Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Reduced impact on mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

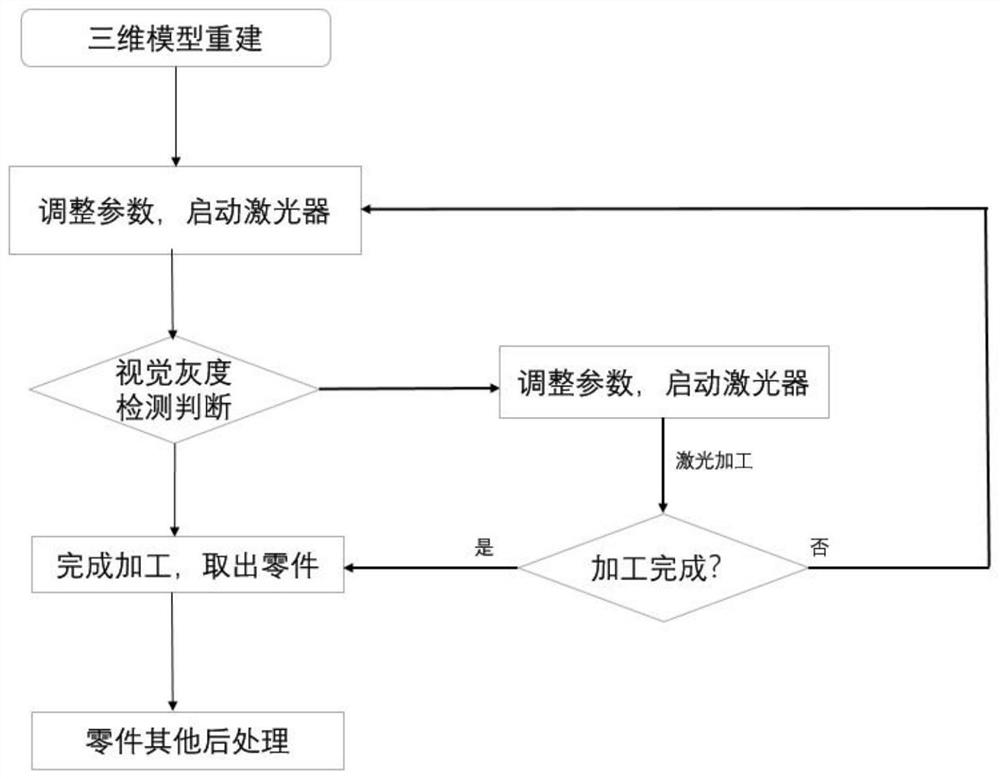

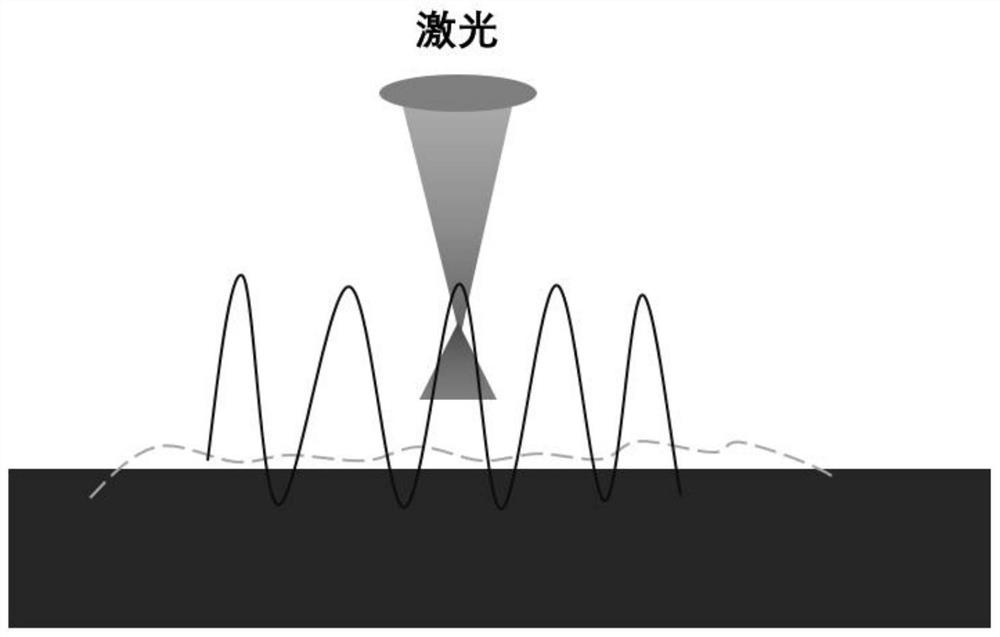

Single-step pulse laser polishing method for metal surfaces

InactiveCN107225328ARapid remeltingTo achieve reinforcementLaser beam welding apparatusElectrochemistryMachining process

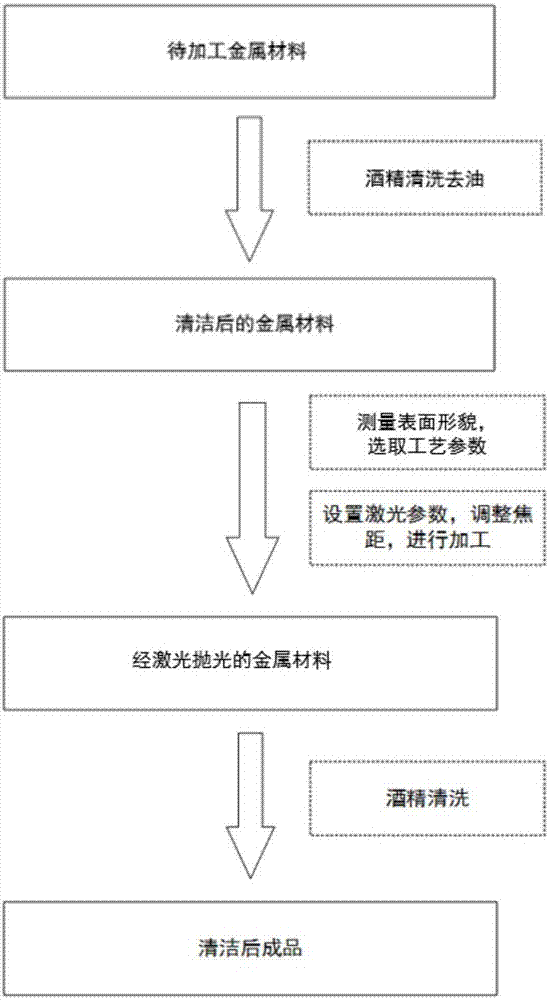

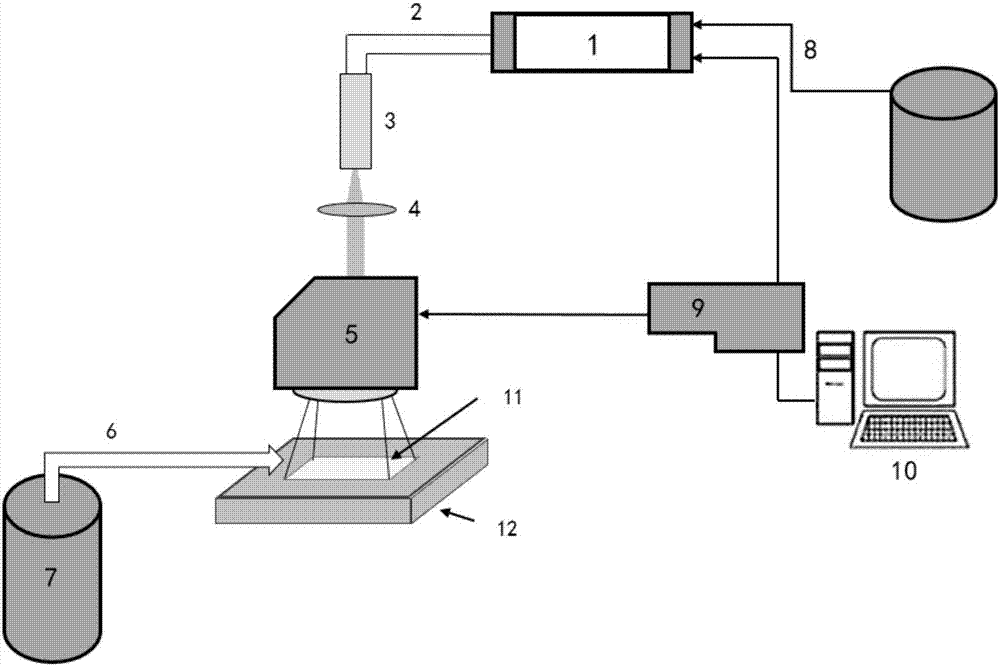

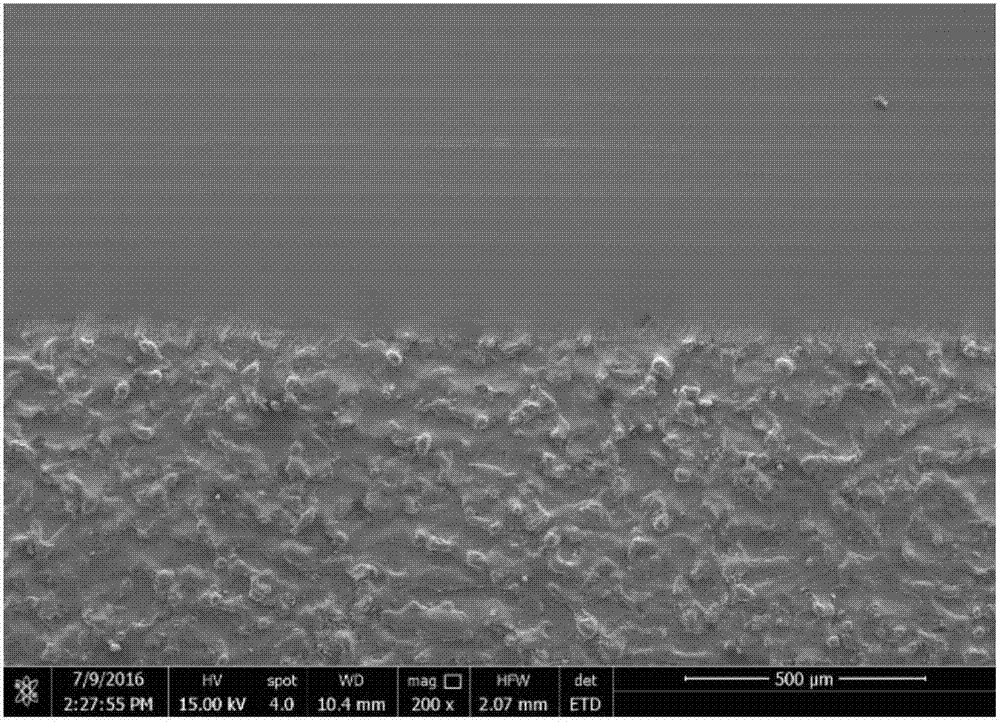

The present invention is a single-step pulse laser polishing method for metal surfaces: 1. Simply clean and degrease the surface of the metal material to be processed. 2. Use a three-dimensional profiler to measure the surface to be polished. 3. Place the metal material to be processed on the workbench of the laser processing system, set the laser parameters, start the laser processing system, use the galvanometer to scan the laser at a certain speed and path on the surface of the metal material, and finally obtain remelting on the surface Layer, inert gas is used for protection during processing. 4. Simple cleaning of processed metal materials. Compared with traditional metal surface polishing methods such as mechanical polishing and chemical / electrochemical polishing, the present invention uses laser heating and melting to form a molten pool under the multi-directional action of surface tension and gravity, and the molten material in the molten pool will be redistributed through flow. Around the initial position, the peak-to-valley height difference of most rough surfaces is reduced after rapid solidification, thereby obtaining a polishing effect on the rough surface.

