Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Reduce the hassle of manual cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

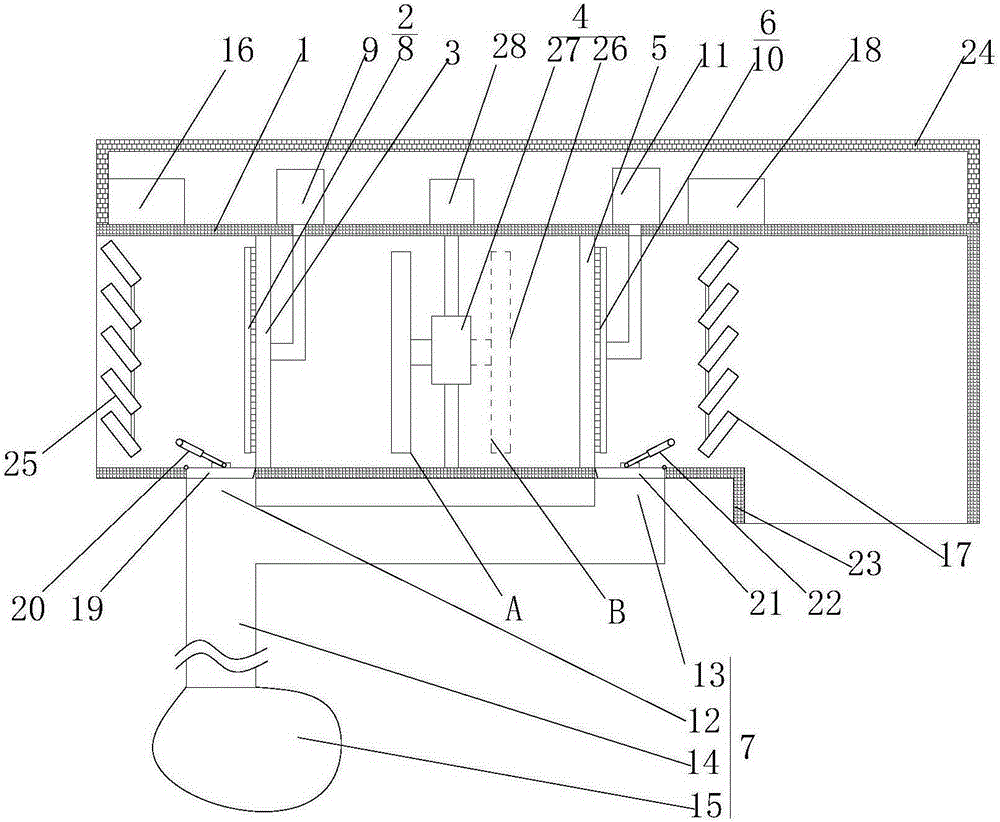

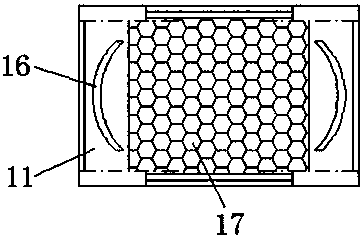

Self-cleaning negative pressure blower

ActiveCN105201924AGuaranteed work efficiencyPlay a protective effectPump componentsPumpsEngineeringDirt

The invention provides a self-cleaning negative pressure blower which comprises a first cylindrical shell, a first cleaning assembly, a first filter screen, a suction assembly, a second filter screen, a second cleaning assembly and a dirt collecting assembly, wherein a first end of the first cylindrical shell along the axial direction is provided with an indoor port, and a second end is an outdoor port; the first cleaning assembly, first filter screen, suction assembly, second filter screen and second cleaning assembly are respectively arranged in the cavity of the first cylindrical shell, and are sequentially arranged along the first cylindrical shell from the first end to the second end; the dirt collecting assembly comprises a drainage pipe and a collecting bag; a first end of the drainage pipe is provided with a first branch pipe and a second branch pipe; the first branch pipe and second branch pipe are respectively communicated with the inner cavity of the first cylindrical shell; and a second end of the drainage pipe is connected with the collecting bag. The self-cleaning negative pressure blower is simple and practical, can implement self-cleaning, and saves time and labor.

Owner:蚌埠新开泰环境设备有限公司

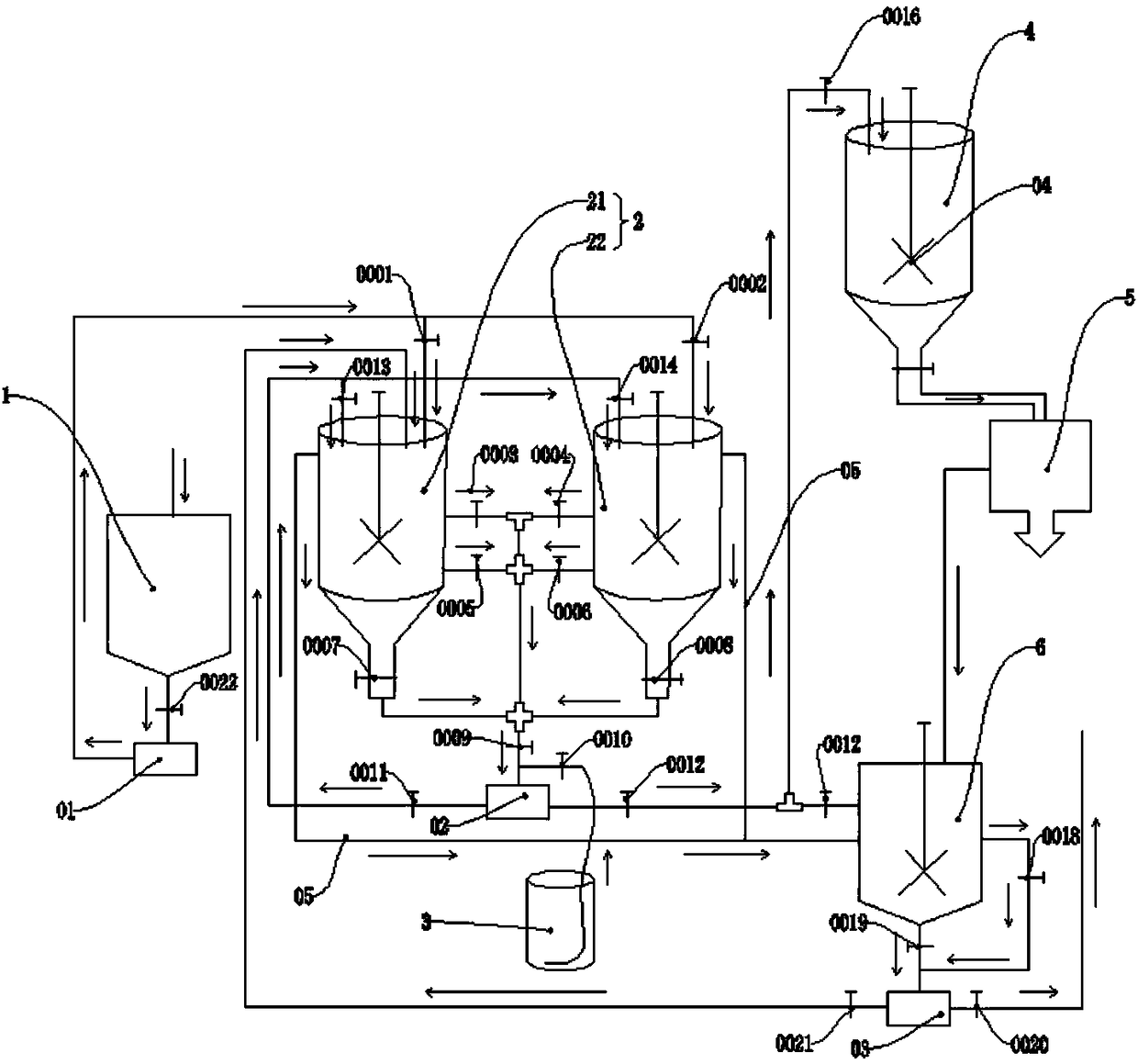

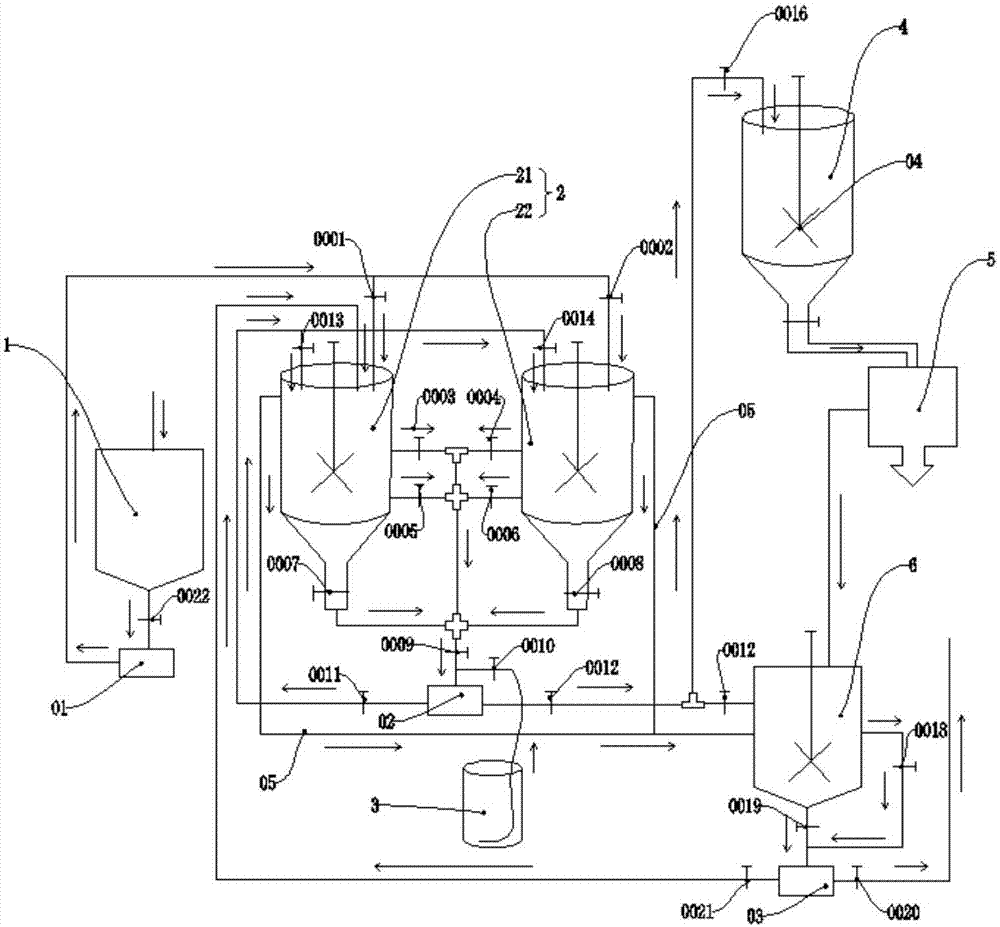

System and process for recovering aluminum hydroxide by pot mold liquid

ActiveCN108083305ARealize high-value resource utilizationReduce foulingAluminium oxides/hydroxidesChemical reactionAluminium hydroxide

The invention relates to a system for recovering aluminum hydroxide by pot mold liquid. The system comprises a pot mold liquid collecting system, a pot mold liquid treating system, a pot mold liquid separating system and a system for re-reacting and recovering water for pot mold liquid; the pot mold liquid collecting system comprises a pot mold liquid recovering tank and a first pump; the pot moldliquid collecting system is used for collecting the pot mold liquid; the pot mold liquid treating system comprises a reaction tank, a second pump and an aluminum hydroxide crystal seed storage tank;the pot mold liquid treating system is used for performing chemical reaction on the pot mold liquid and generating aluminum hydroxide; the pot mold liquid separating system comprises a recovering tankand a centrifugal machine; the system for re-reacting and recovering water for pot mold liquid is used for recovering and treating waste water after solid and liquid separation. Sodium hydroxide is recovered by using the pot mold liquid, the recovery utilization rate of waste residues of the aluminum industry is increased, and the problem that the system is easy to scale is solved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

System and process replacing alkali etching liquid with corrosive wash liquid and recovering aluminum hydroxide

ActiveCN108149017ARealize high-value resource utilizationReduce foulingProcess efficiency improvementAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSolution treatmentCollection system

The invention relates to a system for replacing alkali etching liquid with corrosive wash liquid and recovering aluminum hydroxide. The system comprises a corrosive wash liquid generating system, an alkali etching solution generation system, an alkali etching solution collection system, an alkali etching solution treatment system and an alkali etching solution separation system, wherein the corrosive wash liquid generating system comprises a plurality of corrosive wash grooves, a wastewater flow guide ditch, a water tank, a sixth pump and a pot corrosive wash liquid recovery tank; the alkali etching liquid generating system comprises an oil removing tank, a first flowing water washing tank, a second flowing water washing tank, an alkali etching tank, a first alkali etching solution intercepting tank, a second alkali etching solution intercepting tank, a spraying tank, a fourth pump and a fifth pump; the alkali etching liquid collecting system comprises an alkali etching liquid recycling tank and a first pump; the alkali etching liquid treatment system comprises a reaction tank, a second pump and an aluminum hydroxide seed crystal tank; and the alkali etching liquid separation system comprises a recovery tank and a centrifuge. The method has the advantages that the corrosive wash liquid can be converted into alkali etching liquid for production, the aluminum hydroxide can be recycled, and the problem of descaling can be solved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

