Novel telescopic wire and manufacturing method thereof

A manufacturing method and wire technology, applied in cable/conductor manufacturing, extensible conductor cables, circuits, etc., can solve the problems of conductor wire damage, cracked wrapping, lack of flexibility, etc., and achieve high durability and simple structural design. Ingenious, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

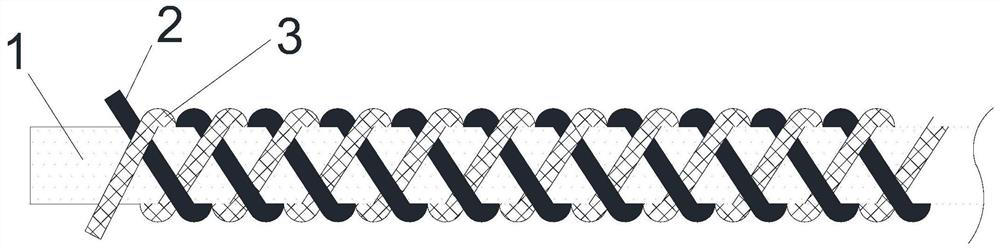

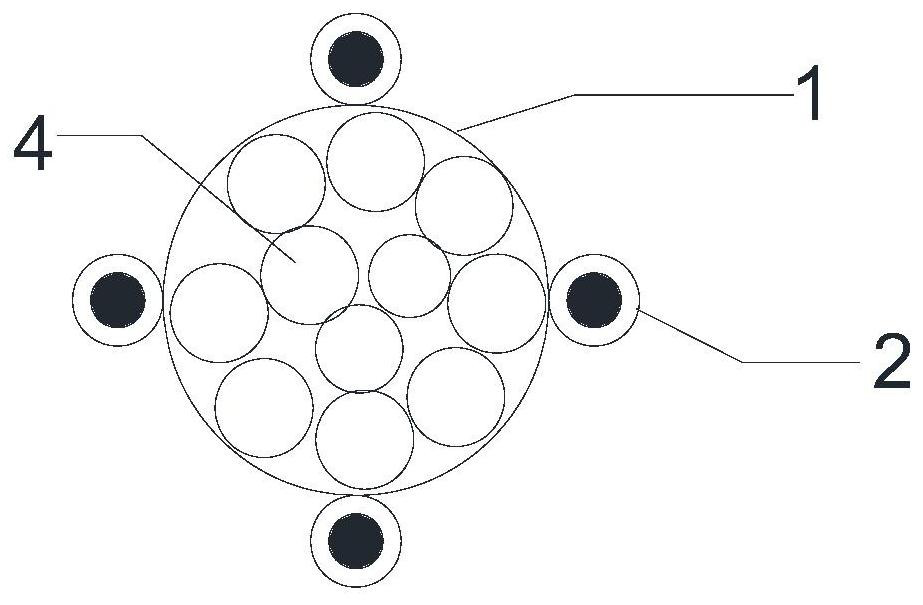

[0024] Example: such as figure 1 As shown, a new type of telescopic electric wire includes an elastic core 1 and a conductor. The elastic core 1 is an elastic plastic 4 in the shape of a cylinder. The conductor is an elongated wire 2 wound around the elastic core 1. The outer circumference, the winding shape of the wire 2 is helical; the outer circumference of the elastic core 1 is also wound with an insulating thin wire 3, and the insulating thin wire 3 is also helically wound, and the insulating thin wire 3 is braided on the wire 2 to insulate Thin wire 3 and wire 2 interweave each other; this structure cancels the covering part of the outer periphery of wire 2, and uses insulated thin wire 3 to weave on wire 2, so that insulated thin wire 3 and wire 2 are interwoven together to form a whole; this structure can Explain in detail: If only the helical wire 2 is wound on the elastic core 1, when the elastic core 1 is stretched, the helical wire 2 wound on the elastic core 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com