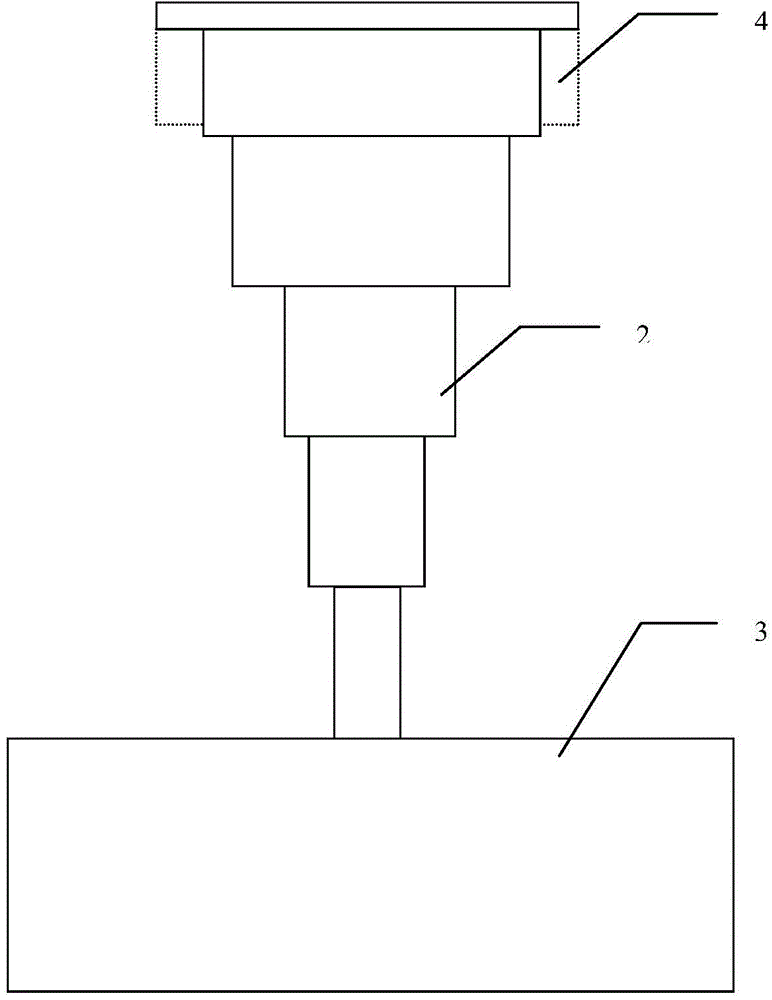

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

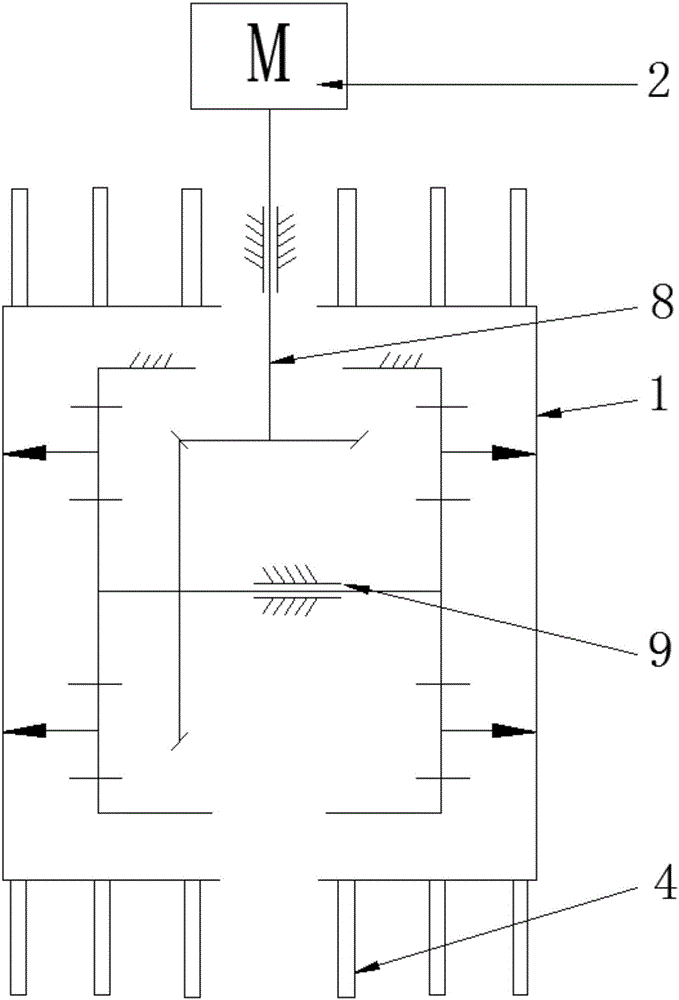

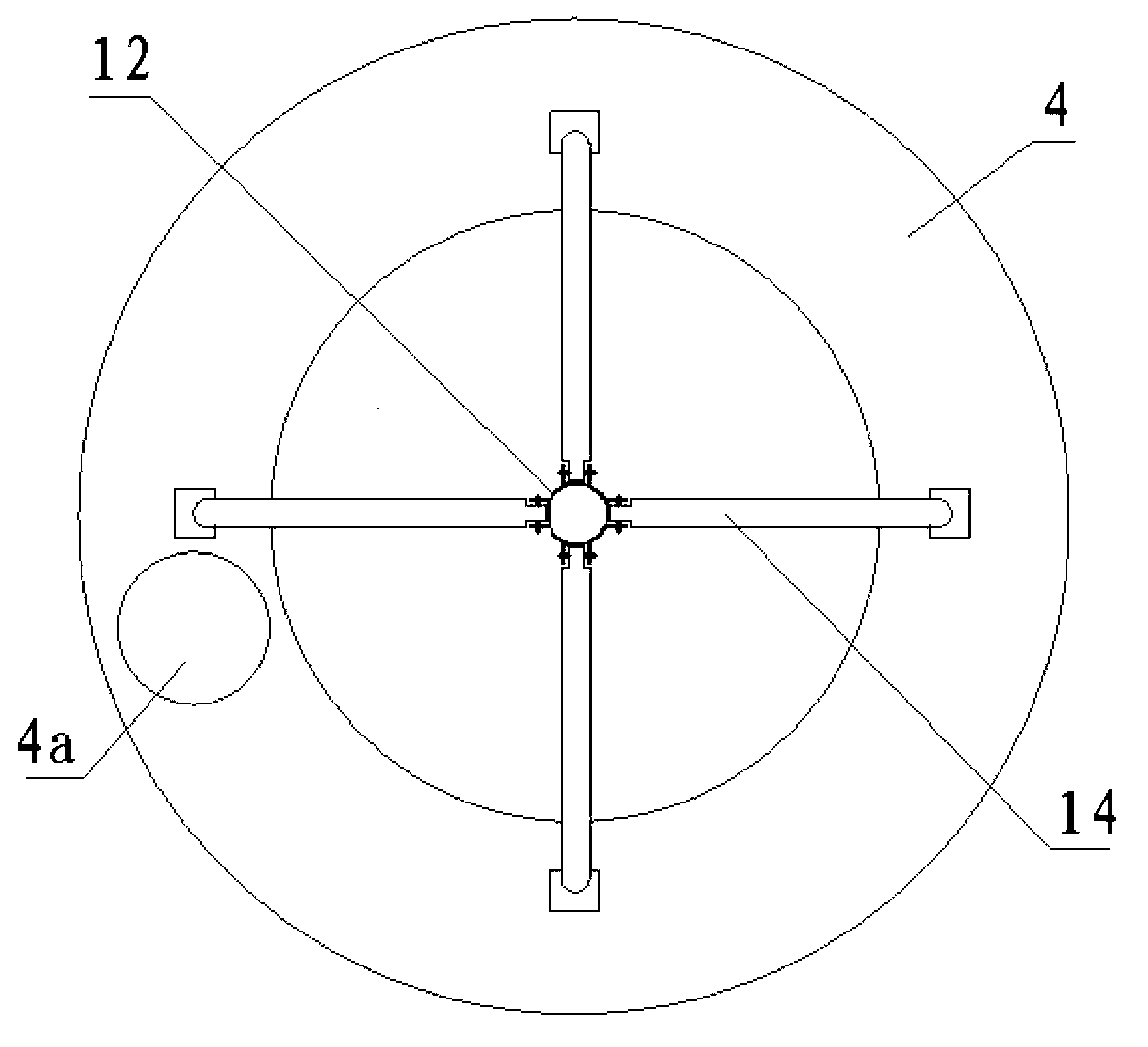

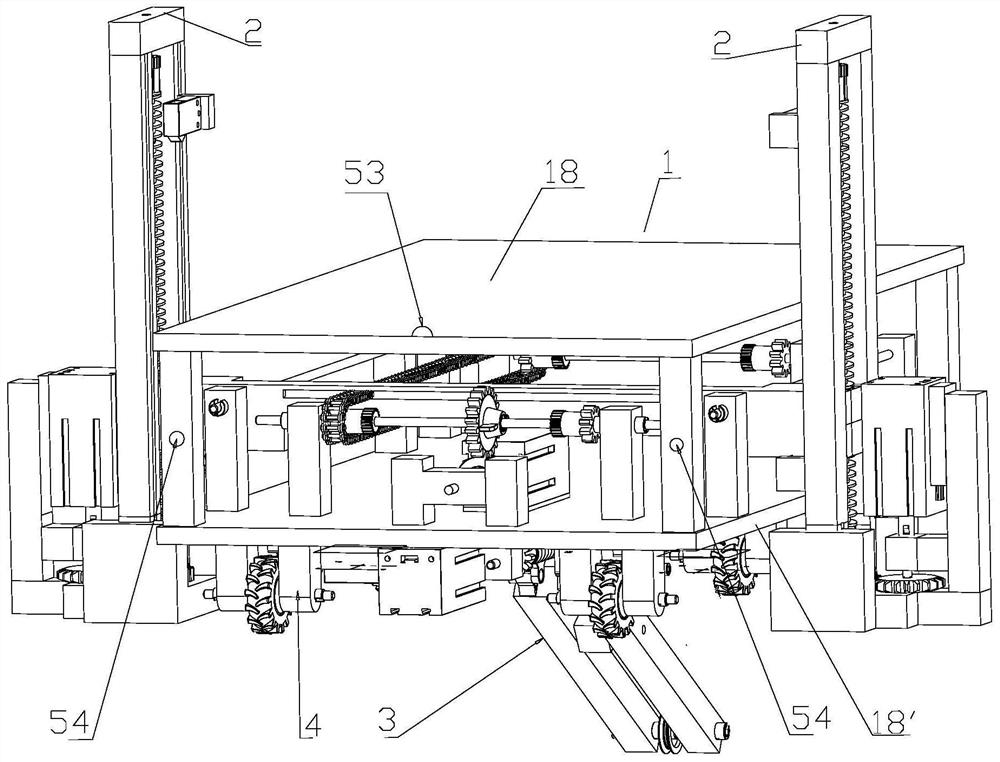

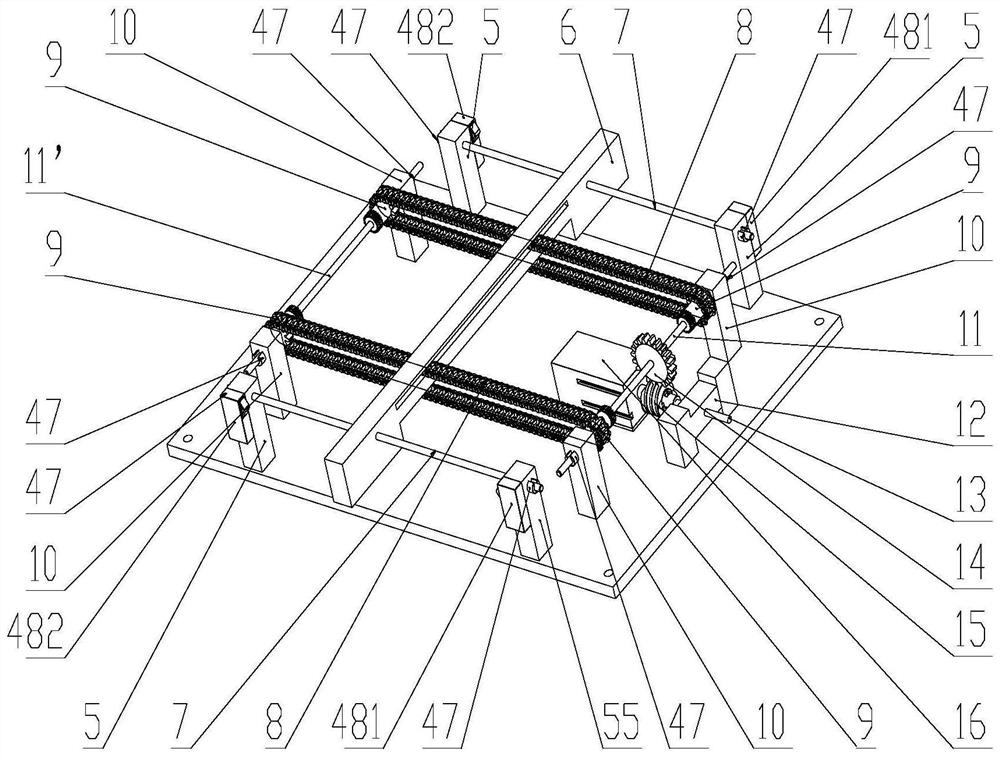

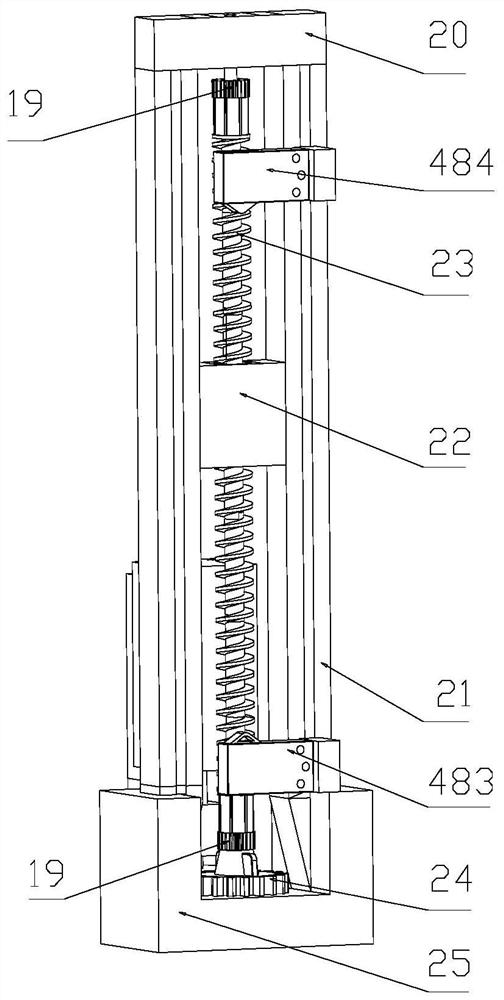

Eight-arm mechanical pusher

The invention discloses a mechanical eccentering arm with eight arms including a motor, a clutch, a roller threaded spindle, drive parts and an eccentering arm; the motor is connected to the roller threaded spindle by the clutch and is transferred to the drive parts by the roller threaded spindle after the circumference direction rotating displacement changes to the axial direction moving displacement, an elasticity thrust mechanism is arranged on the drive parts, the eccentering arm stretches out or folds up under the action of the elasticity thrust mechanism. The invention has advantages of simple and reasonable structure, convenient maintenance and high reliability and so on.