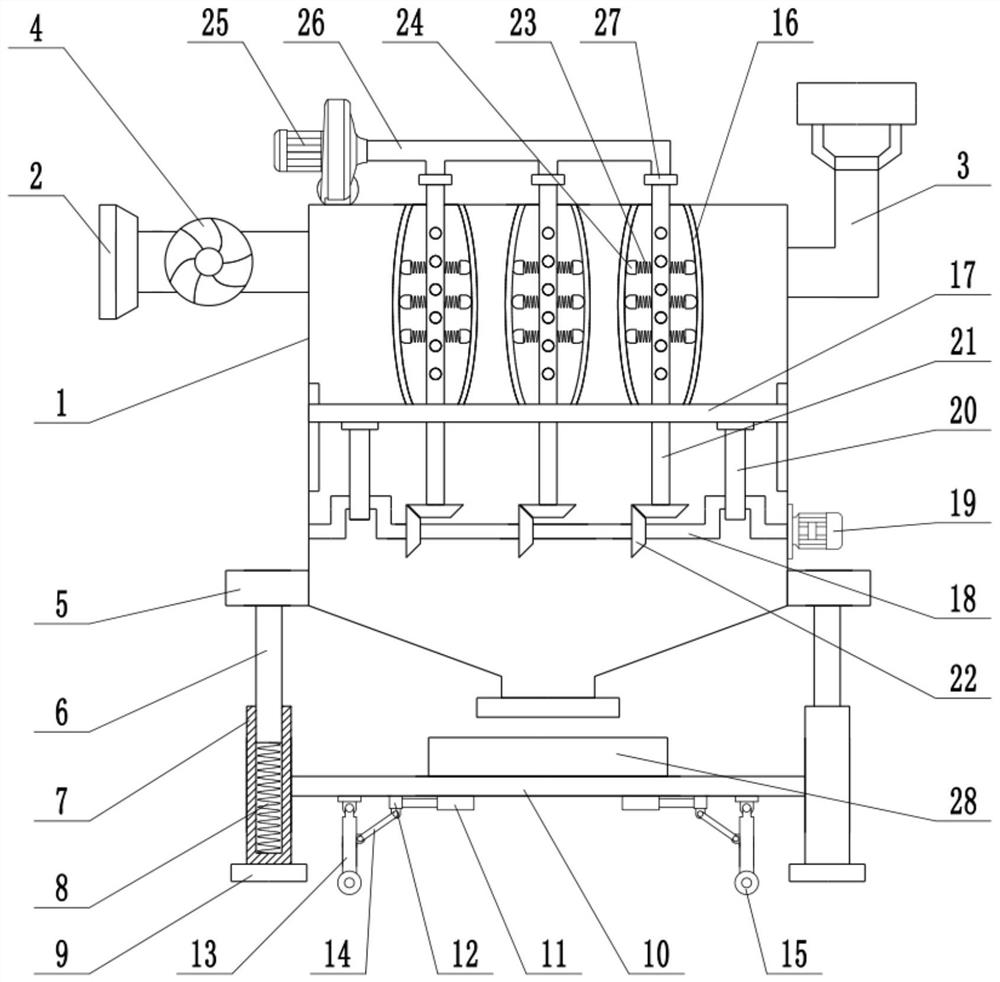

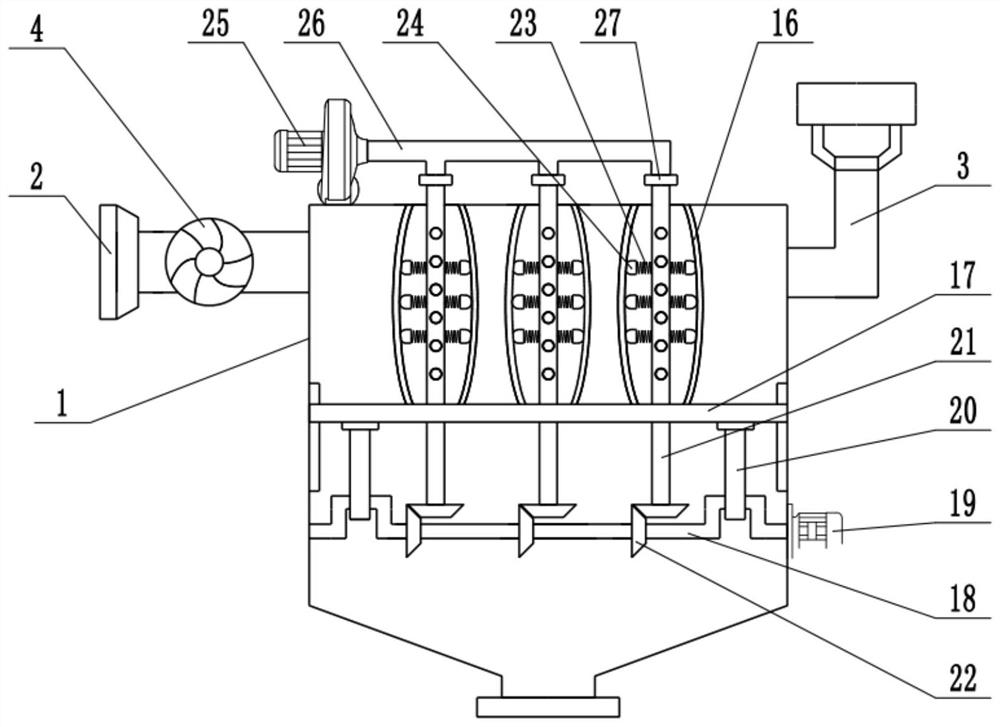

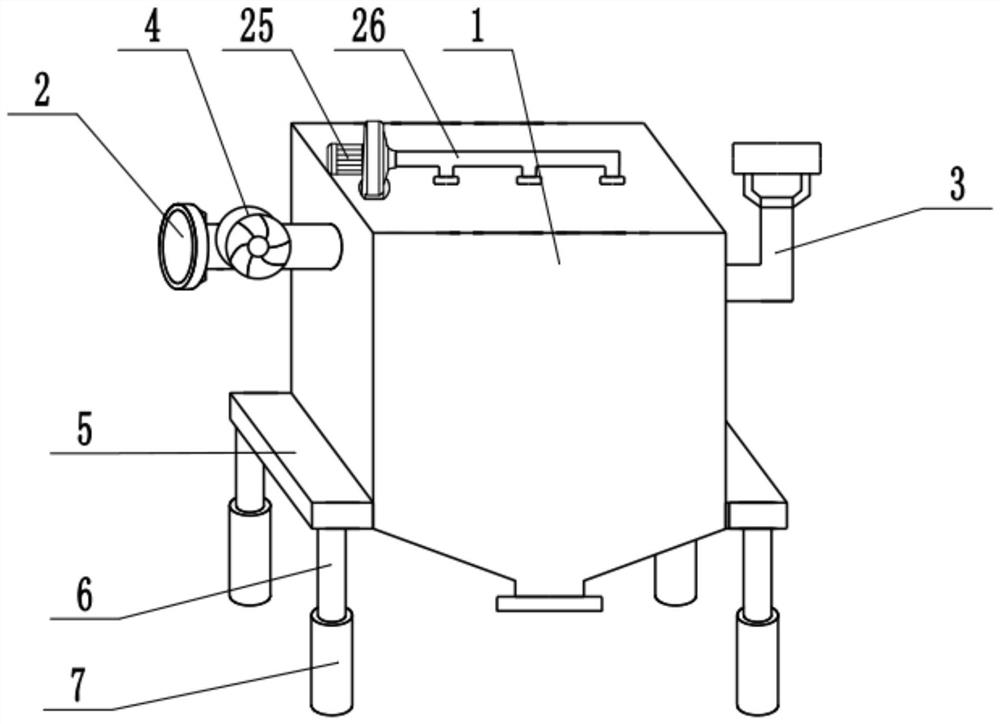

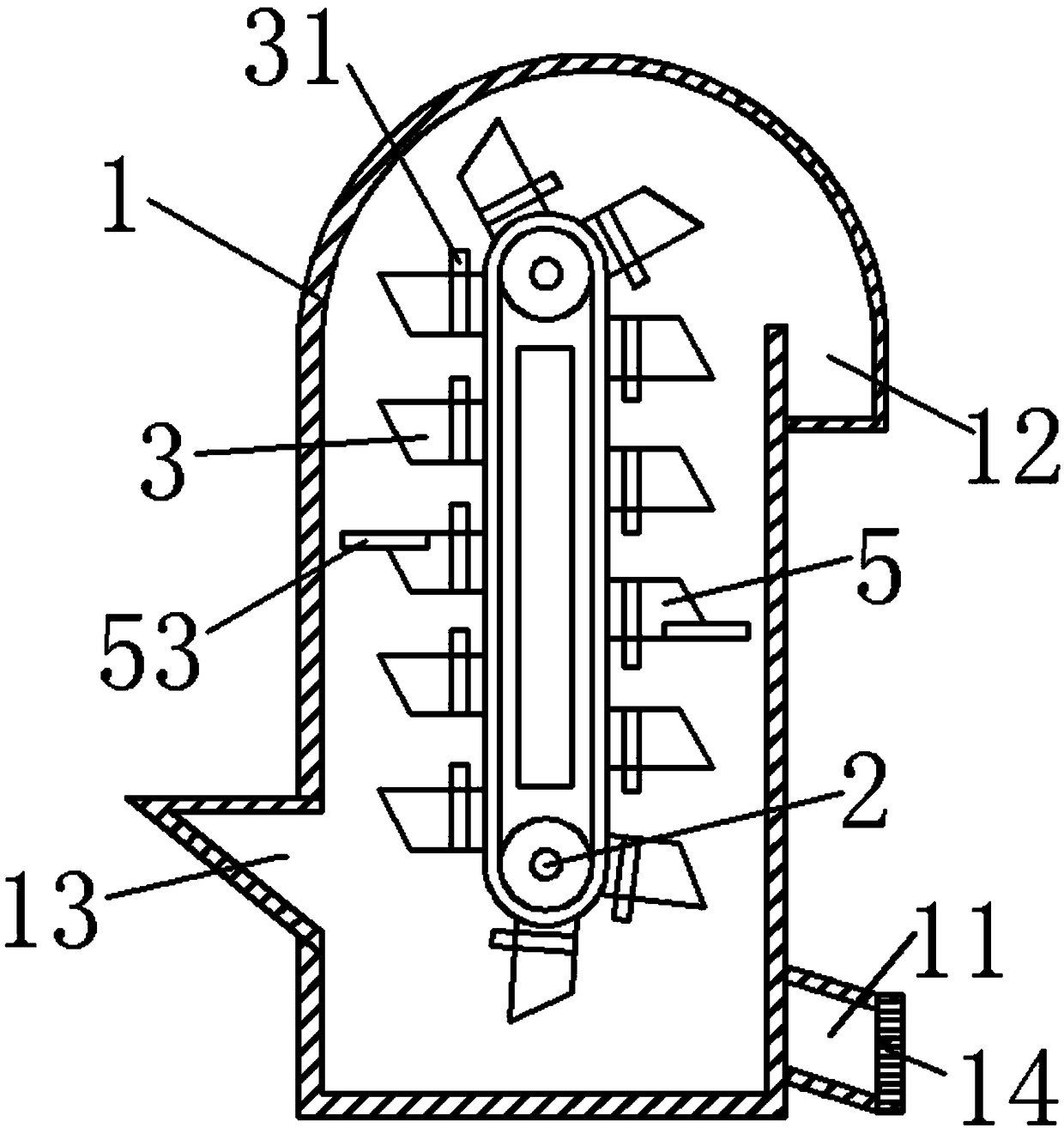

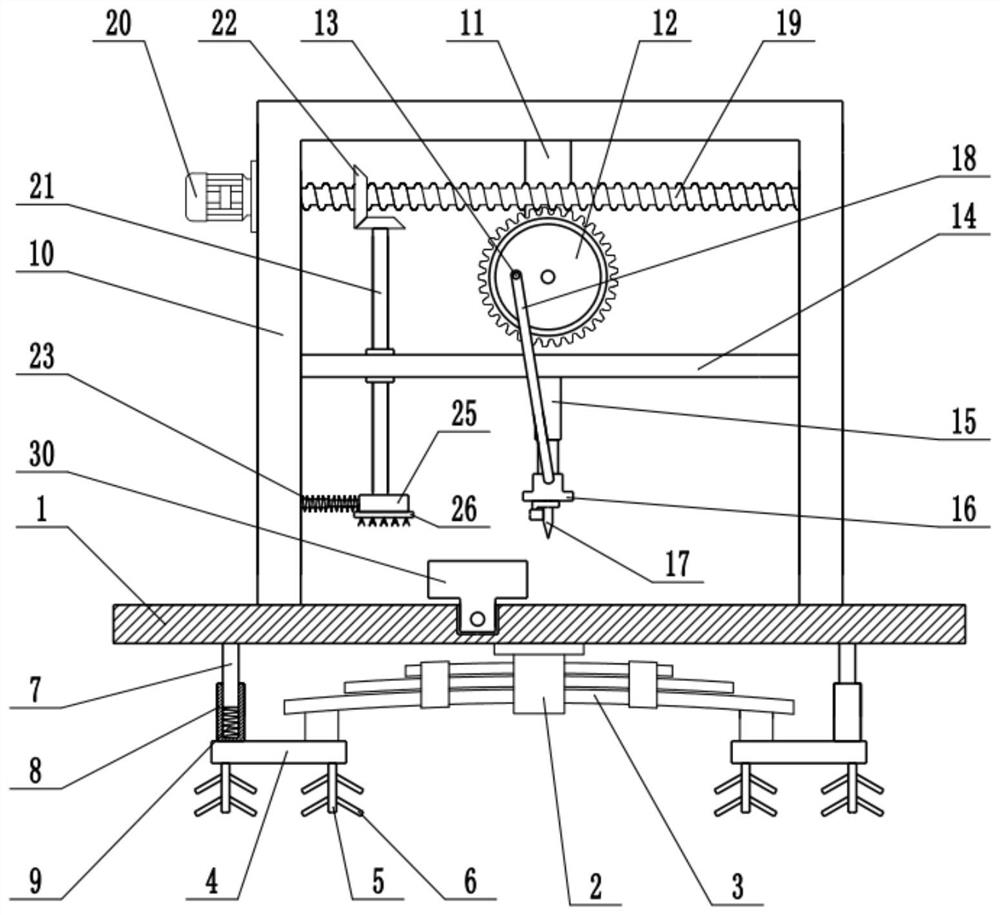

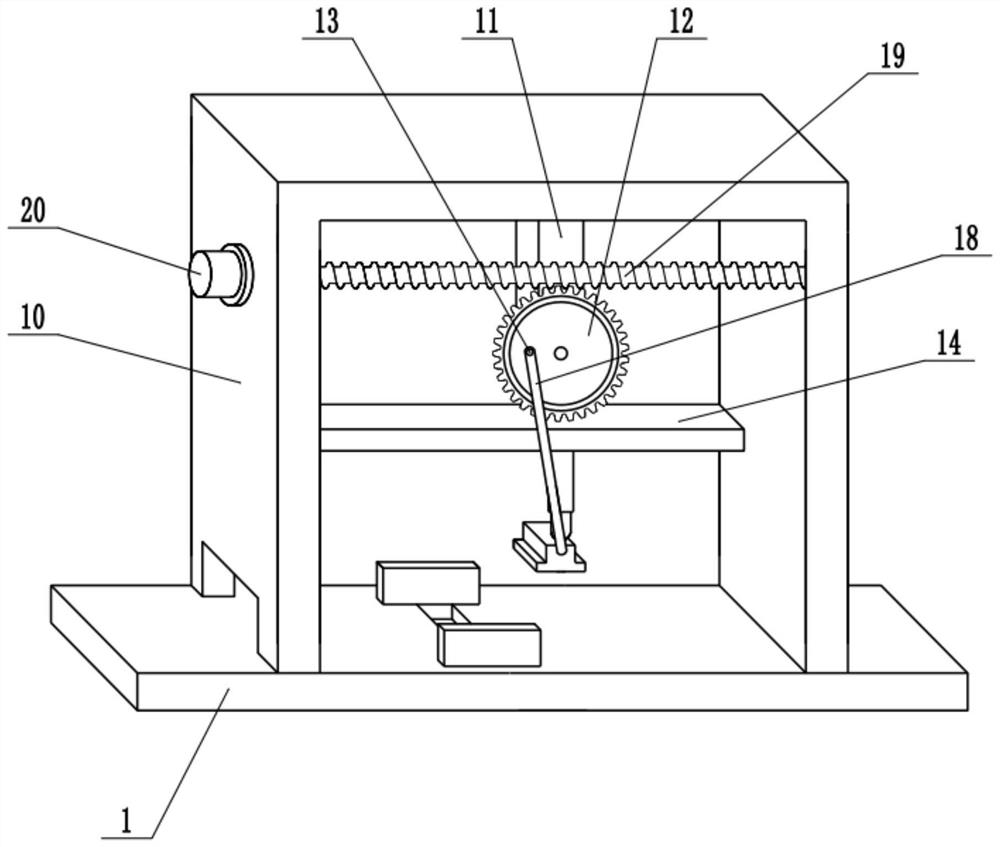

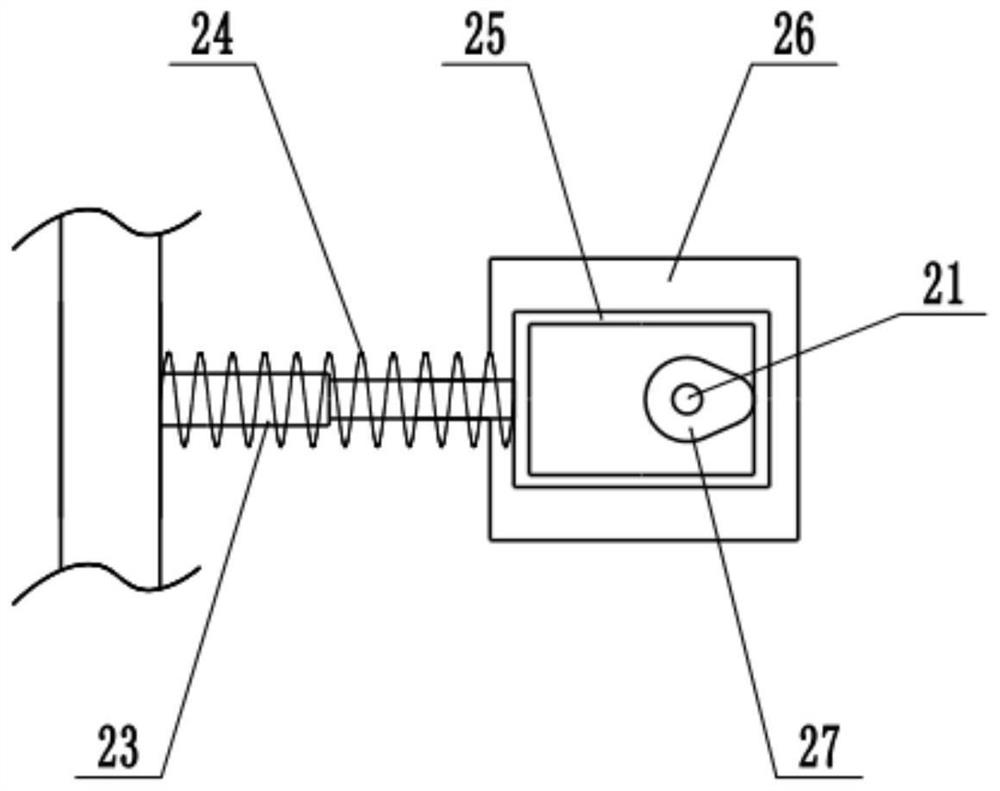

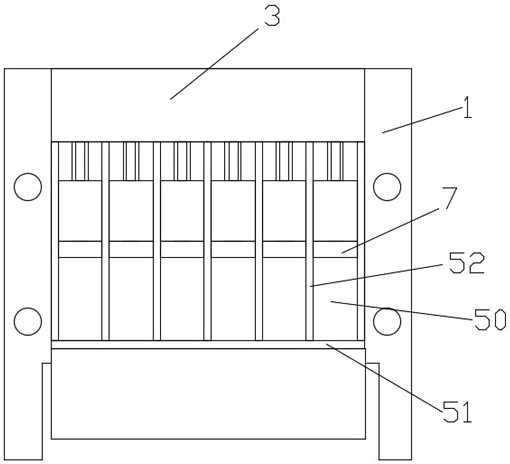

Cloth bag dust removal equipment convenient to clean

InactiveCN111729427AIncrease the jitter amplitudeReduce workloadDispersed particle filtrationTransportation and packagingElectric machineDust control

The invention relates to the technical field of air purification. More particularly, the present invention relates to cloth bag dust removal equipment convenient to clean. The equipment comprises a shell, an air inlet, an air outlet and a cloth bag assembly. A fixing plate is arranged below the shell, and the cloth bag assembly is installed in the shell. The lower end of the cloth bag assembly isfixedly connected with a lifting frame, and the end of the lifting frame is slidably connected with the inner wall of the shell. A crankshaft is arranged below the lifting frame, a shaft neck of the crankshaft is sleeved with a pull rod, and the upper end of the pull rod is hinged to the lifting frame. A hollow rotating shaft is mounted in the cloth bag assembly. When the device works, the cloth bag assembly is used for carrying out dust removal operation on dusty gas, and when the cloth bag assembly needs to be cleaned, a driving motor is started to drive the cloth bag assembly to shake to peel off dust attached to the cloth bag assembly, a hammer head is used for knocking the inner wall of the cloth bag assembly, the shaking amplitude of the cloth bag assembly is further improved, and the dust attached to the cloth bag assembly is cleaned more thoroughly.

Owner:谢树彩

Workshop system and technology for producing aluminum hydroxide from corrosive wash liquid

ActiveCN107986308ARestore production capacityReduce labor intensityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSeed crystalCollection system

The invention relates to a workshop system for producing aluminum hydroxide from corrosive wash liquid. The workshop system comprises a corrosive wash liquid generating system, a corrosive wash liquidcollecting system, a corrosive wash liquid processing system and a corrosive wash liquid separating system, wherein the corrosive wash liquid generating system comprises a plurality of corrosive washtanks, a wastewater guide ditch, a water tank and a No.4 pump; the corrosive wash liquid generating system is used for