Flame-retardant material used for cable sheath and preparation method thereof

A technology for flame retardant materials and cable protection, applied in the field of flame retardant materials, can solve the problems of cable surface sheath damage, poor wear resistance, damage, etc., and achieve the effects of improving flame retardant performance, improving dispersion, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

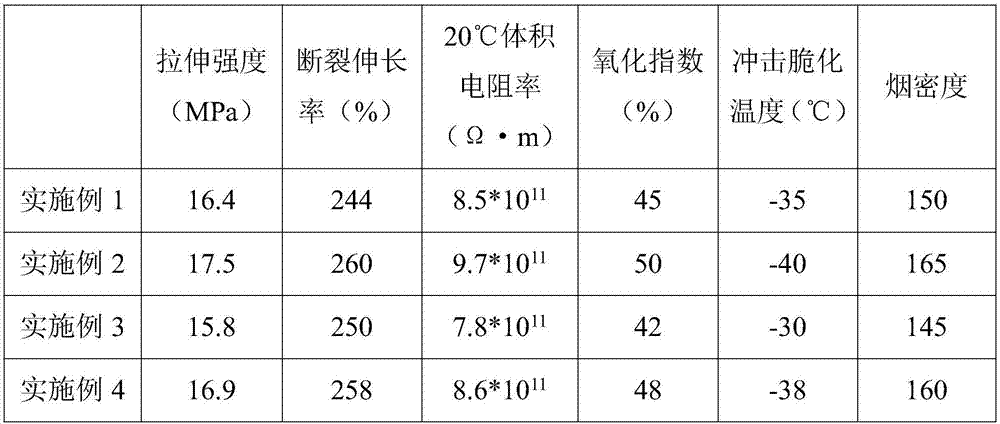

Examples

Embodiment 1

[0021] The preparation method of composite flame retardant:

[0022] Add 6 parts by weight of nano-silicon carbide and 2 parts by weight of carboxylated multi-walled carbon nanotubes into an ethanol solution of 80 parts by weight of magnesium chloride, fully stir and disperse and add 2 parts by weight of sodium dodecylbenzenesulfonate, After ultrasonic dispersion, add 50 parts by weight of ammonia water to the dispersed suspension to obtain a mixed solution, transfer the mixed solution to a 110°C hydrothermal kettle for constant temperature reaction, and perform subsequent treatment after the reaction to obtain a composite flame retardant.

Embodiment 2

[0024] The preparation method of composite flame retardant:

[0025] 12 parts by weight of nano-silicon carbide and 8 parts by weight of carboxylated multi-walled carbon nanotubes are added to 90 parts by weight of magnesium sulfate ethanol solution, fully stirred and dispersed, and then 1 part by weight of sodium hexadecylbenzenesulfonate is added After ultrasonic dispersion, add 100 parts by weight of ammonia water to the dispersed suspension to obtain a mixed solution, transfer the mixed solution to a 180°C hydrothermal kettle for constant temperature reaction, and perform follow-up treatment after the reaction to obtain a composite flame retardant.

Embodiment 3

[0027] A flame retardant material for cable sheaths, calculated in parts by weight, comprising the following raw materials:

[0028] 8 parts of metallocene polyethylene, 24 parts of ethylene vinyl acetate copolymer, 63 parts of polyethylene resin, 10 parts of dioctyl adipate, 15 parts of composite flame retardant of embodiment 1, 4 parts of organic silicone, Dilauryl propionate 2 parts and polyethylene wax 4 parts.

[0029] Preparation:

[0030] 1) According to the proportioning ratio, weigh 8 parts of metallocene polyethylene, 24 parts of ethylene vinyl acetate copolymer, 63 parts of polyethylene resin, 10 parts of dioctyl adipate, 15 parts of the composite flame retardant of Example 1, organic Mix 4 parts of silicone, 2 parts of dilauryl thiodipropionate and 4 parts of polyethylene wax for later use;

[0031] 2) Put the mixture of step 1) into the internal mixer, and when it is heated to 115-135°C, lift the upper bolt of the internal mixer to turn over the material. 155°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com