Owner:BEIHANG UNIV

Phosphorus and nitrogen fire retardant and preparation method thereof

InactiveCN102827399AImprove compatibilityReduced impact on mechanical propertiesFireproof paintsFlame-proof filament manufactureSolid phasesIon

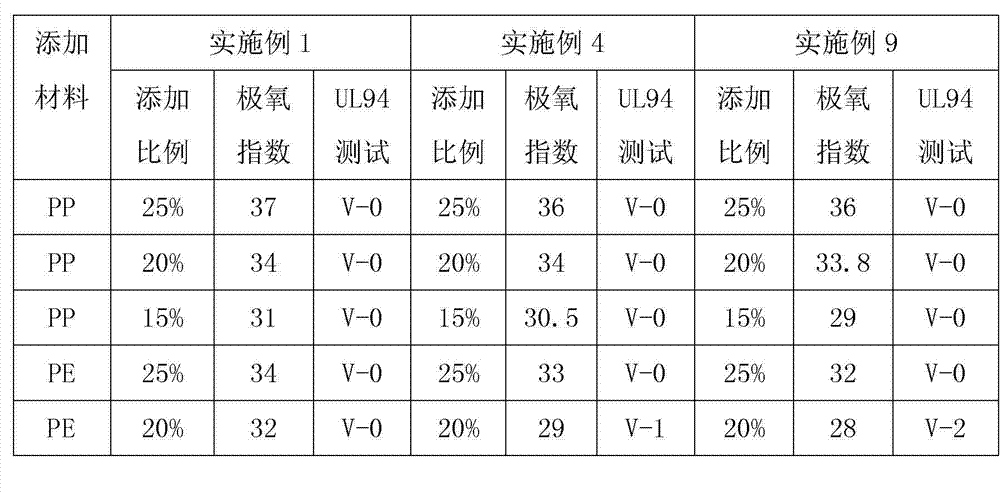

The invention discloses a phosphorus and nitrogen fire retardant and a preparation method of the phosphorus and nitrogen fire retardant. The preparation method is characterized by comprising the steps of: preparing suspended slurry with concentration of 5-50% by 1-20 parts by weight of ammonium polyphosphate and 20-40 parts by weight of solvent, and agitating uniformly at 30-120 DEG C; preparing melamine and formaldehyde solution according to a molar ratio of 1:3-15, and reacting for 15-130min at 30-120 DEG C; preparing a pre-polymer; adding the melamine formaldehyde resin pre-polymer into the slurry quickly, wherein the adding amount is 5-70% of ammonium polyphosphate, and agitating uniformly by using the solvent as a dispersing agent; then insulating and reacting for 2-5h; obtaining a phosphorus and nitrogen fire retardant product; then filtering or centrifugally dewatering the product, washing the product by deionized water for 2-5 times, re-hydrating solid phase product filtered, and smashing the product to obtain the phosphorus and nitrogen fire retardant. The production process of the compound fire retardant is simple, the raw materials are easy to obtain, and the preparation method is convenient to operate and low in cost, and is beneficial for industrialized production.

Owner:SICHUAN UNIV

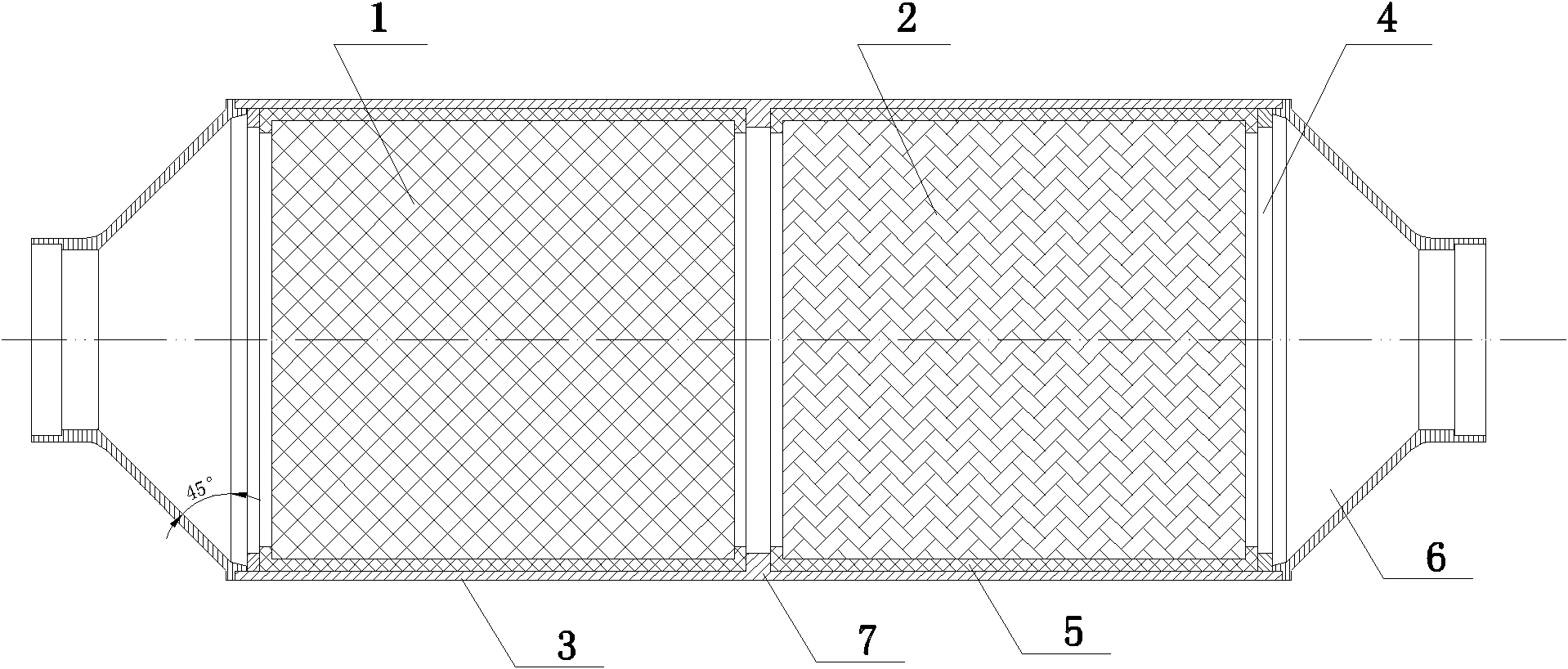

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

ActiveCN102489322ANo sheddingImprove uniformityExhaust apparatusDispersed particle separationOrganic fractionCombustion

The invention relates to a catalyst for purifying tail gas of diesel automobiles, a preparation method and a purification device thereof. The catalyst comprises a first carrier taking cordierite honeycomb ceramics as a matrix, and a second carrier taking SiC or a cordierite wall-flow structure as a matrix, a first coating and active components on the first carrier, as well as a second coating and active components on the second carrier. In the invention, coating, roasting and reduction processes are adopted for preparing the coatings composed of composite oxides. The catalyst and the device in the invention employ a technology combining a DOC (diesel oxidation converter) and a CDPF (catalyzed diesel particulate filter). By means of the DOC at a front end, HC, CO as well as the soluble organic fractions (SOF) in PM are removed through oxidation. Meanwhile, NO is converted to NO2 that has stronger reducibility so as to be good for the reaction of NO2 and C, thus reaching the purposes of removing NO and lowering the combustion temperature of C simultaneously. Depending on the self-temperatures of diesel automobiles to realize regeneration of a particulate filter, the purification device in the invention has the characteristics of high purification efficiency and convenient usage, etc.

Owner:CHONGQING MATERIALS RES INST

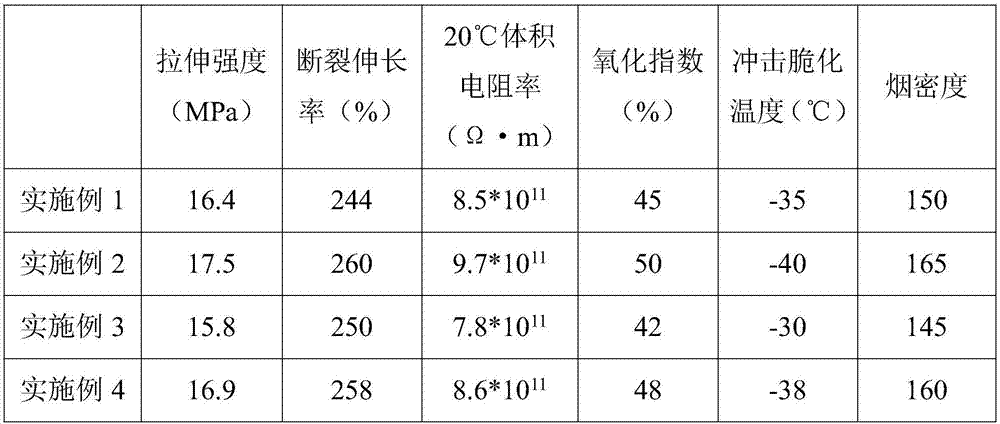

High-performance flame retardant polyethylene sheath material

The invention discloses a high-performance flame retardant polyethylene sheath material. The polyethylene sheath material comprises, by weight, high density polyethylene, linear low density polyethylene, bimodal polyethylene, a polyolefin elastomer, an ethylene-vinyl acetate copolymer, maleic anhydride grafted polyethylene, powdery magnesium hydroxide, layered aluminum hydroxide, a flame retardantsynergist, magnesium stearate, silicone oil, an antioxidant, a melamine salt of cage phosphate, polyphenylether, silicone powder and a lubricant. The halogen-free efficient flame-retardant polyolefincable material has the advantages of reduction of the addition amounts of the magnesium hydroxide and aluminum hydroxide, great improvement of the flame retardant efficiency of the hydroxides, reduction of the influences of the addition of the flame retardant on mechanical properties, good tensile strength of 15 MPa, and excellent elongation at break.

Owner:SUZHOU HENGLI COMM MATERIAL

Flame-retardant high toughness polyethylene cable material

InactiveCN109836654AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsElastomerLinear low-density polyethylene

The invention discloses a flame-retardant high toughness polyethylene cable material. The polyethylene cable material comprises, by weight, high density polyethylene, linear low density polyethylene,bimodal polyethylene, a polyolefin elastomer, an ethylene-vinyl acetate copolymer, maleic anhydride grafted polyethylene, powdery magnesium hydroxide, layered aluminum hydroxide, a flame retardant synergist, magnesium stearate, silicone oil, an antioxidant, a melamine salt of cage phosphate, polyphenylether, silicone powder, a lubricant and fluorophosphorous acid. The halogen-free efficient flame-retardant polyolefin cable material has the advantages of great improvement of the flame retardant efficiency of hydroxides, reduction of the influences of the addition of the flame retardant on mechanical properties, good tensile strength of 15 MPa, excellent elongation at break, good extrusion fluidity and wide processing temperature range.

