A kind of microcapsule red phosphorus, its preparation method and application

A technology of microencapsulated red phosphorus and red phosphorus, which is applied in chemical instruments and methods, dyed high molecular organic compound treatment, dyed low molecular organic compound treatment, etc., can solve the problem of poor compatibility of resin materials and poor flame retardant effect , large amount of flame retardant and other problems, to achieve the effect of large-scale industrial production, low water absorption and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

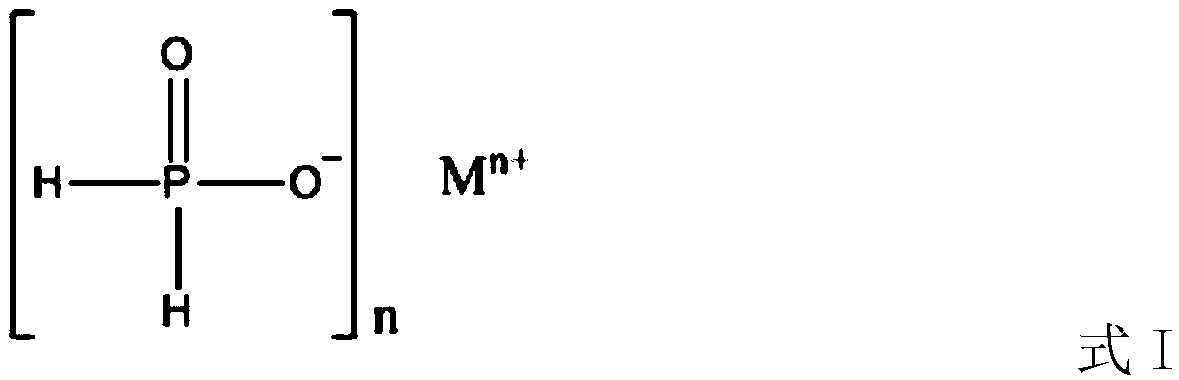

[0068] Preparation of microcapsule red phosphorus coated with aluminum hypophosphite

[0069] 10 g of red phosphorus, 100 ml of deionized water and 44.77 g of sodium hypophosphite monohydrate were added into the reaction vessel and heated to 95° C., mixed and stirred for 15 minutes. Slowly drip 30.03g of aluminum chloride solution with a mass concentration of 50% into the system for 1.5 hours, adjust the pH value of the system to 2-3 with hydrochloric acid, keep stirring for 2 hours, and coat the aluminum hypophosphite on the On the outside of the red phosphorus particles, a single-layer coated microcapsule red phosphorus is obtained, which is designated as sample 1 # .

Embodiment 2

[0071] Preparation of microcapsule red phosphorus coated with aluminum hypophosphite

[0072] Add 10 g of red phosphorus, 100 ml of deionized water, 44.77 g of sodium hypophosphite monohydrate and 0.05 g of sodium dodecylbenzenesulfonate into a reaction vessel, heat to 95° C., and mix and stir for 15 minutes. Slowly drip 30.03g of aluminum chloride solution with a mass concentration of 50% into the system for 1.5 hours, adjust the pH value of the system to 2-3 with hydrochloric acid, keep stirring for 2 hours, and coat the aluminum hypophosphite on the On the outside of the red phosphorus particles, a single-layer coated microcapsule red phosphorus is obtained, which is designated as sample 2 # .

Embodiment 3

[0074] Preparation of microcapsule red phosphorus coated with aluminum hypophosphite

[0075] Add 10 g of red phosphorus, 50 ml of deionized water, 71.63 g of sodium hypophosphite monohydrate and 0.05 g of sodium dodecylbenzenesulfonate into a reaction vessel, heat to 75° C., and mix and stir for 30 minutes. Slowly drip 48.06g of aluminum chloride solution with a mass concentration of 50% into the system for 2 hours, adjust the pH value of the system to 2-3 with hydrochloric acid, keep stirring for 6 hours, and coat the aluminum hypophosphite on the On the outside of the red phosphorus particles, a single-layer coated microcapsule red phosphorus is obtained, which is recorded as sample 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com