Owner:CHINA NAT OFFSHORE OIL CORP +1

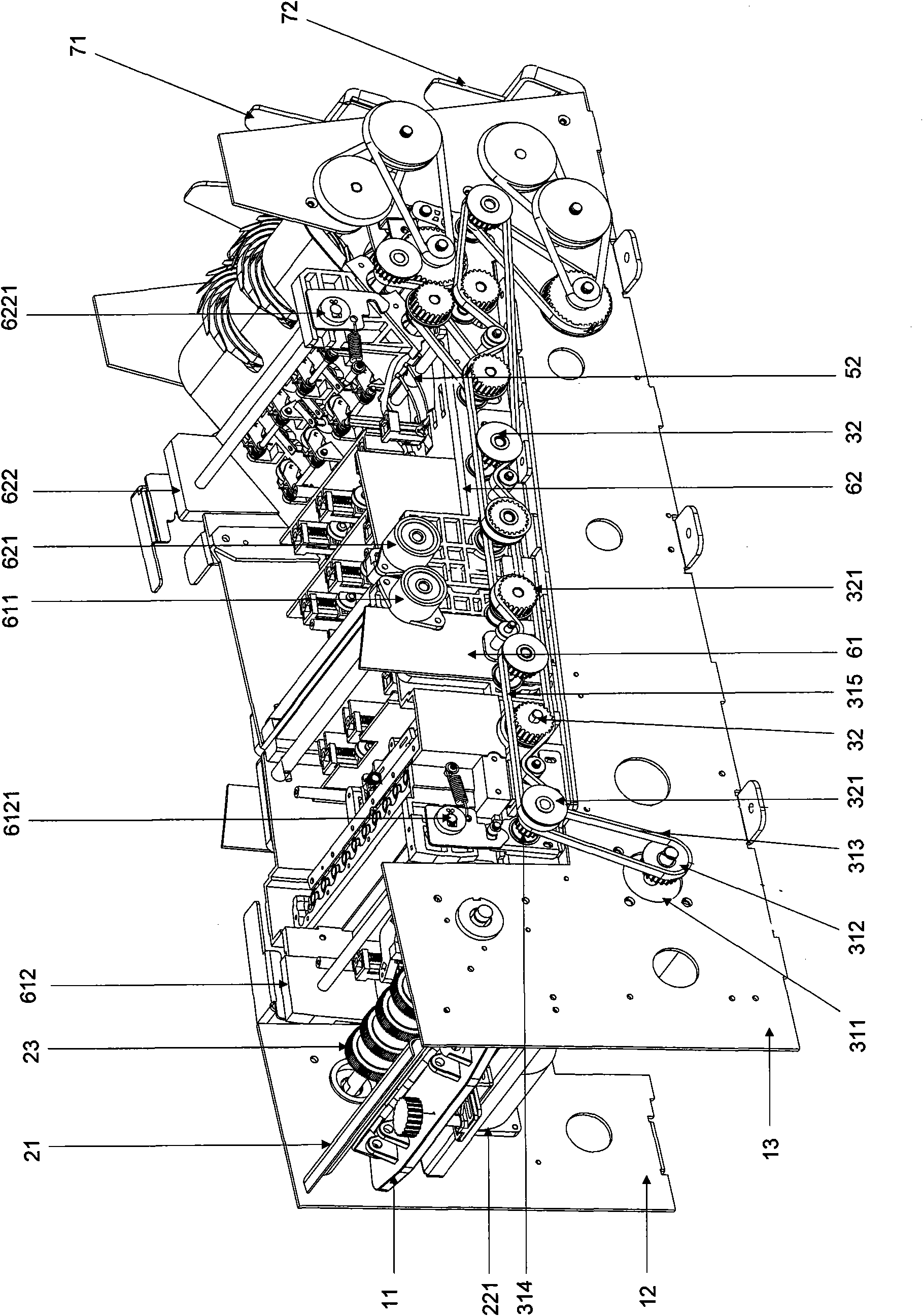

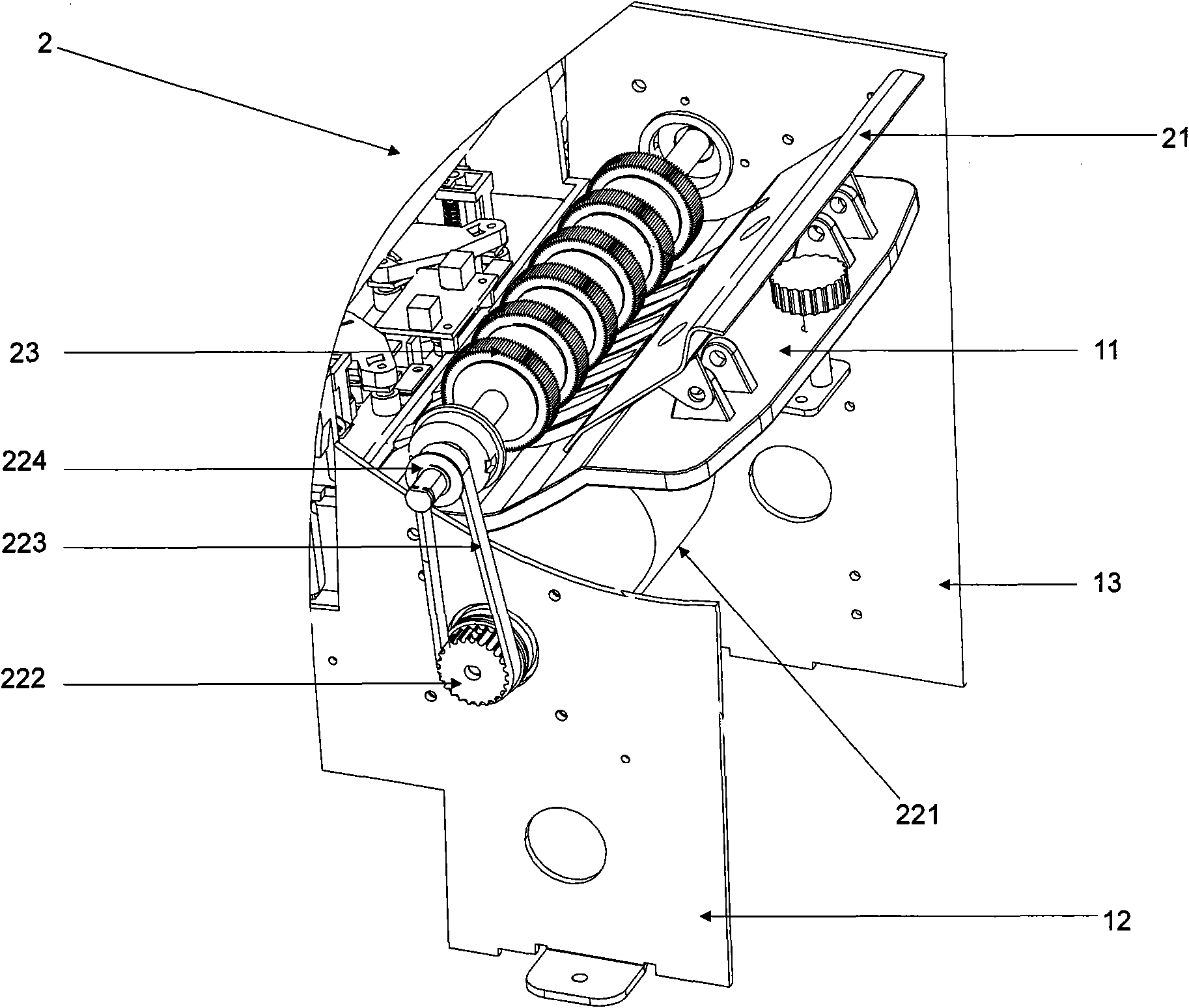

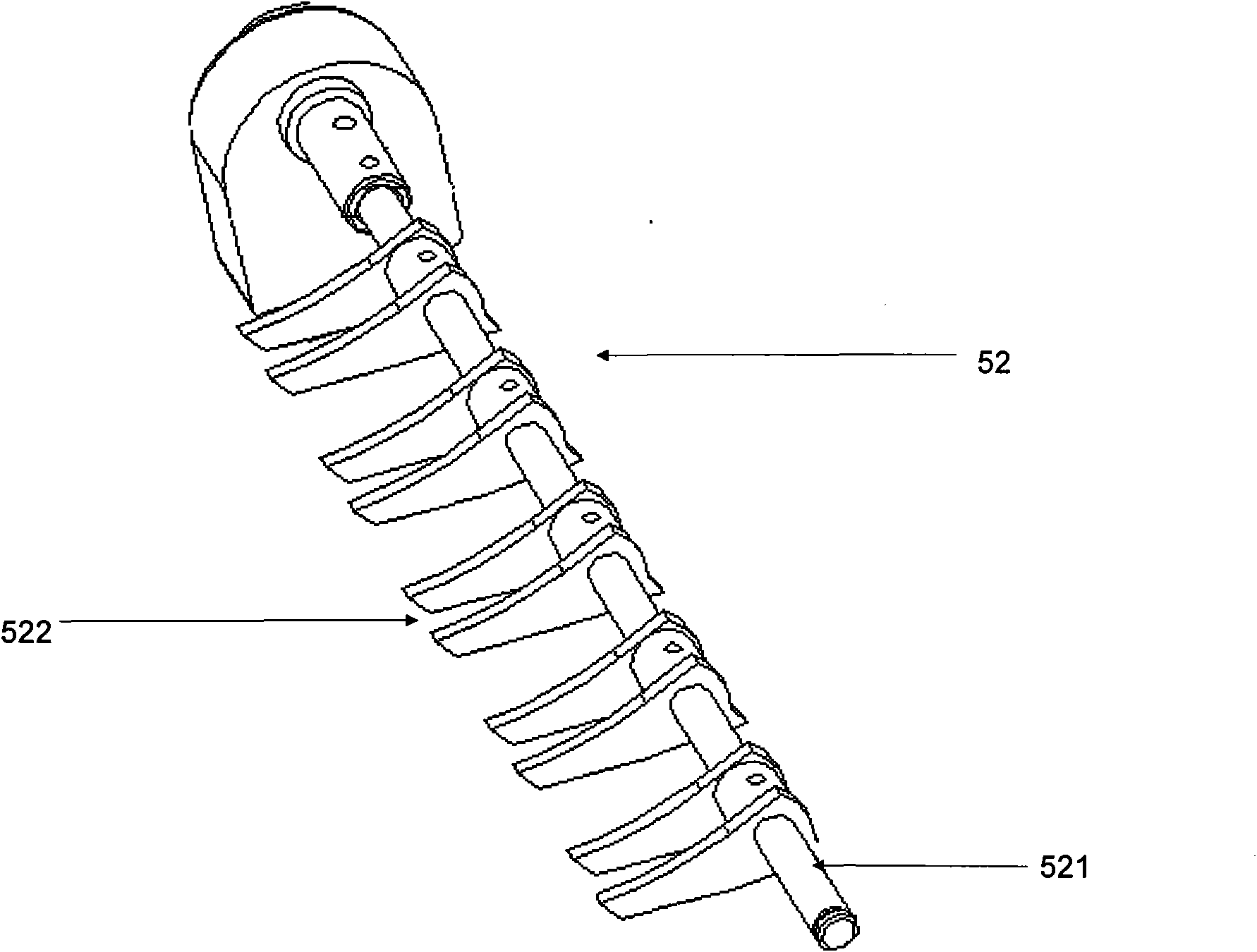

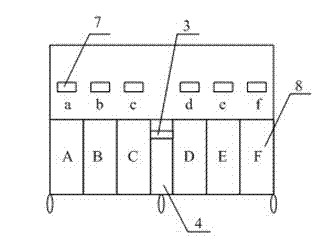

Paper currency sorting device and control method thereof

ActiveCN101826232AAccelerateStable performancePaper-money testing devicesSortingImage resolutionEngineering

The invention relates to a financial device used for paper currency sorting, in particular to a paper currency sorting device and a control method thereof. The invention has the advantages that the structural design is simple, the maintenance of a sorter is easy, the acquisition speed of the sorter can be adjusted in time in the process of sorting paper currency to adapt to the requirement of keeping high image resolution during the high-speed paper currency processing of the sorter, the extraction of the characteristic zones of paper currency is realized, the sorter has the functions of outputting currency, denomination, surface condition, integrity condition, numbers, infrared fluorescence color-changing ink and other anti-counterfeit features of paper currency, the speed is high, the performance is stable, the counterfeit identification accuracy is high, the resolution of the numbers and the images of paper currency can reach above 200DPIx200DPI at the paper currency processing speed of 600 pieces / minutes, and the image resolution requirement of an OCR under the condition of 99 percent of accuracy is satisfied.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