Owner:SUZHOU HENGLI COMM MATERIAL

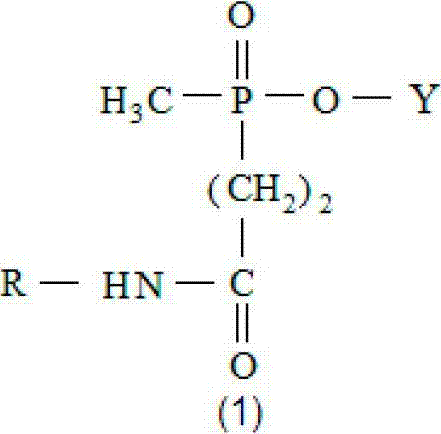

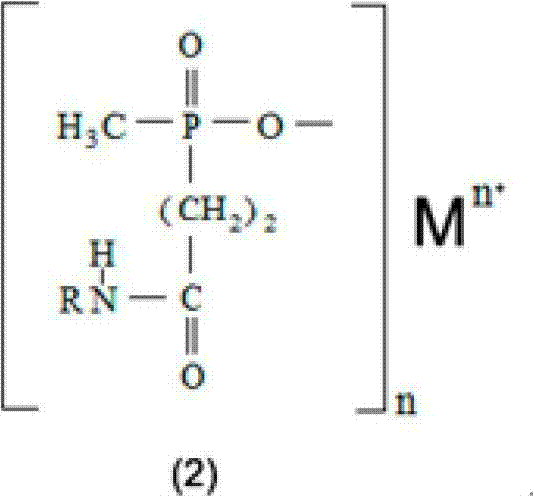

Flame retardant composite of epoxy resin and preparation method thereof

InactiveCN102875972AImprove compatibilityImprove mechanical propertiesPhosphinic AcidsPolymer chemistry

The invention discloses flame retardant composite of epoxy resin and the preparation method thereof, and belongs to field of flame retardant. The composite comprises epoxy resin, curing agent and fire retardant, wherein the fire retardant at least comprises single amide group functionalized dialkyl group phosphinic acid, single amide group functionalized dialkyl group phosphinic acid ester or single amide group functionalized dialkyl group phosphinic acid metal salt. By accounting in 100 parts of weight, the fire retardant and the curing agent account for 10 to 50 parts of weight and 10 to 30 parts of weight respectively. The fire retardant in the composite provided by the invention is a new-type and efficient halogen-free fire retardant, which can be used for realizing multi-element cooperative flame retardant, such as the cooperation of phosphorus, nitrogen and metal elements, and the flame retardant effect is excellent. The preparation method of the flame retardant composite of epoxy resin provided by the invention is simple.

Owner:JIANGHAN UNIVERSITY

Flame-retarding non-halogen silicon core pipe as special material and its preparing process

InactiveCN1369518AReduce smokeReduce toxic gasInsulated cablesInsulated conductorsToxic gasProcedure Agents

A non-halogen fire-retarding material for the conduit of electric wire, electric cable or optical cable is prepared from HCPE resin (51-73 wt%), non-haloen composite fire retardant (25-45%), assistant (1-5%) and stabilizer (0.1-2%) through mixing, dual-screw extruding out and granulating. Its advantages are high fire-retarding effect and not releasing a lot of toxic gas.

Owner:SINOPEC YANGZI PETROCHEM

Preparation method of ABS composite plastic product capable of reducing loss of plant extract

InactiveCN111019288AReduce churnReduce high temperature lossComposite materialManufacturing engineering

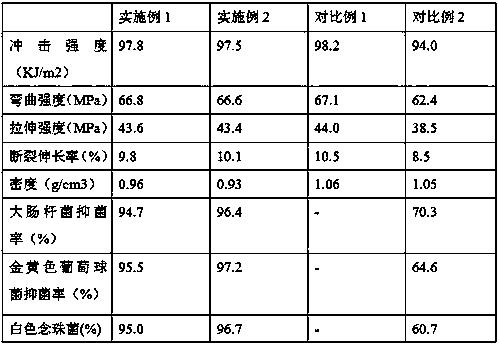

The invention provides a preparation method of an ABS composite plastic product capable of reducing loss of a plant extract. The content of the plant extract in the ABS composite plastic product is 0.1-5%. When the plant extract and the ABS composite plastic product are prepared, the loss of the plant extract can be reduced. According to the invention, the plant extract is modified and then made into a functional master batch, so the influence of the addition of the plant extract on the mechanical properties of the ABS plastic product can be reduced under the condition of reducing the high-temperature loss of the plant extract. The ABS plastic product prepared by the invention has the plant extract content 0.1-5%, preferably 2.4-4.5%, impact strength of 97.5-97.8 KJ / m<2>, bending strengthof 66.6-66.8 MPa, tensile strength of 43.4-43.6 MPa, and the elongation at break of 9.8-10.1%.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

High-conductivity wool top fiber and preparation method thereof

InactiveCN110318119ALow volume specific resistanceImprove conductivityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsElastomerFiber

The invention discloses a high-conductivity wool top fiber. The high-conductivity wool top fiber comprises an inner layer and an outer layer, wherein the cross section of the inner layer is triangular, the outer layer wraps the outer circumference of the inner layer, and the cross section of the outer layer is circular; the inner layer is prepared from, by weight, 65-75 parts of polyamide-6, 15-22parts of poly-p-benzoyl hexamethylenediamine, 10-14 parts of an elastomer, 4.5-6.5 parts of graphene, 6-10 part of carbon black and 6.5-10.5 parts of a nanofiller; the outer layer is prepared from 6-100 parts of polyamide by weight. The high-conductivity wool top fiber is formed by finely selecting raw materials, and the contents of various raw materials are optimized, so that the prepared high-conductivity wool top fiber has low volume resistivity, good electrical conductivity, long-lasting electrical conductivity and good antistatic performance, the high-conductivity wool top fiber also hasthe advantages of soft hand feeling, elasticity, higher strength, good wear resistance and weather resistance and the like, and therefore, the high-conductivity wool top fiber is suitable for being prepared into various conductive fabrics, is comfortable to wear, and is especially suitable for places sensitive to static electricity.

