Femtosecond laser cleaning method for 3D printing metal surface

A 3D printing and femtosecond laser technology, applied in cleaning methods and appliances, laser welding equipment, metal processing equipment, etc., can solve problems such as inability to guarantee polishing, surface performance and mechanical properties, and affect overall shape and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

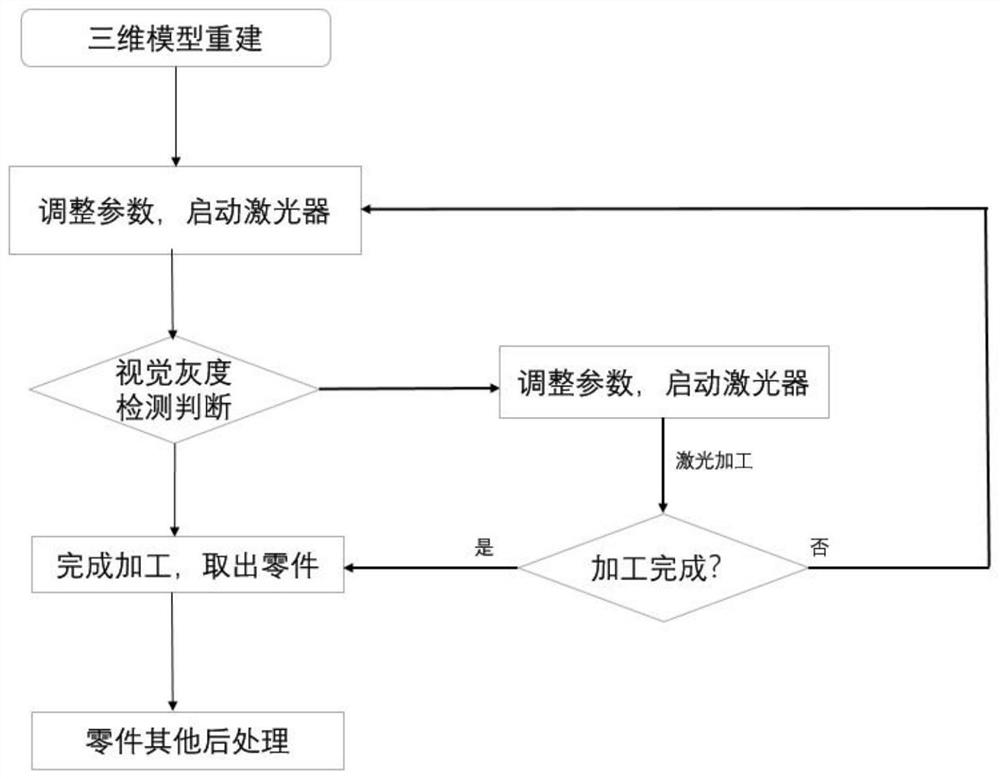

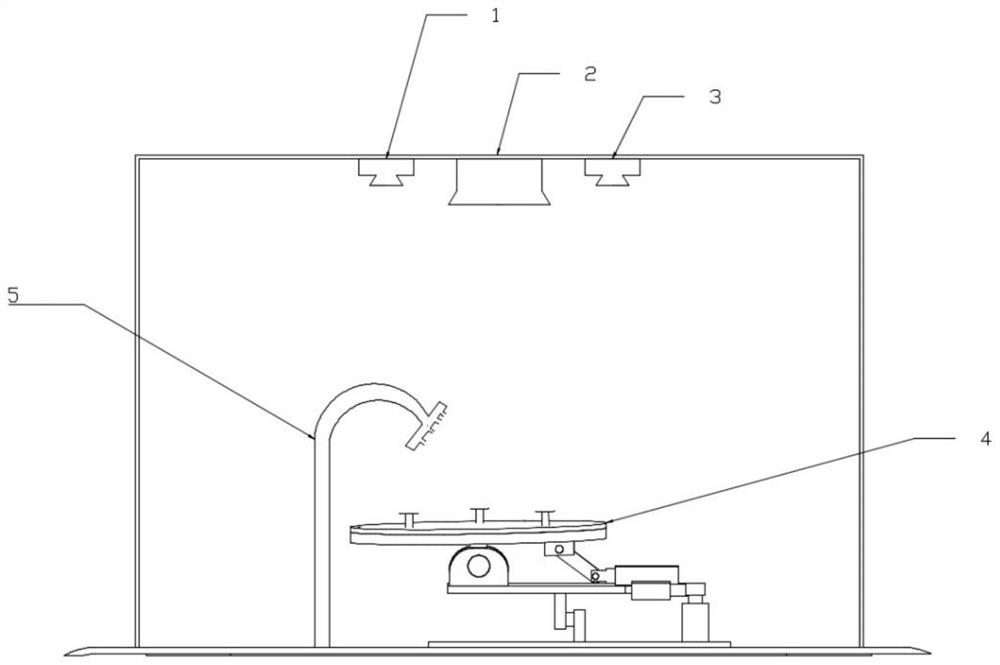

[0043] On laser cleaning equipment (such as figure 1 As shown in the figure: 1 is visual scanning; 2 is vibrating mirror; 3 is visual scanning; 4 is mobile platform; 5 is blowing device. ) to realize the cleaning of Ti6Al4V manufactured by additive materials, the process flow is as follows figure 2 The specific steps shown are as follows:

[0044] (1) Fix the Ti6Al4V metal component on the fixture of the numerically controlled three-dimensional translation table, and the surface of the workpiece can form a certain angle with the incident direction of the laser. In the embodiment of the present invention, the incident direction of the laser is perpendicular to the surface of the workpiece to be processed.

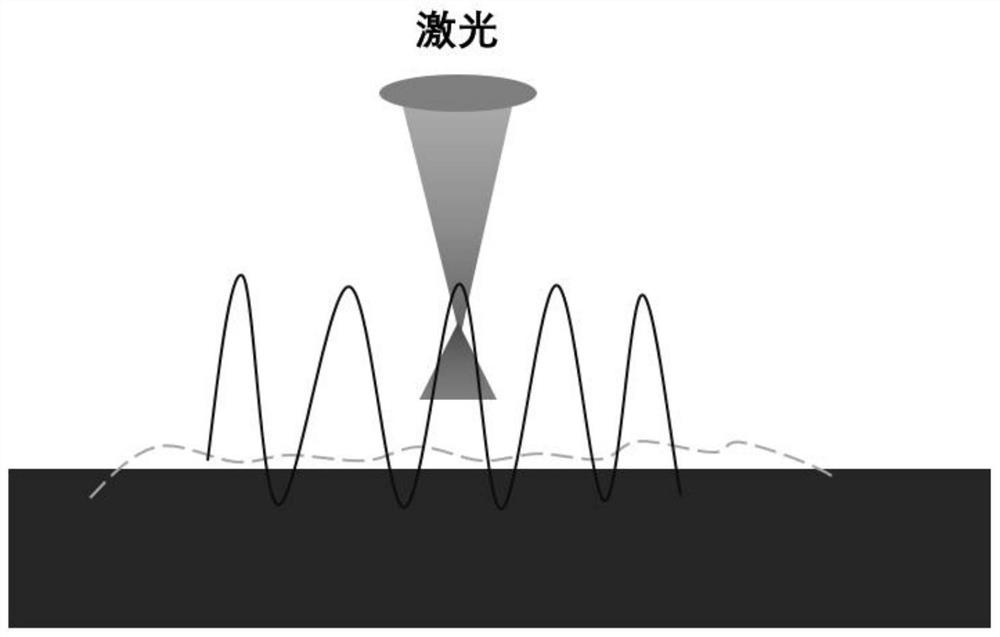

[0045] (2) Use the visual inspection system to determine the three-dimensional shape and coordinate parameters of the target component, determine the three-dimensional shape and coordinate parameters of the target component surface, and establish a three-dimensional digita...

Embodiment 2

[0051] The laser cleaning equipment is used to clean the 316L steel manufactured by additives. The specific steps are as follows:

[0052] (1) The 316L steel metal component is fixed on the fixture of the numerical control three-dimensional translation table, and the surface of the workpiece can be at a certain angle with the incident direction of the laser. In the embodiment of the present invention, the incident direction of the laser is perpendicular to the surface of the workpiece to be processed.

[0053] (2) Use the visual inspection system to determine the three-dimensional shape and coordinate parameters of the target component, determine the three-dimensional shape and coordinate parameters of the target component surface, and establish a three-dimensional digital model for the subsequent automatic cleaning of complex surfaces, so as to realize the automatic cleaning process of complex curved surfaces .

[0054] (3) Use the visual inspection system to detect the gray ...

Embodiment 3

[0059] The laser cleaning equipment is used to clean the copper alloy manufactured by additive, and the specific steps are as follows:

[0060] (1) The copper alloy steel metal component is fixed on the fixture of the numerical control three-dimensional translation table, and the surface of the workpiece can be at a certain angle with the incident direction of the laser. In the embodiment of the present invention, the incident direction of the laser is perpendicular to the surface of the workpiece to be processed.

[0061] (2) Use the visual inspection system to determine the three-dimensional shape and coordinate parameters of the target component, determine the three-dimensional shape and coordinate parameters of the target component surface, and establish a three-dimensional digital model for the subsequent automatic cleaning of complex surfaces, so as to realize the automatic cleaning process of complex curved surfaces .

[0062] (3) Use the visual inspection system to det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com