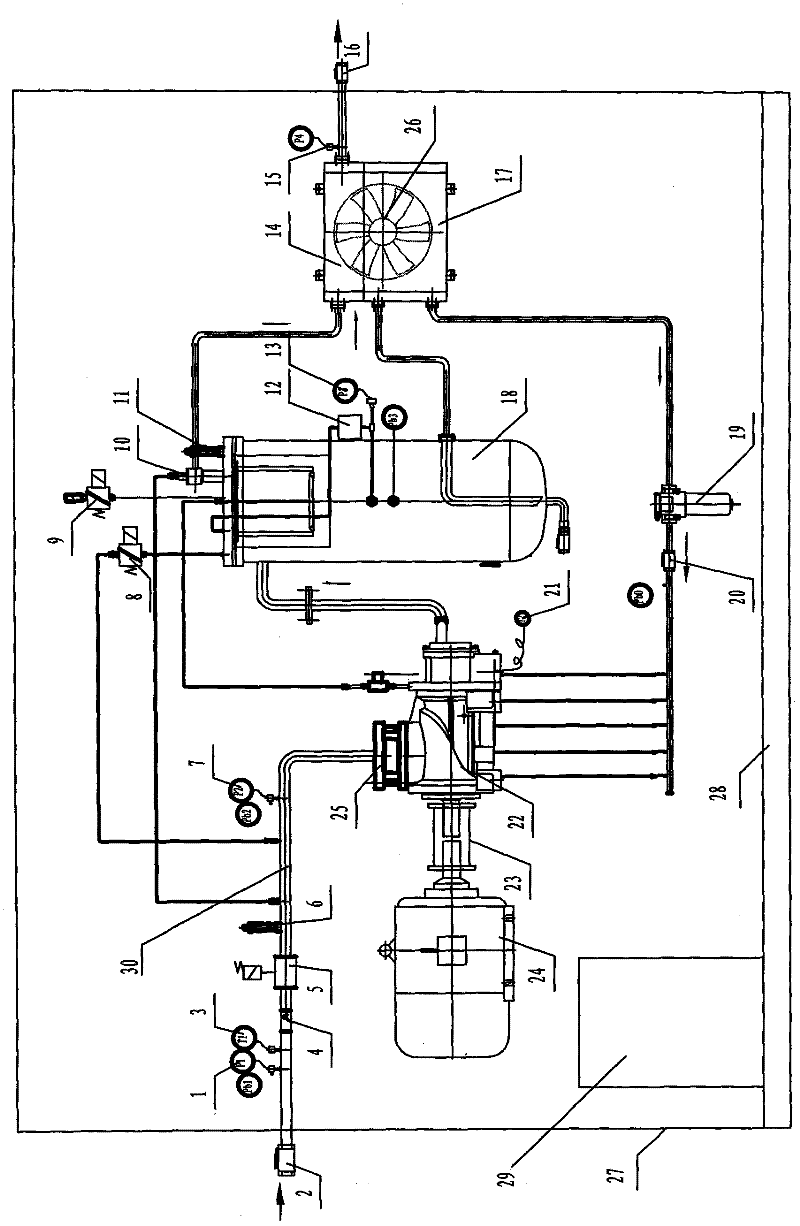

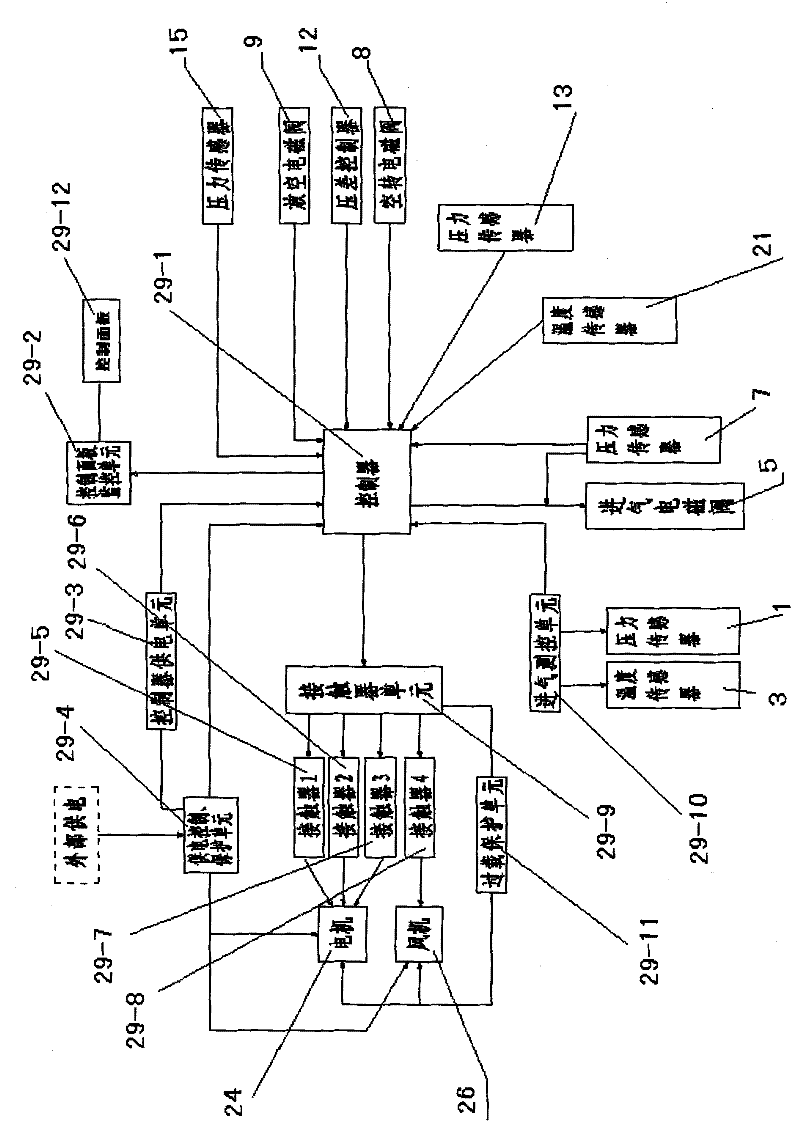

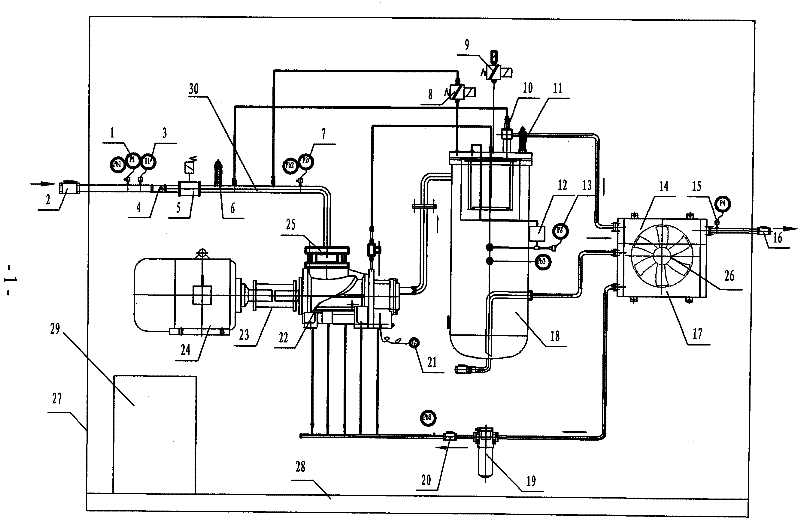

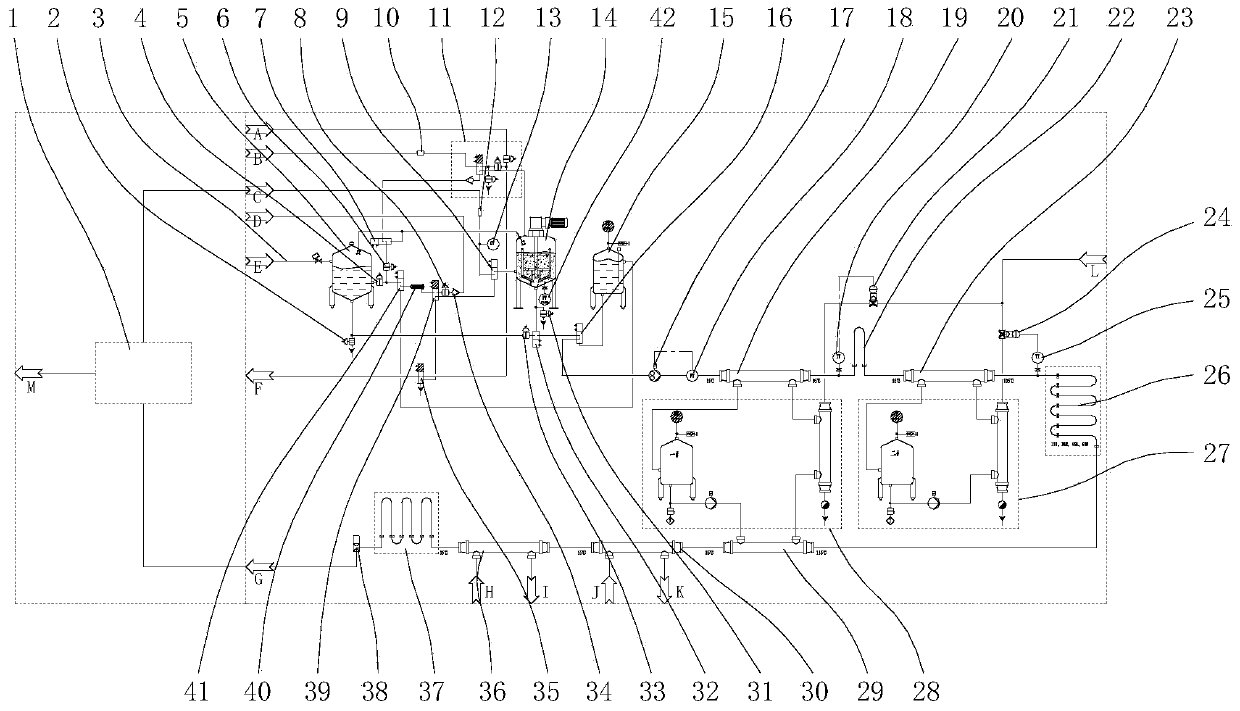

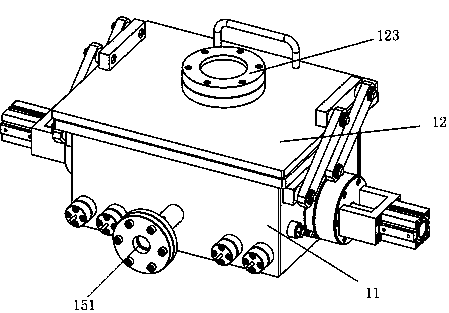

A screw gas booster

ActiveCN102287373ANo relative frictionLess exerciseRotary piston pumpsRotary piston liquid enginesLow noiseSolenoid valve

The invention discloses a screw gas booster, which comprises an electric control cabinet (29), a fan (26), a motor (24) and the like, and is characterized in that: an inlet pipeline (30) of a twin screw compressor (22) is provided with an inlet ball valve (2), a first pressure sensor (1), a first temperature sensor (3), an inlet filter (4), an inlet solenoid valve (5), a safety valve (6), and a second pressure sensor (7) in turn; the twin screw compressor (22) is provided with a second temperature sensor (21), and is connected with a throttle valve (20), an oil filter (19) and an oil separator (18); the oil separator (18) is provided with an idle solenoid valve (8), a release solenoid valve (9), a minimum pressure valve (10), a safety valve (11), a differential pressure controller (12) and a third pressure sensor (13); a rear cooler (14) is connected with a fourth pressure sensor (15) and a vent ball valve (16); and the oil separator (18) is connected with an oil cooler (17). The screw gas booster has the advantages of small volume of the whole machine, compact structure, convenience for maintenance, high reliability and efficiency, good force balance, small vibration and low noise.

Owner:YANTAI MOON

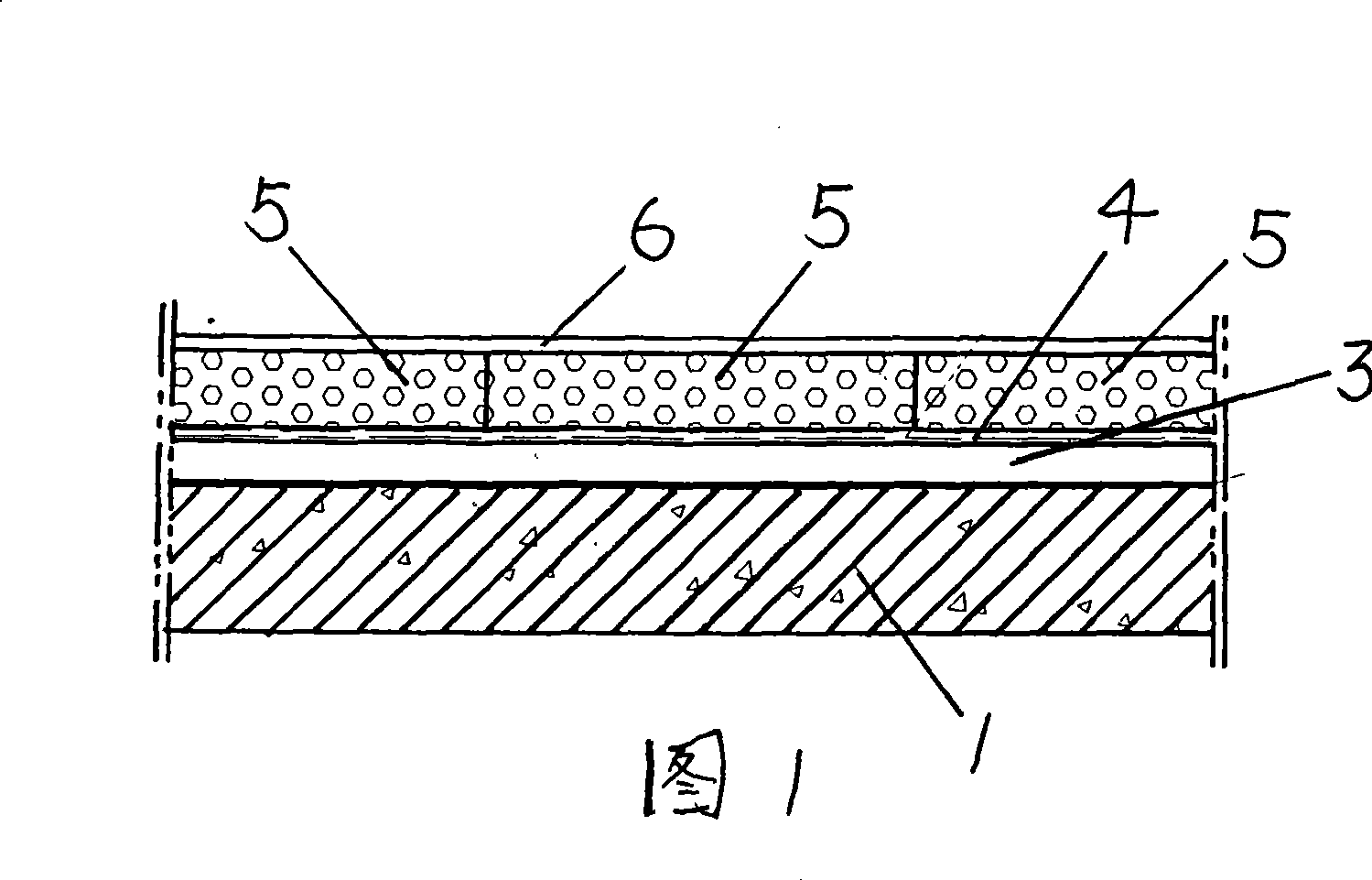

Construction method of thermal insulation buildings roof of foam glass

InactiveCN101363265ASimple daily maintenanceNo shrinkageRoof improvementClimate change adaptationThermal insulationUltraviolet

The invention relates to the technical field of building construction, in particular to construction method which is applicable to sloping roofs, tile roofs, flat roofs, elevated overhead roofs, planted roofs of buildings and basement roof with heat preservation and thermal insulation requirements. The construction method comprises the following steps: a leveling layer is cast on a building roof, the leveling layer is successively provided with a waterproof layer and a thermal insulation panel, a protective layer is cast on the thermal insulation panel which is a foam glass thermal insulation panel. The construction method fully utilizes the characteristics of the foam glass thermal insulation panel namely heat preservation, thermal insulation, incombustibility, water resistance, corrosion prevention, aging resistance, long service life, wide application temperature range, linear expansion coefficient of the panel similar to the concrete materials, etc. By laying the foam glass thermal insulation panel on the waterproof layer of the building roof, the influence of the atmosphere, temperature difference and ultraviolet radiation on the waterproof layer is greatly reduced, thus protecting the waterproof layer from aging, prolonging the service life of the waterproof layer, improving the thermal insulation performance of the building roof, saving the valuable energy sources, changing the waste material into useful material, and reducing the environmental pollution.