Owner:海宁泰尔欣新材料有限公司

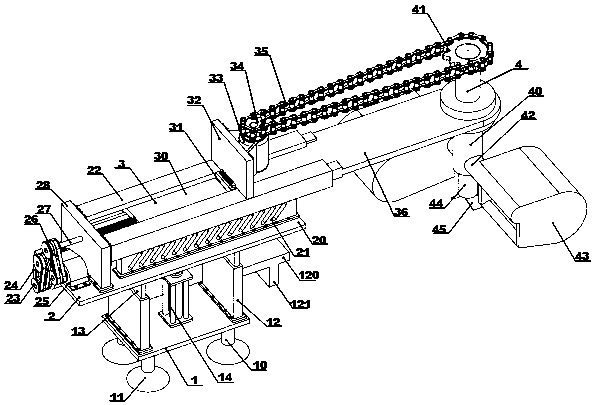

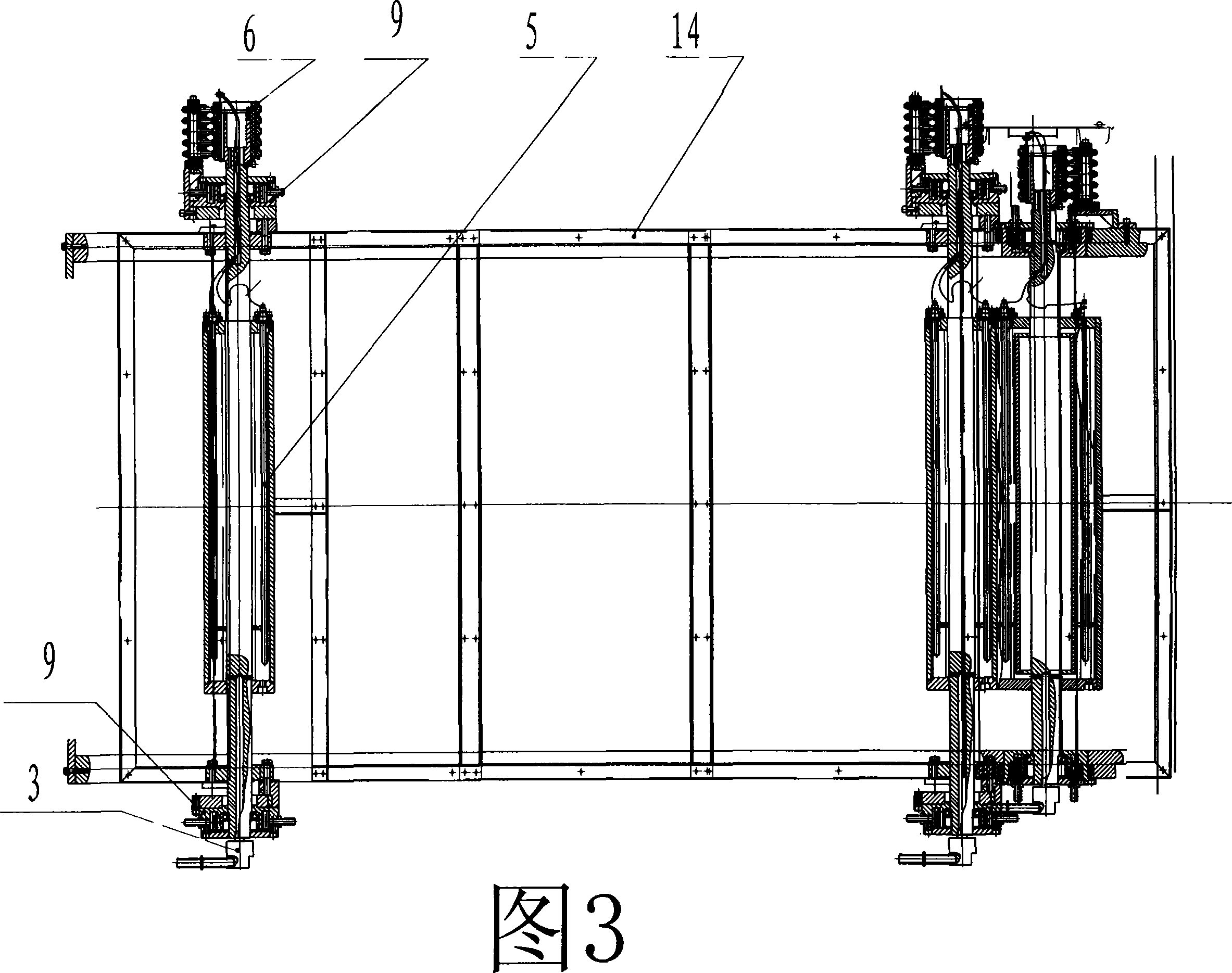

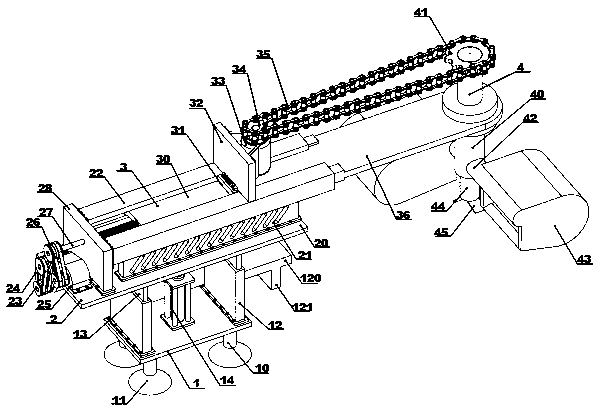

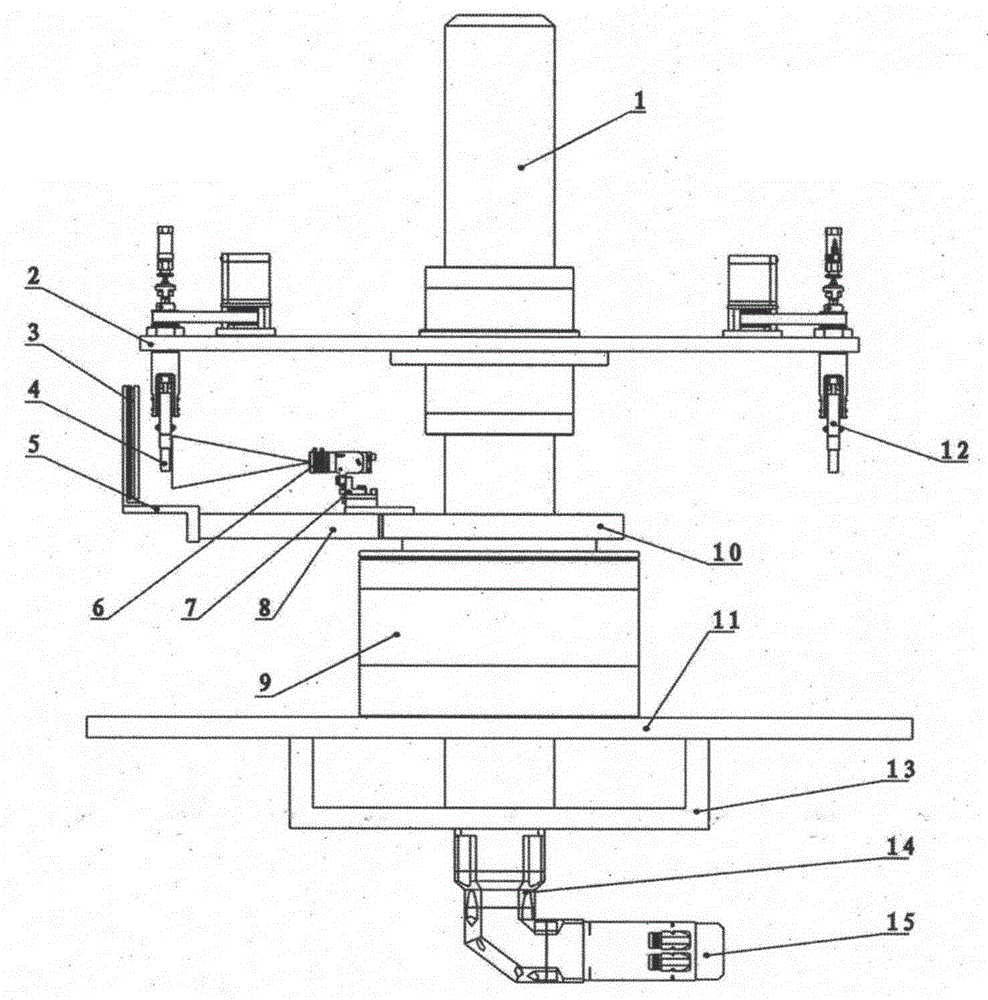

Stirring slag scraping machine used for molten aluminum mixing furnace

The invention discloses a stirring slag scraping machine used for a molten aluminum mixing furnace. The stirring slag scraping machine used for the molten aluminum mixing furnace comprises a base, a movable platform, a forward stretching mechanism and a stirring slag scraping mechanism; the movable platform is arranged on the base; the forward stretching mechanism is arranged on the movable platform; and the stirring slag scraping mechanism is arranged at one end of the forward stretching mechanism. The stirring slag scraping machine used for the molten aluminum mixing furnace is simple in structure, the slag scraping efficiency of the slag scraping machine is greatly improved, and shaking of the slag scraping machine in the slag scraping process is reduced to the maximum extent; and by means of stirring, dispersed slag in the molten aluminum mixing furnace is precipitated out, and high practicability is achieved.

Owner:阿坝铝厂

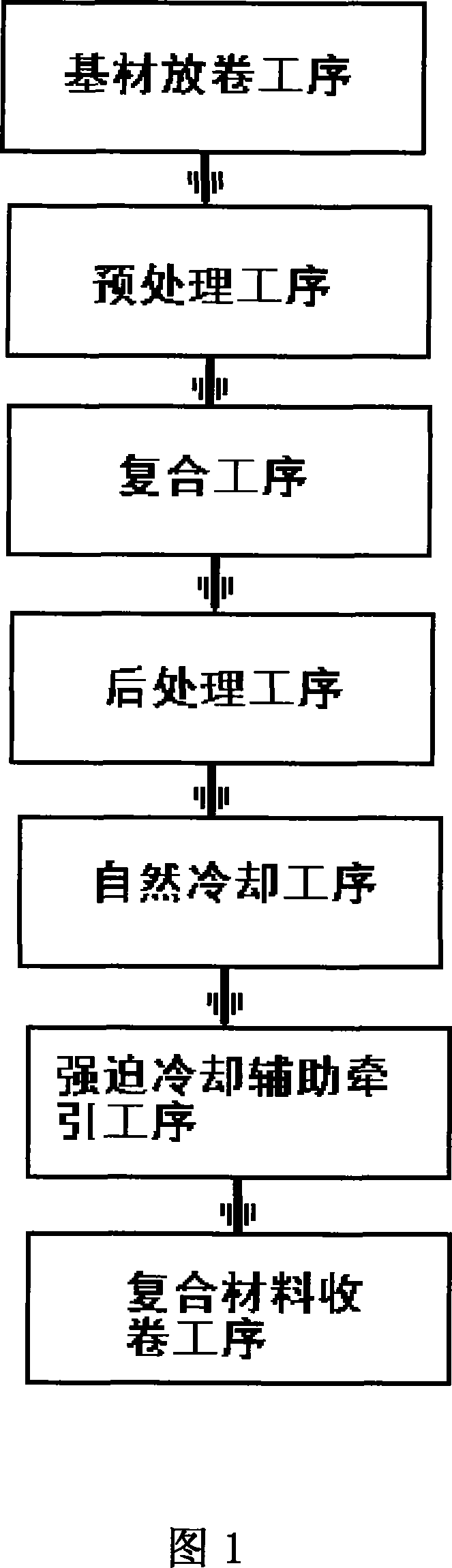

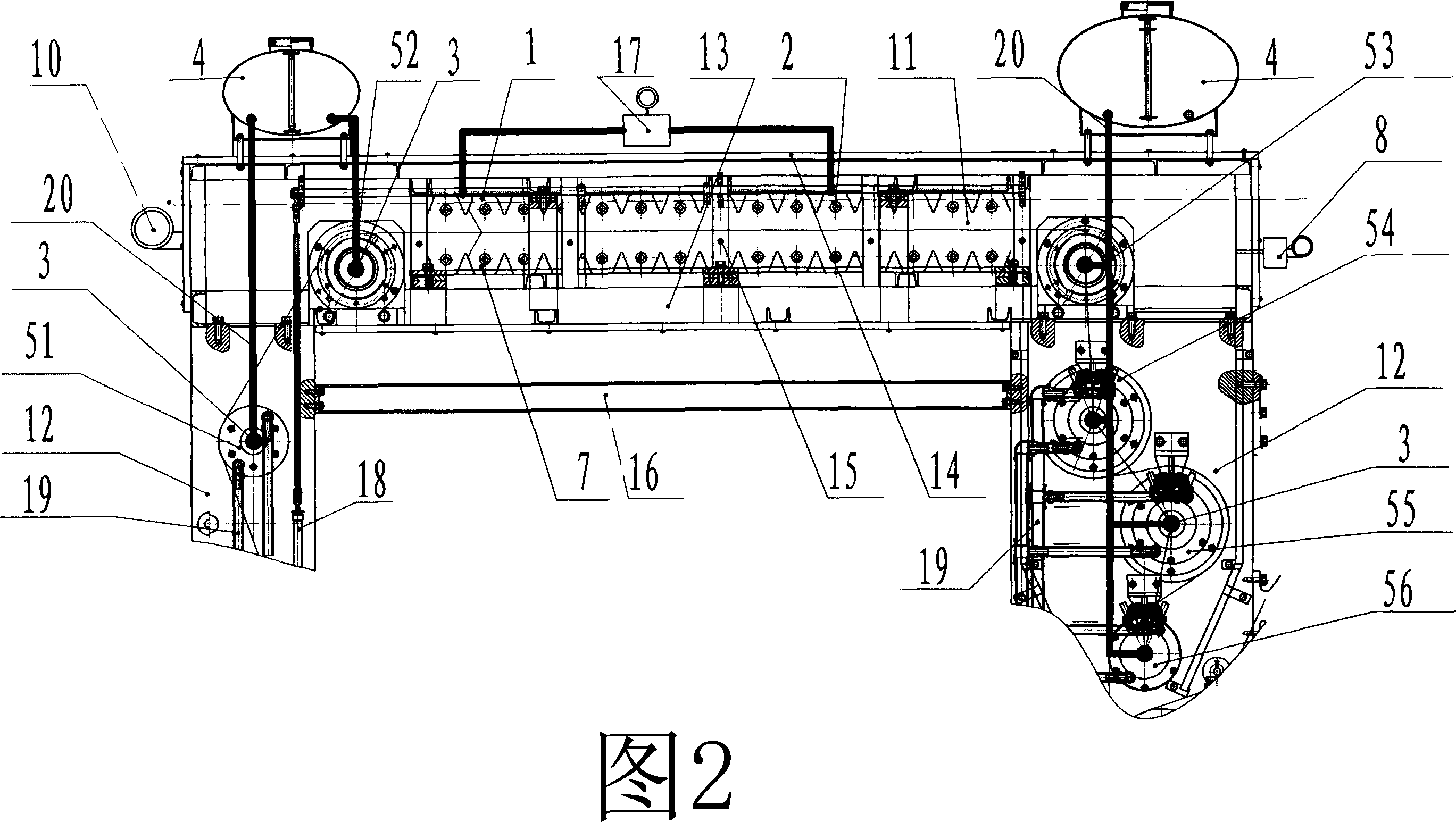

Apparatus for pretreating composite material metal base material and pretreating method

ActiveCN101134997AImprove efficiencyEven heat dissipationFurnace typesHeat treatment furnacesPre treatmentMetal substrate

The present invention relates to pre-treating apparatus and process for composite metal base material. The pre-treating apparatus includes one combined portal frame, heating guide rollers, one guide unit, one energy accumulator, one air blowing unit, heat collecting boxes and one hot blast circulator. During pre-treatment, the composite metal base material is made to pass through the heating guide rollers and the boxes separately in specific temperatures successively in certain linear speed. The present invention has the composite metal base material possess homogeneous heating, less heat deformation and no destruction of mechanical performance.