processing a mould and guiding the corrosive wash liquid to the corrosive wash liquid collecting system; the corrosive wash liquid collecting system comprises a corrosive wash liquid recycling tank and a No.1 pump; the corrosive wash liquid collecting system is used for collecting the corrosive wash liquid; the corrosive wash liquid processing system comprises a reaction tank, a No.2 pump and a aluminum hydroxide seed crystal liquid storage tank; the corrosive wash liquid processing system is used for performing a chemical reaction on the corrosive wash liquid and producing aluminum hydroxide; the corrosive wash liquid separating system comprises a recycling tank and a centrifuge. The invention provides a whole set of circulating system from workshop production to recycling, wherein the system is used for recycling the aluminum hydroxide, saves water and does not scale easily.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

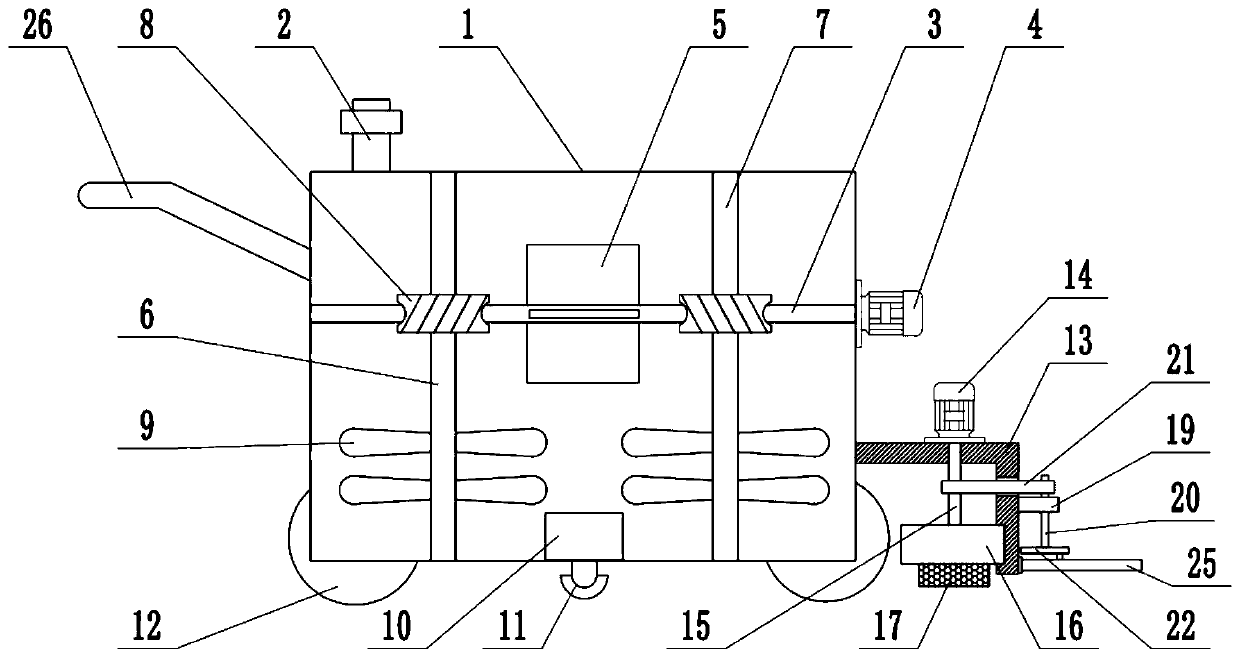

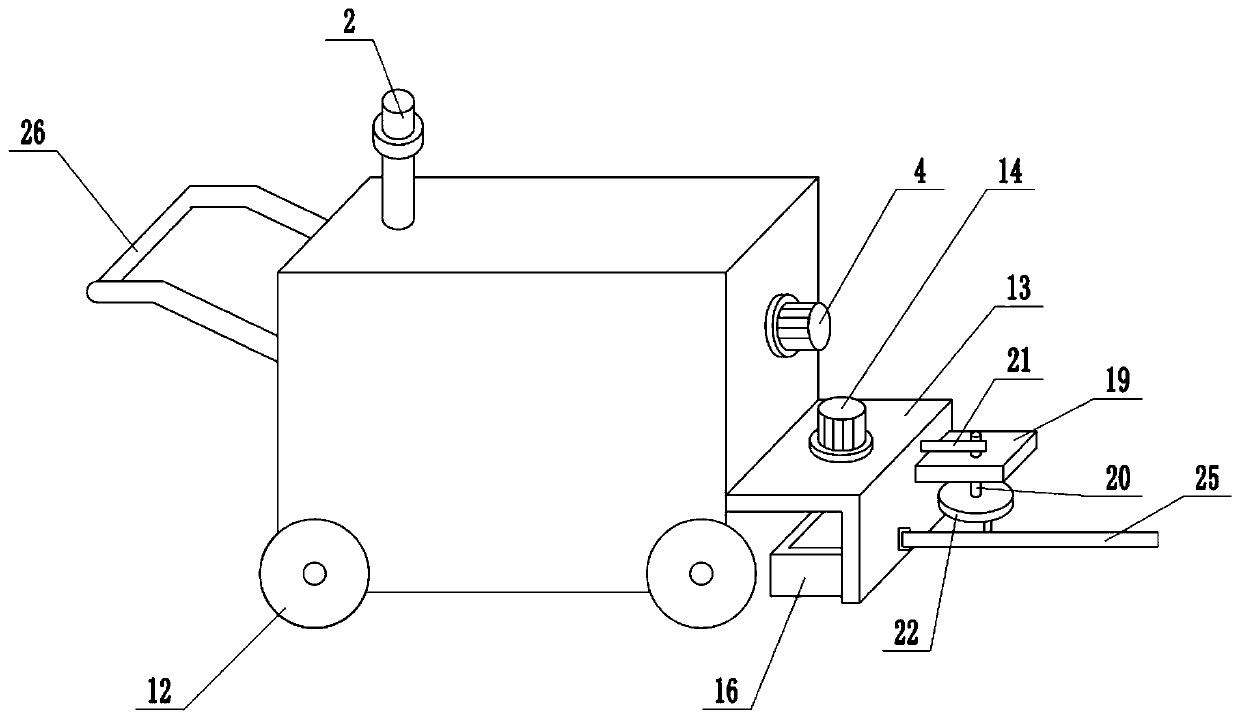

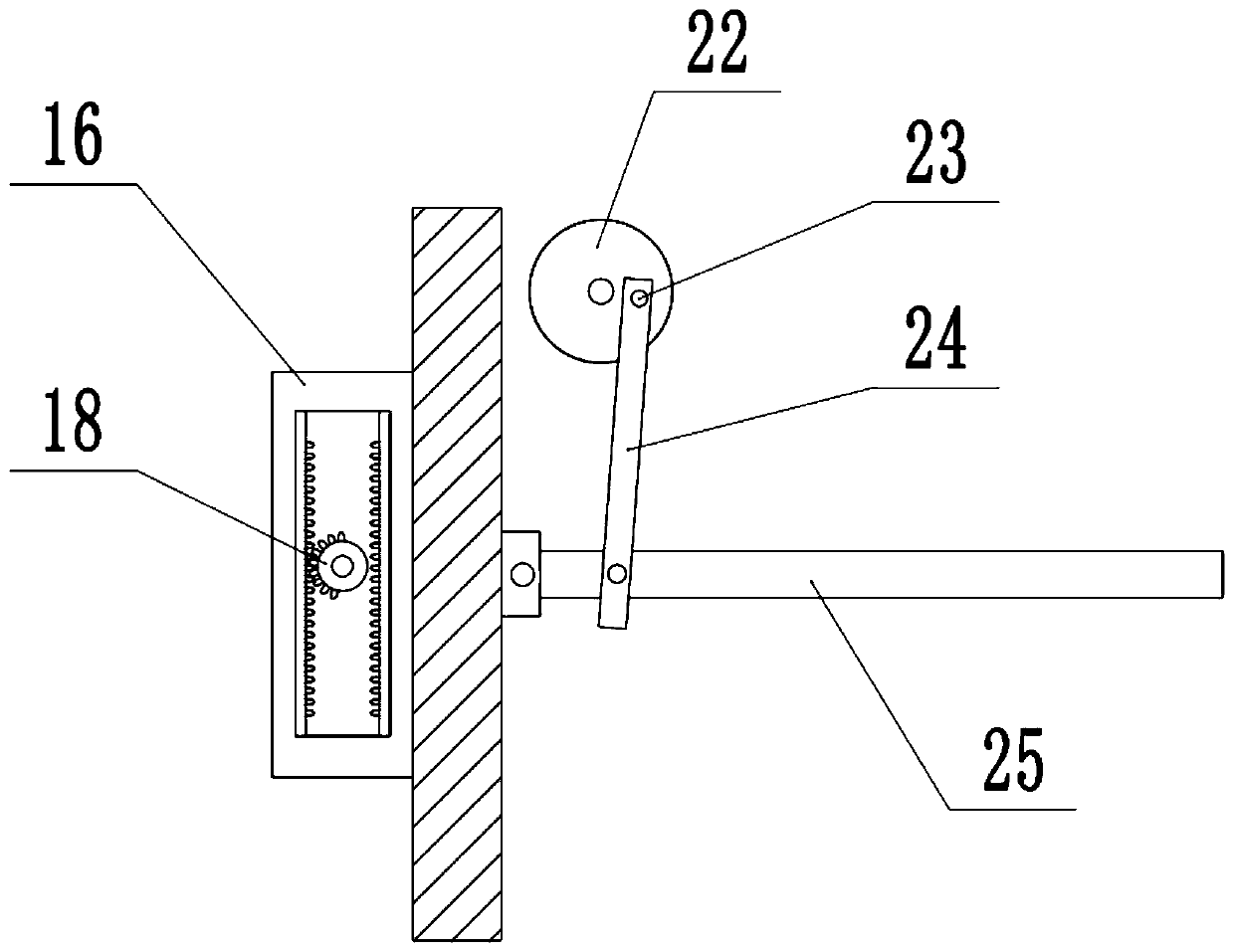

Marking machine used for road construction

ActiveCN110331644APrevent precipitationImprove mixing effectRoads maintainencePlastic bagFixed frame

The invention relates to the field of road construction equipment, in particular to a marking machine for road construction. The machine comprises a box body, a booster pump and a nozzle, wherein thebooster pump is arranged at the bottom of the box body, the nozzle is arranged on the lower surface of the box body, a water outlet of the booster pump communicates with the nozzle through a pipeline,a fixing frame is fixedly connected to the side wall of the box body, a sweeping motor is fixedly connected to the upper surface of the fixing frame, a driving shaft is fixedly connected to a shaft extension end of the sweeping motor, a rack frame is arranged in the fixing frame, a sweeping plate is fixedly connected to the lower surface of the rack frame, a semi-gear is arranged at the lower endof the driving shaft in a sleeving mode, and a stirring mechanism is arranged inside the box body. According to the machine, a stirring plate is used for longitudinally stirring paint, a stirring blade is used for transversely stirring the paint, so that the paint is prevented from depositing, in the marking process, the ground is swept by the reciprocating motion of the sweeping plate, the obstacles such as pebbles and plastic bags on the advancing route of the machine are swept by the aid of an obstacle clearing rod, so that the trouble of manual sweeping is saved.

