A method for directly preparing conductive polyester composites filled with porous carbon materials

A porous carbon material, direct technology, applied in the field of preparation of porous carbon material conductive polyester, can solve the problems of increased melt viscosity, increased cost, poor processability and mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

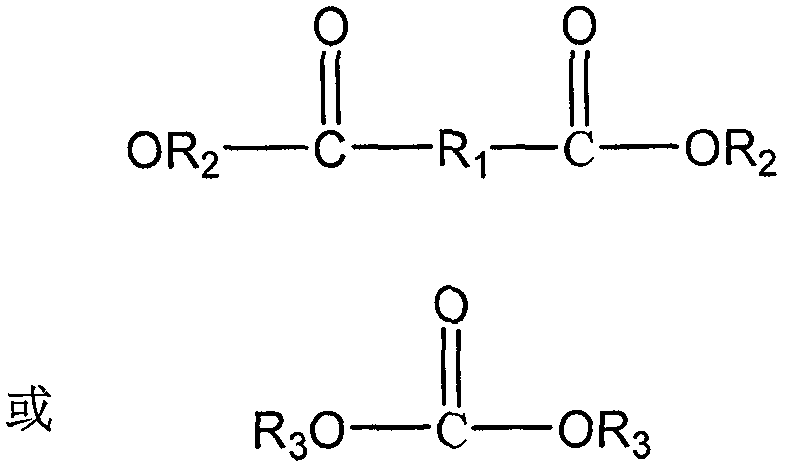

Method used

Image

Examples

Embodiment 1

[0019] Prepare 400.0 mL of 0.10 mol / L KOH solution, then add 40.0 g of carbon black into the solution, stir at room temperature for 12 h, suction filter, wash, and vacuum dry at 100°C for 12 h to obtain a catalyst.

[0020] Weigh 43.2mmol of bisphenol A and 46.7mmol of diphenyl carbonate into a three-necked flask, add 0.5g of catalyst, and then divide into two reaction stages of transesterification and polycondensation.

[0021] use CH 2 Cl 2 Extract the PC in the product, and then according to "GB / T1632-93 Polymer Dilute Solution Viscosity and Intrinsic Viscosity Determination", the viscosity-average molecular weight measured by Ubbelohde's viscometer is 22803g·mol -1 .

[0022] The obtained product is made into a disc with a thickness of about 1.0mm, and the volume resistivity of the sample is measured by a multimeter to be 1.56×10 3 Ω·m.

Embodiment 2-6

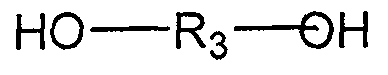

[0024] Under the same conditions, the amount of the catalyst was changed to investigate its influence on the electrical conductivity of the product. The test conditions were the same as in Example 1, and the results are listed in Table 1.

[0025] Table 1 The influence of conductive filling amount on the conductivity of samples

[0026]

[0027]

Embodiment 7

[0029] Prepare 100.0 mL of 0.10 mol / L KOH solution, then add 10.00 g of carbon nanotubes into the solution, stir at room temperature for 12 h, filter with suction, wash, and vacuum dry at 100°C for 12 h to obtain a catalyst.

[0030] Weigh 43.2mmol of bisphenol A and 46.7mmol of diphenyl carbonate into a three-necked flask, add 1.5g of catalyst, and then divide into two reaction stages of transesterification and polycondensation.

[0031] use CH 2 Cl 2 Extract the PC in the product, and then according to "GB / T1632-93 Determination of Viscosity and Intrinsic Viscosity of Dilute Polymer Solution" using Ubbelohde viscometer to measure the viscosity-average molecular weight of 20181g·mol -1 .

[0032] The obtained product is made into a disc with a thickness of about 1.0mm, and the volume resistivity of the sample is measured by a multimeter to be 4.14×10 3 Ω·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com