Owner:上海永丽节能墙体材料有限公司

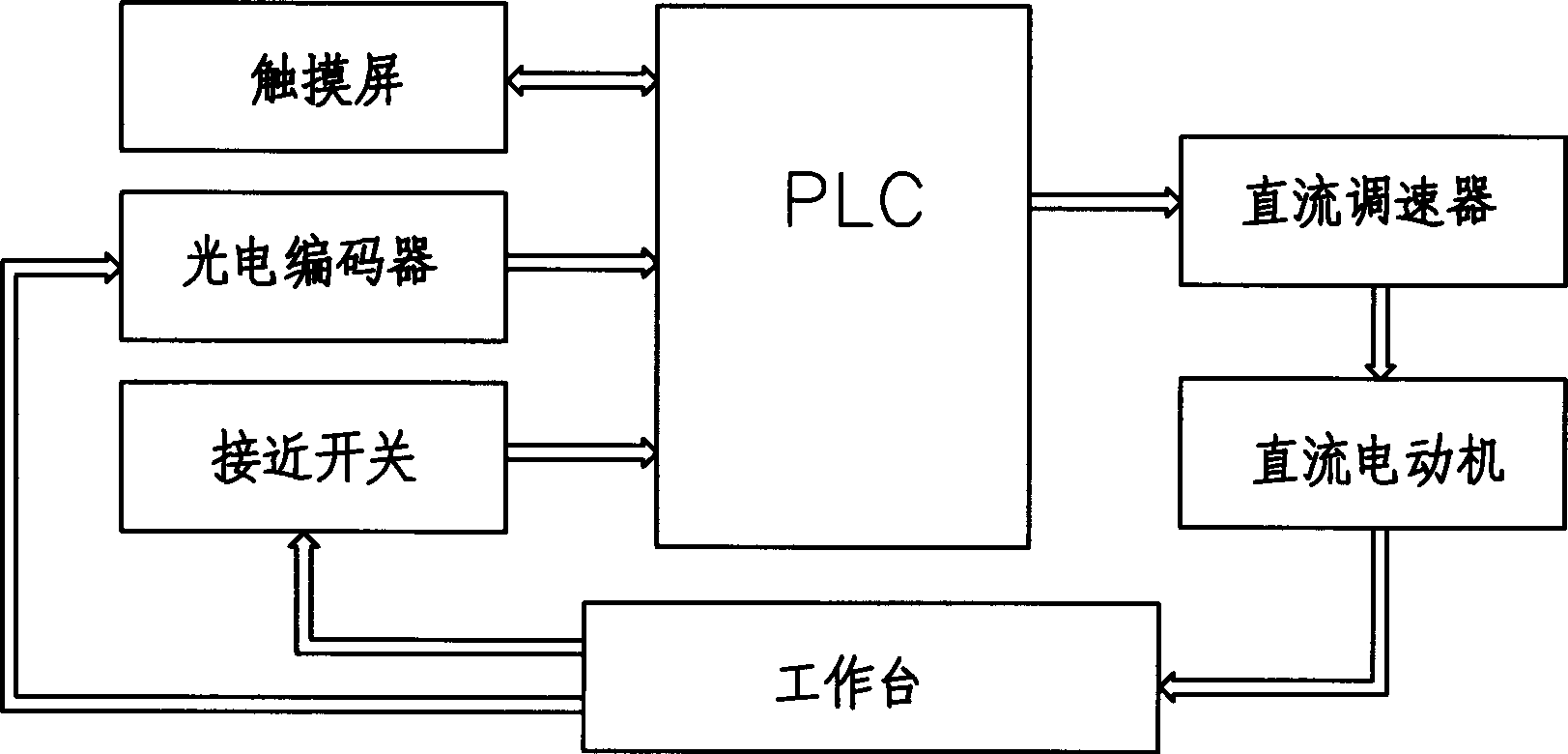

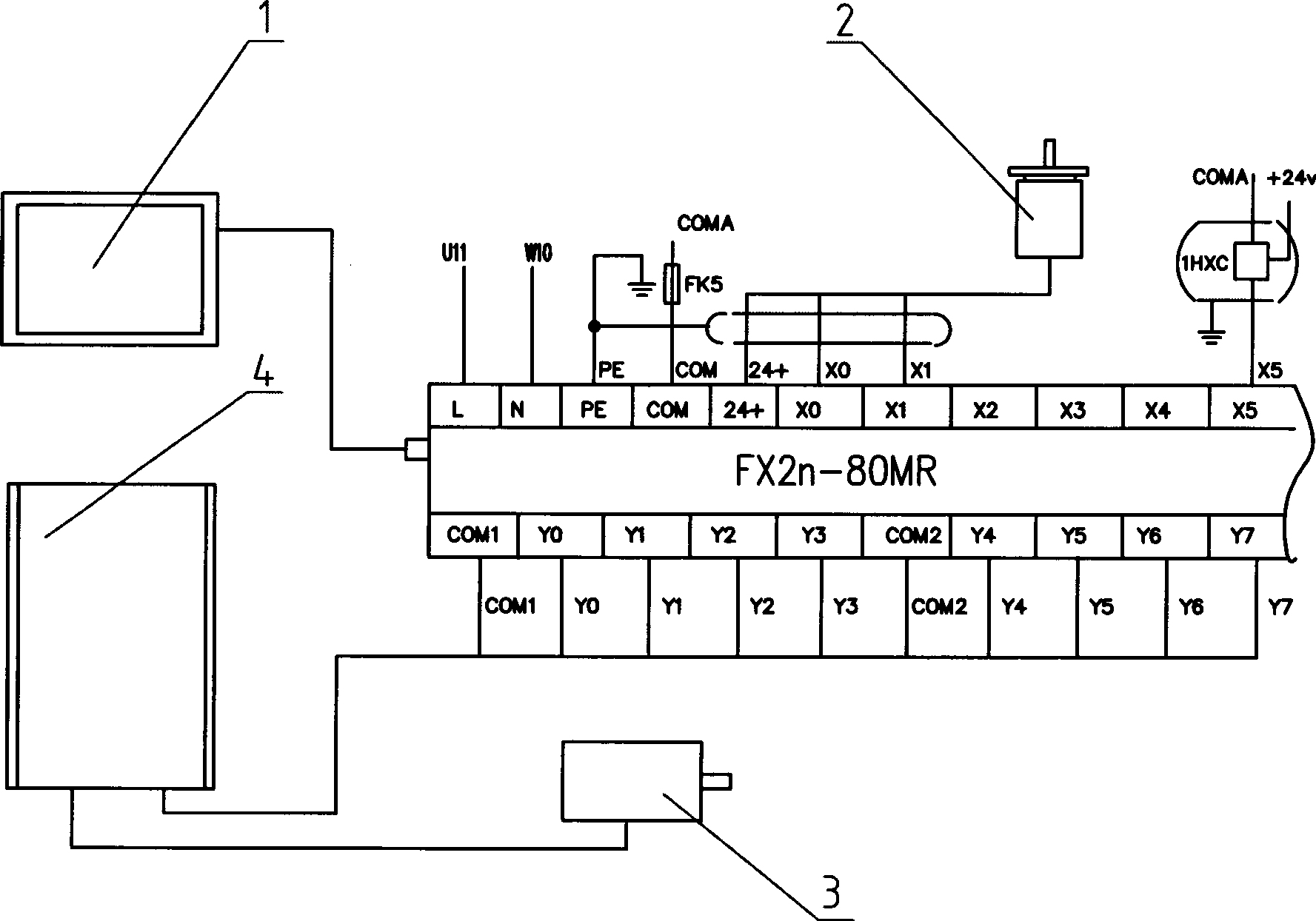

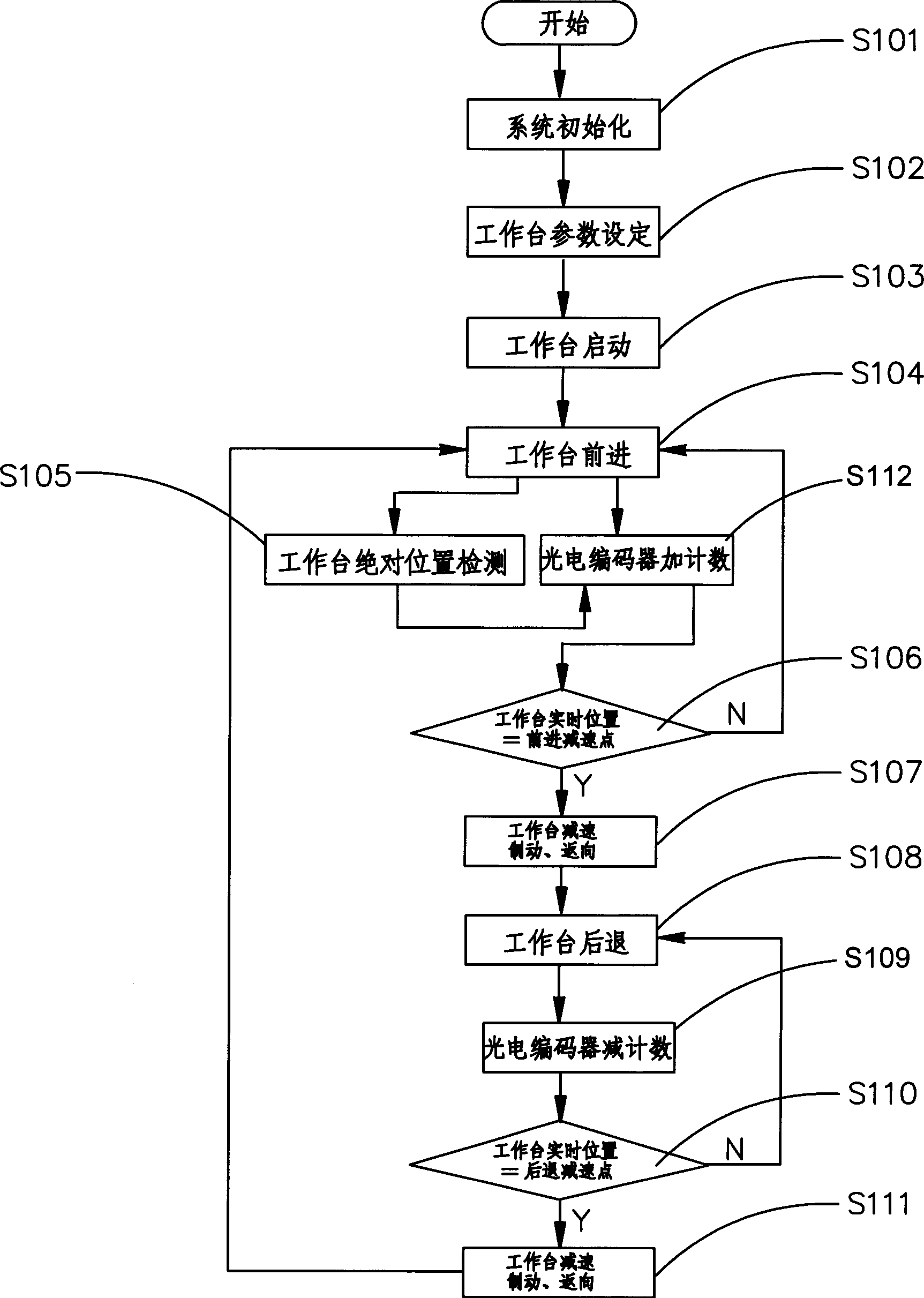

Table stroke control apparatus and control method

ActiveCN101367174AEasy programmingReduce wiringFeeding apparatusMetal working apparatusMachine toolControl logic

The invention discloses a device for controlling stroke of a worktable of a machine tool and a controlling method thereof. The device comprises a PLC, a photoelectric encoder, a touch screen and a speed governor of a direct current motor, wherein the PLC is used as a control logic device, a mechanical axis of the photoelectric encoder is coaxial with a worm for driving the worktable so as to acquire operation parameters of the worktable in real time; the output end of the photoelectric encoder is connected with a port of the input end of a high-speed counter of the PLC; the touch screen is connected with a serial port of the PLC and is used as a main action instruction input interface and a display interface of the worktable; and the speed governor of the direct current motor is connected with the output port of the PLC and is used for receiving a PLC control command and driving a stroke motor of the worktable. The invention provides the device for controlling the stroke of the worktable, which uses few elements, is convenient to adjust the largest stroke of the worktable and has high reliability and realizes the contactless reversing of the worktable.

Owner:JIER MACHINE TOOL GROUP

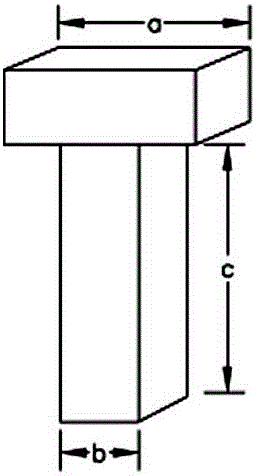

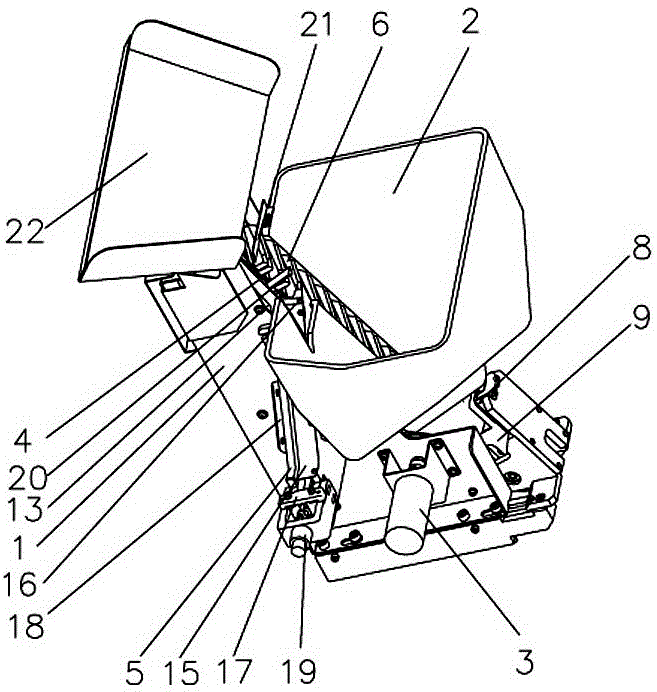

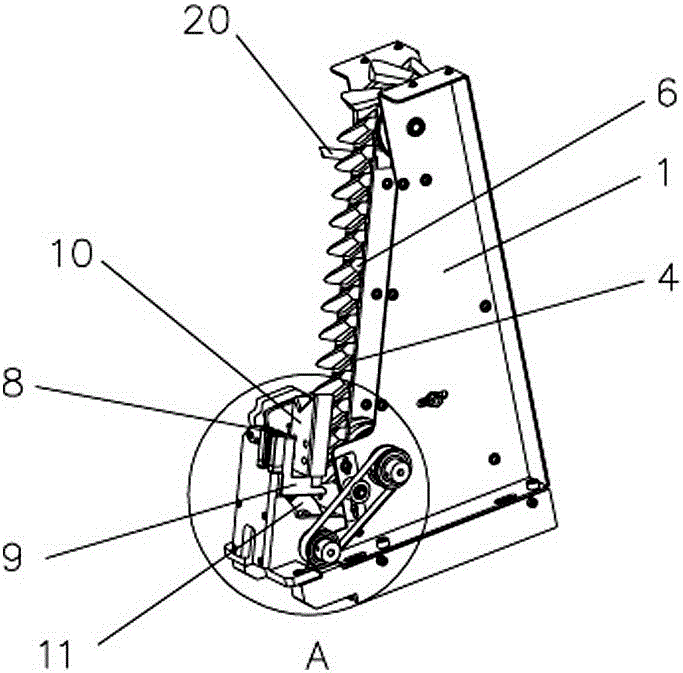

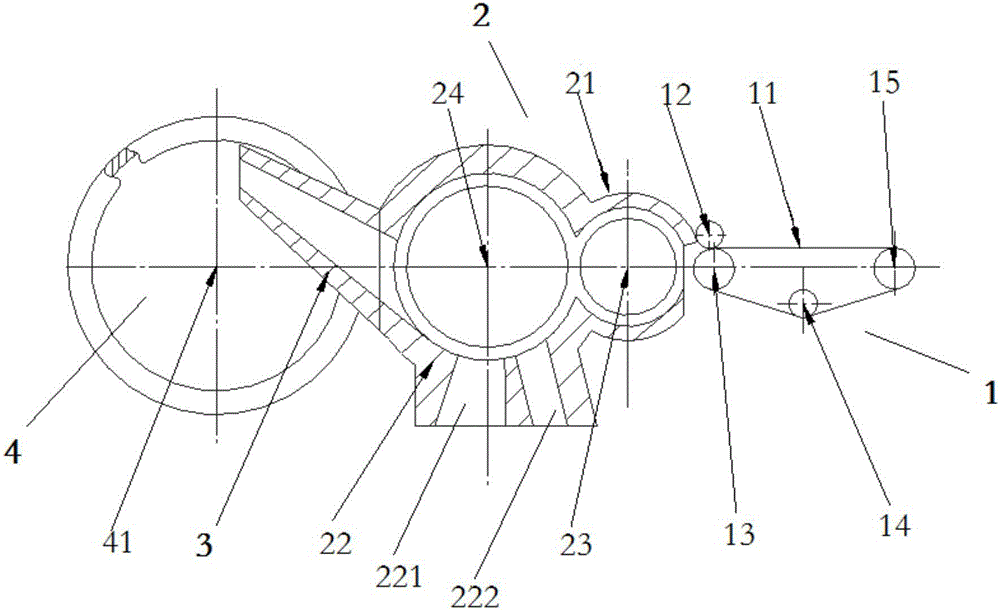

Automatic continuous reaction cup loading device for chemiluminescence immunoassay

The invention discloses an automatic continuous reaction cup loading device for chemiluminescence immunoassay. The automatic continuous reaction cup loading device comprises a frame, a reaction cup container arranged on the frame, a lifting conveying belt driven by a motor and a sliding way positioned at an outlet in the side surface of the lifting conveying belt, wherein the lifting conveying belt is clamped and put at an opening in a rear wall plate of the reaction cup container and runs through the bottom of the reaction cup container; a plurality of lifting blocks inclining towards the sliding way direction are arranged on the lifting conveying belt at intervals; a groove, of which the width is larger than the width b of the cup body of the reaction cup and smaller than the width a of the cup mouth of the reaction cup is formed in the bottom of the sliding way. The automatic continuous reaction cup loading device disclosed by the invention is compact in structure, low in cost, convenient to mount and reliable in running, has relatively high reaction cup loading efficiency, greatly improves the operation efficiency of a chemiluminescence immunoassay system, reduces manual operating strength, reduces manual operation, and is relatively low in cup clamping rate and failure rate, simple and convenient to maintain during failure and simple and easy to maintain daily.

Owner:AUTOBIO LABTEC INSTR CO LTD

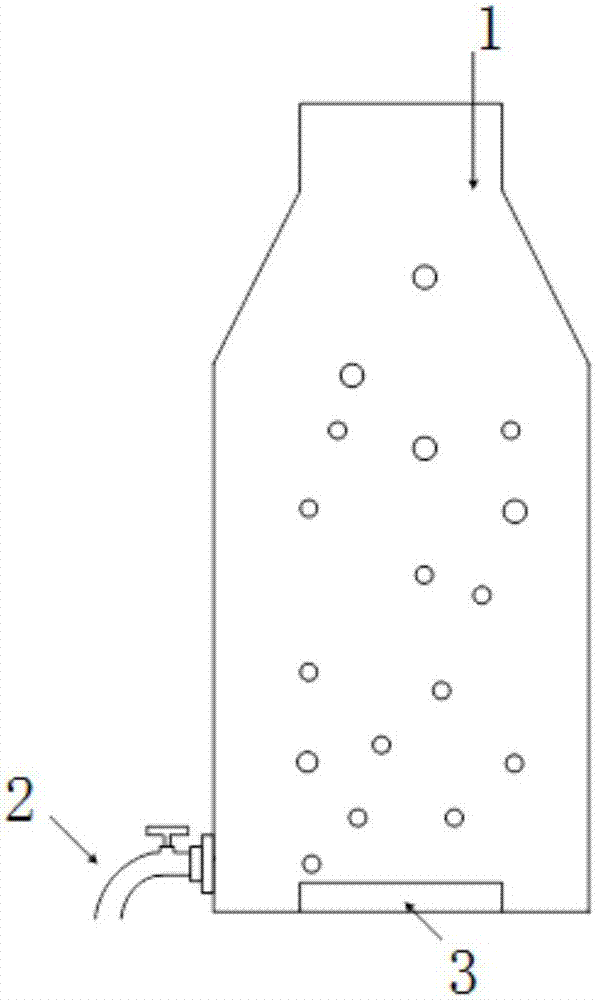

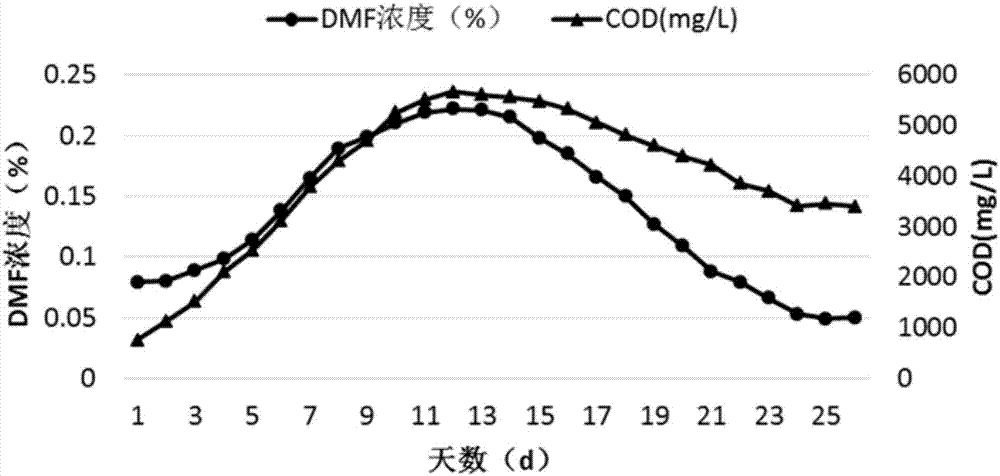

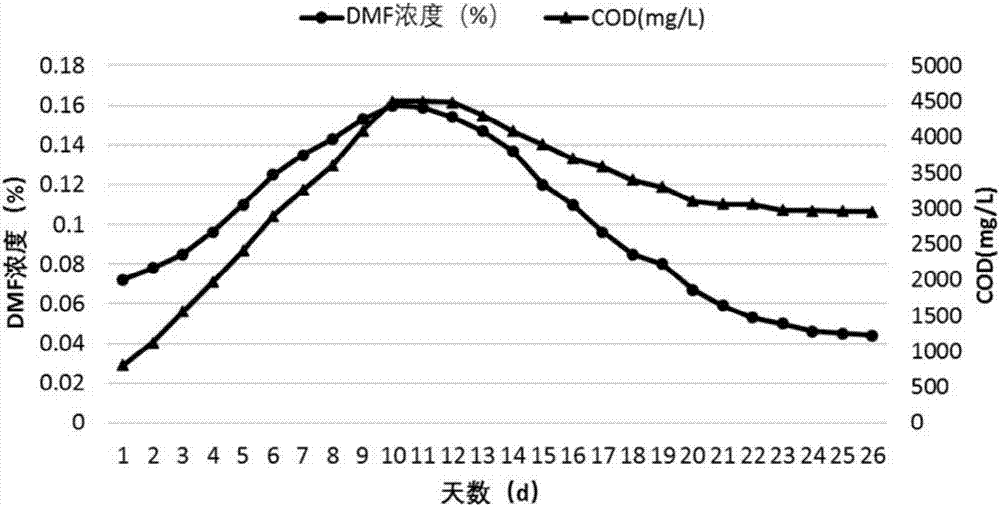

Method for degrading N,N-dimethylformamide in sucralose wastewater by using microorganisms

ActiveCN106986462AImprove degradation efficiencyHigh removal rateBacteriaWater contaminantsSucraloseBiological reaction

The invention discloses a method for degrading N,N-dimethylformamide in sucralose wastewater by using microorganisms. The method comprises: (1) enrichment culture of microbial flora: selecting a microbial flora, inoculating into a culture liquid, and carrying out enrichment culture to obtain an enrichment culture liquid; (2) acclimation of the microbial flora: selecting the enrichment culture liquid, inoculating into an initial acclimation culture liquid containing N,N-dimethylformamide, and carrying out acclimation on the microbial flora by continuously adjusting the N,N-dimethylformamide content in a biological reaction device so as to obtain an acclimation completing culture liquid; and (3) degradation of N,N-dimethylformamide in sucralose wastewater with the microorganisms: continuously introducing sucralose production wastewater containing N,N-dimethylformamide into the acclimation completing culture liquid, and degrading the N,N-dimethylformamide in the sucralose wastewater by using the microorganisms. With the method of the present inventin, the high efficiency and low cost treatment of the N,N-dimethylformamide in the sucralose wastewater can be achieved.