Owner:上海网讯新材料科技股份有限公司

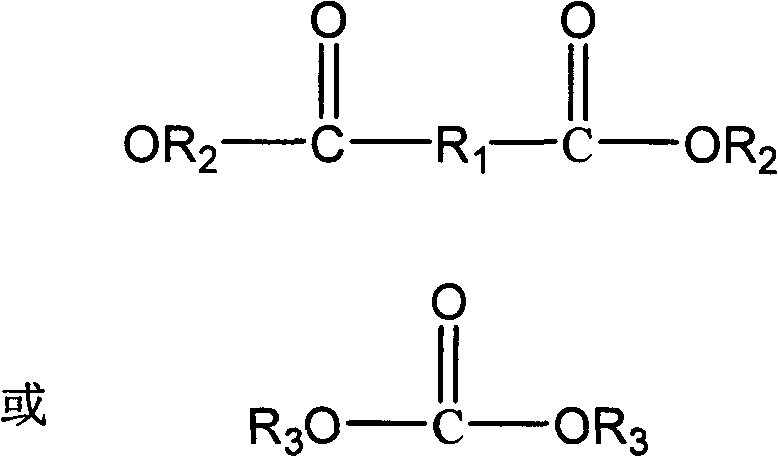

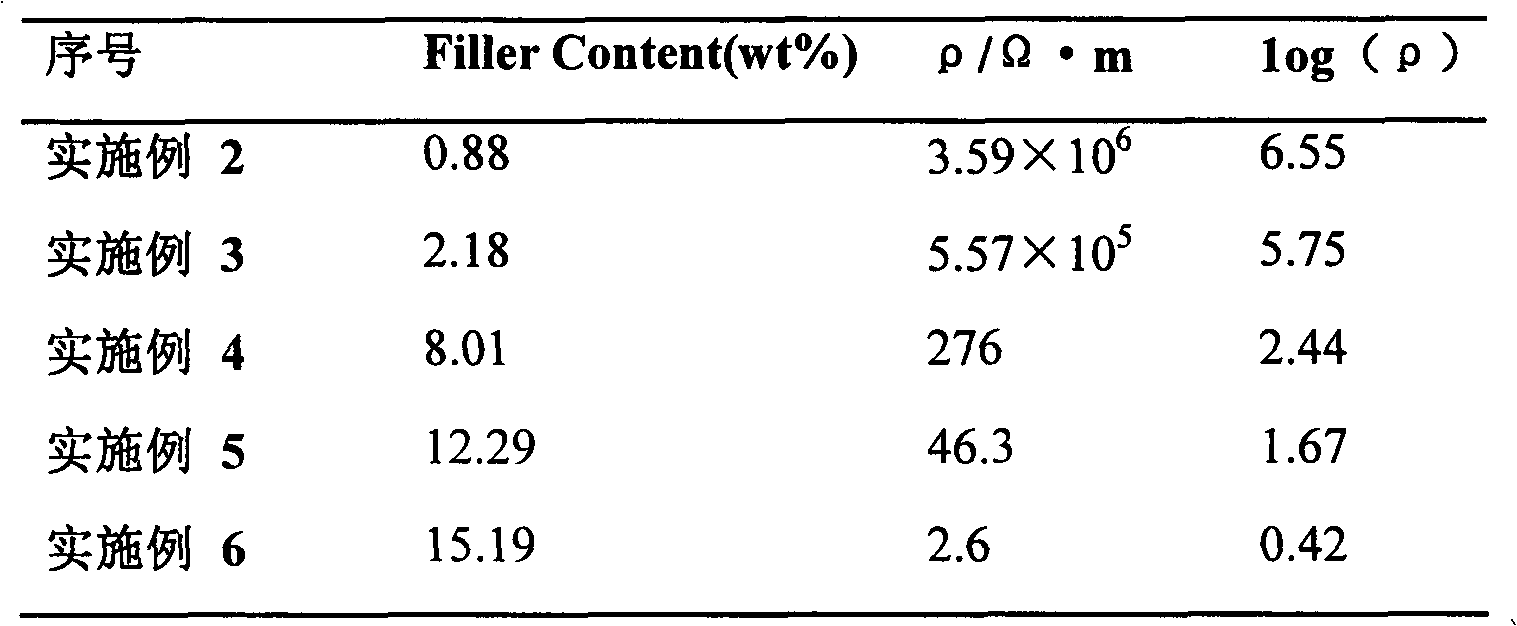

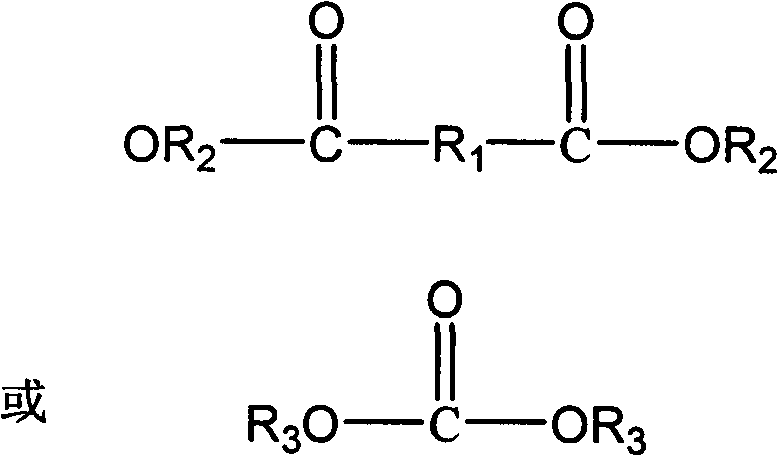

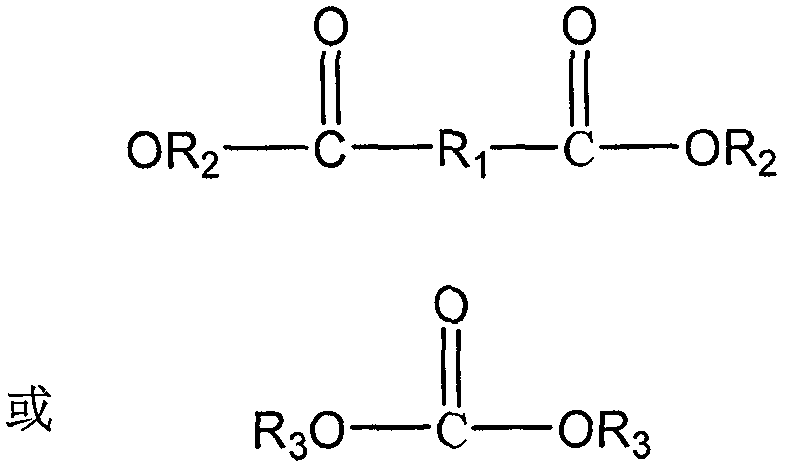

Method for directly preparing porous carbon material filling conducting polyester composite material

The invention relates to a method for directly preparing a porous carbon material filling conducting polyester composite material. The conducting polyester is prepared by a meting transesterification method by taking a porous carbon material loading alkali compound as a catalyst and a dihydroxyl compound and a diester compound as the raw materials. A product of which the volume resistivity is less than 10<3> Omega*m can be obtained under the condition that the filling mass percent of the porous carbon material is 1 to 10 percent. The method is simple and practicable; a small amount of the carbon material is used; and the polyester material with good electrical properties can be directly synthesized by using the raw materials.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