Owner:林盛建设集团有限公司

Accurate machining device of aluminum alloy plate

InactiveCN108620658AImprove cutting efficiencyIncrease profitShearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses an accurate machining device of an aluminum alloy plate. The device comprises a base, the top of the base is provided with a working platform, a supporting rod is welded to thetop of the working platform, a top plate is welded to the top end of the supporting rod, a hydraulic cylinder is fixedly connected to the top of the top plate through a bolt, one end of the hydrauliccylinder is connected with a rotary air cylinder through a hydraulic rod, the bottom of the rotary air cylinder is fixedly connected with an outer cover through a bolt, the outer wall of one side ofthe outer cover is provided with a laser lamp, a supporting frame is welded to the side, close to the supporting rod, of the top of the working platform, a thread hand rod is spirally connected to thetop of the supporting frame through a thread, and the bottom end of the thread hand rod is provided with a lifting plate. On one hand, the cut angle and length can be adjusted according to machiningrequirements, and the cutting efficiency of the aluminum alloy plate is improved; and on the other hand, the utilization rate of the aluminum alloy plate can be improved to the largest degree throughrotating angle cutting.

Owner:长兴宇通机械厂

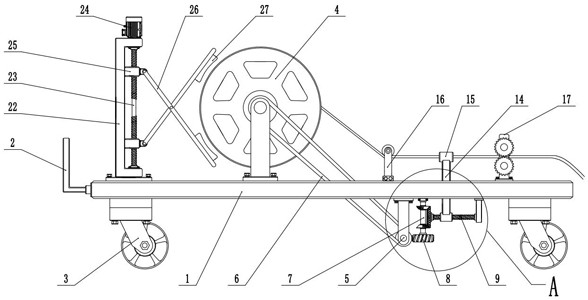

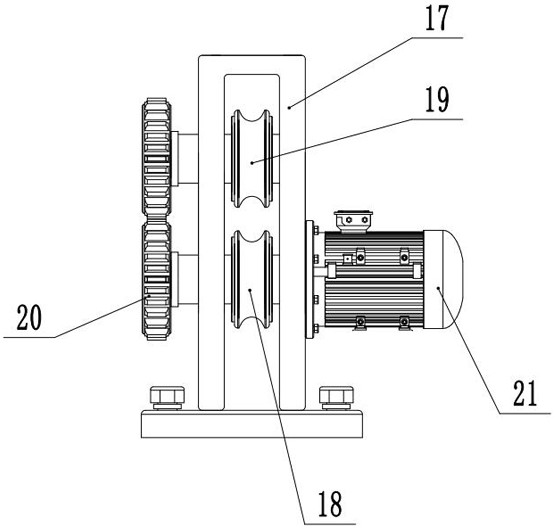

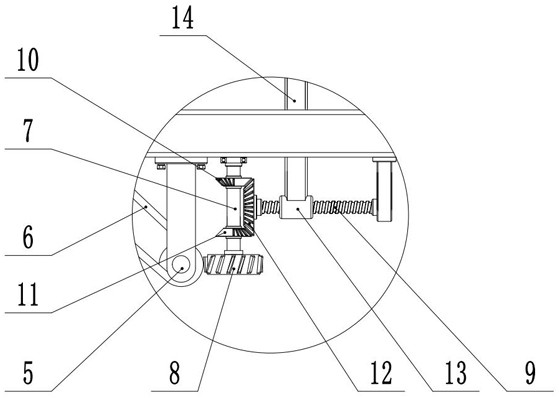

Wire feeding assembly and discharging device for electric power wire laying

PendingCN112660912AAvoid overfeedingReduce laborFilament handlingCleaning using toolsStructural engineeringMechanical engineering

The invention discloses a wire feeding assembly and a discharging device for electric power wire laying. The wire feeding assembly comprises a rack, a wire reel, a power mechanism, a transmission mechanism and a cleaning mechanism. The wire reel is rotatably mounted on the rack, and a wire is wound on the wire reel; the power mechanism is installed on the rack and used for pulling the wire wound on the wire reel to carry out wire feeding operation; the transmission mechanism is mounted at the bottom of the rack, and the transmission mechanism is connected with the wire reel; the cleaning mechanism is installed on the rack, the wire penetrates through the cleaning mechanism, the cleaning mechanism is connected with the transmission mechanism, during wire feeding operation, the wire sequentially penetrates through the cleaning mechanism and the power mechanism, the power mechanism is used for continuously pulling the wire, and during wire feeding operation, the cleaning mechanism works synchronously; and the cleaning mechanism is used for cleaning the surface of the wire, and when wire feeding operation is finished, an emergency stop mechanism is used for clamping the wire reel, so that the wire reel stops rotating as soon as possible, and excessive discharging of the wire is avoided.

Owner:国网内蒙古东部电力有限公司呼伦贝尔供电公司

Bucket elevator capable of avoiding material residues

InactiveCN108945968AIncrease distanceAvoid wear and tearConveyorsConveyor partsMaterial scatteringEngineering

The invention provides a bucket elevator capable of avoiding material residues. The bucket elevator comprises a case, a traction mechanism and a plurality of conveying hoppers fixed to the traction mechanism; first mounting seats are fixed to one sides of the conveying hoppers; movable plates are hinged to the sides, close to the first mounting seats, in the conveying hoppers; driving assemblies are arranged in the first mounting seats and fixedly connected with the movable plates; scraping hoppers are arranged on the traction mechanism and comprise hopper bodies, second mounting seats and scrapers fixed to the hopper bodies; and a discharging hopper is obliquely arranged at the bottom end of one side of the case. The driving assemblies push the movable plates to rotate, the parabolic angle of throwing out of a material is increased, the distance of flowing out of the material is prolonged, and material scattering is avoided; by arranging the scraping hoppers, the scrapers scrape an agglomerated material on the inner wall in the moving process of the scraping hoppers, and the situation that the conveying hoppers are abraded due to the excessively thick agglomerated material is avoided; and by forming a discharging opening in the bottom end of the elevator, a residual material at the bottom end of the elevator is discharged, and blocking of hopper movement due to material accumulation is avoided.

Owner:WUHU HUAJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD

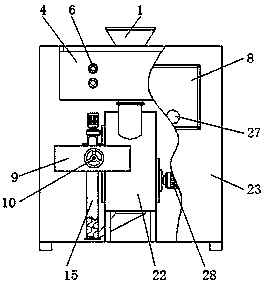

Efficient treatment device for waste bricks and tiles

InactiveCN108745585AReduce pollutionPromote environmental protectionGrain treatmentsEngineeringFuel tank

The invention discloses an efficient treatment device for waste bricks and tiles. The efficient treatment device comprises a box. A hydraulic pump, a hydraulic oil tank and a smashing box are fixedlyconnected to the inner bottom of the box through bolts. The hydraulic oil tank is located between the hydraulic pump and the smashing box. A breaking box is fixedly connected to the top of the smashing box through bolts. A feed hopper is fixedly connected to the top of the breaking box through a bolt. A support ring is welded to the inner wall of one side of the feed hopper. A baffle is rotationally connected to the outer wall of the side, away from the feed inlet, of the support ring through a hinge. The baffle is connected with the feed hopper through a spring. A limiting plate is installedin the position, close to the upper portion of the baffle, of the top of the support ring. According to the efficient treatment device, the waste bricks and tiles are broken, screened and ground in arelatively sealed environment in the whole process, the problem that dust produced by the waste bricks and tiles pollutes the work environment and the atmosphere is avoided effectively, environmentalfriendliness of the treatment device is improved, and trouble of manual cleaning is reduced.

