An image synchronous follow-up acquisition device of an ampoule bottle lamp inspection machine using a backlight

An ampoule lamp and image synchronization technology, which is applied in the direction of optical testing for flaws/defects, can solve problems such as high requirements for mechanical parts processing and structural installation, assembly accuracy can not meet the requirements, and affect detection accuracy, etc., to improve detection accuracy performance, easy debugging, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

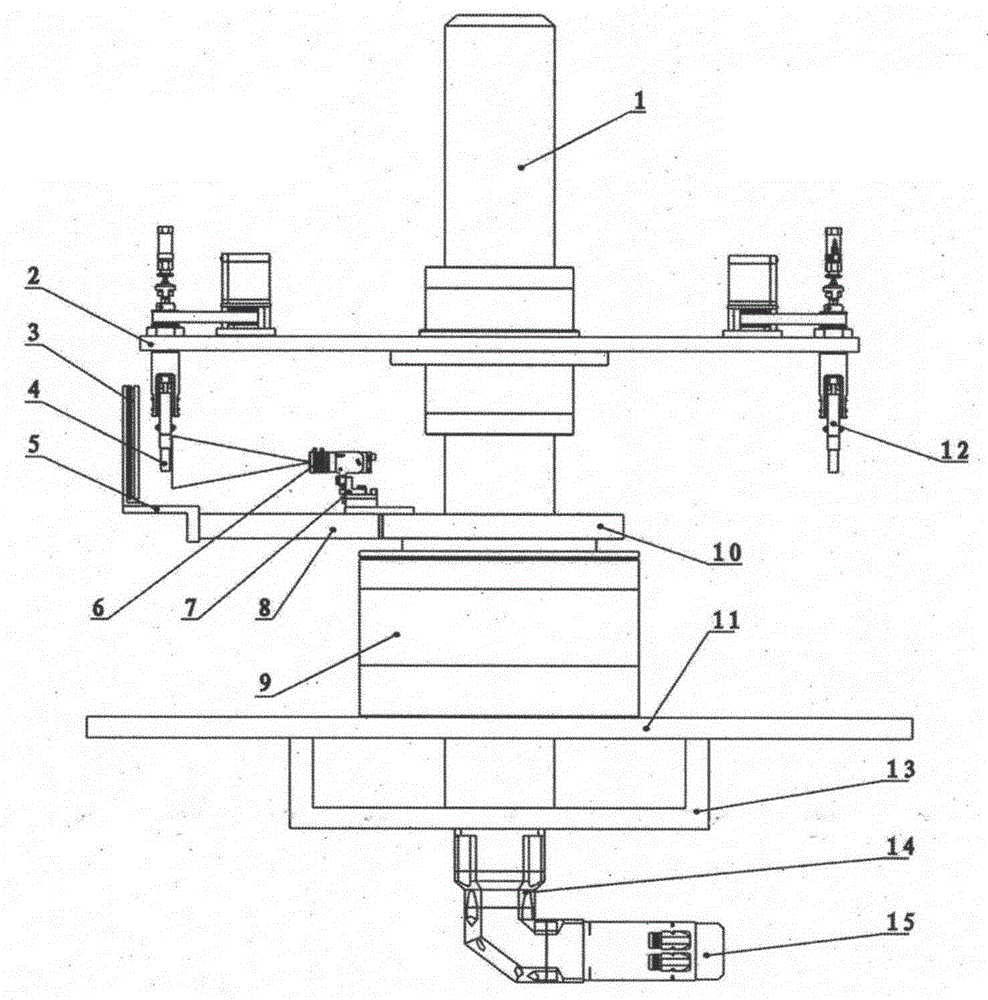

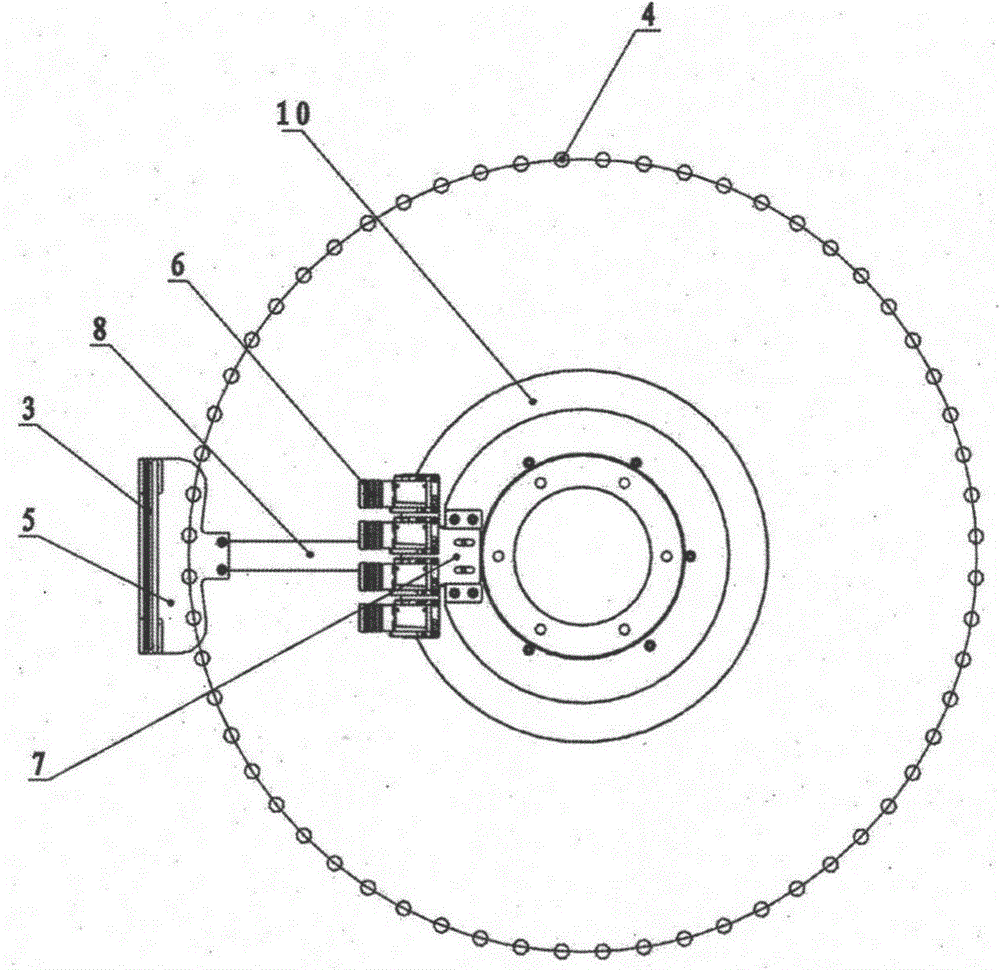

[0016] like figure 1 As shown, it is the front view of the image synchronous follow-up acquisition device of the ampoule light inspection machine using backlight. The image synchronization follow-up acquisition device of the ampoule light inspection machine with backlight mainly includes: main shaft 1, light inspection plate 2. Backlight 3. Ampoule bottle to be inspected 4. Backlight mounting plate 5. Industrial camera 6. Industrial camera mounting plate 7. Rotary arm 8. Hollow direct drive servo motor 9. Hollow direct drive servo motor output flange 10. Main Platform 11, jaw 12, motor mounting frame 13, speed reducer 14 and main motor 15.

[0017] The main platform 11 is fixed with a hollow direct drive servo motor 9, the main shaft 1 is rotatably arranged in the center hole of the hollow direct drive servo motor 9, and the main shaft 1 passes through the hollow direct drive servo motor 9 and is rotatably installed on the main platform 11 , concentric with the hollow direct-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com