Owner:GUANGDONG FOOD IND INST +1

Water-base epoxy color sand mortar and its preparing process and construction process

InactiveCN1986479ASimple preparation processLow equipment requirementsIn situ pavingsEpoxyPolymer science

The water-base epoxy color sand mortar consists of two components, including component A of KNP WEM601A in 16.5-17.5 weight portions; and component B comprising KNP WEM601B in 10.0-10.6 weight portions, quartz sand in 62.0-64.0 weight portions, water-base epoxy color sand in 2.0-3.0 weight portions and water in 5.0-5.5 weight portions. The water-base epoxy color sand mortar as one kind of environment friendly decoration product has specific decoration effect and is water resistant, chemical corrosion resistant, oil contamination resistant, wear resistant, high in strength and high in adhesion strength.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

Differential air-pressure spray dust removing system and implementation method thereof

InactiveCN102764552AGuaranteed functionEfficient use ofUsing liquid separation agentTraffic signalsPublic placeSpray nozzle

The invention discloses a differential air-pressure spray dust removing system and solves the problems that power potential energy losing after deceleration of motorized or non-motorized objects by deceleration strips or public place buffering is not utilized effectively, current dust removing systems are complicated in structure, high in cost, need external power supplies or other power supplies in the prior art. The spray dust removing system comprises a deceleration strip, air sacs, a water and pressure storage device, and a spray actuation mechanism. The air sacs are disposed in the deceleration strip or a public passage. The water and pressure storage device is communicated with the air sacs through an air guide tube. The spray actuation mechanism is disposed on the water and pressure storage device. The water and pressure storage device mainly comprises a water and pressure storage tank. The spray actuation mechanism comprises a flow guide tube. The lower end of the flow guide tube penetrates into the water and pressure storage tank. The upper end of the flow guide tube is located outside the water and pressure storage tank. A spray nozzle is disposed at the upper end of the flow guide tube. The invention further discloses an implementation method of the spray dust removing system. The spray dust removing system is simple in structure, convenient to implement, energy-saving and environment-friendly.

Owner:吴英戈

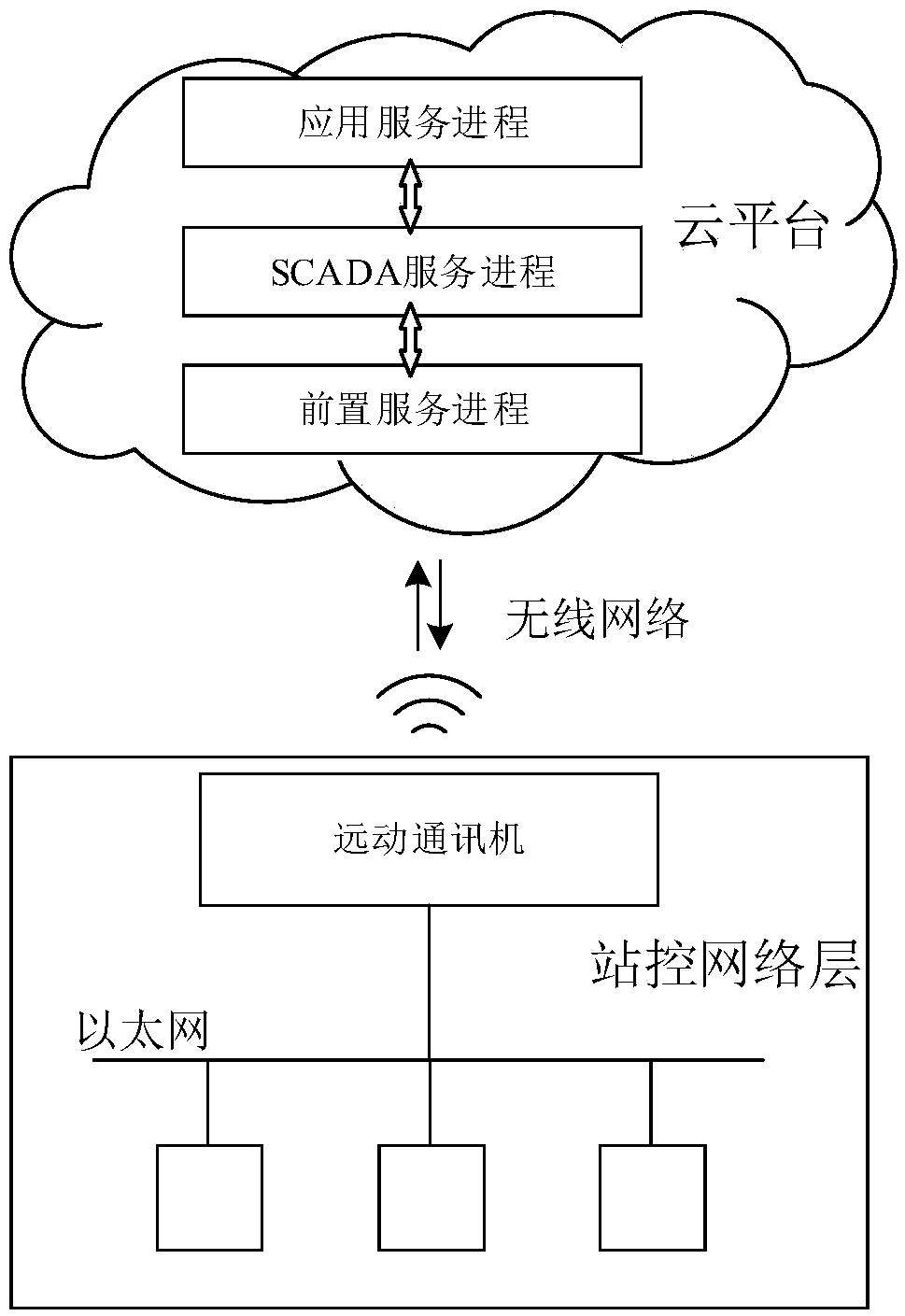

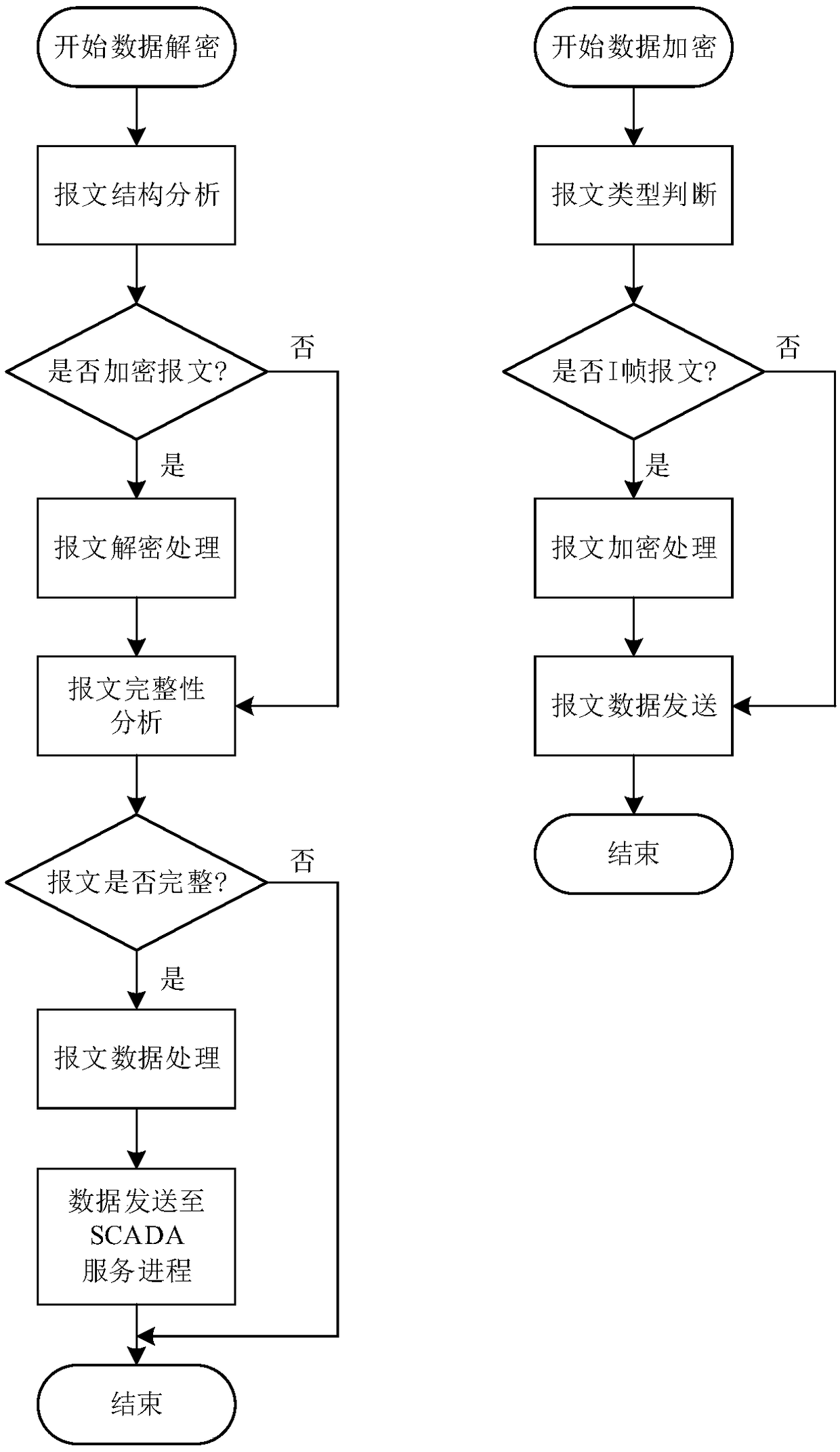

New energy power station operation control method based on cloud monitoring and data encryption transmission

A new energy power station operation control method based on cloud monitoring and data encryption transmission comprises an optimization operation control strategy of the new energy power station in acloud platform, a data encryption transmission strategy of the new energy power station in the cloud platform, and a data encryption transmission strategy of a station control network layer of the new energy power station. The control strategy comprises: performing power and load prediction according to the data transmitted from the station control network layer to the cloud platform and sendinga relevant curve to the station control network layer for execution; the data encryption transmission strategy comprises: transmitting the data uploaded by the station control network layer to SCADA service process of the cloud platform after collection and decryption, and transferring the data sent by the cloud platform to the station control network layer after encryption; and the encryption transmission strategy of the station control network layer comprises: transmitting the power station operation data to the cloud platform after collection and decryption, receiving the data from the cloud platform, and decrypting and distributing the data to each terminal of the station control layer. The method provided by the invention places the optimized operation strategy of the power station onthe cloud platform side, and adopts an encryption algorithm to ensure the security of the system network and the data, which saves the land in the power station, and improves the reliability of the system.

Owner:长园深瑞继保自动化有限公司 +1

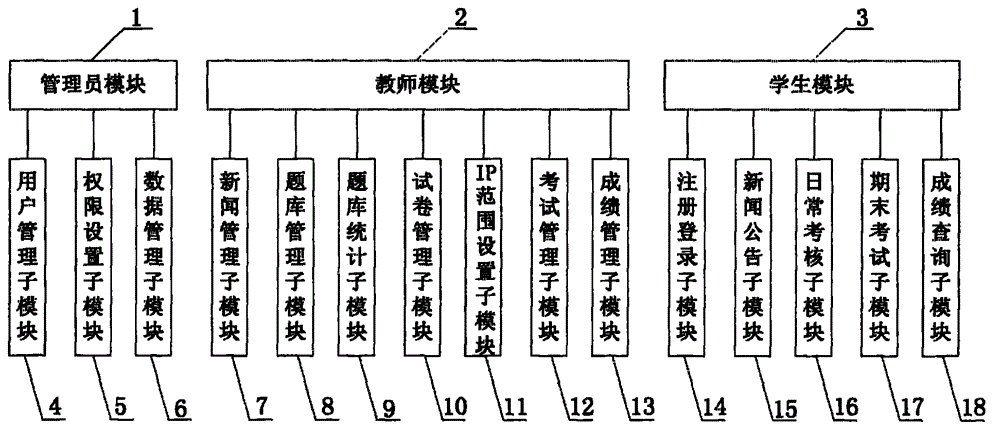

Webpage-based human anatomy specimen examination system

InactiveCN104599207AImprove efficiencyImprove teaching qualityData processing applicationsElectrical appliancesHuman anatomySpecimen preparation

The invention provides a webpage-based human anatomy specimen examination system. The webpage-based human anatomy specimen examination system comprises an administrator module, a teacher module and a student module. The administrator module comprises a user management sub-module, a permission setting sub-module and a data management sub-module. The teacher module comprises a news management sub-module, an examination base management sub-module, an examination base statistics sub-module, an examination paper management sub-module, an IP (Internet Protocol) range setting sub-module, an examination management sub-module and an examination result management sub-module. The student module comprises a register and login sub-module, a news bulletin sub-module, a routine examination sub-module, a final examination sub-module and a result inquiry sub-module. The webpage-based human anatomy specimen examination system uses the computer and network technology for opening anatomy specimen examination new ideas, avoids formalin stimulation to teachers and students for being beneficial to health and saving specimen preparation costs and maintenance costs and improves anatomy specimen examination efficiency and teaching quality. The webpage-based human anatomy specimen examination system is simple in routine maintenance and easy to operate and use.

Owner:菏泽医学专科学校

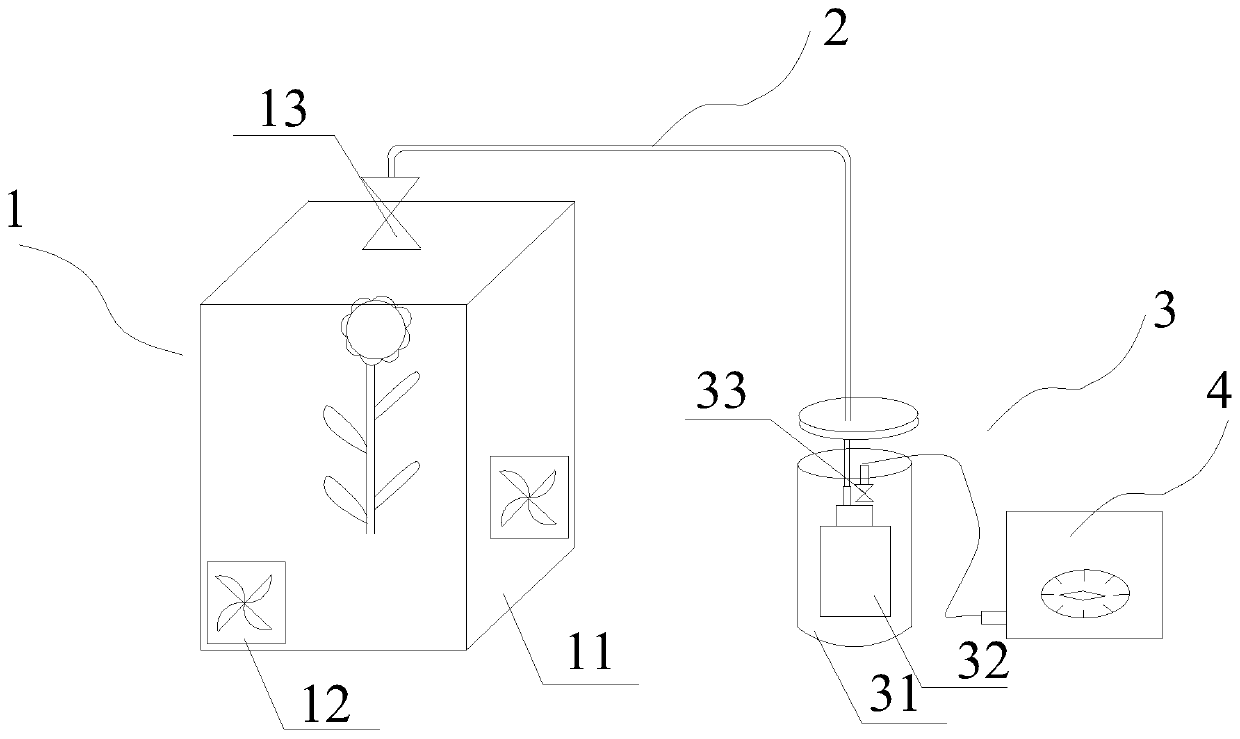

Collecting and measuring device for soil evaporation and plant transpiration water vapor and use method of collecting and measuring device

PendingCN110108845AEasy to collectEasy to observeWeighing by removing componentMeasurement deviceWater vapor

The invention relates to the technical field of evaporation and transpiration water vapor collecting and measuring devices, in particular to a collecting and measuring device for soil evaporation andplant transpiration water vapor. The collecting and measuring device comprises an evapotranspiration reaction chamber, an evapotranspiration water vapor collector, an air extracting pump, and a connecting pipeline, wherein the evapotranspiration reaction chamber is used for collecting the evaporation and transpiration water vapor from soil and plants; the evapotranspiration water vapor collector is used for condensing the evaporation and transpiration water vapor; the evapotranspiration water vapor collector is provided with a collecting bottle which is used for holding the evaporation and transpiration water vapor; the air extracting pump is connected with the collecting bottle, and used for drawing out air inside the collecting bottle and keeping the inside of collecting bottle in the negative pressure state; and one end of the connecting pipeline extends out from the evapotranspiration reaction chamber, the other end of the connecting pipeline extends in from the collecting bottle,and the evaporation and transpiration water vapor from the evapotranspiration reaction chamber enters the collecting bottle through the connecting pipeline, and meanwhile, the collecting and measuringdevice has the characteristics of easy operation and low cost.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