Owner:傅花宁

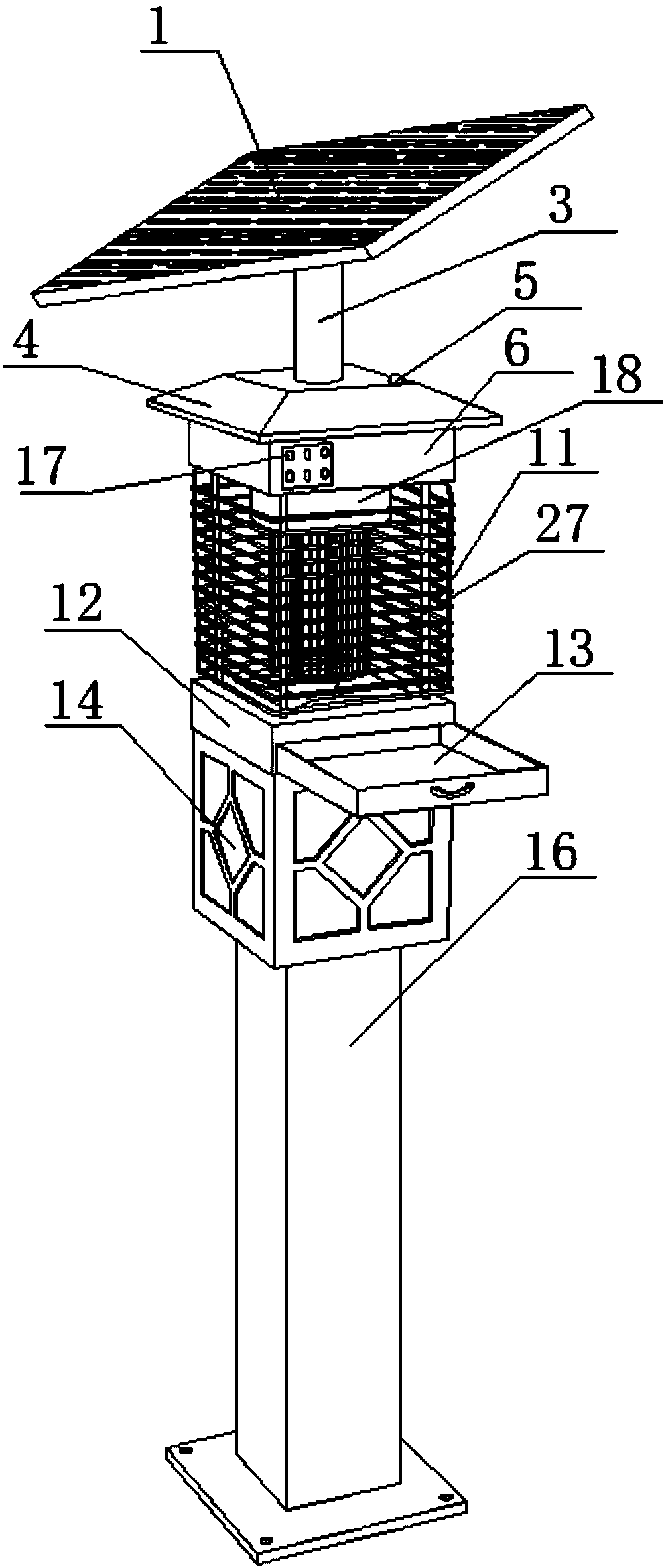

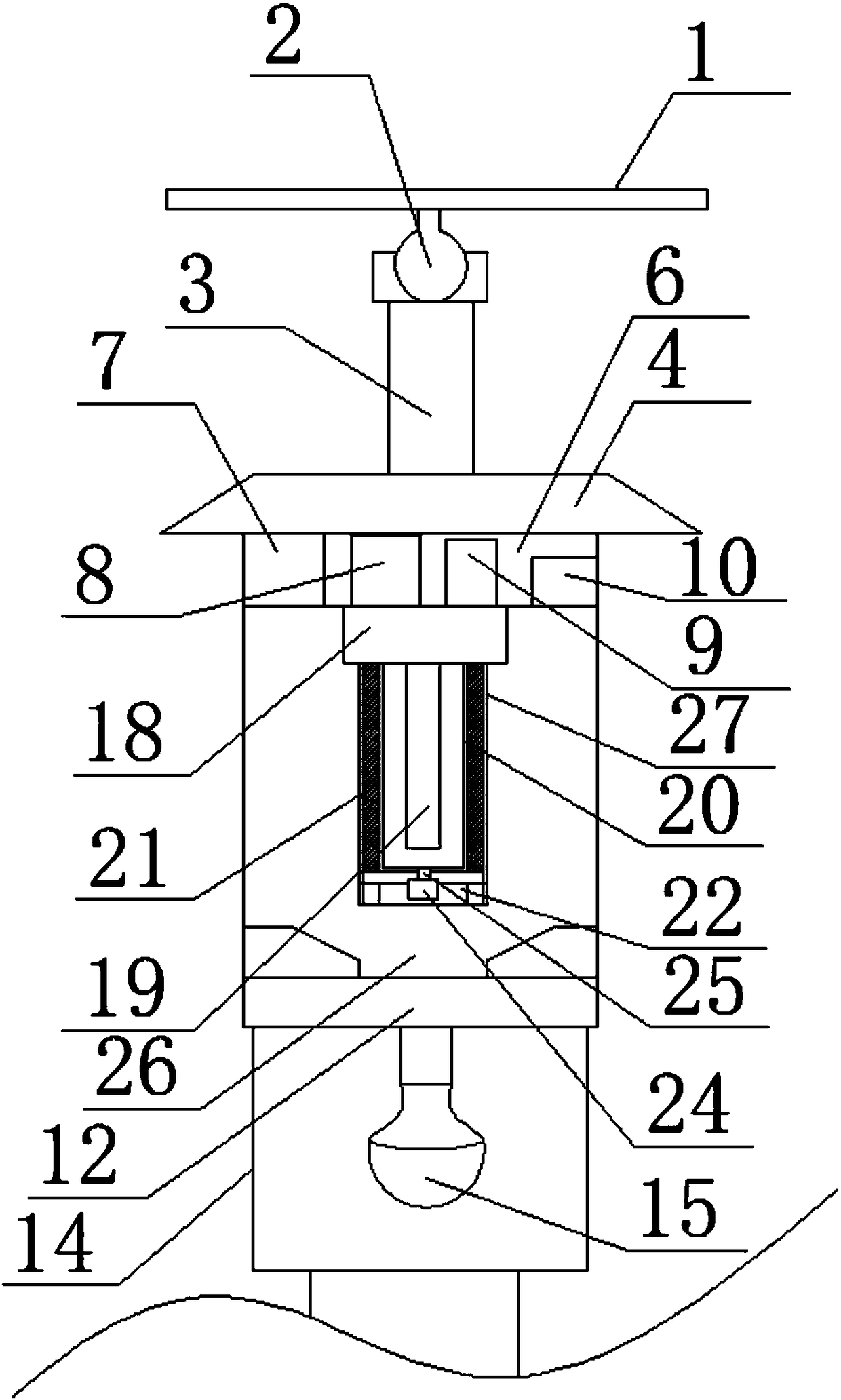

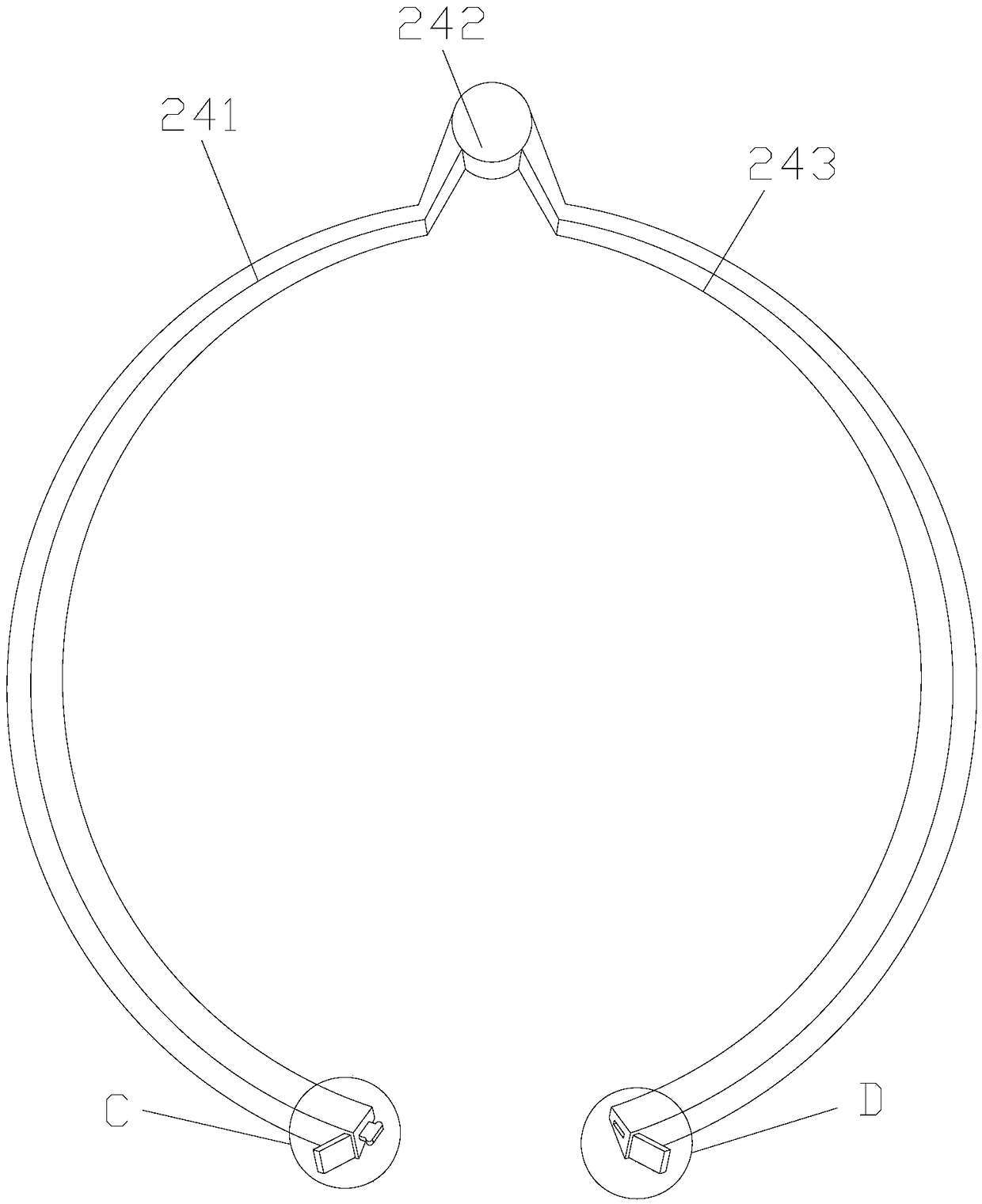

Combined type new-energy garden insect killing lamp

InactiveCN108522462AEnvironmental EnergyReduce the hassle of manual cleaningMechanical apparatusElectric circuit arrangementsTrappingUniversal joint

The invention belongs to the technical field of new energy, and discloses a combined type new-energy garden insect killing lamp which comprises a solar panel, a photosensitive sensor, an equipment tank, an insulation net, a mosquito and insect collecting box, an illuminating lamp, a support column, an insect trapping lamp, a transparent rotary cover and two insulation brushes. The bottom of the solar panel is connected with one end of a rotary universal joint, and the other end of the rotary universal joint is connected with the top of a fulcrum bar. The combined type new-energy garden insectkilling lamp has the advantages that the combined type new-energy garden insect killing lamp is provided with the solar panel, light energy can be transformed into electric energy by the solar panel by the aid of a converter, the electric energy can be stored in a storage battery and can be used by the combined type new-energy garden insect killing lamp, and accordingly energy sources for the combined type new-energy garden insect killing lamp are environmentally friendly; the rotatable transparent rotary cover is arranged inside an electric net, the two insulation brushes are arranged on thetransparent rotary cover, residual insect dead bodies on the electric net can be brushed down and can be collected by the mosquito and insect collecting box at circuits of a through opening in a unified manner, and accordingly manual cleaning trouble can be prevented; the combined type new-energy garden insect killing lamp is provided with the illuminating lamp, illumination still can be providedto people by the combined type new-energy garden insect killing lamp even in seasons with few mosquitoes and insects, and accordingly the combined type new-energy garden insect killing lamp is practical.

Owner:芜湖杰汇环保科技有限公司

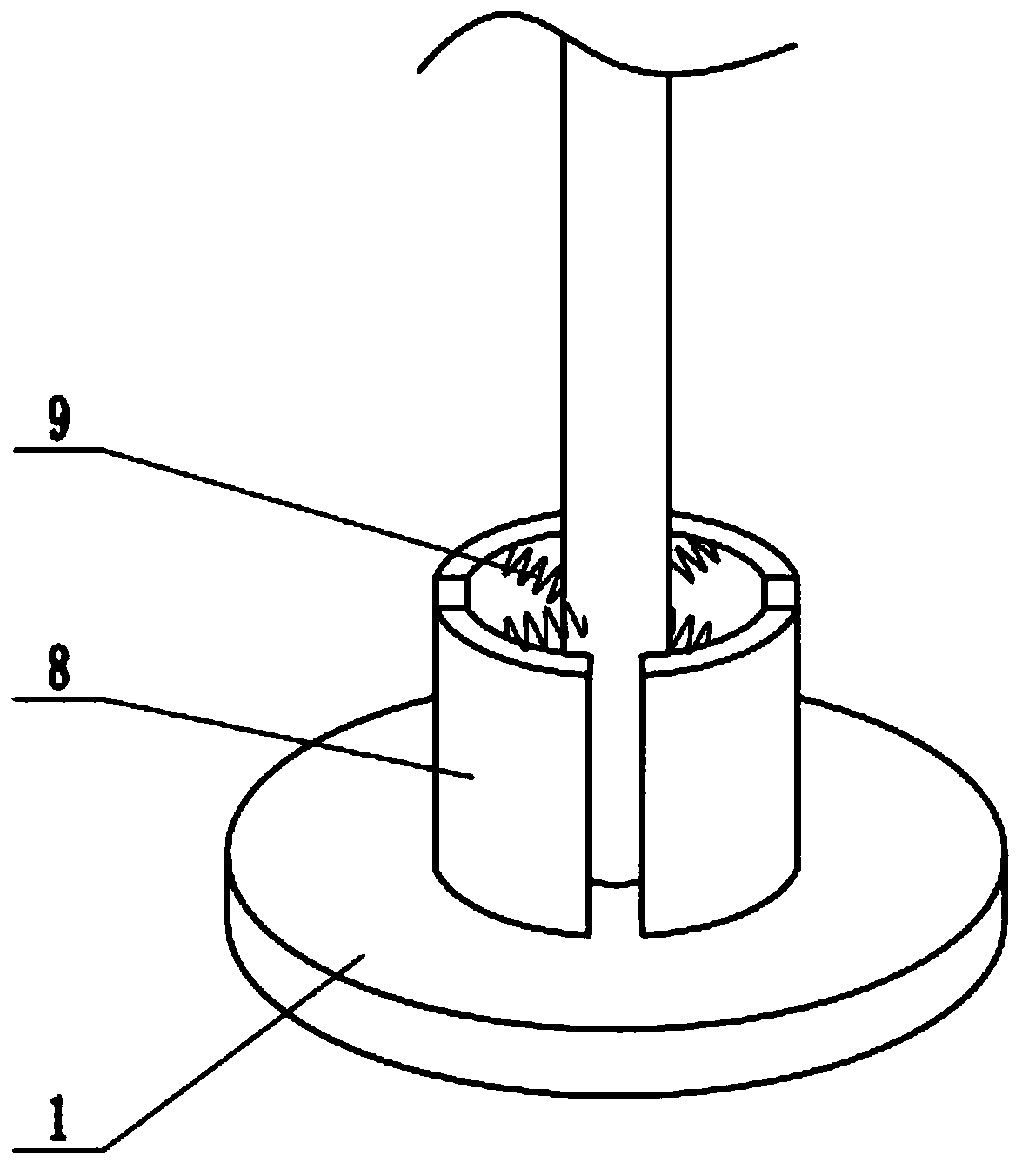

Self-cleaning solar street lamp convenient to maintain

InactiveCN111043554APlay an impactReduce impactPhotovoltaic supportsMechanical apparatusLight equipmentFixed frame

The invention relates to the field of lighting equipment. More particularly, the present invention relates to a self-cleaning solar street lamp convenient to maintain, the solar street lamp is a self-cleaning solar street lamp convenient to maintain. The street lamp comprises a base, a lamp post, a transverse rod and a bulb, a fixed pile is mounted on the lower surface of the base; the upper surface of the base is fixedly connected with the lamp post; the side wall of the lamp post is fixedly connected with a fixed frame. A screw rod is mounted in the fixed frame; the top of the fixed frame isfixedly connected with an adjusting motor; the screw rod is sleeved with a sliding block. The side wall of the sliding block is fixedly connected with the transverse rod; the bulb is mounted on the lower surface of the transverse rod; a solar panel is mounted on the upper surface of the transverse rod; the upper surface of the solar panel is rotationally connected with a rotating shaft; a cleaning rod is mounted on the rotating shaft; the stability of the device is further improved through the fixed pile and a movable rod, an anti-collision plate and springs can play an anti-collision role, impact force generated when the lamp post is impacted is reduced, the lamp post is protected against damage, the height of the bulb can be adjusted through the adjusting motor, maintenance is convenient, and the upper surface of the solar panel is cleaned through the cleaning rod.

Owner:赣州明龙照明科技有限公司

Mixing device used on asphalt road surface site heat regeneration compound mixer

ActiveCN102322013AUniform material temperatureConducive to constructionRoads maintainenceHeat regenerationHot blast

The invention relates to a mixing device used on an asphalt road surface site heat regeneration compound mixer, which comprises a hydraulic motor, a hot air heating furnace, a gas circuit interface, a mixing box body, a mixture stirrer, a control device and a temperature detector; the mixing box body comprises two circular arc-shaped side wall plates of the box body, two end surface plates of thebox body, a top plate of the box body and a support of the box body; a feed opening and a hot air interface are arranged on the top plate of the box body; the hot air interface is connected with the hot air heating furnace; the hot air heating furnace is hinged with a base support; the feed opening is connected with a pneumatic gate valve; a discharge port is arranged at a joint between the bottoms of the circular arc-shaped side wall plates of the box body; the discharge port is connected with a pneumatic arc-shaped swing valve; the pneumatic arc-shaped swing valve and the pneumatic gate valve are connected with the control device; and the temperature detector is arranged on the hot air heating furnace. The mixing device used on the asphalt road surface site heat regeneration compound mixer can realize a heating while stirring function in the closed mixing box body, the feeding, the discharge and the temperature can be automatically controlled, so that the regenerated mixture is moreuniform, the requirements of a construction process are met, and the road surface pavement quality is improved.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