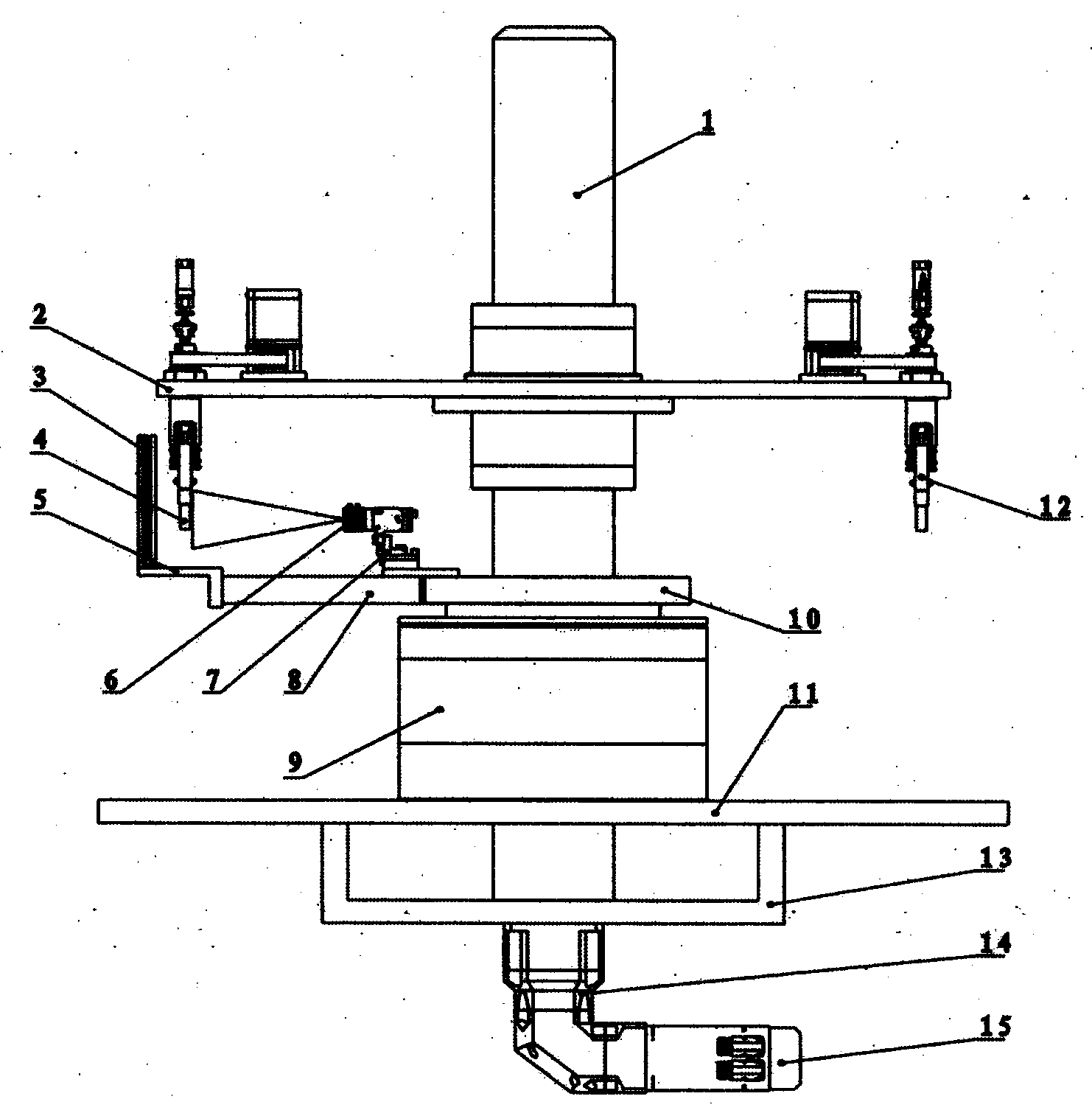

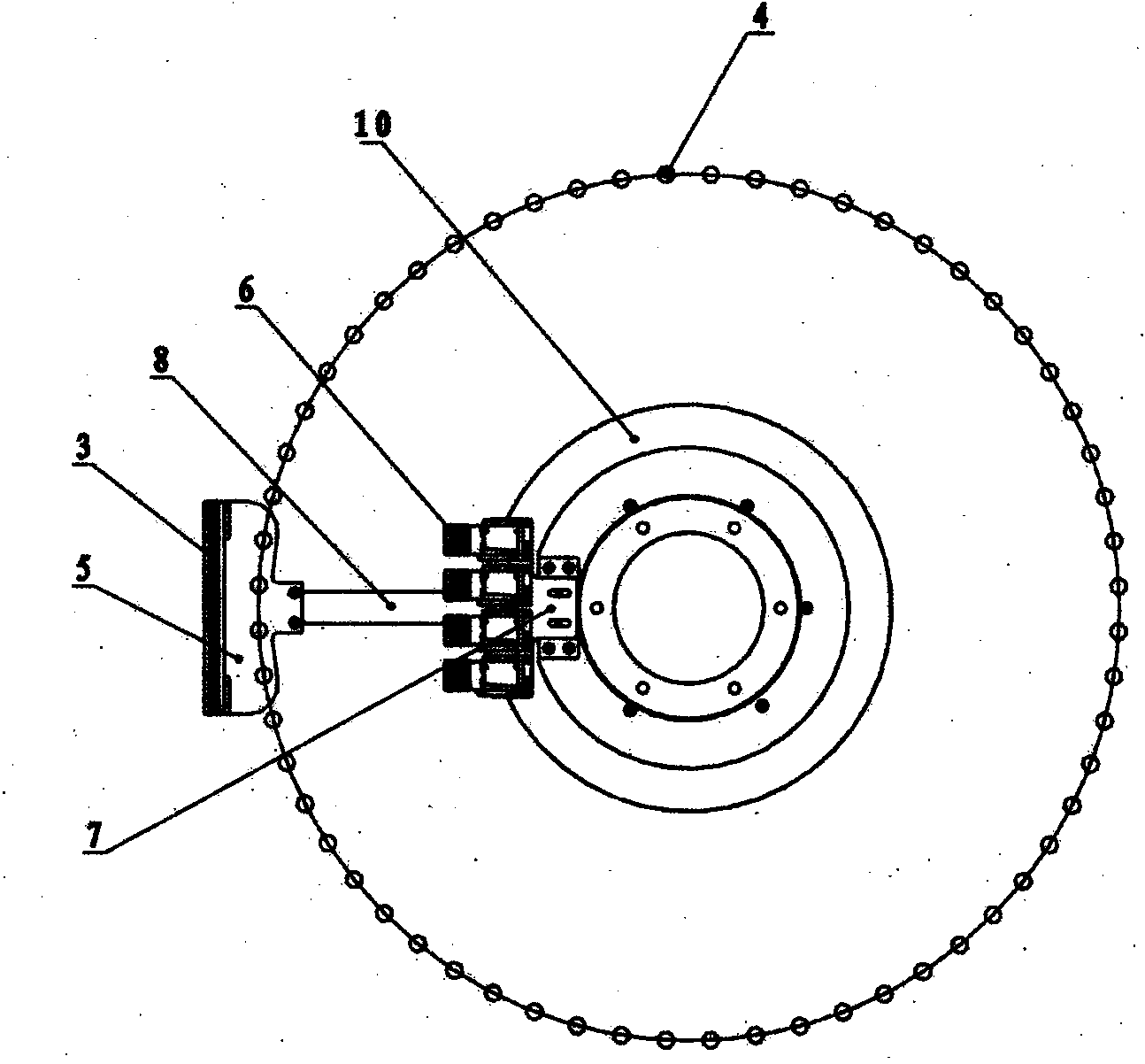

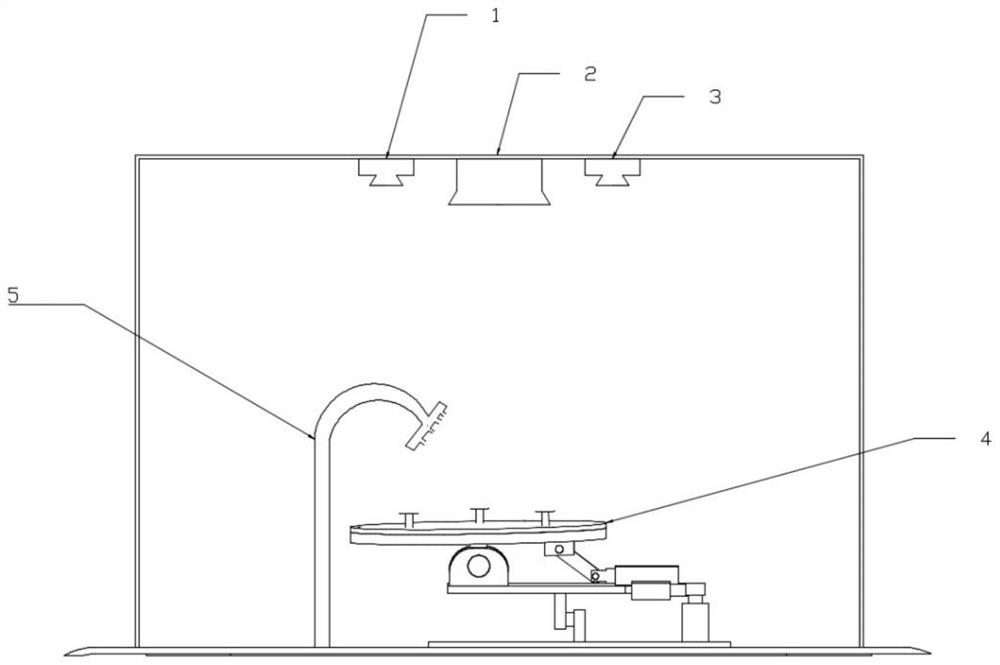

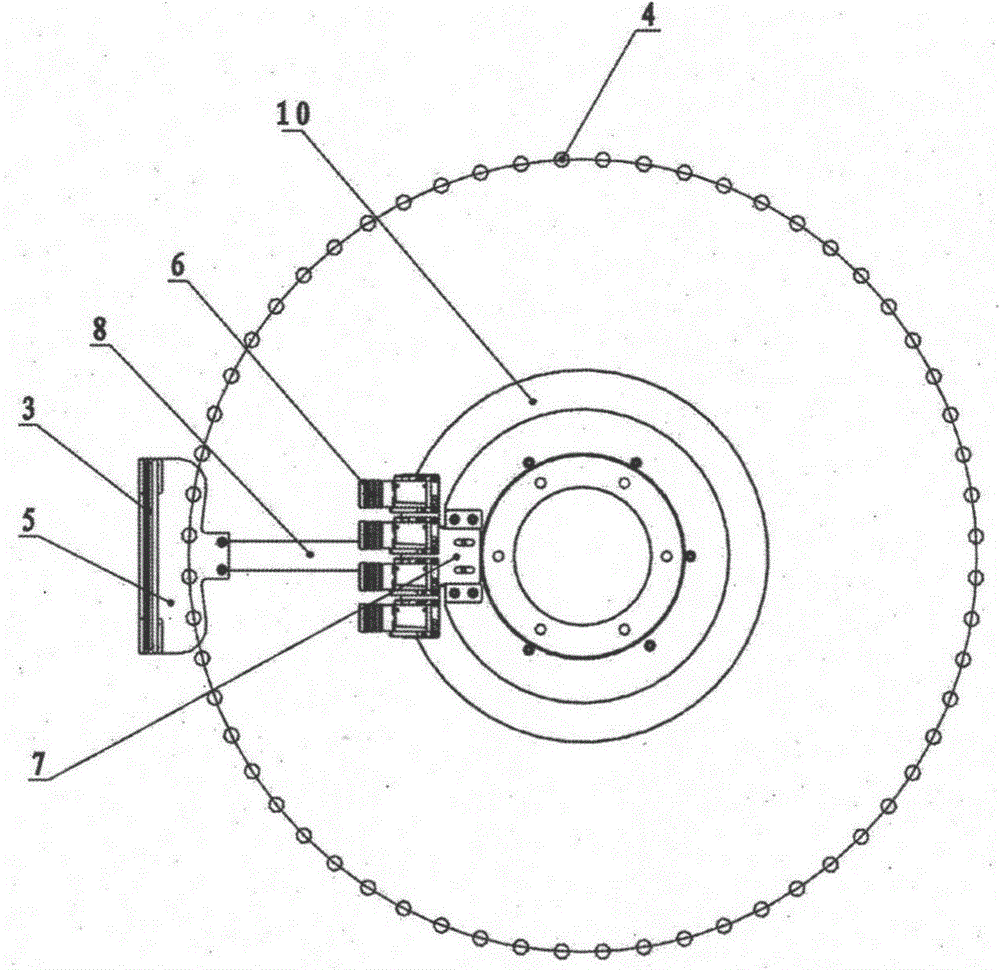

Image synchronous following acquisition device of ampoule bottle light inspection device adopting backlight

ActiveCN103512898AImprove detection efficiencyImprove detection accuracyOptically investigating flaws/contaminationEngineeringReducer

The invention provides an image synchronous following acquisition device of an ampoule bottle light inspection device adopting a backlight. The device is characterized by comprising a spindle, wherein the spindle is rotatably arranged in the central hole of a hollow direct-drive servo motor; the spindle is concentric with the hollow direct-drive servo motor; one end of the spindle is connected with a reducer; the reducer is connected with a main motor; the other end of the spindle is arranged in the center of a light inspection plate and fixedly connected with the light inspection plate; clamping jaws are arranged at the periphery of the light inspection plate; a to-be-inspected ampoule bottle is fixed on the clamping jaws; a hollow direct-drive servo motor output flange is fixed on the hollow direct-drive servo motor; the hollow direct-drive servo motor output flange is connected with a rocker arm; the rocker arm is fixedly connected with a backlight mounting plate and an industrial camera mounting plate; the backlight is arranged on the backlight mounting plate; an industrial camera is arranged on the industrial camera mounting plate; the to-be-inspected ampoule bottle is arranged between the backlight and the industrial camera. The device can complete image acquisition without halting, so that the inspection efficiency of the device is greatly improved.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

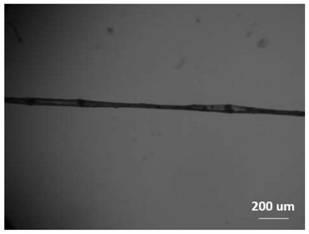

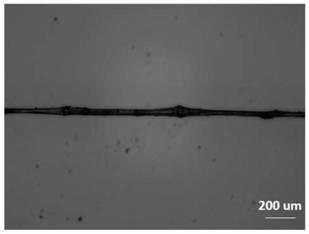

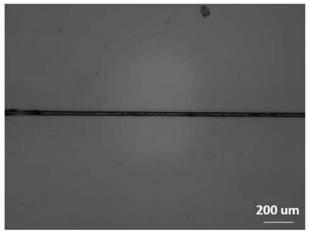

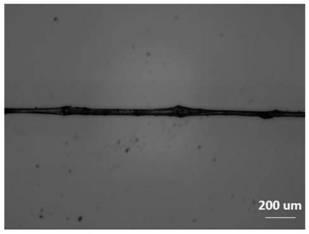

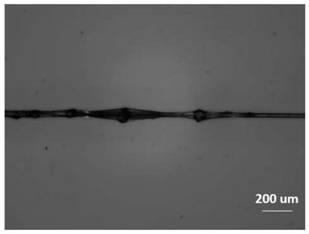

Spider silk-like polymer fiber and preparation method thereof

ActiveCN109208109AEasy to collectSolve the problem of weak interface interactionMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolymer science

The invention relates to a spider silk-like polymer fiber and a preparation method thereof in the technical field of chemobionics. The spider silk-like polymer fiber comprises the following componentsby weight: 100 parts of a fiber matrix polymer and 1-50 parts of porous particles. The monofilament of the polymer fiber has a spider silk-like microstructure with spindle knot structural units in interval distribution, and the spindle knot structural units have a radial height of 10-300 microns, an axial length of 10-1000 microns, and an interval of 10-5000 microns. The method provided by the invention has no need for substantial change of the existing spinning technology and has no need for change of equipment, the process is simple, and the cost is low. The spider silk-like polymer fiber obtained by the invention can realize directional movement of water droplets on the fiber surface, has water gathering function, and also has good mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

ActiveCN102489322BNo sheddingImprove uniformityPhysical/chemical process catalystsAir quality improvementOrganic fractionCombustion

The invention relates to a catalyst for purifying tail gas of diesel automobiles, a preparation method and a purification device thereof. The catalyst comprises a first carrier taking cordierite honeycomb ceramics as a matrix, and a second carrier taking SiC or a cordierite wall-flow structure as a matrix, a first coating and active components on the first carrier, as well as a second coating and active components on the second carrier. In the invention, coating, roasting and reduction processes are adopted for preparing the coatings composed of composite oxides. The catalyst and the device in the invention employ a technology combining a DOC (diesel oxidation converter) and a CDPF (catalyzed diesel particulate filter). By means of the DOC at a front end, HC, CO as well as the soluble organic fractions (SOF) in PM are removed through oxidation. Meanwhile, NO is converted to NO2 that has stronger reducibility so as to be good for the reaction of NO2 and C, thus reaching the purposes of removing NO and lowering the combustion temperature of C simultaneously. Depending on the self-temperatures of diesel automobiles to realize regeneration of a particulate filter, the purification device in the invention has the characteristics of high purification efficiency and convenient usage, etc.

Owner:CHONGQING MATERIALS RES INST

A stirring slag removal machine for aluminum liquid mixing furnace

ActiveCN108277363BAvoid jitterImprove efficiencyStirring devicesCasting cleaning apparatusSlagMaterials science

Owner:阿坝铝厂

Color-changing powder preparation method

PendingCN110628412AEasy to operateParticle size controllableOrganic dyesTenebresent compositionsPolyolefinAntioxidant

The invention provides a color-changing powder preparation method, wherein the color-changing powder comprises polyolefin, a photochromic dye, an antioxidant, an ultraviolet absorbent and a sensitizer. The preparation method comprises: uniformly mixing the substances in a melting manner, carrying out low temperature crushing, and screening to obtain the required color-changing powder. According tothe invention, the prepared color-changing powder is suitable for various photochromic dyes, has characteristics of wide applicability, simple preparation method, high operability, good color changing and developing effect, long service life and broad market prospect, and can be used in various fields.