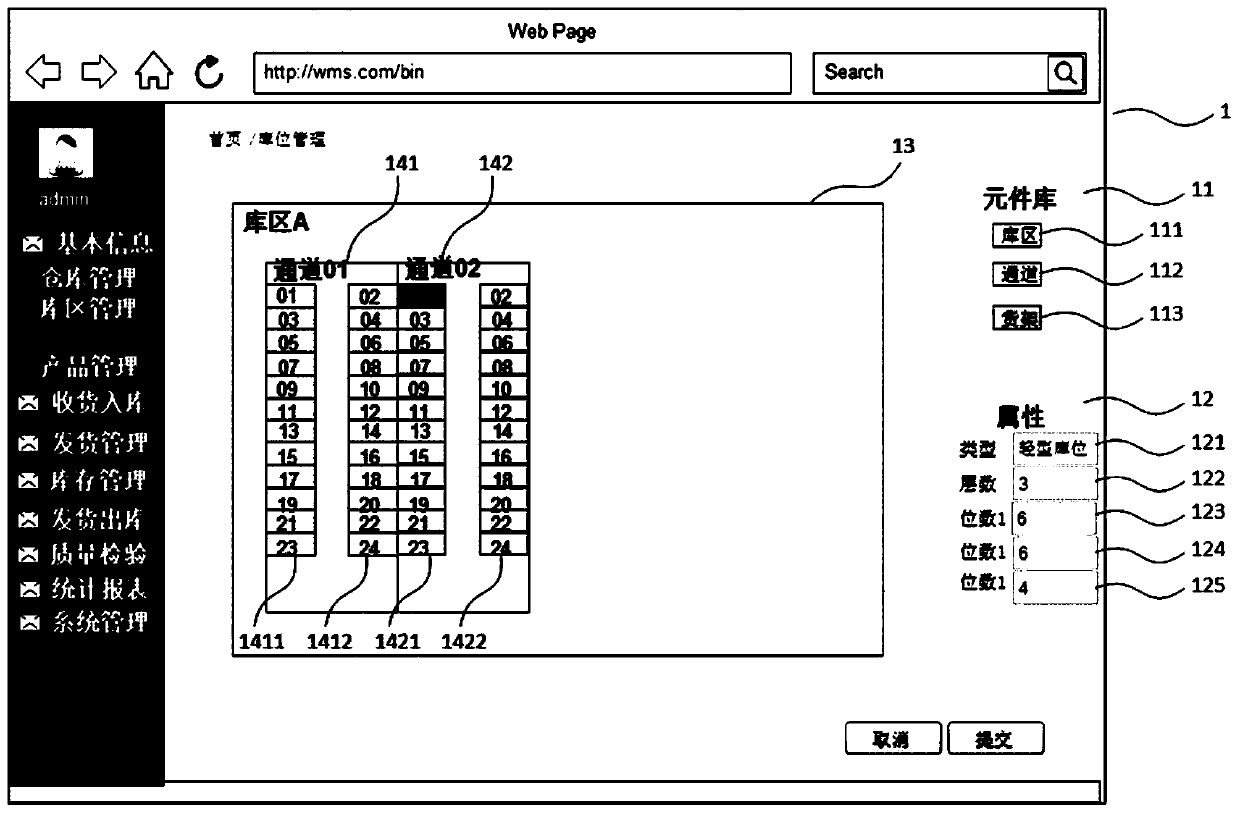

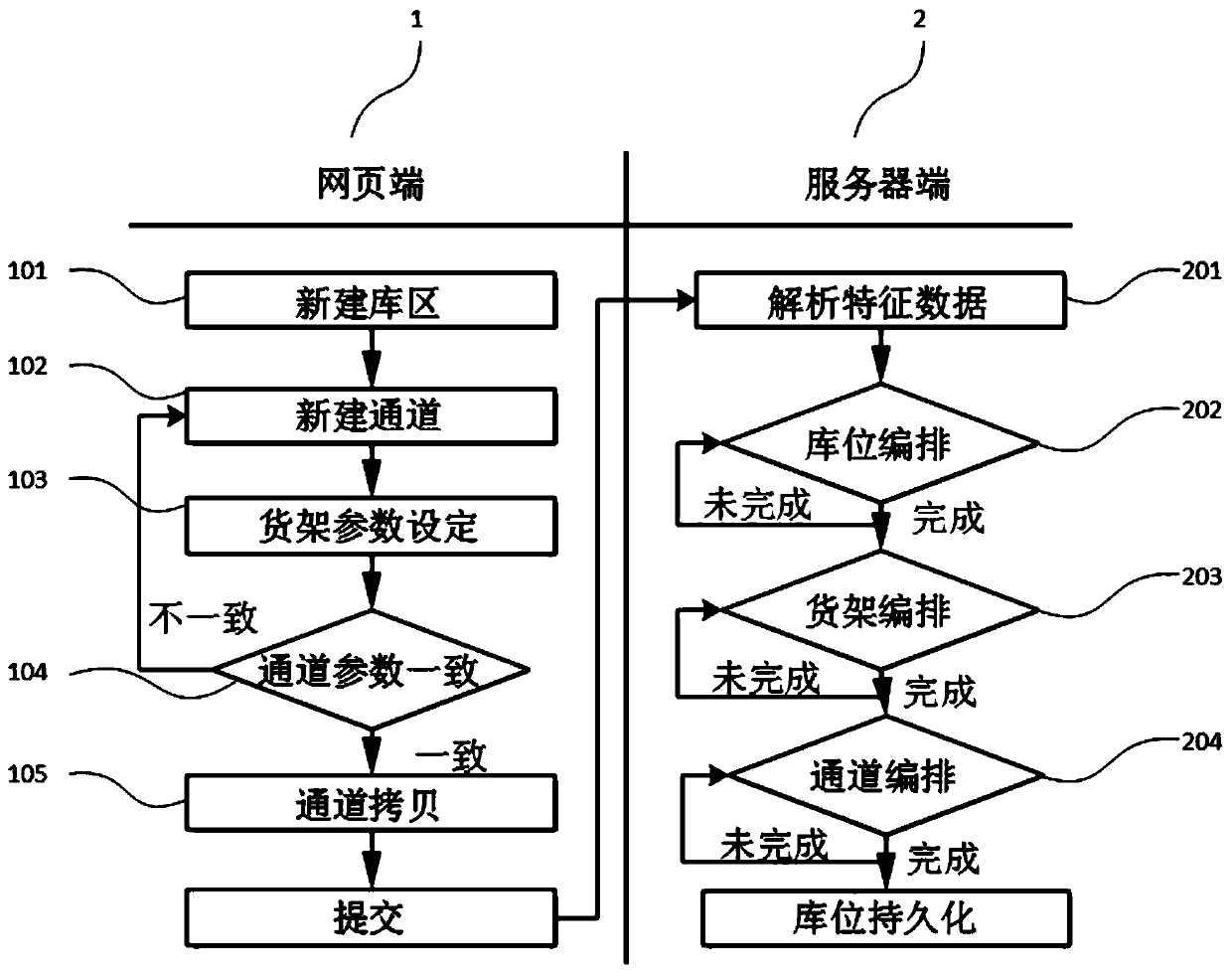

Visual webpage intelligent warehouse location arrangement system

The invention provides a visual webpage intelligent warehouse location arrangement system, which comprises a webpage end and a server end, and is characterized in that the webpage end comprises an element library module, wherein the element library module comprises library area marks, channel marks and shelf marks; an editing area used for creating a library area by clicking or dragging the library area marks and creating a corresponding channel and a shelf by clicking or dragging the channel marks and the shelf marks; an attribute module used for respectively displaying a parameter input boxto set a first parameter for creating a warehouse area, a second parameter for creating a channel and a third parameter for creating a goods shelf in an input mode when the warehouse area mark, the channel mark and the goods shelf mark are clicked or dragged; the server end comprises an analysis module, a storage location arrangement module, a goods shelf arrangement module and a channel arrangement module so as to analyze, confirm or change the first parameter, the second parameter and the third parameter. The system and the method have the beneficial effects that the warehouse location is arranged by utilizing the webpage visual page end, the server confirms and changes, the arrangement layout is intuitive, simple and rapid, the operation is simple, the daily maintenance is simple, and the operation cost is low.

Owner:SHANGHAI IND U TECH RES INST

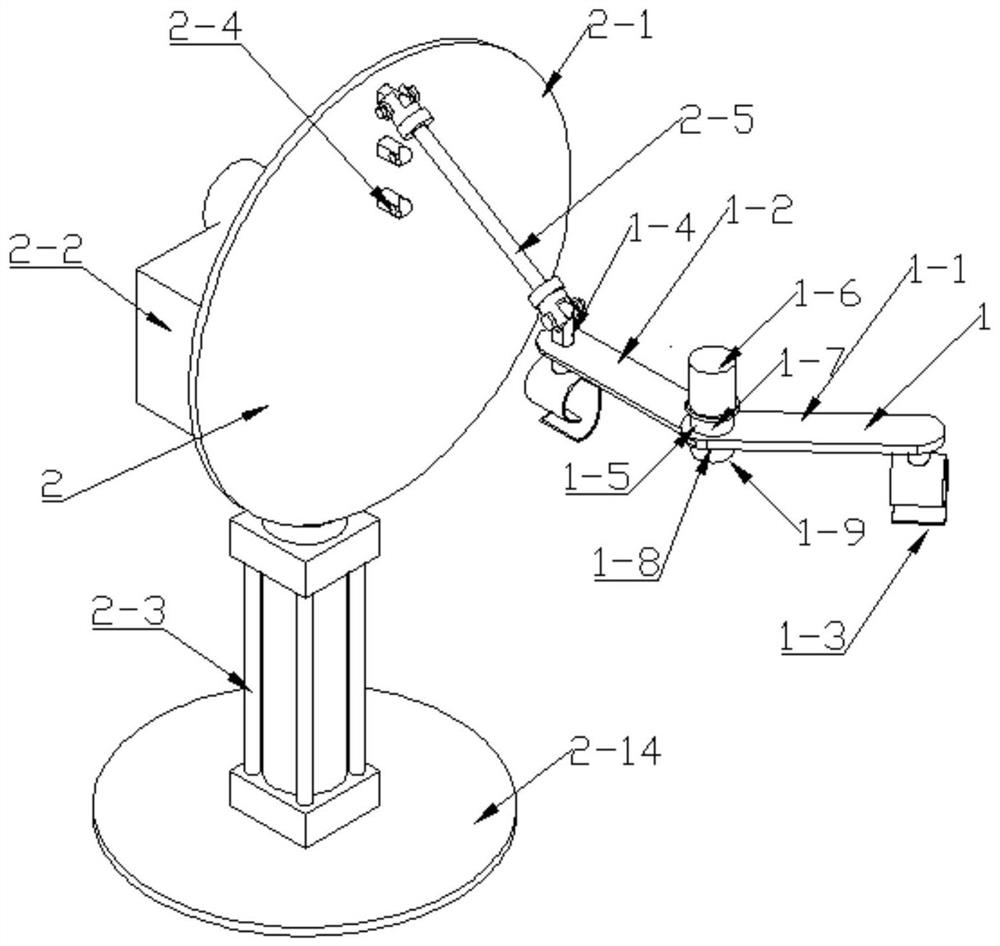

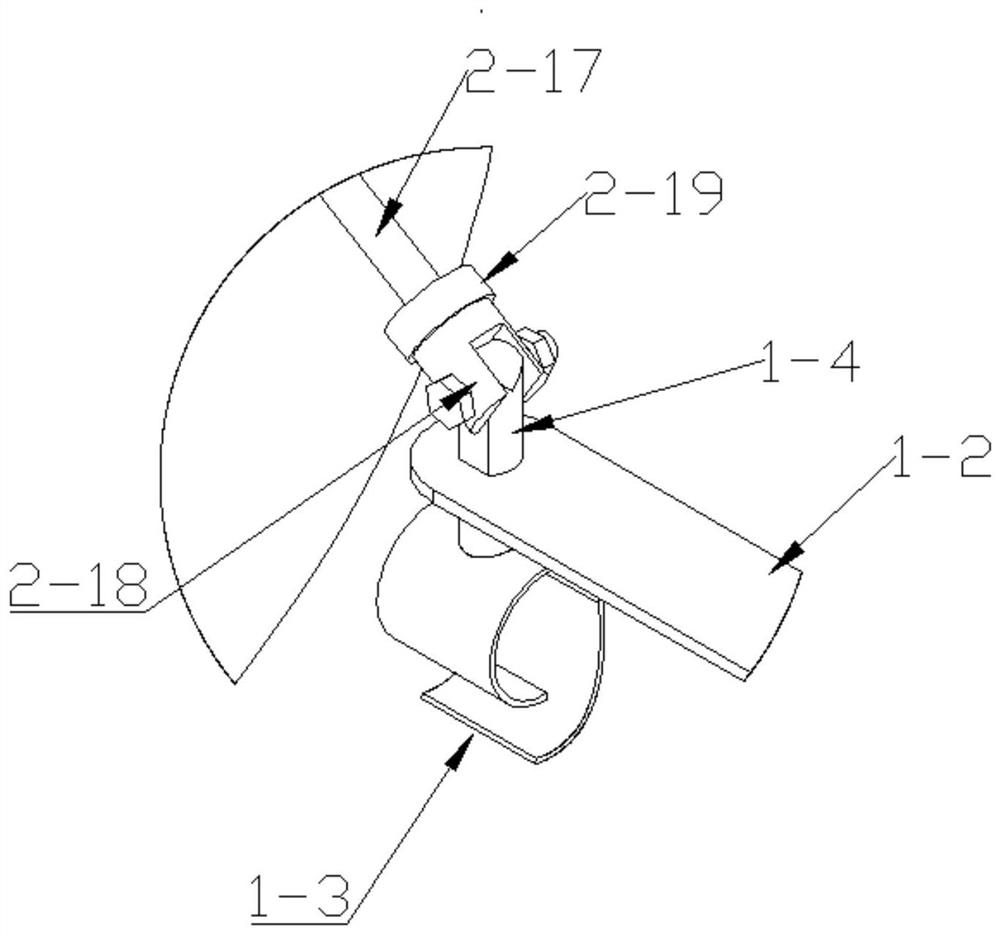

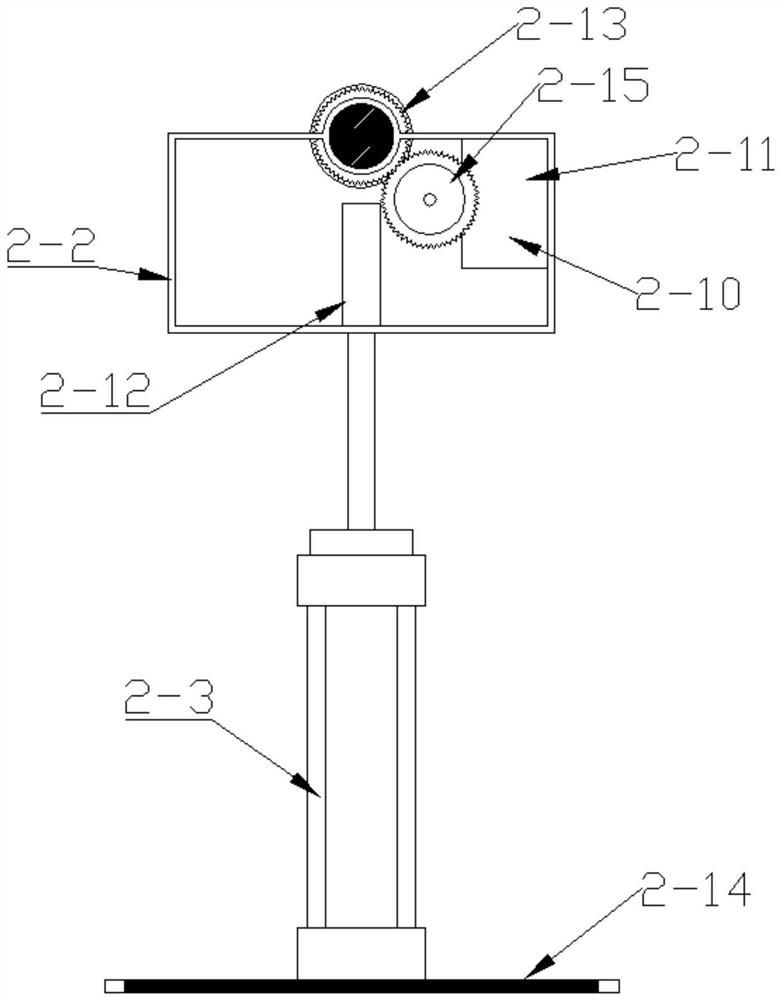

Dynamic and static combined upper limb rehabilitation brace and using method thereof

ActiveCN111956447ASimple structureMany replaceable partsChiropractic devicesMuscle exercising devicesMicrocontrollerCircular disc

The invention relates to a dynamic and static combined upper limb rehabilitation brace. The brace comprises an elbow joint support, a shoulder joint movable frame and a controller; the elbow joint support comprises a forearm fixing rod and an elbow fixing rod; the forearm fixing rod and the elbow fixing rod are movably connected, can be bent, are driven by a servo motor I to complete bending and unbending, and a brake I and an angle sensor assist in completing movement of upper limb elbow joints; the shoulder joint movable frame comprises a rotating disc, a disc driving supporting mechanism and an air cylinder; the rotating disc is connected to the elbow joint support through a movable connecting rod, a servo motor II, a servo motor driver and a brake II are arranged in the disc driving supporting mechanism and jointly drive the rotating disc to rotate to drive the elbow joint support to move, and the air cylinder adjusts the height of the upper limb rehabilitation brace; and the controller is a square box, a single-chip microcomputer is installed in the controller, and a control panel is arranged on the upper surface of the controller. The dynamic and static combined upper limb rehabilitation brace is used for simply and movably supporting the upper limb, and is simple in structure and easy to realize.