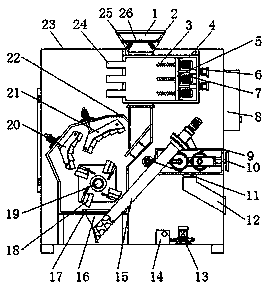

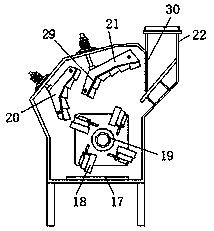

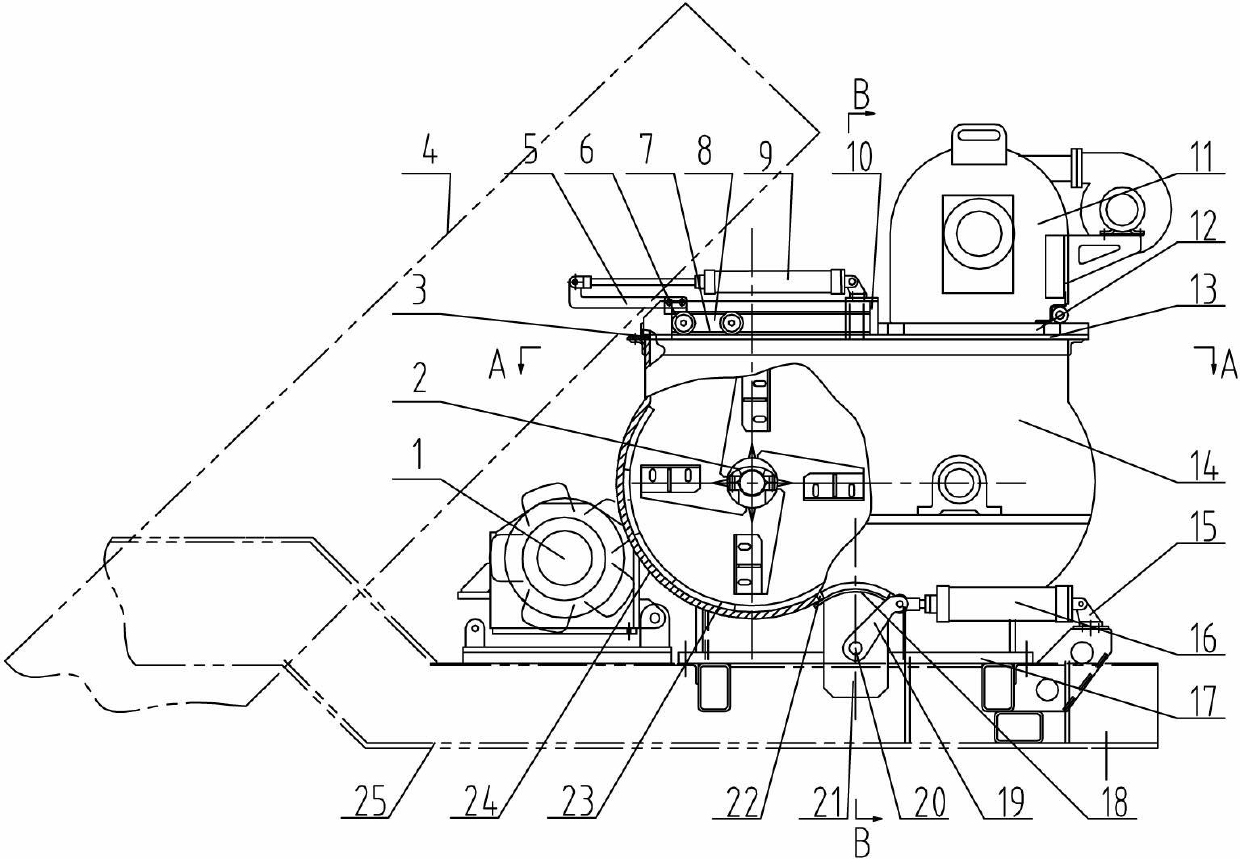

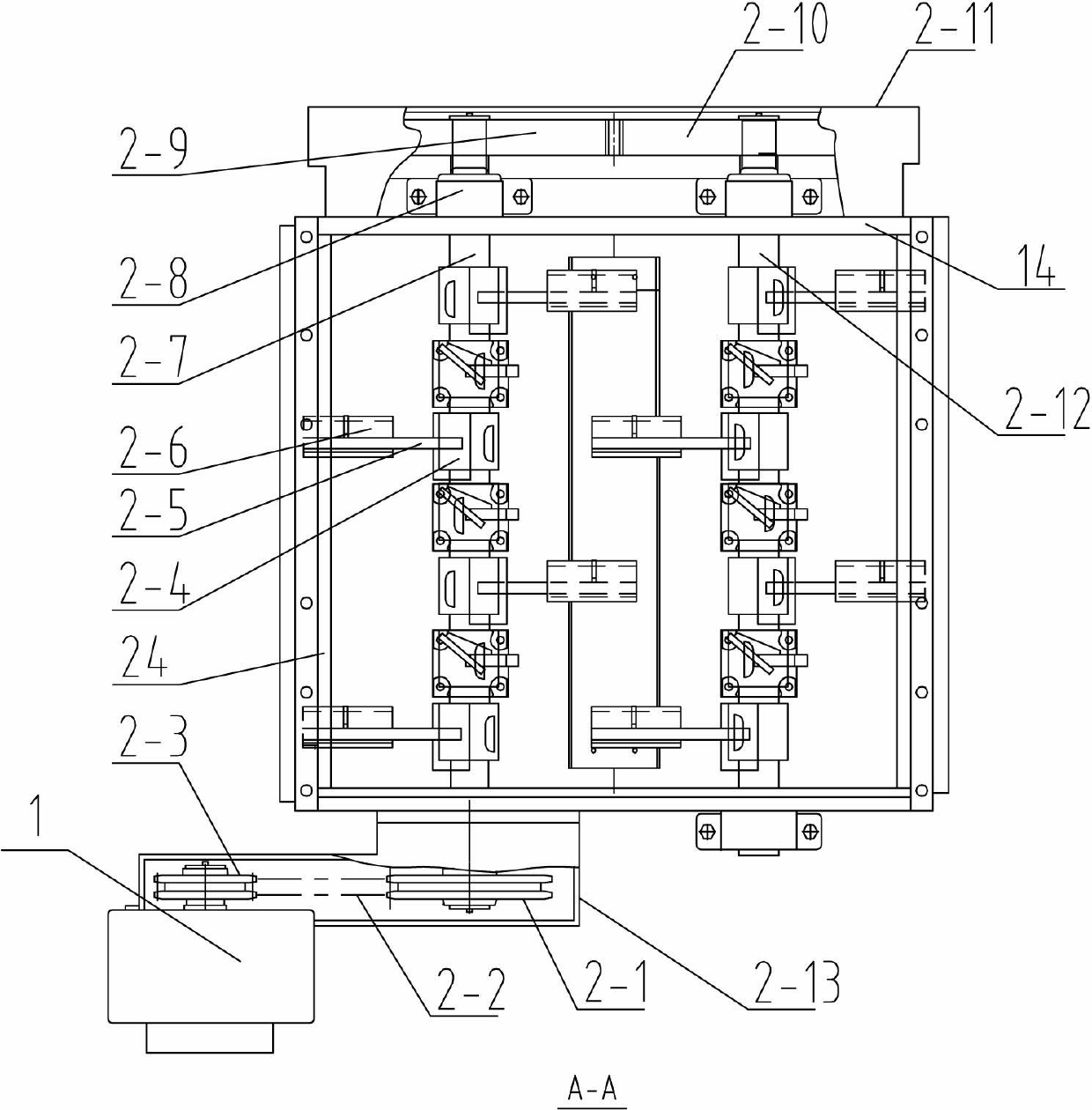

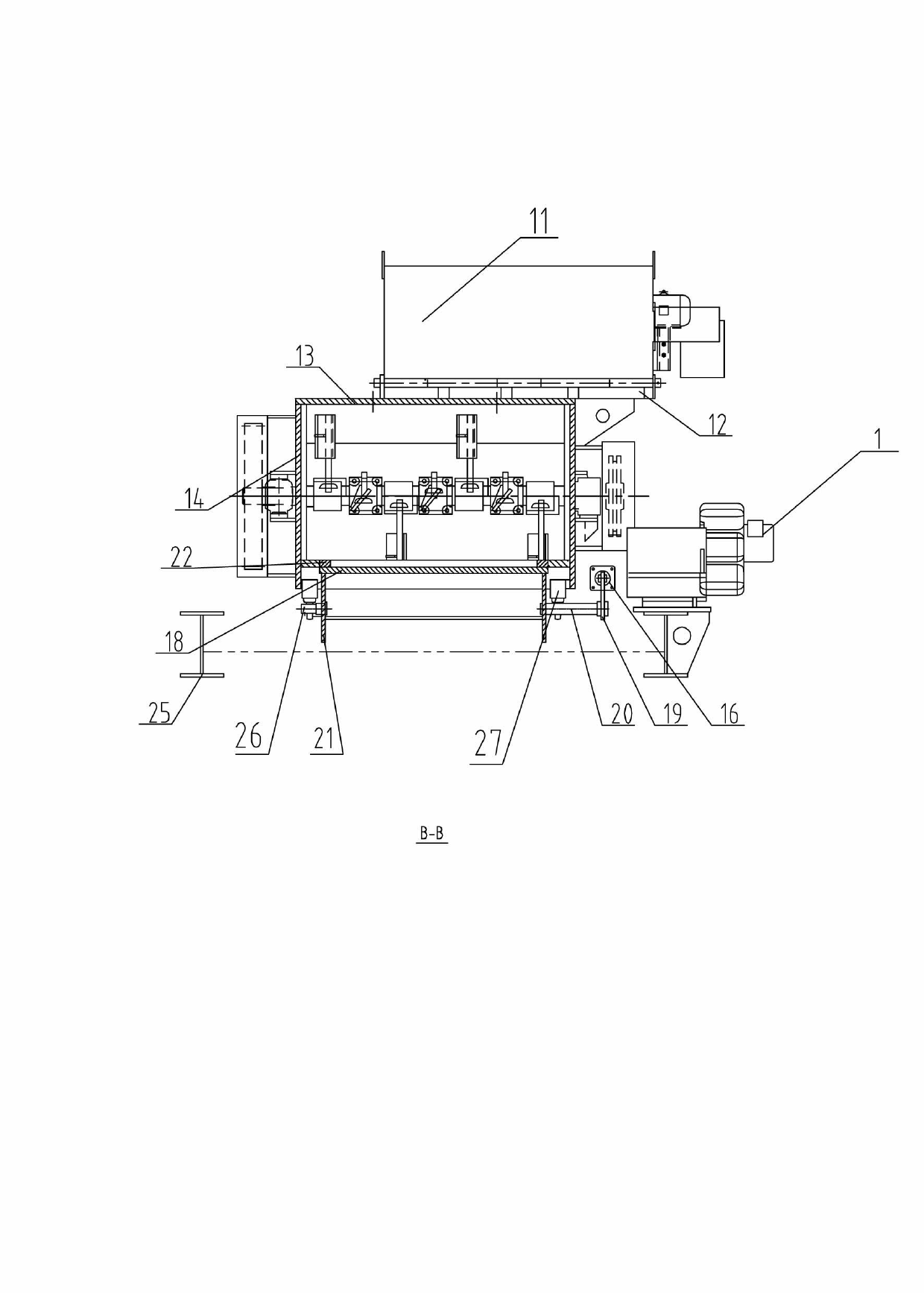

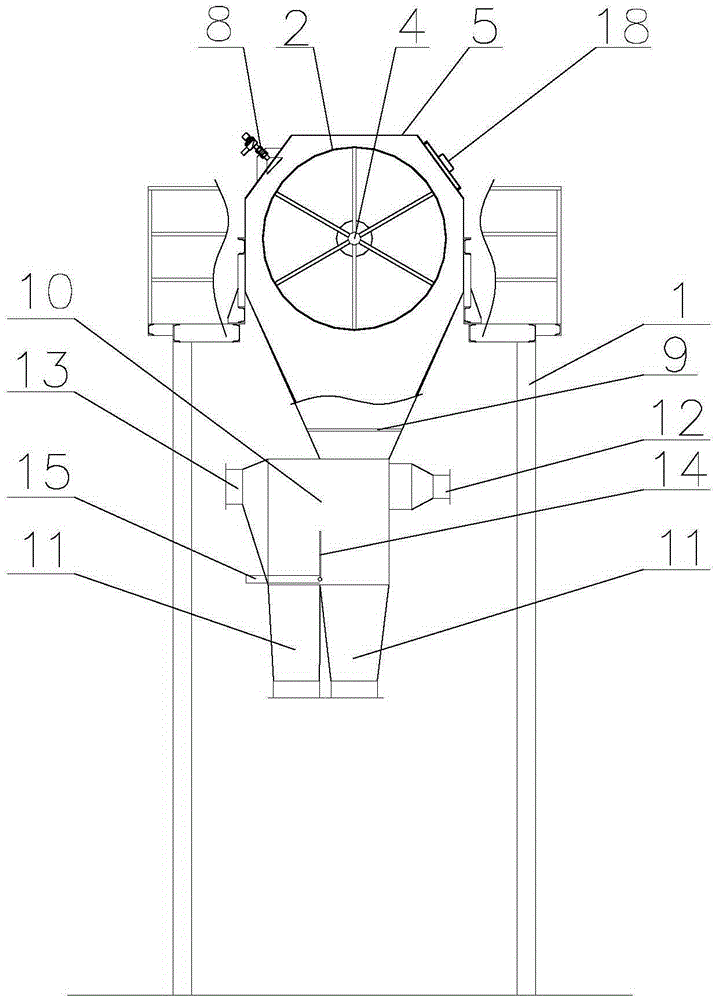

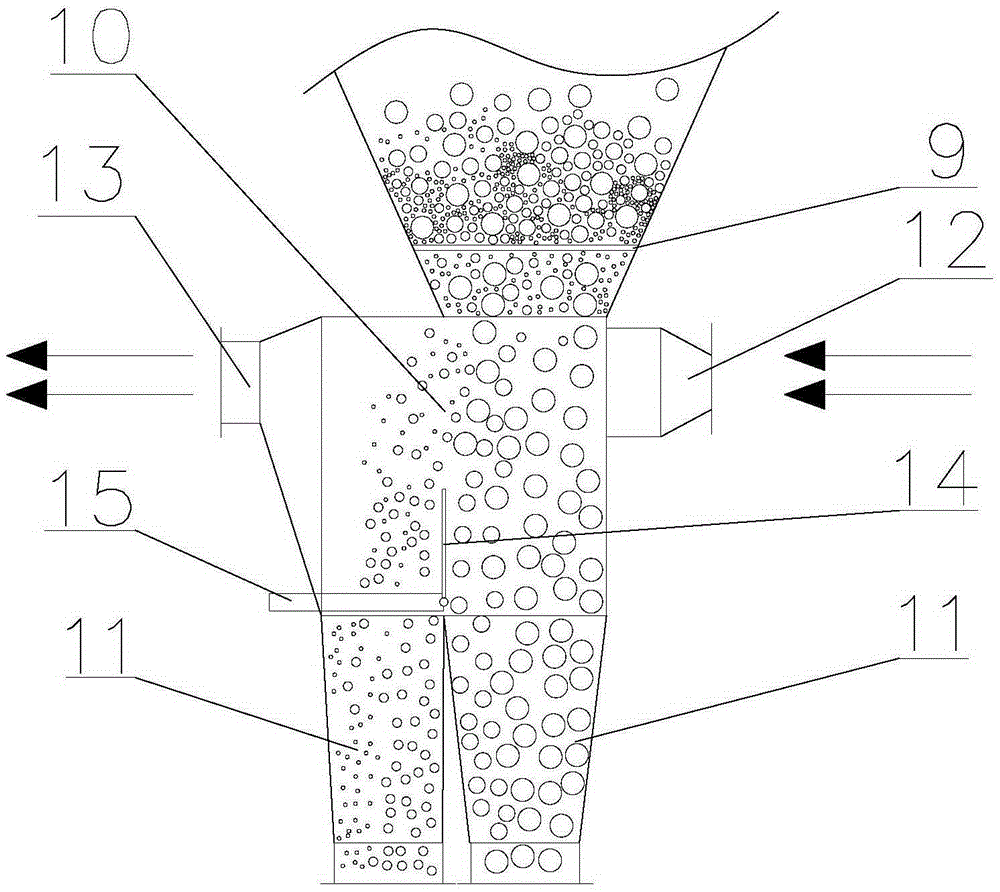

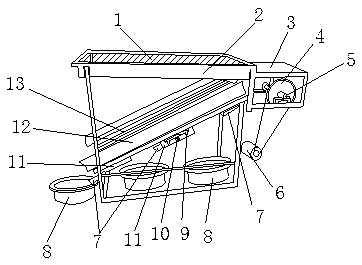

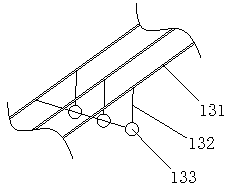

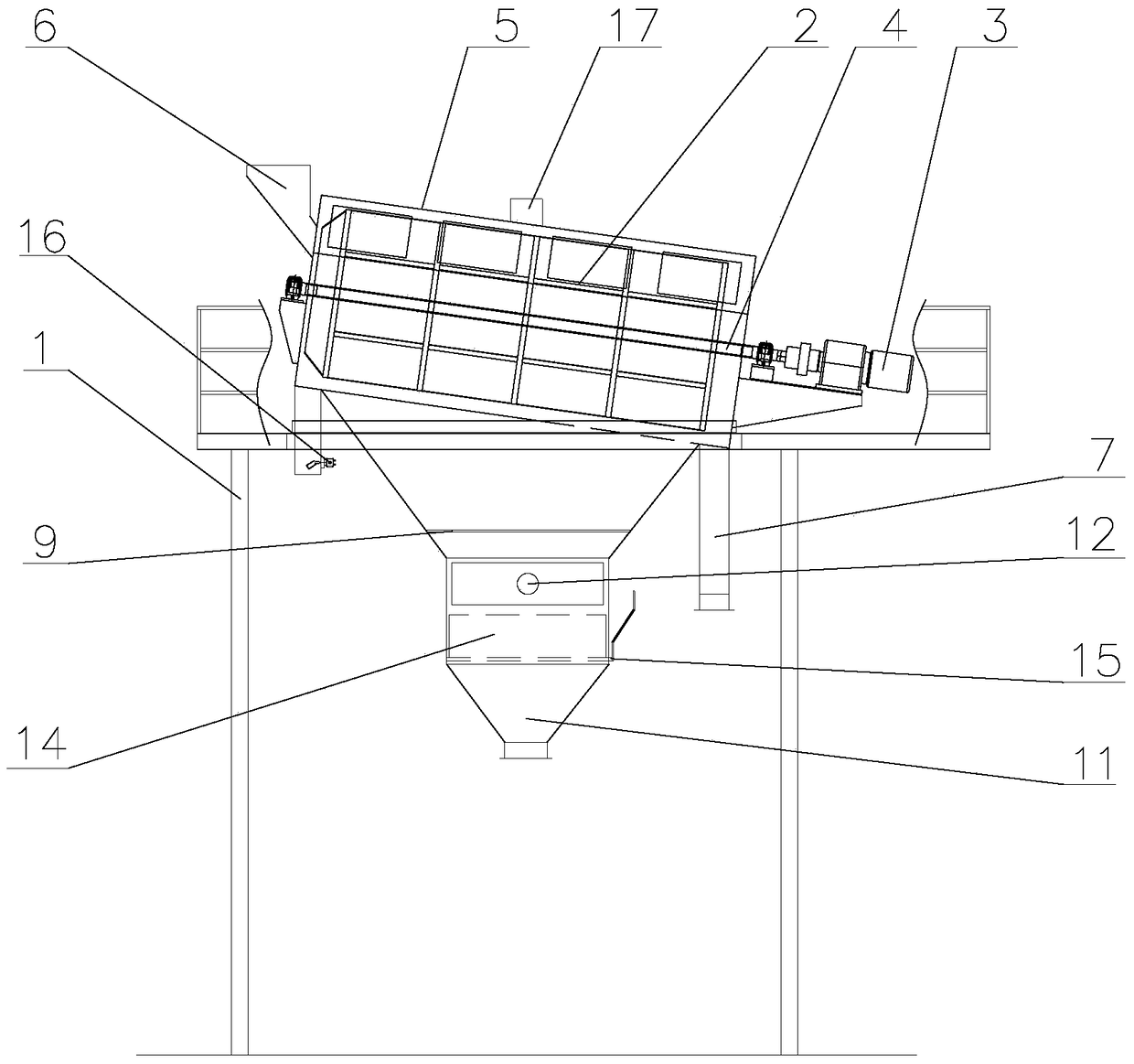

Anti-blocking type drum screen with secondary screening device

ActiveCN105344601AImprove utilization efficiencyReduce the hassle of manual cleaningSievingGas current separationElectric machineryEngineering