Owner:SHANGHAI DIFANG TEXTILE TECHCAL FLOCKING

Spider silk-like polymer fiber based on polystyrene porous microspheres and preparation method thereof

ActiveCN109208100AEasy to collectSolve the problem of weak interface interactionMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolymer science

The invention relates to a spider silk-like polymer fiber based on polystyrene porous microspheres and a preparation method thereof in the technical field of chemobionics. The spider silk-like polymerfiber comprises the following components by weight: 100 parts of a fiber matrix polymer and 1-46 parts of polystyrene porous microspheres. The monofilament of the polymer fiber has a spider silk-likemicrostructure with spindle knot structural units in interval distribution, and the spindle knot structural units have a radial height of 10-300 microns, an axial length of 10-1000 microns, and an interval of 10-5000 microns. The method provided by the invention has no need for substantial change of the existing spinning technology and has no need for change of equipment, the process is simple, and the cost is low. The spider silk-like polymer fiber obtained by the invention can realize directional movement of water droplets on the fiber surface, has water gathering function, and also has good mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retarding non-halogen silicon core pipe special material and its preparing process

InactiveCN1212349CStrong self-extinguishingGood self-extinguishingInsulated cablesInsulated conductorsToxic gasProcedure Agents

A non-halogen fire-retarding material for the conduit of electric wire, electric cable or optical cable is prepared from HCPE resin (51-73 wt%), non-haloen composite fire retardant (25-45%), assistant (1-5%) and stabilizer (0.1-2%) through mixing, dual-screw extruding out and granulating. Its advantages are high fire-retarding effect and not releasing a lot of toxic gas.

Owner:SINOPEC YANGZI PETROCHEM

A light-to-heat conversion, heat storage and temperature-regulating cellulose fiber and its preparation method

ActiveCN110528097BLight-to-heat conversionImprove absorption rateMonocomponent cellulose artificial filamentMicroballoon preparationSpinningInfrared lamp

Owner:TIANJIN POLYTECHNIC UNIV +1

Femtosecond laser cleaning method for 3D printing metal surface

PendingCN112372142AWill not cause deformation and crackingMeet cleaning needsLaser beam welding apparatusCleaning processes and apparatus3d printHeat-affected zone

The invention discloses a femtosecond laser cleaning method for a 3D printing metal surface. According to the femtosecond laser cleaning method, the combination of femtosecond pulse laser and a scanning galvanometer system are adopted to clean the complex surface of a 3D printing metal component, so that the surface roughness of the 3D printing metal component is reduced, and the surface quality is improved. By adopting the surface treatment method, the surface roughness (Ra) of the 3D printing metal component can be reduced from 20 [mu]m to 2 [mu]m, and the application range of a 3D printingproduct is further expanded. According to the surface cleaning method, compared with a traditional grinding and polishing process, laser polishing is free of pollution and high in efficiency, a heat affected zone in the machining process is small, rapid and automatic complex surface cleaning treatment can be achieved under the condition that a component base body is not damaged, micropores and cracks are repaired in the cleaning process, crack initiation is reduced, and the fatigue life of samples is obviously prolonged. The method has an important application prospect in the aspect of 3D printing metal component post-treatment.

Owner:HEBEI UNIV OF TECH

Flame-retardant material used for cable sheath and preparation method thereof

InactiveCN107383527AImprove dispersionImprove flame retardant performancePlastic/resin/waxes insulatorsChemistryHigh oxygen

The invention provides a flame-retardant material used for a cable sheath and a preparation method thereof. The flame-retardant material used for the cable sheath is prepared from the following raw materials in parts by weight: 5-10 parts of metallocene polyethylene, 20-30 parts of an ethylene-vinyl acetate copolymer, 60-70 parts of polyethylene resin, 6-12 parts of a plasticizer, 10-20 parts of a composite flame retardant, 3-6 parts of organic silicone, 1-3 parts of an antioxidant and 2-6 parts of a lubricating agent, wherein the composite flame retardant is prepared from magnesium salt, nano silicon carbide and carbon nanotubes. The preparation method comprises the following steps: putting the raw materials into an internal mixer, heating to 115-135 DEG C, lifting the internal mixer to a top peg, reversing materials, after the materials are reversed, continuously mixing until temperature in the internal mixer reaches 145-155 DEG C, stopping heating, then continuously mixing for 2-5 minutes, then extruding by virtue of a single screw extruder, and pelletizing, so that the flame-retardant material is obtained. The flame-retardant material provided by the invention has good flame retardant effect and has the advantages of high oxygen index and strong self-extinguishing property while mechanical properties of the cable sheath are met.

Owner:佛山杰致信息科技有限公司

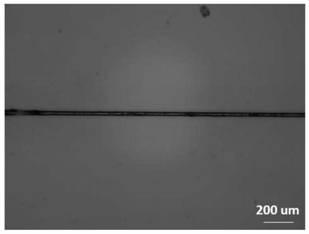

A spider silk-like polymer fiber and its preparation method

ActiveCN109208109BSolve the problem of weak interface interactionReduced impact on mechanical propertiesMonocomponent synthetic polymer artificial filamentWet spinning methodsPolymer scienceSpinning

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of spider silk-like polymer fiber based on column chromatography silica gel and preparation method thereof

ActiveCN109208102BReduced impact on mechanical propertiesSolve the problem of weak interface interactionMonocomponent polyurethanes artificial filamentWet spinning methodsPolymer scienceSpinning

Owner:CHINA PETROLEUM & CHEM CORP +1

An image synchronous follow-up acquisition device of an ampoule bottle lamp inspection machine using a backlight

ActiveCN103512898BImprove detection efficiencyImprove detection accuracyOptically investigating flaws/contaminationAcquisition apparatusElectric machine

The invention provides an image synchronous following acquisition device of an ampoule bottle light inspection device adopting a backlight. The device is characterized by comprising a spindle, wherein the spindle is rotatably arranged in the central hole of a hollow direct-drive servo motor; the spindle is concentric with the hollow direct-drive servo motor; one end of the spindle is connected with a reducer; the reducer is connected with a main motor; the other end of the spindle is arranged in the center of a light inspection plate and fixedly connected with the light inspection plate; clamping jaws are arranged at the periphery of the light inspection plate; a to-be-inspected ampoule bottle is fixed on the clamping jaws; a hollow direct-drive servo motor output flange is fixed on the hollow direct-drive servo motor; the hollow direct-drive servo motor output flange is connected with a rocker arm; the rocker arm is fixedly connected with a backlight mounting plate and an industrial camera mounting plate; the backlight is arranged on the backlight mounting plate; an industrial camera is arranged on the industrial camera mounting plate; the to-be-inspected ampoule bottle is arranged between the backlight and the industrial camera. The device can complete image acquisition without halting, so that the inspection efficiency of the device is greatly improved.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Self-healing microcapsules and preparation method thereof, self-healing coating and preparation method thereof

ActiveCN111087845BSpontaneous shrinkage of the capsule wallHeavy loadPolyurea/polyurethane coatingsMicroballoon preparationPolymer sciencePolymer chemistry

The invention relates to a self-repairing microcapsule and a preparation method thereof, a self-repairing coating and a preparation method thereof. The self-repairing microcapsule is composed of a capsule wall and a capsule core, and is characterized in that the capsule wall is polyurethane, and the polyurethane Having an imino functional group; the capsule core includes a repair agent. When the self-healing microcapsule provided by the invention is stimulated by the change of the external pH environment, the shrinkage phenomenon of the capsule wall can occur spontaneously, and the hole structure in the capsule wall structure expands so that more repairing agent seeps out to repair the damaged paint film. Compared with existing products, the prepared self-healing coating has the characteristics of low cost, simple process and excellent performance, and meets the needs of large-scale production and application.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

A method for directly preparing conductive polyester composites filled with porous carbon materials

The invention relates to a method for directly preparing a porous carbon material filling conducting polyester composite material. The conducting polyester is prepared by a meting transesterification method by taking a porous carbon material loading alkali compound as a catalyst and a dihydroxyl compound and a diester compound as the raw materials. A product of which the volume resistivity is less than 10<3> Omega*m can be obtained under the condition that the filling mass percent of the porous carbon material is 1 to 10 percent. The method is simple and practicable; a small amount of the carbon material is used; and the polyester material with good electrical properties can be directly synthesized by using the raw materials.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

