A screw gas booster

A gas supercharging and screw technology, applied in liquid fuel engines, mechanical equipment, machines/engines, etc., can solve the problems of small volume flow of single compressor, low reliability of piston engine, easy to delay production, etc., and achieve compact structure. , The effect of less motion pair and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

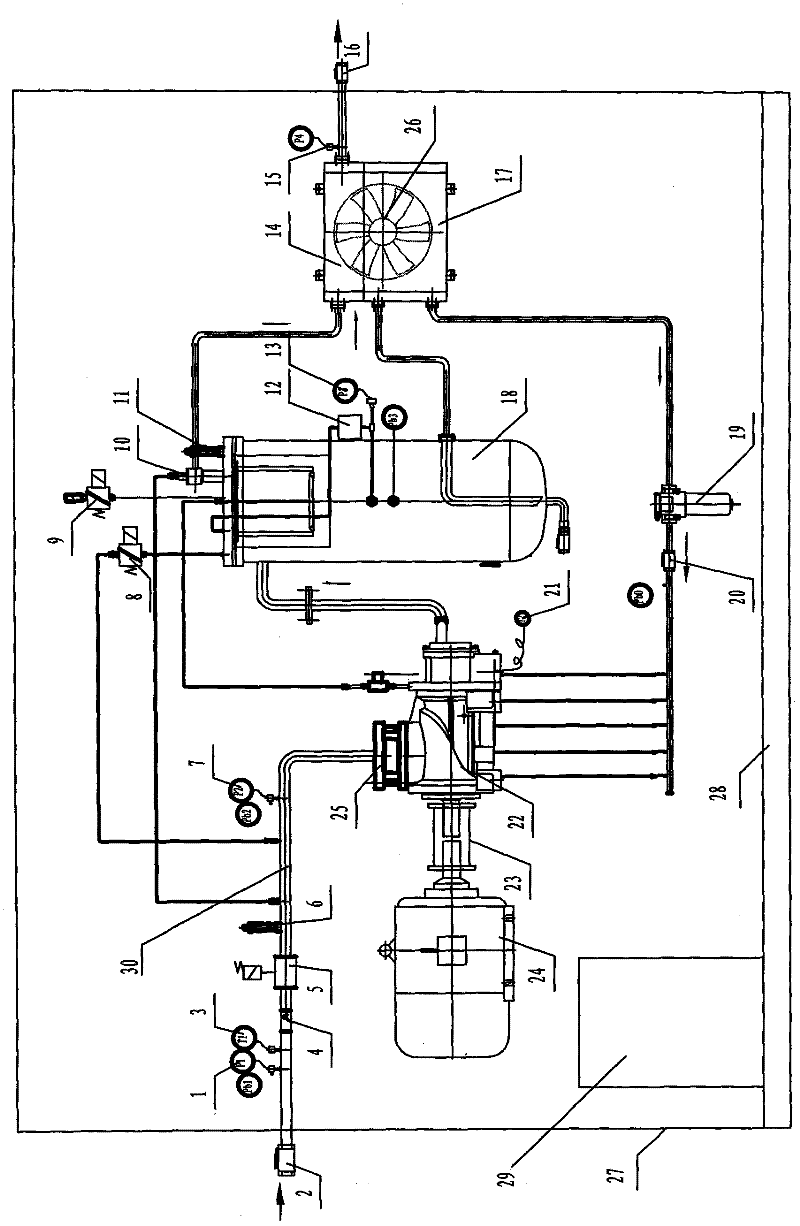

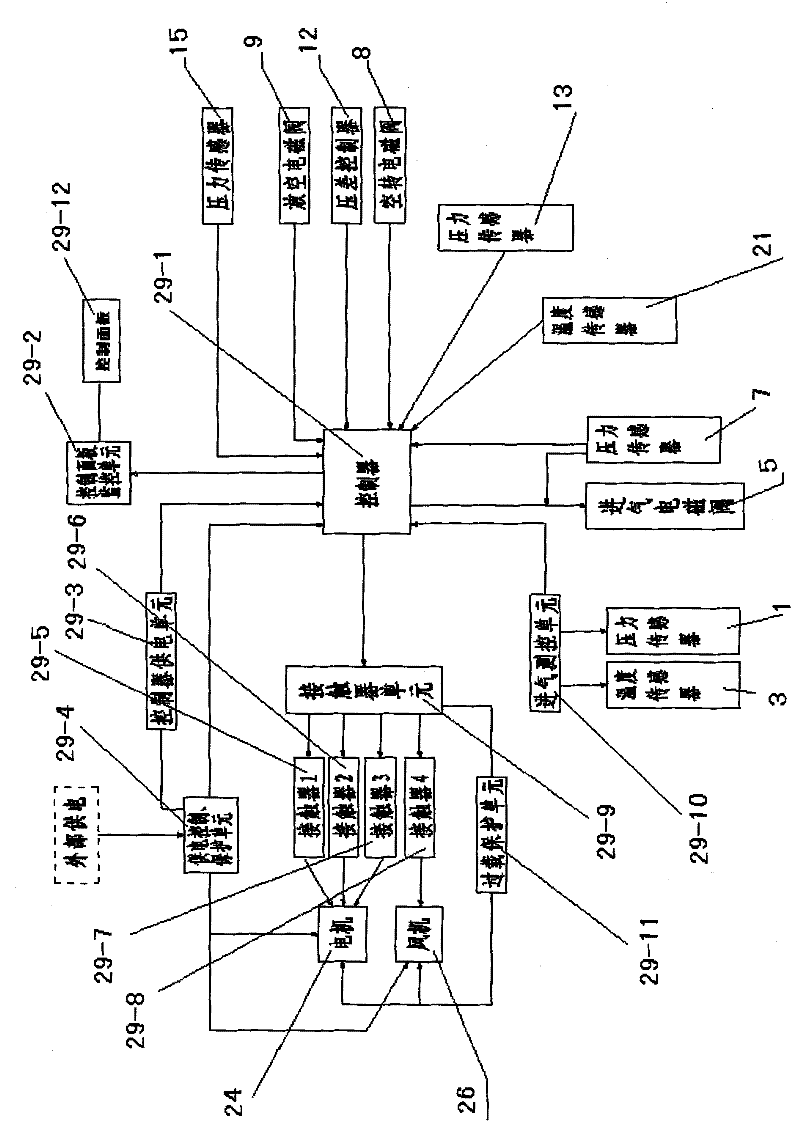

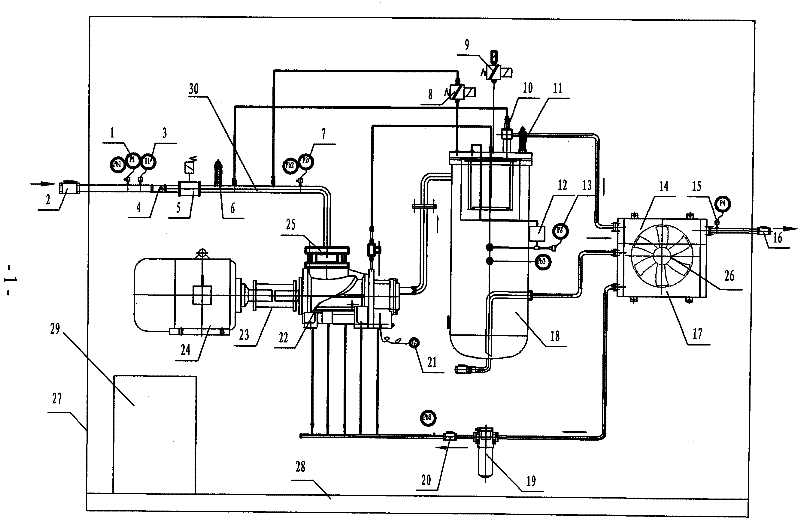

[0015] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

[0016] Embodiment: a kind of screw gas supercharger (referring to Figure 1-Figure 2 ), it includes a base 28, the base 28 is provided with a box body 27, and the box body 27 includes an electric control cabinet 29, a fan 26, a motor 24, and the motor 24 is connected to the twin-screw compressor 22 through a coupling 23, and the twin-screw compressor 22 is connected to the intake pipe 30 through a one-way valve 25, and the intake pipe 30 is provided with an intake ball valve 2, a first pressure sensor 1, a first temperature sensor 3, an intake filter 4, an intake solenoid valve 5, a safety valve Valve 6, the second pressure sensor 7, the twin-screw compressor 22 is provided with the second temperature sensor 21, the exhaust port of the twin-screw compressor 22 is connected to the air inlet of the oil separator 18, and the upper end of the oil separator 18 is respectively connected to Idling solenoid valve 8, venting solenoid valve 9, minimum pressure valve 10, safety valve 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com