The invention relates to the technical field of screening equipment, in particular to an anti-blocking type drum screen with a secondary screening device. The anti-blocking type drum screen mainly consists of a rack, a drum screen body, a rotary motor, a rotary shaft, an outer cover, a charge hole formed in one end of the outer cover, a waste discharge hole formed in the other end of the outer cover, anti-blocking devices and the secondary screening device positioned at the lower end of the outer cover; the drum screen body and the horizontal plane are arranged on the rack at an angle of 5-10 degrees; the rotary shaft is inserted into the drum screen body; one end of the rotary shaft passes through the drum screen body and is connected with the rotary motor; the outer cover covers the outer side of the drum screen body; and the plurality of anti-blocking devices are uniformly arranged on the outer surface of the outer cover. After adopting the structure, the screen can be cleared at fixed time by virtue of a pulse type air cannon, so that manual clearing trouble is avoided in case of not affecting using efficiency of the drum screen body, and therefore, labor intensity is reduced; and the secondary screening device can be utilized to further screen materials, and materials in precise proportion are obtained by virtue of a collecting and mixing regulating plate, so that the utilization efficiency of the drum screen body is improved.

Owner:JIANGSU WOLVES MACHINERY

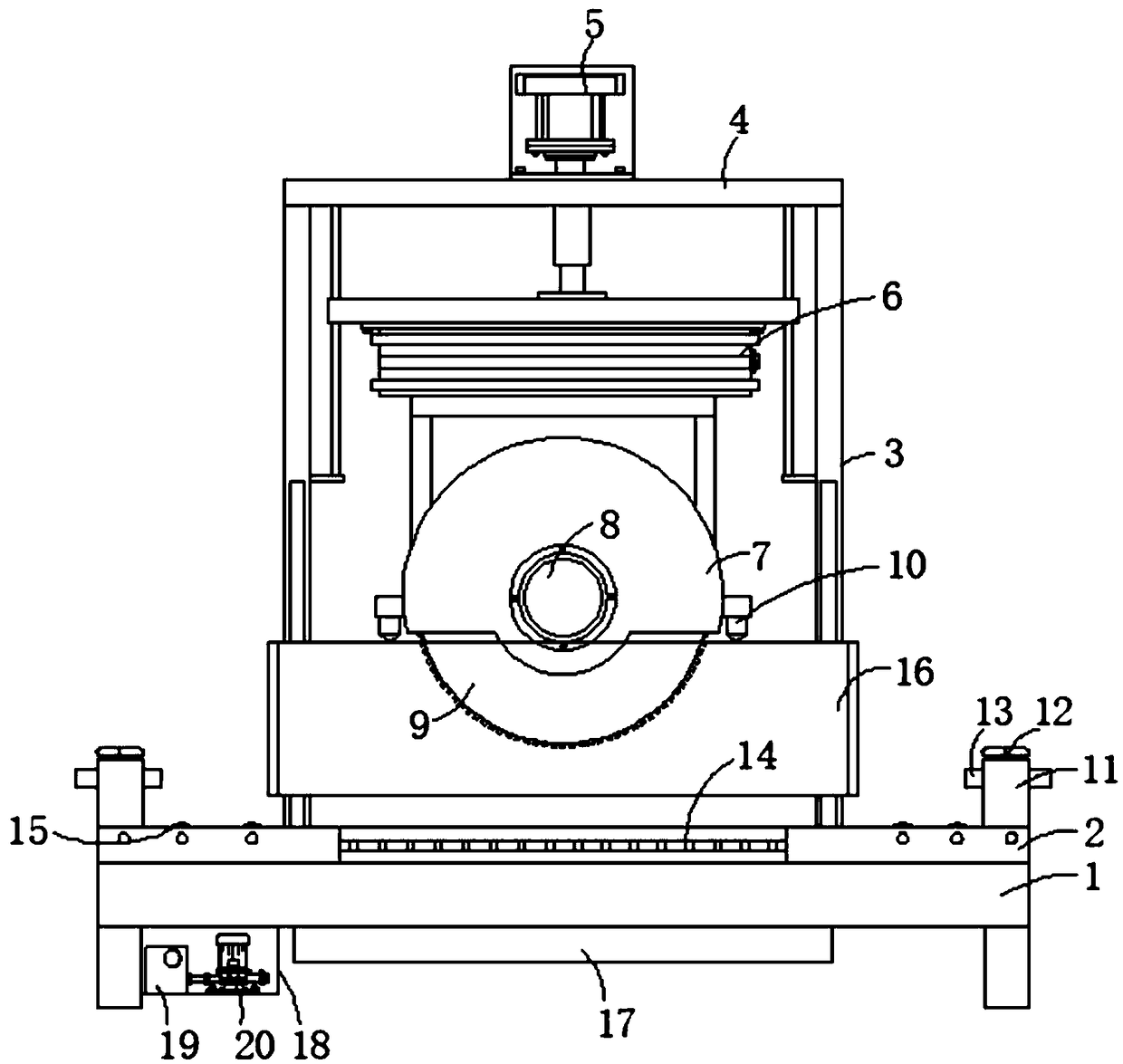

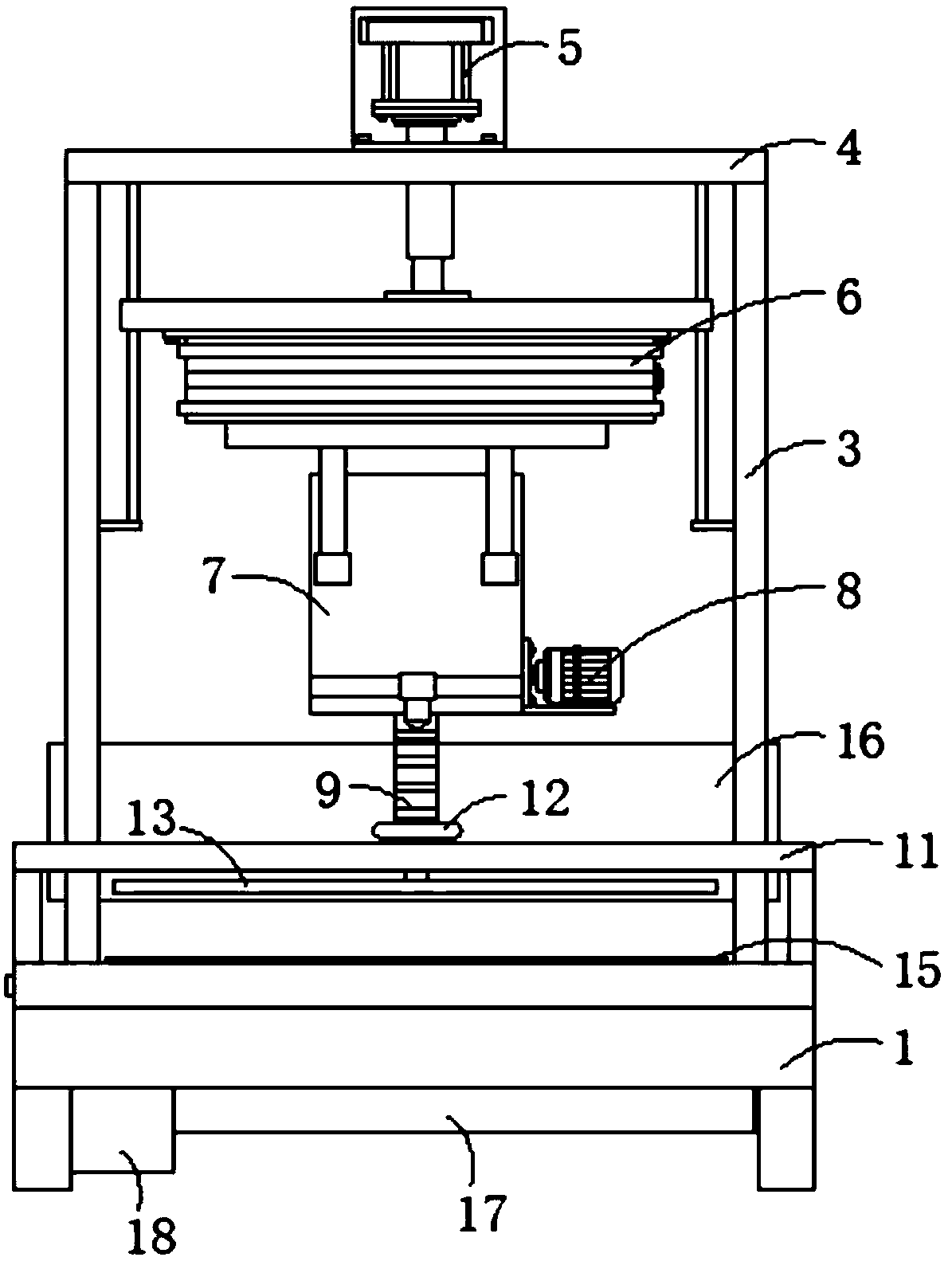

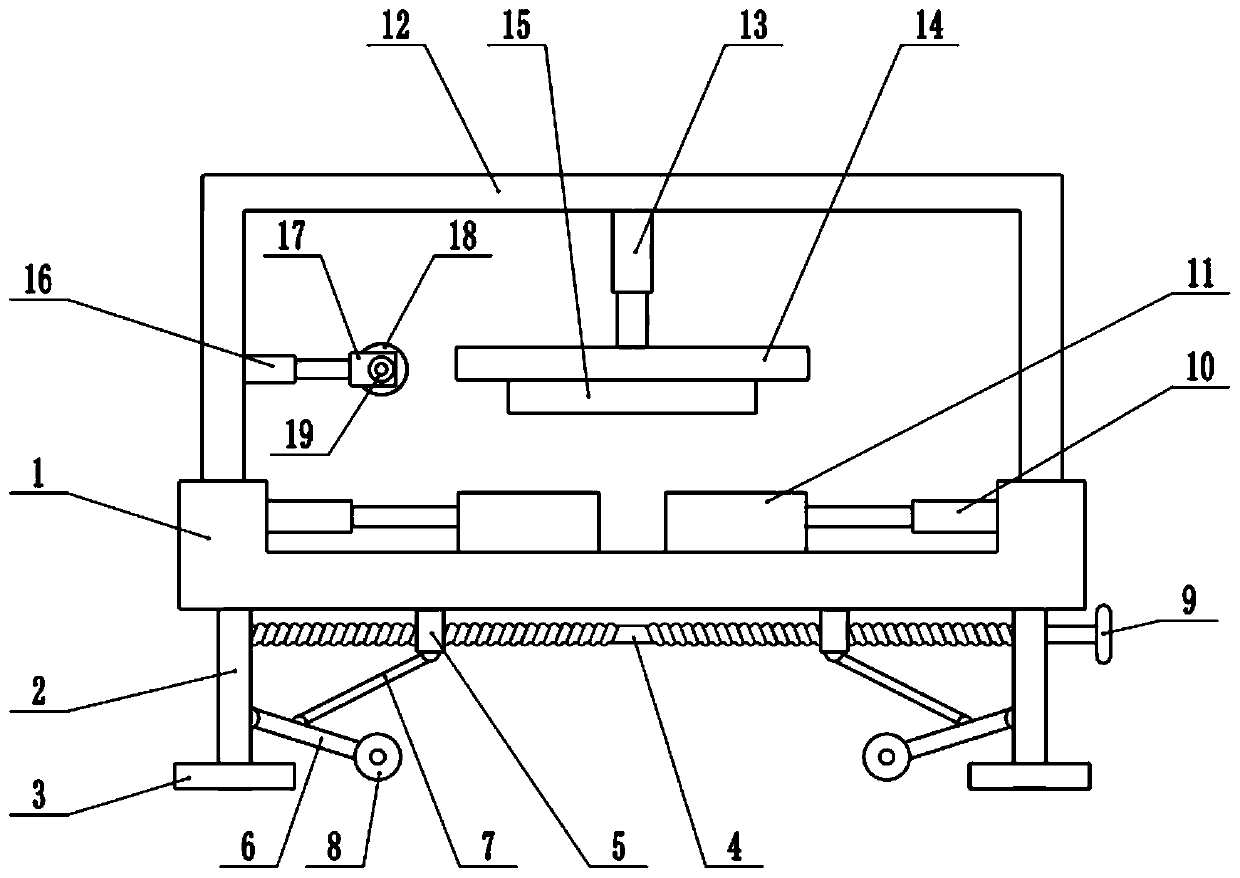

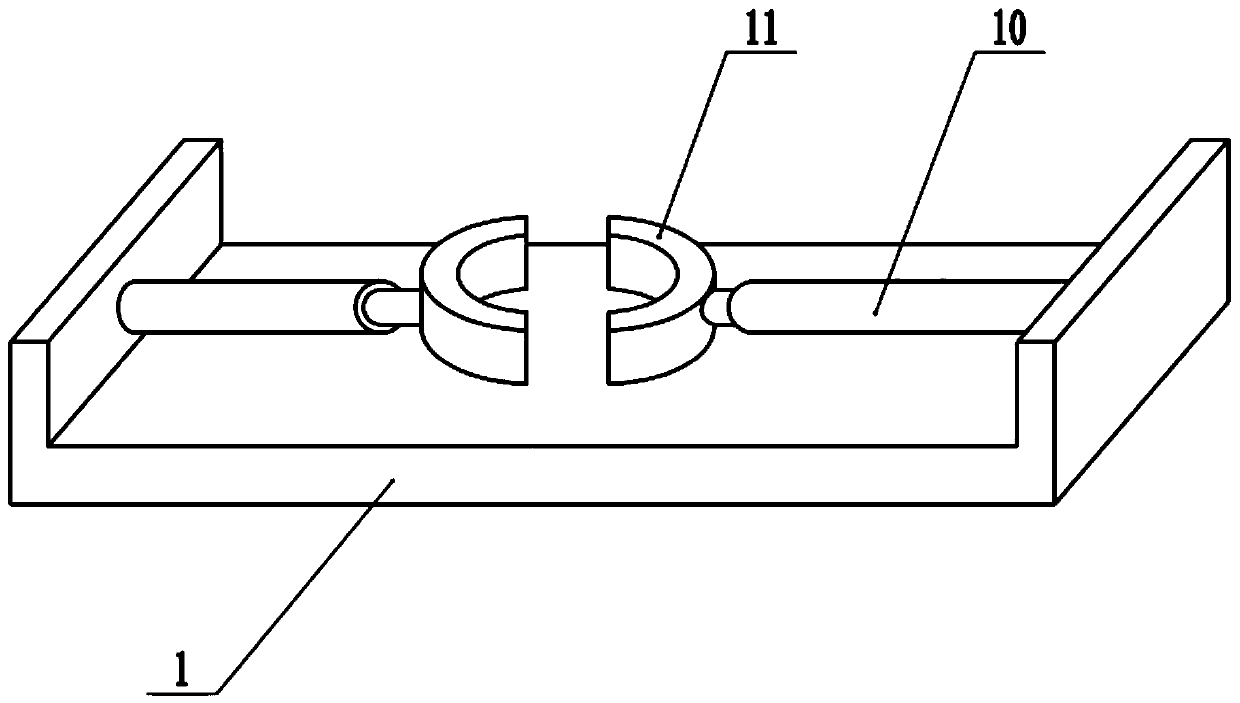

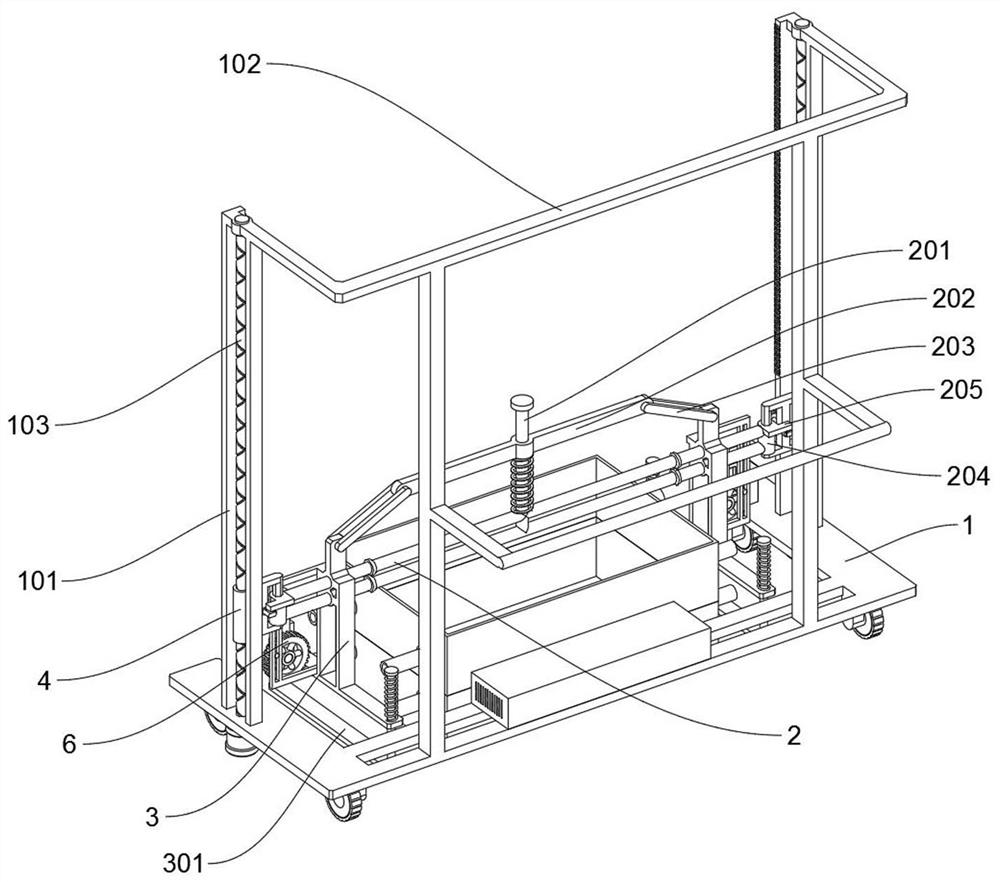

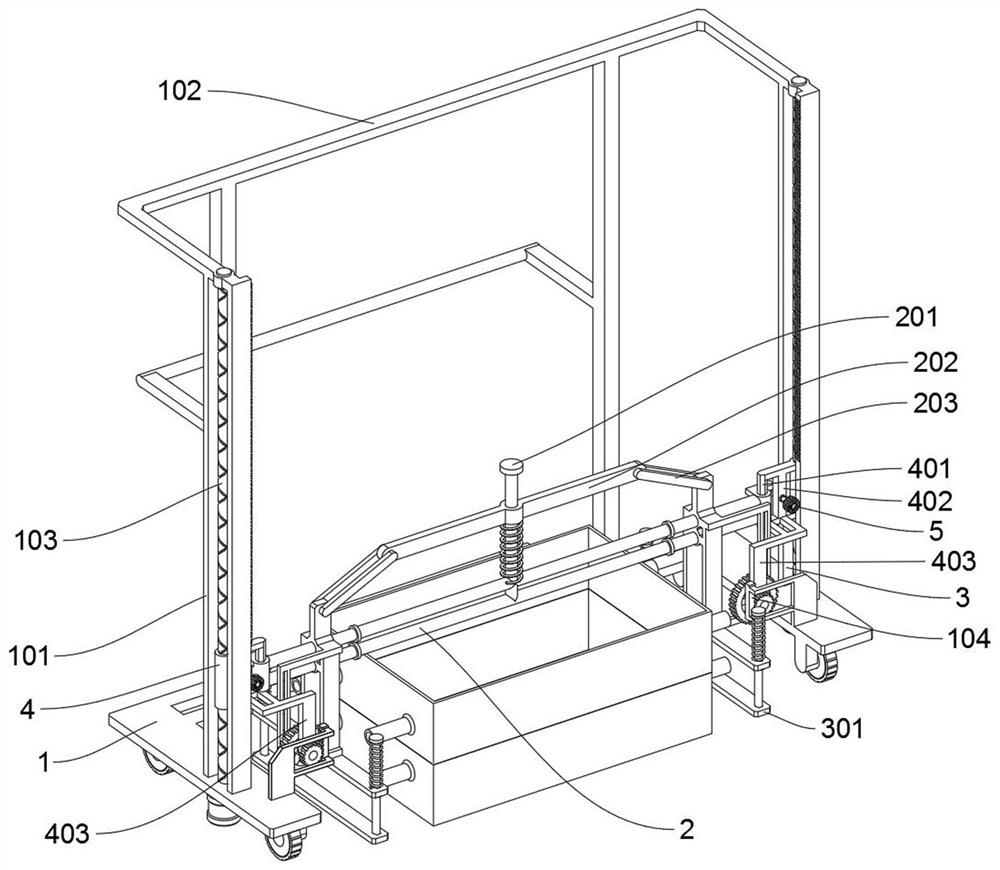

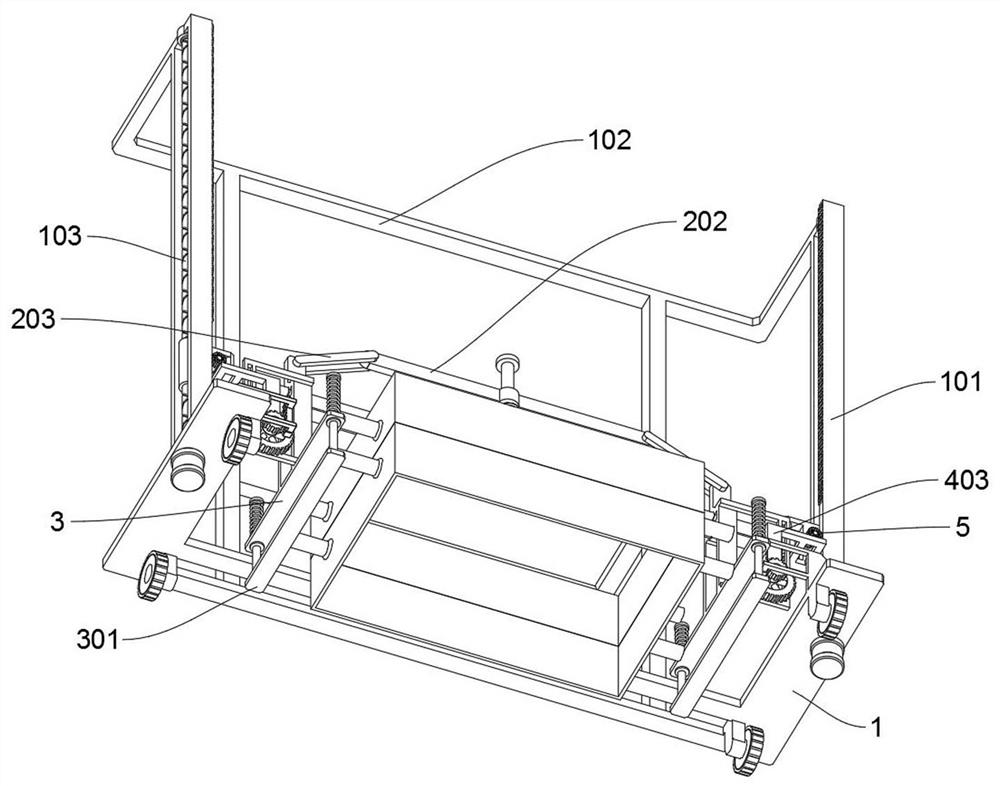

