Preparation method of ABS composite plastic product capable of reducing loss of plant extract

A technology of plant extracts and composite plastics, applied in the field of preparation of ABS composite plastic products, can solve the problems of low content, loss, and loss of finished products, and achieve the effect of reducing high temperature loss and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

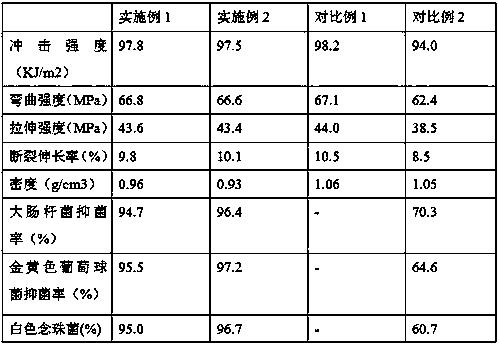

Examples

Embodiment 1

[0041] Embodiment 1 A kind of preparation method of the ABS composite plastic product that reduces the loss of plant extract

[0042] Include the following steps:

[0043] (1) Select SiO2 2 Airgel Microspheres

[0044] The SiO 2 Airgel microspheres have a surface density of 0.4g / cm3, a specific surface area of 500m2 / g, an average pore size of 18nm, a porosity of 88%, and a surface particle size of 20 microns.

[0045] (2) Ultrasonic dispersion

[0046] Grinding the plant extract to 4nm, adding 8 times the weight of deionized water, adding a dispersant, and performing ultrasonic dispersion, the ultrasonic dispersion, the ultrasonic frequency is 55KHz, and the processing time is 10 minutes to obtain a dispersion of the plant extract;

[0047] The mass ratio of described dispersant and deionized water is 5:100;

[0048] The plant extract is valerian extract.

[0049] (3) Modification

[0050] SiO 2 Airgel microspheres are added to the above-mentioned dispersion of plant...

Embodiment 2

[0060] Embodiment 2 A kind of preparation method of the ABS composite plastic product that reduces the loss of plant extract

[0061] Include the following steps:

[0062] (1) Select SiO2 2 Airgel Microspheres

[0063] The SiO 2 Airgel microspheres have a surface density of 0.4g / cm3, a specific surface area of 500m2 / g, an average pore size of 18nm, a porosity of 88%, and a surface particle size of 30 microns.

[0064] (2) Ultrasonic dispersion

[0065] Crush the plant extract to 5nm, add 10 times the weight of deionized water, add a dispersant, and carry out ultrasonic dispersion. The ultrasonic dispersion has an ultrasonic frequency of 50-60KHz and a processing time of 8-12 minutes to obtain the plant extract. Dispersions;

[0066] The mass ratio of described dispersant and deionized water is 6:100;

[0067] The plant extract is quercetin.

[0068] (3) Modification

[0069] SiO 2 Airgel microspheres are added to the dispersion of the above plant extracts, and ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com