Phosphorus and nitrogen fire retardant and preparation method thereof

A technology of phosphorus-nitrogen flame retardants and solvents, which is applied in the manufacture of fire-resistant and flame-retardant filaments, the treatment of dyed polymer organic compounds, and fire-resistant coatings. Larger, shortened flame retardant aging and other issues, to achieve the effect of low cost, easy to obtain raw materials, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

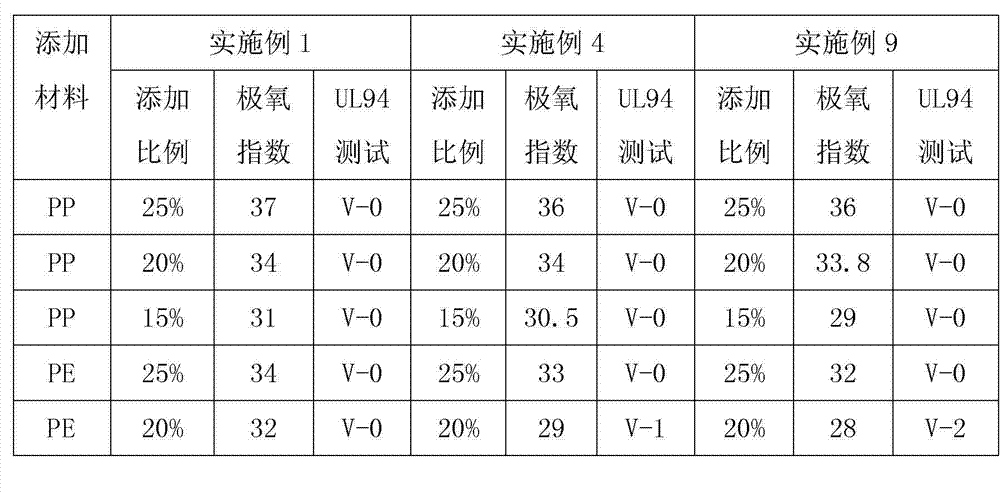

Examples

Embodiment 1

[0024] 1) Stir the type I ammonium polyphosphate and water together evenly, prepare 1000g of suspension slurry with a concentration of 50%, and stir evenly at a temperature of 30°C;

[0025] 2) Prepare a melamine formaldehyde solution at a molar ratio of 1:15, and react at a temperature of 30°C for 60 minutes to form a prepolymer;

[0026] 3) Quickly add the prepolymer produced by the above reaction to the slurry in the first step, the amount added is 30% of the ammonium polyphosphate, and stir evenly with water as the dispersant; then keep warm for 2 hours;

[0027] 4) Filter or centrifugally dehydrate the above product, wash it twice with deionized water, and re-dehydrate, dry, and pulverize the filtered solid-phase product to obtain a phosphorus-nitrogen flame retardant.

Embodiment 2

[0029] 1) Stir the type I ammonium polyphosphate and ethanol evenly together to prepare 1000g of suspension slurry with a concentration of 5%, and stir evenly at a temperature of 120°C;

[0030] 2) Prepare a melamine formaldehyde solution at a molar ratio of 1:3, and react at a temperature of 120°C for 15 minutes to form a prepolymer;

[0031] 3) Quickly add the prepolymer produced by the above reaction into the slurry in the first step, the amount added is 50% of the ammonium polyphosphate, and stir evenly with ethanol as the dispersant; then keep warm for 2 hours;

[0032] 4) Filter or centrifuge the above product, wash it with deionized water for 5 times, re-dehydrate the filtered solid phase product, dry and pulverize to obtain a phosphorus nitrogen flame retardant.

Embodiment 3

[0034] 1) According to type I: type II = 1:1 weight ratio, ammonium polyphosphate and water are stirred together evenly, and prepared into 1000g of suspension slurry with a concentration of 30%, and stirred evenly at a temperature of 120°C;

[0035] 2) Prepare a melamine formaldehyde solution at a molar ratio of 1:6, and react at a temperature of 80°C for 30 minutes to form a prepolymer;

[0036] 3) Quickly add the prepolymer produced by the above reaction into the slurry in the first step, the addition amount is 35% of the ammonium polyphosphate, and stir evenly with water as the dispersant; then keep warm for 3 hours;

[0037] 4) Filter or centrifugally dehydrate the above product, wash it with deionized water for 3 times, and re-dehydrate the filtered solid phase product, dry and pulverize to obtain a phosphorus-nitrogen flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com