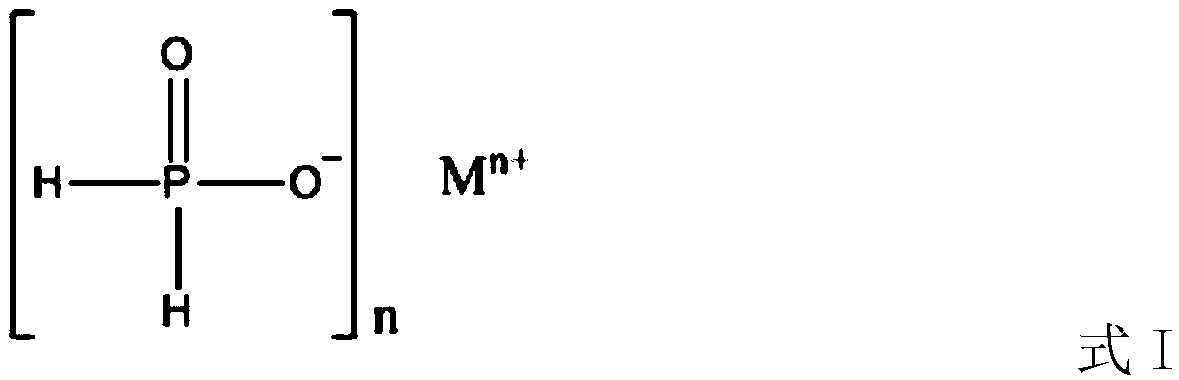

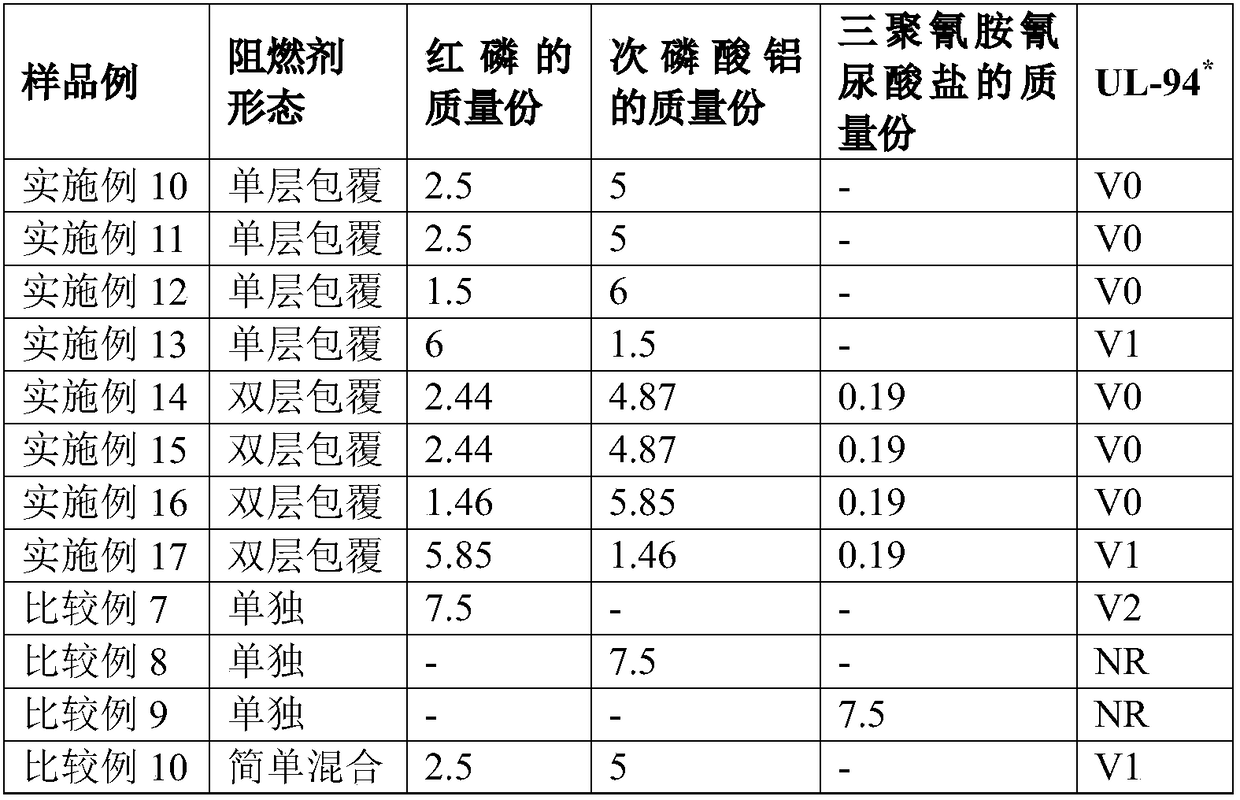

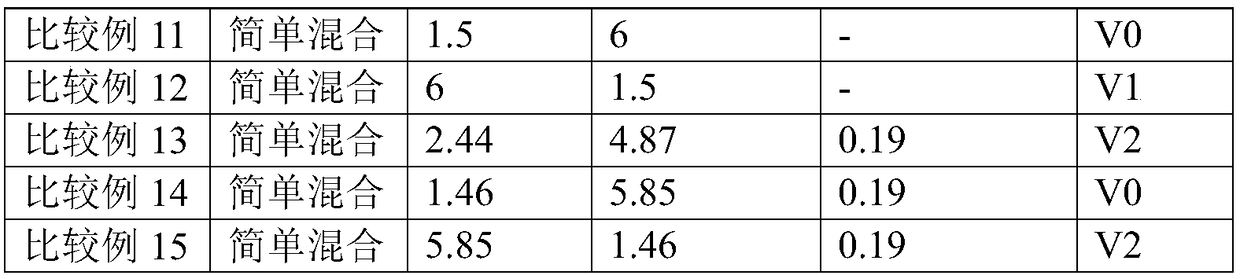

A kind of microcapsule red phosphorus, its preparation method and application

ActiveCN106009045BHigh degree of albinismImprove heat resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPhosphateOrganic compound

The invention provides microencapsulated red phosphorus, and a preparation method and application thereof. The microencapsulated red phosphorus is prepared from red phosphorus and a coating layer outside the red phosphorus; the microencapsulated red phosphorus is characterized in that the coating layer is a coating layer I containing inorganic hypophosphite, optionally, a coating layer II containing an organic compound also wraps the outside of the coating layer I. The microencapsulated red phosphorus provided by the invention is used as a flame retardant, the whitening degree is high, the heat resistance is good, the water absorption is low, the compatibility with high polymer materials is better, and the influence on mechanical performance of the high molecular materials due to the adding of the flame retardant can be reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

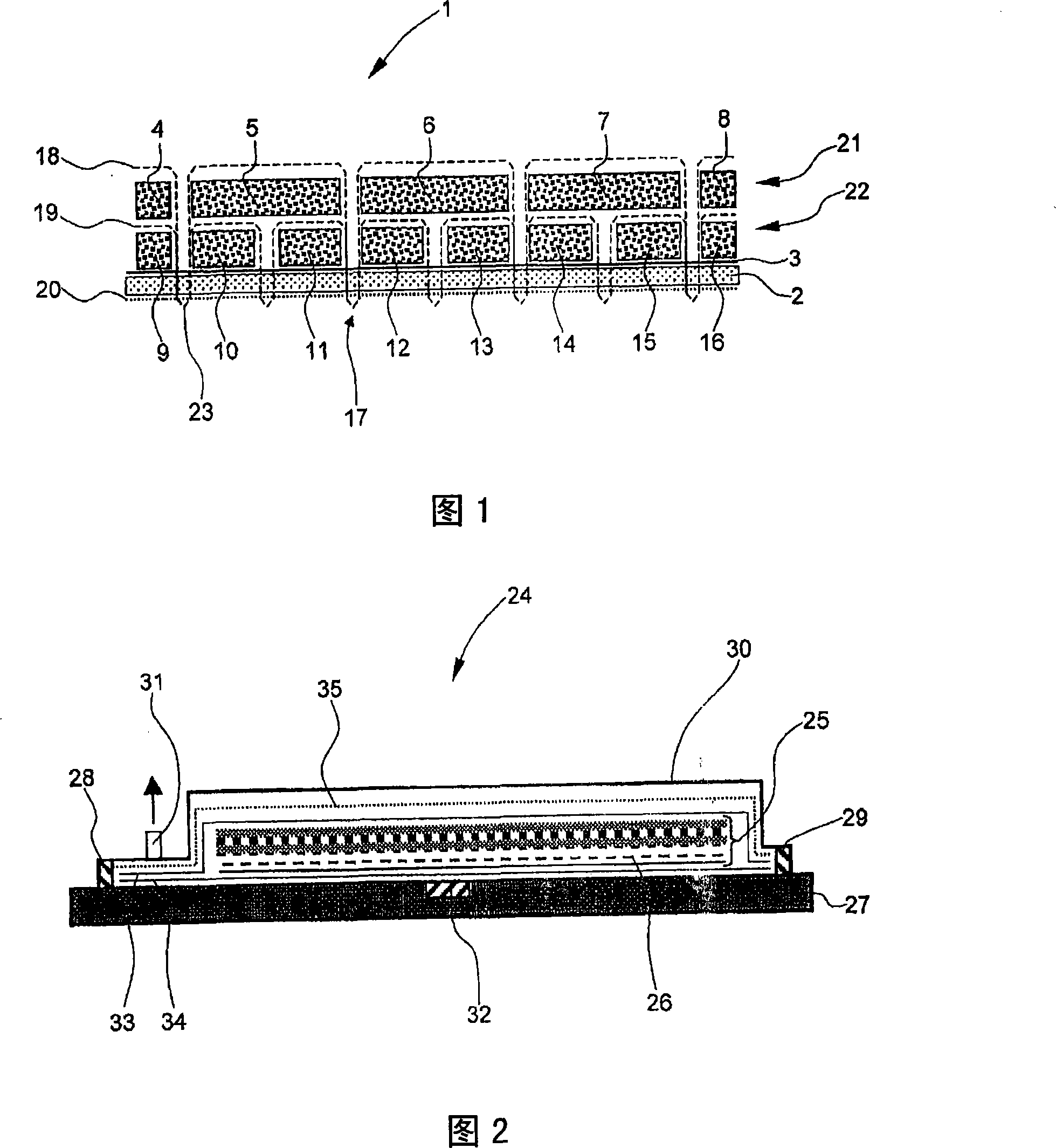

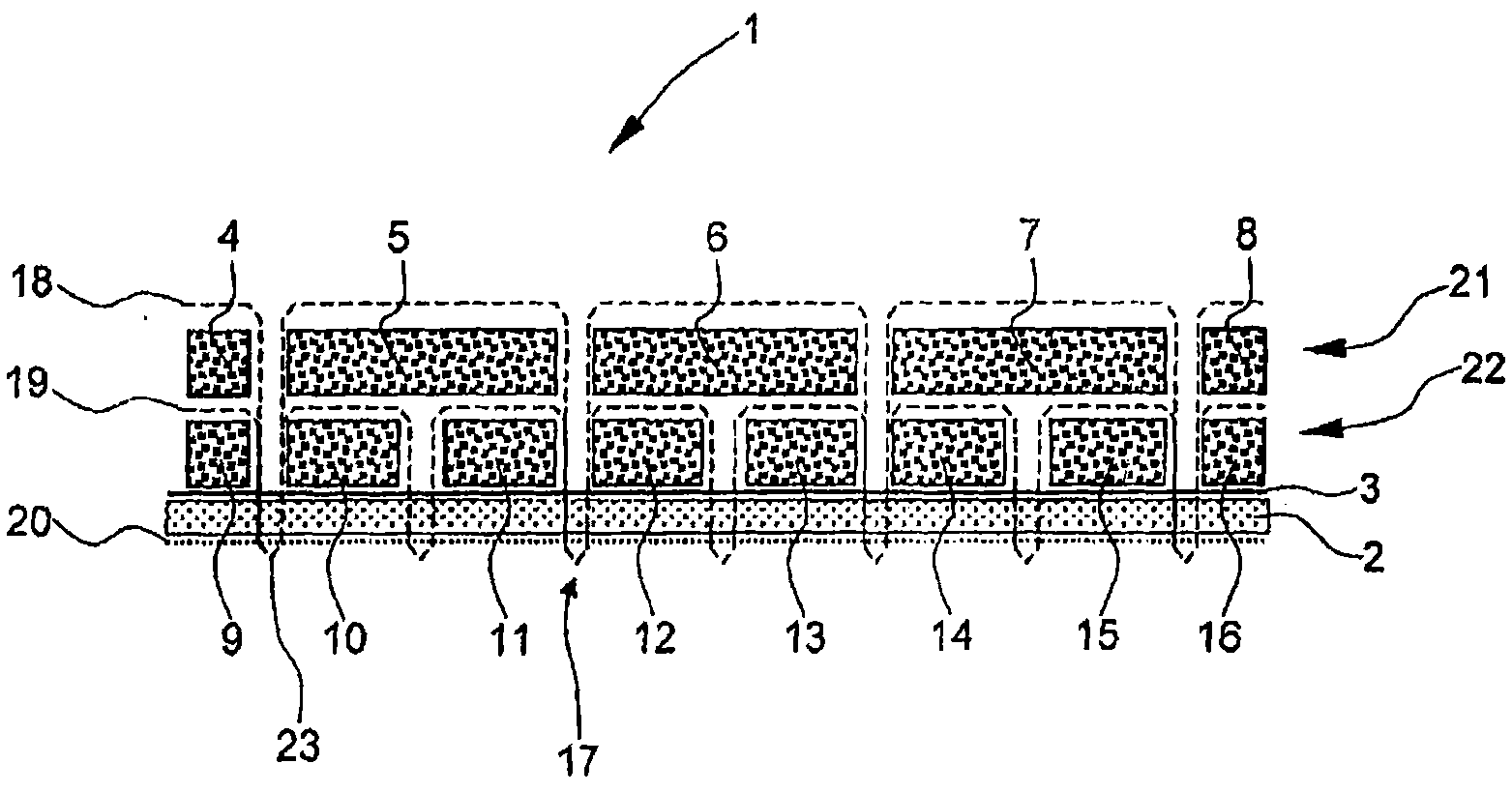

Method for producing in a TFP method one-or multi-layer layer fibre preforms

InactiveCN101228022BReduced impact on mechanical propertiesEasy to disengageSynthetic resin layered productsVehicle componentsOptoelectronicsMono layer

Owner:AIRBUS OPERATIONS GMBH

Preparation method of composite color-changing and temperature-adjusting fiber

InactiveCN112981599AImprove functionalityReduced impact on mechanical propertiesConjugated synthetic polymer artificial filamentsDye addition to spinning solutionFiberUv protection

The invention discloses a preparation method of composite color-changing and temperature-adjusting fiber. A composite color-changing and energy-storing capsule is added to a fiber core layer, so that the composite color-changing and temperature-adjusting fiber has the effects of energy storage, temperature adjustment, ultraviolet protection and visual display of environmental ultraviolet intensity and temperature, the functionality of the fiber is improved, meanwhile, the fiber can show various colors under different environmental conditions, and the color changing types of the fiber are enriched. An anti-settling agent added in the preparation process of the composite color-changing and energy-storing capsule can ensure that a core material component is uniformly and stably dispersed in the capsule, so that the phenomenon that the color development capability of the capsule is reduced due to dye agglomeration after multiple times of thermal cycling is effectively avoided, and the service life of the fiber color-changing function is prolonged. The synthesis process is simple, the requirement for equipment is low, reaction conditions are easy to control, large-scale production is facilitated, and the method has wide application prospects.

Owner:广州盛色科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com