Owner:昆明医科大学第二附属医院

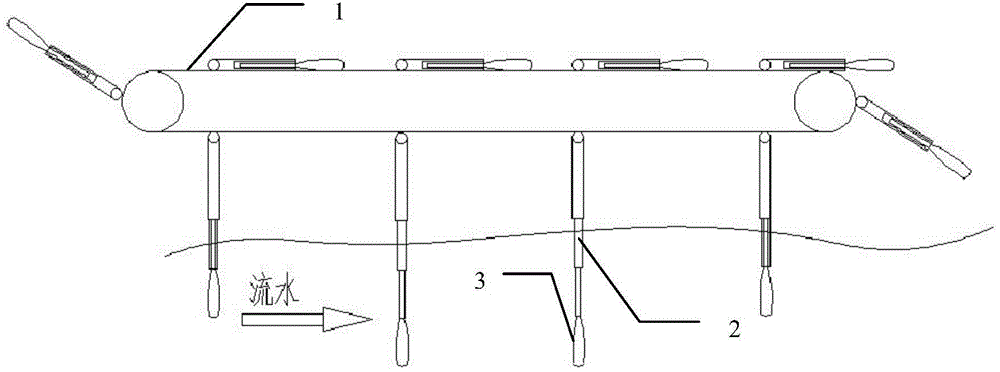

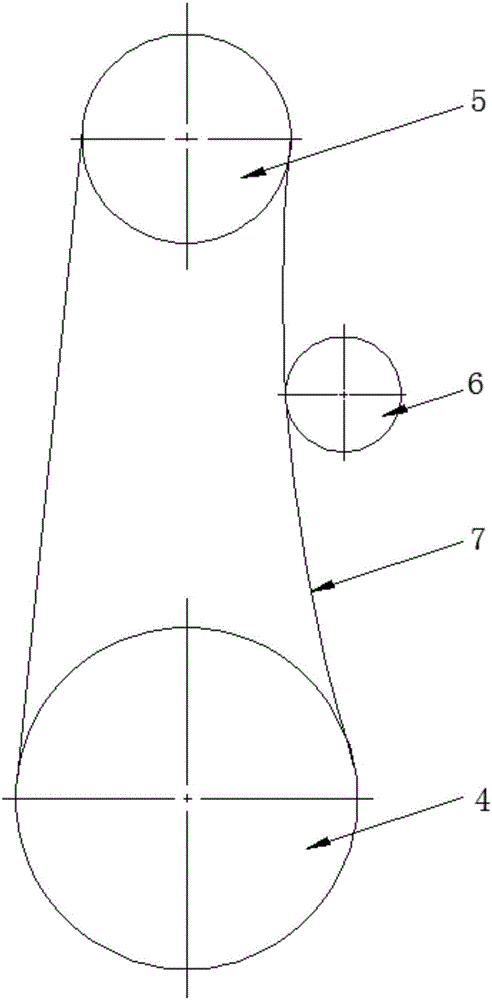

Flowing water power generation device achieving automatic pitch varying and pitch varying method thereof

InactiveCN104791178ALarge thrustSave installation spaceHydro energy generationSafety/regulatory devicesWater channelWater flow

The invention discloses a flowing water power generation device achieving automatic pitch varying and belongs to the field of hydroelectric generation technologies. The power generation device comprises floating platforms, generators and anchoring devices. The floating platforms can float on the water surface, the generators are arranged on the floating platforms, and the anchoring devices are used for fixing the floating platforms. Flowing water channels which are through in the front and back direction are formed in the lower portions of the floating platforms, belt wheels are arranged inside the flowing water channels and can rotate in the longitudinal direction of the flowing water channels, and rotating shafts of the belt wheels are connected with rotating shafts of the generators through transmission mechanisms. The flowing water power generation device further comprises a set of blades movably connected with the outer rings of the belt wheels and a set of limiting mechanisms corresponding to the blades one by one. The limiting mechanisms can make the blades corresponding to the limiting mechanisms be in a working state, and make the blades corresponding to the limiting mechanisms be in a non-working state, wherein the blades in the working state and the flowing water direction form an included angle below the belt wheels, the blades in the non-working state and the flowing water direction are parallel basically above the belt wheels, and the length of the blades can be actively adjusted. The invention further discloses a pitch varying method of the power generation device. The power generation device is simple in structure, high in energy conversion efficiency and wide in application range.

Owner:包金明 +1

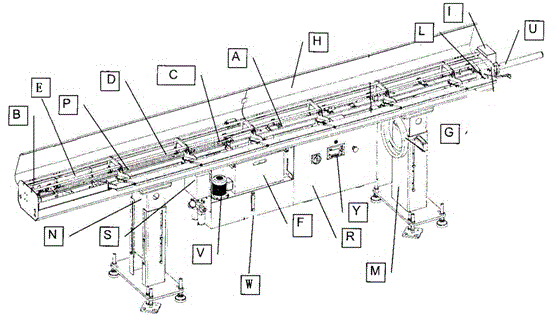

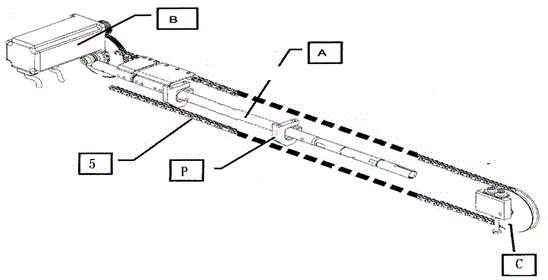

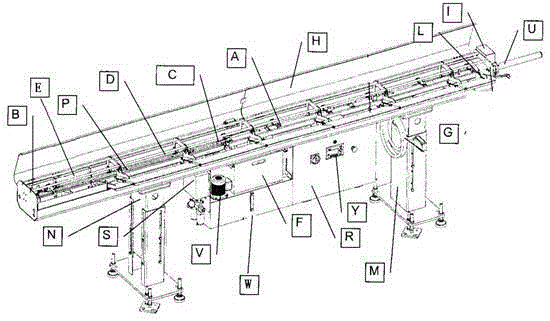

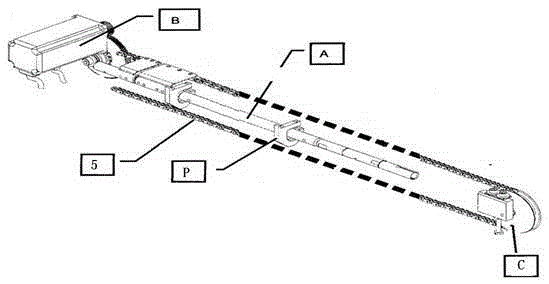

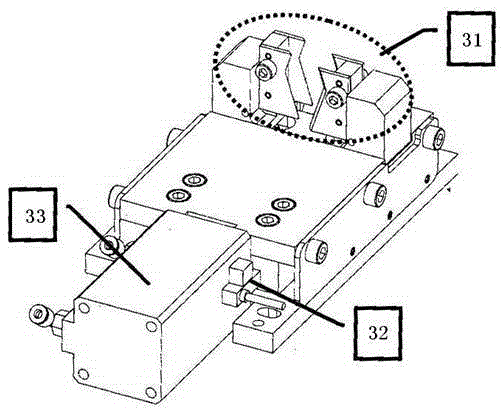

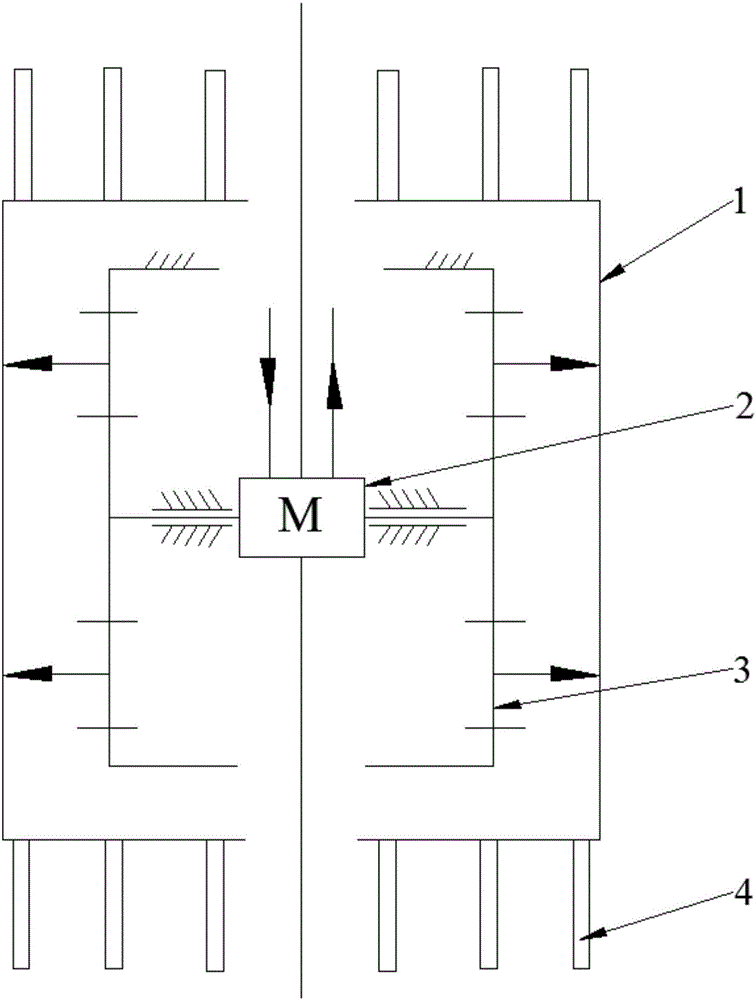

Automatic feeding mechanism and feeding method of rod numerically controlled lathe

ActiveCN104827058AImprove applicabilityEasy to operateMetal working apparatusControl systemTransmitted power

The invention discloses an automatic feeding mechanism and a feeding method of a rod numerically controlled lathe. The automatic feeding mechanism of the rod numerically controlled lathe comprises a circuit control system, a feeding system, a detection system and a hydraulic system, wherein the circuit control system adopts a programmable controller to control the assembly action of a workpiece and the detection action of the detection system; the feeding system comprises a rod tampering group and a transmission group, and a servo motor transmits power to the rod tampering group so as to enable the rod tampering group to move back and forth, so that the actions of feeding, inserting and pulling are completed; the detection system is used for realizing accurate positioning of rod materials; the hydraulic system is used for injecting hydraulic oil into a hydraulic oil slot in a constant oil pressure way, so that the rod materials are suspended in the hydraulic oil in the hydraulic oil slot.

Owner:GUANGDONG JUNCHI TECH HLDG

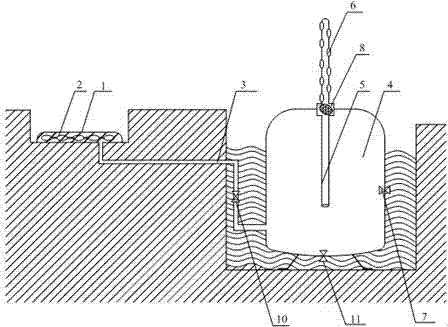

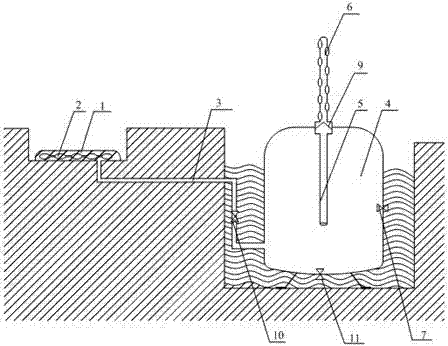

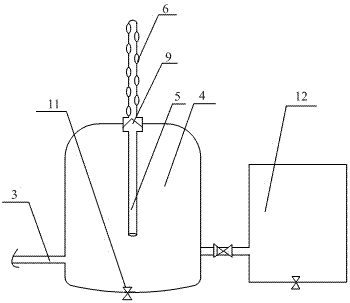

Activated carbon filter coupling solar energy driven device for treating bitter salty water through membrane capacitive deionization and application method thereof

InactiveCN105948187AAvoid wastingConstant water levelSpecific water treatment objectivesDispersed particle separationCapacitanceDihydrogen oxide

The invention discloses an activated carbon filter coupling solar energy driven device for treating bitter salty water through membrane capacitive deionization and an application method thereof, and belongs to the technical field of bitter salty water treatment. The problems that MCDI electrode organic pollution is serious, effluent quality is poor and non-renewable energy resources are used for supplying power of an existing method for treating bitter salty water through MCDI are solved. The device comprises a raw water tank, a check valve, a raw water inlet valve, an activated carbon filter, a drainage valve, a back washing water storage tank, a back washing valve, intermediate water tank, an MCDI water inlet valve, an MCDI assembly, a regeneration valve, a concentrated brine storage tank, a fluid flowmeter or water meter, a water outlet valve, a clean water tank and a solar power supply system. According to the device, gravity flow exists in the whole application process, the water supply power cost is saved, meanwhile, working pressure is low, clean and renewable solar energy is used as the power supply, and power saving and environmental protection are achieved; effluent quality is improved, and MCDI organic pollution is avoided; operation is easy, the maintenance rate is low, and no chemical agent exists.

Owner:NAT ENG RES CENT OF URBAN WATER RESOURCE

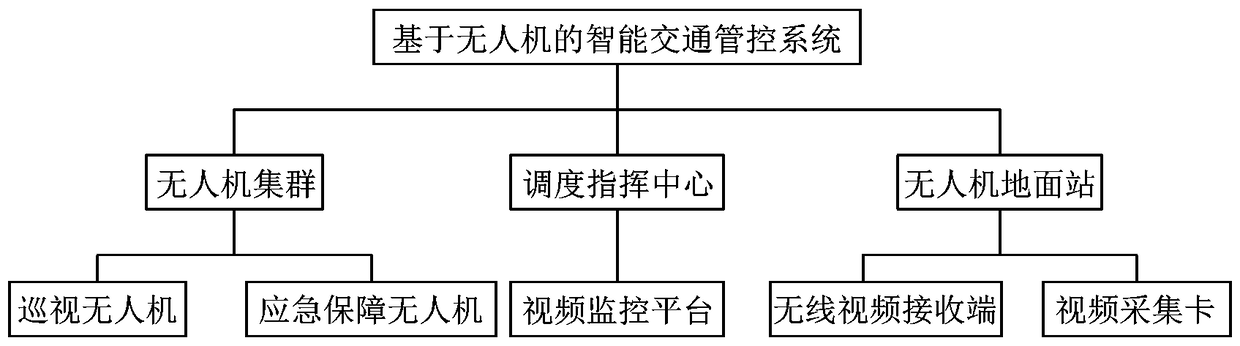

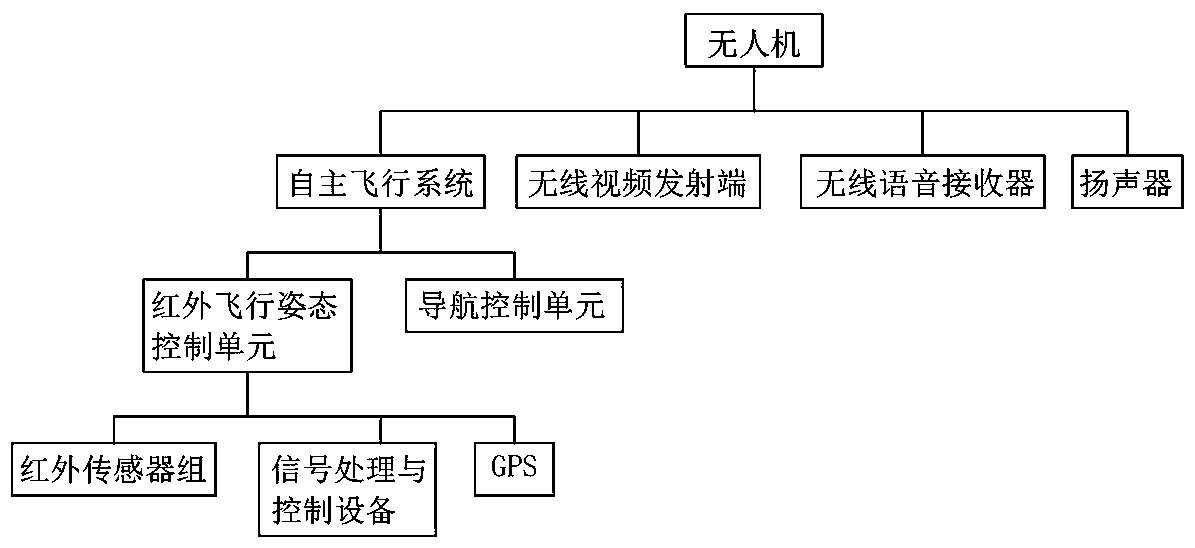

Intelligent traffic management control system based on unmanned aerial vehicle

InactiveCN109345830ALow priceSimple daily maintenanceDetection of traffic movementClosed circuit television systemsControl systemComputer module

The invention discloses an intelligent traffic management control system based on an unmanned aerial vehicle (UAV). The system comprises a UAV cluster, a dispatching command center and a UAV ground station. The UAV cluster comprises one or more types of UAVs, and each different type of UAV is used for performing different tasks. The dispatching command center is used for monitoring the UAV clusterin real time, and overall controlling traffic conditions. The UAV ground station is used for unified management and control of the UAV. The UAV and the UAV ground station communicate with each otherthrough a wireless communication module. The dispatching command center and the UAV ground station interact with each other through a base station by means of wireless communication. The invention provides the intelligent traffic management control system based on the UAV. The intelligent traffic management control system based on the UAV adopts different types of UAVs to perform different tasks,which reduces costs and saves resources.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

Automatic feeding mechanism and feeding method of rod CNC lathe

ActiveCN104827058BImprove applicabilityEasy to operateMetal working apparatusControl systemTransmitted power

The invention discloses an automatic feeding mechanism and a feeding method of a rod numerically controlled lathe. The automatic feeding mechanism of the rod numerically controlled lathe comprises a circuit control system, a feeding system, a detection system and a hydraulic system, wherein the circuit control system adopts a programmable controller to control the assembly action of a workpiece and the detection action of the detection system; the feeding system comprises a rod tampering group and a transmission group, and a servo motor transmits power to the rod tampering group so as to enable the rod tampering group to move back and forth, so that the actions of feeding, inserting and pulling are completed; the detection system is used for realizing accurate positioning of rod materials; the hydraulic system is used for injecting hydraulic oil into a hydraulic oil slot in a constant oil pressure way, so that the rod materials are suspended in the hydraulic oil in the hydraulic oil slot.

