Method for degrading N,N-dimethylformamide in sucralose wastewater by using microorganisms

A technology of dimethylformamide and microbial degradation, applied in the field of N,N-dimethylformamide, which can solve the problems of high cost and difficult treatment of DMF wastewater, and achieve simple daily maintenance and operation and low equipment requirements Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

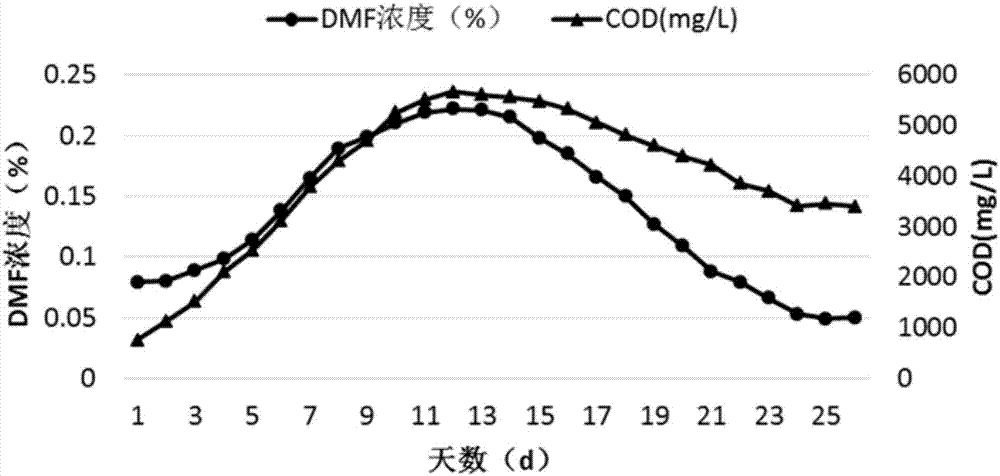

Embodiment 1

[0041] 1. Enrichment culture of microbial flora

[0042] 1) Weigh 2 g of tryptone, 1 g of yeast extract, and 2 g of sodium chloride, add water to 200 mL, adjust the pH to 7.0, and then sterilize under high temperature and high pressure (sterilization conditions: 121°C, 20 minutes).

[0043] 2) Inoculate microbial colonies into the above-mentioned culture solution and culture for 24 hours. The culture conditions are: temperature 30°C, DO=3mg / L, to obtain enriched culture solution.

[0044] The microbial flora can grow rapidly in the above-mentioned medium, so that the concentration of the microbial flora reaches a high level, and the enrichment culture of the microbial flora is conducive to the rapid start of the next bioreactor.

[0045] The microbial flora was Pseudomonas aeruginosa (No. GIM1.843) purchased from Guangdong Microbial Culture Collection Center.

[0046] 2. Domestication of microbial flora

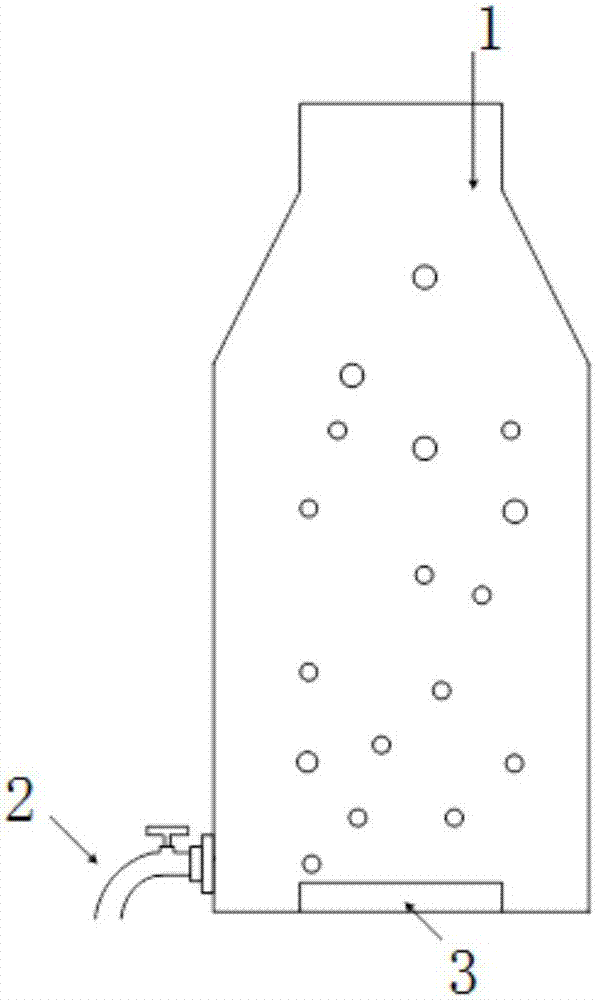

[0047] The domestication of microbial flora is carried out in a biore...

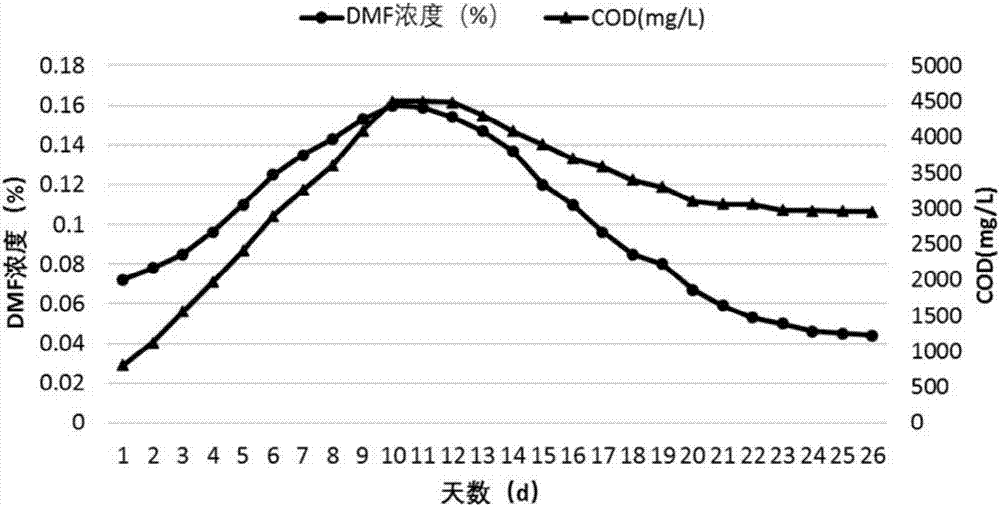

Embodiment 2

[0061] 1. Screening of microbial flora from sludge of sucralose production sewage plant

[0062] (1) Weigh 1 g of disodium hydrogen phosphate, 0.5 g of potassium dihydrogen phosphate, and 0.02 g of sodium chloride, and add water to 200 mL. Inoculate 5g of sucralose production sewage plant sludge, the culture condition is 25-35°C, the dissolved oxygen is 1-3mg / L, the pH is 7.0-8.0, and the culture time is 5 days.

[0063] Take 10mL (5-10% ratio, volume percentage) from the above culture solution and transfer it to fresh screening culture solution. The fresh culture solution includes disodium hydrogen phosphate 5g / L, potassium dihydrogen phosphate 2.5g / L, chlorine Sodium chloride 0.1g / L, cultivated for 5 days.

[0064] (2) Repeat step (1) for 6 times to obtain a microbial flora that can be grown with DMF as the only carbon source and nitrogen source. This microbial flora includes Pseudomonas and parasitoids through routine physiological and biochemical identification and gene s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com