Owner:GUANGDONG JUNCHI TECH HLDG

Milling wheel drive system of double-wheel slot milling machine for underground continuous wall construction

ActiveCN105864388AEasy to adjust the output speedQuality improvementToothed gearingsSoil-shifting machines/dredgersSlurry wallHydraulic motor

The invention discloses a milling wheel drive system of a double-wheel slot milling machine for underground continuous wall construction. A motor gear is mounted on a rotating shaft of a hydraulic motor, the motor gear is in meshed connection with a first gear of coaxial double gears, a second gear of the coaxial double gears is in meshed connection with a first middle gear, the multiple middle gears are in meshed connection and series connection with one another, the final middle gear is in meshed connection with an output gear, the two ends of a center rotating shaft of the output gear are connected with input ends of two planetary reducers, and the hydraulic motor, the motor gear and the coaxial double gears are arranged outside a milling wheel shell. The milling wheel drive system of the double-wheel slot milling machine for underground continuous wall construction has the advantages that the transverse position is convenient to adjust, the output rotation speed is convenient to adjust, high-quality rotation power transmission can be achieved, the transmission path is linear, the rotation power of the two planetary reducers is absolutely synchronous and of the same direction, and the use requirement that the whole transmission system is applied to a narrow environment is met.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

Continuous ultra high-temperature sterilization technology for granule-containing beverage

PendingCN110140849AFix damageSolve precipitationTransportation and packagingRotary stirring mixersLiquid level sensorHeating system

The invention discloses a continuous ultra high-temperature sterilization technology for a granule-containing beverage. The continuous ultra high-temperature sterilization technology comprises the steps of (1) arranging a liquid level sensor in a granule stirring balance tank, and according to a liquid level signal fed by the liquid level sensor, controlling the stirring rotation speed; (2) conveying the granule-containing beverage which is uniformly stirred in the granule stirring balance tank into a preheating system, performing preheating, and performing heat preservation for some time; (3)conveying the granule-containing beverage after preheating and heat preservation into a sterilization system, performing heating sterilization, and performing heat preservation for some time; (4) cooling the granule-containing beverage after sterilization and heat preservation; and (5) sequentially enabling the cooled granule-contained beverage to pass through an outlet pressure controller and anoutlet backpressure valve which is in a completely opened state, and then performing conveying into a filling region, wherein the outlet pressure controller can be a pipeline of which the length andthe caliber can be selected according to requirements to be used for enabling granules to pass through without damage. Through the technology disclosed by the invention, the problem of warming of coretemperature of the granules is solved, the damage problem after sterilization of the granules is solved, the precipitation problem of the granules is solved, and the problem that the granules are rotten due to long-time cycled sterilization is solved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Experimental fiber strip forming device

The invention discloses an experimental fiber strip forming device including a conveying mechanism, a carding mechanism, a fiber conveying channel, and a cup rotating mechanism that are successively connected, the conveying mechanism conveys at least one block-shaped or beam-shaped fiber to the carding mechanism, the carding mechanism combs the at least one fiber into a single fiber and conveys the single fiber to the fiber conveying channel, the fiber conveying channel conveys the single fiber to the high-speed cup rotating mechanism, circular fiber fringings that are uniformly distributed are formed in the fiber-condensing groove of the cup rotating mechanism, The experimental fiber strip forming device saves the step of manual operation in the prior art, and the combed fibers can be directly prepared to be a fiber strip without drawing; and the experimental fiber strip forming device has the advantages of convenient operation, concise procedure, less raw material input, low cost, short period, less area occupation, simple structure, convenient cleaning, and easy school daily maintenance.

Owner:温州虹南机械有限公司

Mobile type solar electric vehicle charge system

ActiveCN102904313ASimple daily maintenanceEase the dire situationBatteries circuit arrangementsElectric powerAutomotive engineeringCharge controller

The invention discloses a mobile type solar electric vehicle charge system which comprises a transparent ceiling, a photovoltaic array, a main controller, an energy storage device, a stainless steel frame, six electric vehicle charge controllers and six electric vehicle positions, wherein the transparent ceiling is installed at the top of the stainless steel frame; the photovoltaic array is installed at the front side plane of the stainless steel frame and in an inclined angle of 30 degrees with the horizontal line; the main controller and the energy storage device are installed at the middle position of the stainless steel frame and are sealed by a box body; and the six electric vehicle charge controllers are installed at the back surface of the photovoltaic array. According to the mobile type solar electric vehicle charge system, the charge to the energy storage device is controlled through the main controller, and six electric vehicles are charged with power at the same time through the electric vehicle charge controllers; and the electric vehicle charge controllers can automatically identify positive and negative terminals of electric vehicles to be charged with the power, is automatically connected with corresponding terminals of the energy storage device and judging the voltages of storage batteries of the electric vehicles, and the appropriate charge voltages are adopted to charge the electric vehicles. Roller wheels are installed under the stainless steel frame, so that the charge system can move conveniently.

Owner:南通哥润尼电子有限公司

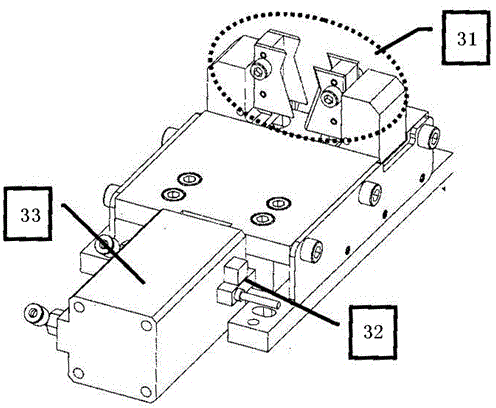

Roboticized intelligent fixture system

InactiveCN100551609CSimple mechanical structureReduce complexityProgramme-controlled manipulatorPositioning apparatusFlight vehicleManipulator

The invention relates to a roboticized intelligent manufacture-equipment system, which is used for the processing field of airborne craft thin-wall curved parts. The roboticized intelligent manufacture-equipment system is characterized in that the whole system comprises a base component, a dynamic beam component, a saddle component, a telescopic unit, a universal vacuum sucker, a left robot and a right robot, as well as a control computer. Under the control of the computer, after realizing the accurate abutting joint on the dynamic beam component through a docking mechanism, the robots do the synchronized motion together for adjusting to a certain position in the X direction, and the dynamic beam component realizes that the base component is locked through a retaining mechanism; at the same time, after the large arm of the robot main machine hand is rotated to the horizontal position, small arms extend out in turn, the palm moves, and then the fingers extend to grasp the telescopic unit fixed on the saddle component, so as to ensure that the telescopic unit moves in the Y direction for adjusting to a certain position; later, the telescopic unit moves in the Z direction for adjusting; in the end, through the universal vacuum sucker fixed on a telescopic mast, the curved face shape used for supporting the thin-wall curved parts is formed. The roboticized intelligent manufacture-equipment system is used for processing various parts, thereby greatly improving the flexibility of the production.

Owner:TSINGHUA UNIV

Device and method for in-situ sludge reduction by intensive AOMBR (anoxic/aerobic membrane bioreactor) process

ActiveCN109896629AIncrease metabolic strengthSmall volumeTreatment with aerobic and anaerobic processesMembrane bioreactorSewage

The invention belongs to the technical field of sewage treatment and discloses a device and method for in-situ sludge reduction by an intensive AOMBR (anoxic / aerobic membrane bioreactor) process. Themethod includes steps: feeding sewage into an anoxic pond from a water inlet, mechanically stirring to well mix the sewage with sludge, enabling mixed liquid to enter the upper portion of an aerobic pond from the bottom of the anoxic pond, completely mixing solution through an aeration device and a submersible pump, controlling dissolved oxygen, enabling the solution to enter the upper portion ofa high-oxygen membrane pool from the bottom of the aerobic pond, controlling dissolved oxygen through the aeration device, discharging the solution through a discharging pump and an MBR membrane component, returning a part of mixed liquid in the high-oxygen membrane pool to the anoxic pond through a nitrification liquid return pump and a pump pipe, enabling the other part of the mixed liquid to laterally flow to an anaerobic reactor through a sludge return pump and a pump pipe, mechanically stirring to make the sludge in a suspended state and well contact with filler, and flowing into the anoxic pond from an overflow pipe through a connection pipe. By adoption of the method, pollutant removal effects can be improved, the excess sludge yield can be reduced, and system nutrient substance removal effects can be improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

High-frequency brazing machine

ActiveCN104174960AImprove qualityReduce precisionHeating appliancesSoldering auxillary devicesEddy currentEngineering

The invention discloses a high-frequency brazing machine which comprises a worktable, a vacuum system component and a cooling component. A welding work box, a high-frequency generator, a programmed control device and a temperature detection component are arranged on the worktable, a work fixture and a high-frequency magnetic bar coil are arranged in the welding work box, the work fixture fixes a workpiece to be welded, a pneumatic drive workpiece is arranged at one end of the welding work box and connected with the work fixture and drives the work fixture to run, and the programmed control device is connected with the vacuum system component, the pneumatic drive workpiece, the high-frequency generator, the cooling component and the temperature detection component. By the mode, the high-frequency brazing machine realizes brazing by the aid of eddy current, safety can be guaranteed, and the high-frequency brazing machine is low in risk and cost, high in efficiency and fine in welding performance.

Owner:CHANGSHU JUNCHI SCI & TECH

Rotary distributor with point-to-point feeding discharging and point-to-point dust absorption

The invention provides a rotary distributor with point-to-point feeding discharging and point-to-point dust absorption. The rotary distributor with point-to-point feeding discharging and point-to-point dust absorption comprises a feeding distribution platform component, a feeding articulated chute component and driving part of the feeding articulated chute component, and a column component used for installing the driving part. A shaft sleeve component is arranged on a main shaft of the driving part on the upper side of the feeding distribution platform. 3-4 umbrella type support bars are stretched from the shaft sleeve component in a sloping downward direction in an equal central angle mode. The lower ends of the support bars are connected with an annular rotating disc which is placed horizontally. The rotating disc is on the feeding distribution platform and matched with the feeding distribution platform gap. The radial width of the annular rotating disc covers a multi-position feeding distribution opening of the feeding distribution platform. A feeding discharging opening of the annular rotating disc is corresponding to a feeding discharging distribution opening of the feeding distribution platform. A lower port of an articulated chute of the feeding articulated chute component is connected with the feeding discharging opening of the annular rotating disc. A dedusting component is connected with the lower end of the main shaft of the driving part. The dedusting component comprises a dedusting component support connected with a flange at the lower end of the main shaft and a dust absorption bending pipe fixed on the dedusting component support. Two ports of the dust absorption bending pipe are respectively corresponding to a bunker dust absorption opening and a system dedusting opening.

Owner:HUBEI SANJIANG SPACE MECHANICAL & ELECTRICAL EQUIP

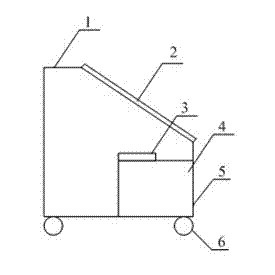

Manned electric cart capable of going up and down stairs

PendingCN111700744AReduce fearCenter of gravity fluctuation is smallWheelchairs/patient conveyanceGear driveGear wheel

The invention discloses a manned electric cart capable of going up and down stairs. The cart comprises a main box body, a lifting device, an auxiliary supporting device, a walking and braking device and a safe device, wherein a first motor is fixed on a baseplate of the main box body, and an output end of the first motor drives a slide main beam to move along two guiderails by a worm wheel-worm transmission mechanism and a chain wheel-chain transmission mechanism successively. The lifting device comprises two sets of lifting leg components with a same structure, wherein each lifting leg component comprises a base and a second motor and an output end of the second motor drives the main box body to move along a supporting guiderail by a gear transmission mechanism, a spiral rod, a square nutand the slide main beam respectively. The auxiliary supporting device comprises a third motor and an auxiliary leg land supporting rod, wherein an output end of the third motor drives the auxiliary leg land supporting rod to rotate around a connecting rotation shaft by a pair of gears, a screw rod, a movable slide block and an auxiliary leg supporting rod respectively, so that a roller on an endpart of the auxiliary leg land supporting rod can touch the ground. The cart is simple in motion form and stable in motion.

Owner:TIANJIN UNIV

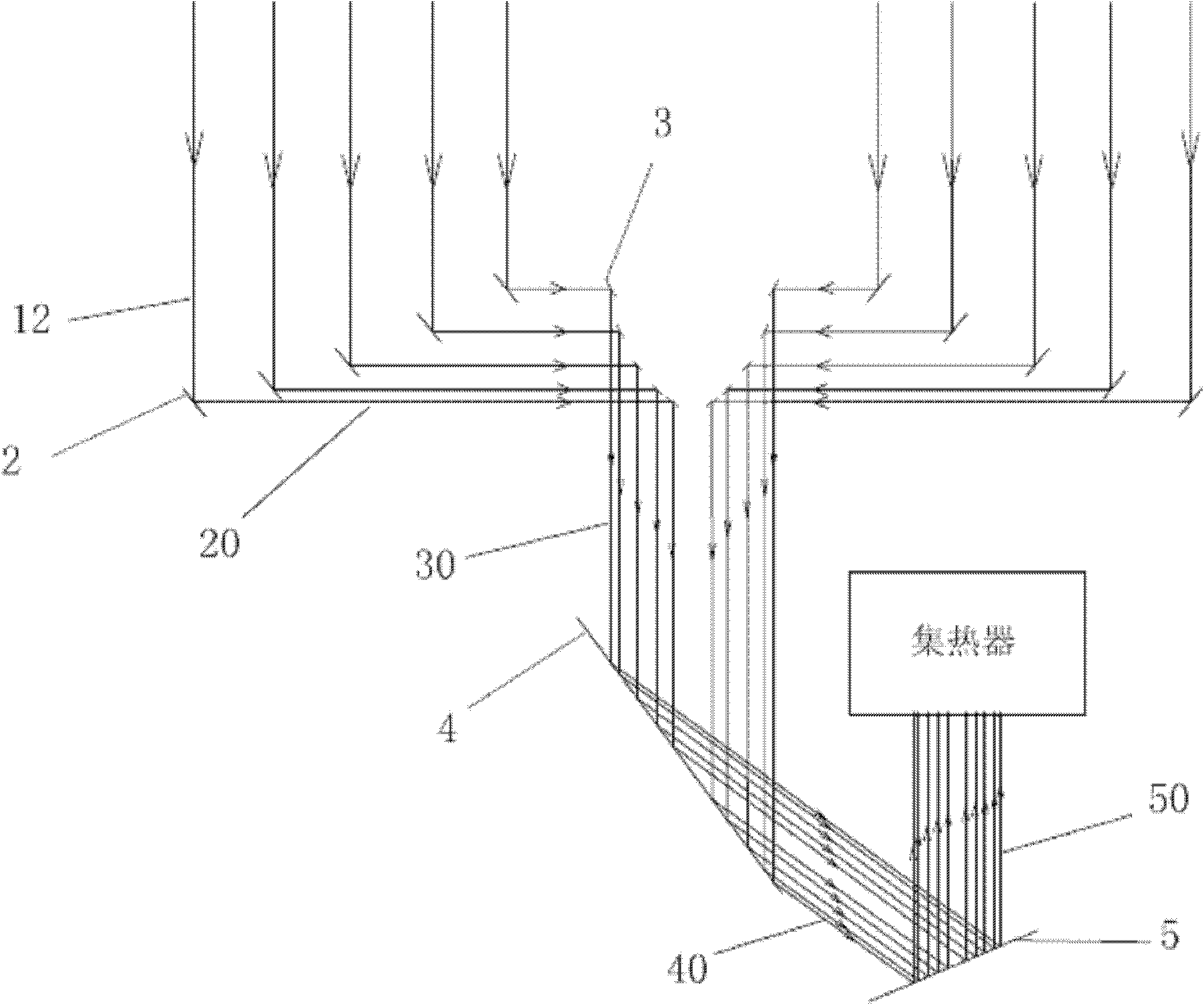

Solar energy beam concentration and light focusing control system

InactiveCN103175310AEasy maintenanceReduced precision requirementsSolar heating energySolar heat devicesComputer control systemLight beam

The invention relates to a solar energy beam concentration and light focusing control system. The solar energy beam concentration and light focusing control system comprises a mirror array for tracing the sun in real time and a solar thermal collector for receiving beam concentration light beams. The mirror array is provided with collecting mirror units, wherein the number of the collecting lens units is M lines * N rows, each collecting lens unit comprises a paraboloid collecting mirror and an upper layer reflecting mirror, and the bottom portion of the paraboloid collecting lens is provided with a through hole. A middle layer first reflecting mirror is arranged in the direction of the light path of each through hole, a middle layer second reflecting mirror is arranged in the direction of the light path reflected through each middle first reflecting mirror. The middle first layer reflecting mirrors and the middle layer second reflecting mirrors can enable M*N light beams on the upper layer to be gathered to form dense balanced light beams. The lower layer reflecting mirrors which enable the dense balanced light beams to be reflected to the solar thermal collector are arranged in the direction of the light path of the dense balanced light beams. The solar energy beam concentration and light focusing control system enables mirror array light beams to be concentrated,reduces control points, simplifies maintenance and installation, and employs a single integrated circuit to replace a complex computer control system.

Owner:深圳市阳能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com