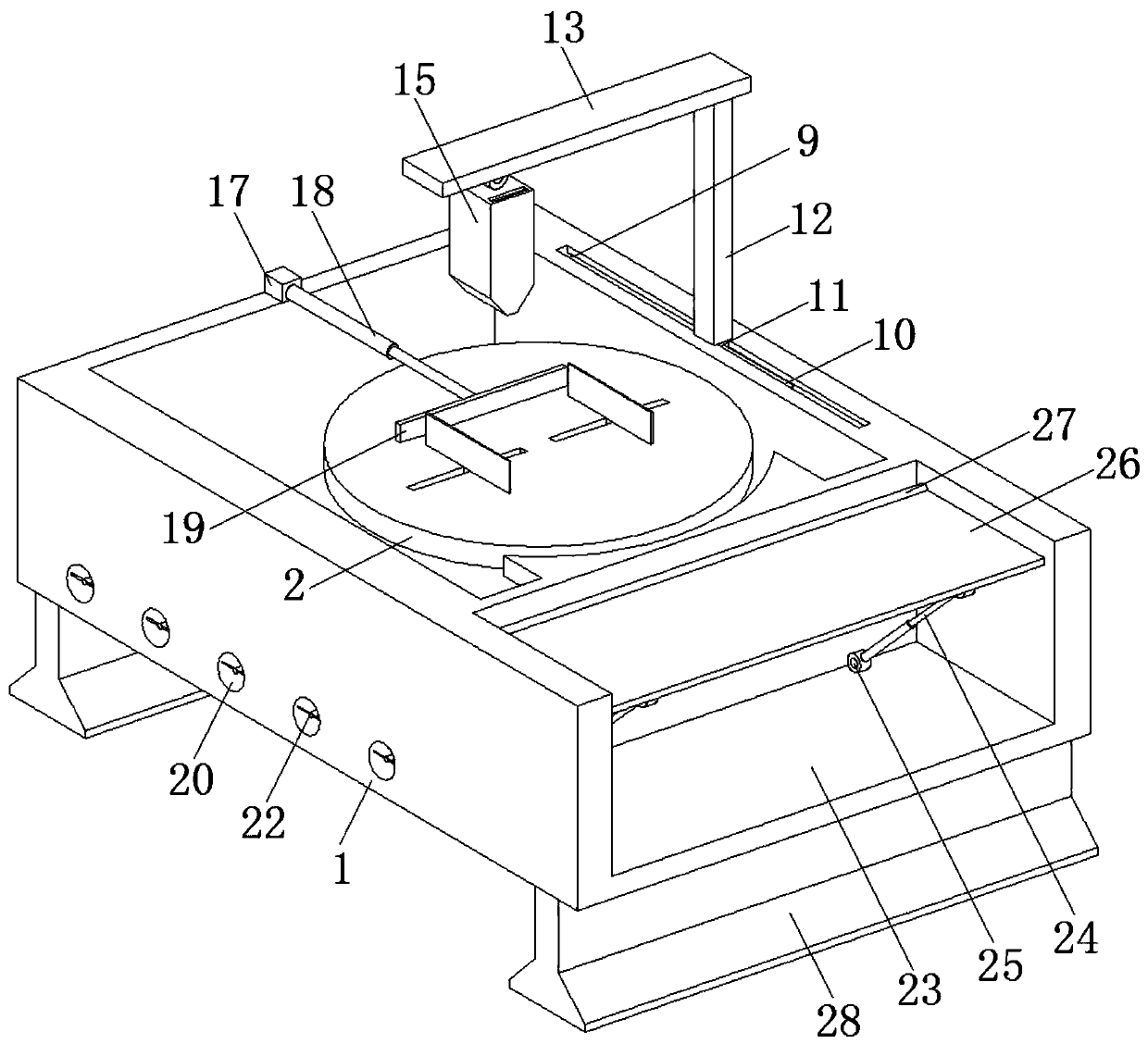

Movable powder metallurgy forming equipment

InactiveCN111331133AEasy to take outSolve the problem that it is difficult to take out the finished product and the movement of the molding equipment is inconvenientCleaning using toolsStructural engineeringMachining

The invention relates to the field of machining equipment, in particular to movable powder metallurgy forming equipment. The movable powder metallurgy forming equipment comprises a workbench, a supporting plate, a fixing frame, a lifting plate and an upper die, wherein a bidirectional lead screw is arranged below the workbench, the bidirectional lead screw is sleeved with a sliding block, a connecting rod is hinged to the lower surface of the sliding block, a movable rod is hinged to the side wall of the supporting plate, lower dies are installed on the workbench, the fixing frame is fixedly connected to the workbench, a second telescopic mechanism is fixedly connected to the top of the fixing frame, the lifting plate is fixedly connected to the lower end of the second telescopic mechanism, the upper die is fixedly connected to the lower surface of the lifting plate, and a cleaning mechanism is further installed on the side wall of the fixing frame. The two lower dies are separated through the first telescopic mechanism, a pressed and formed finished product can be conveniently taken out, the lower surface of the upper die can be cleaned by using the cleaning mechanism, raw material adhering to the lower surface of the upper die is removed, the trouble of manual cleaning is omitted, and the movable powder metallurgy forming equipment can be conveniently pushed to move through arrangement of liftable universal wheels.

Owner:NINGBO QUNXING POWDER METALLURGY

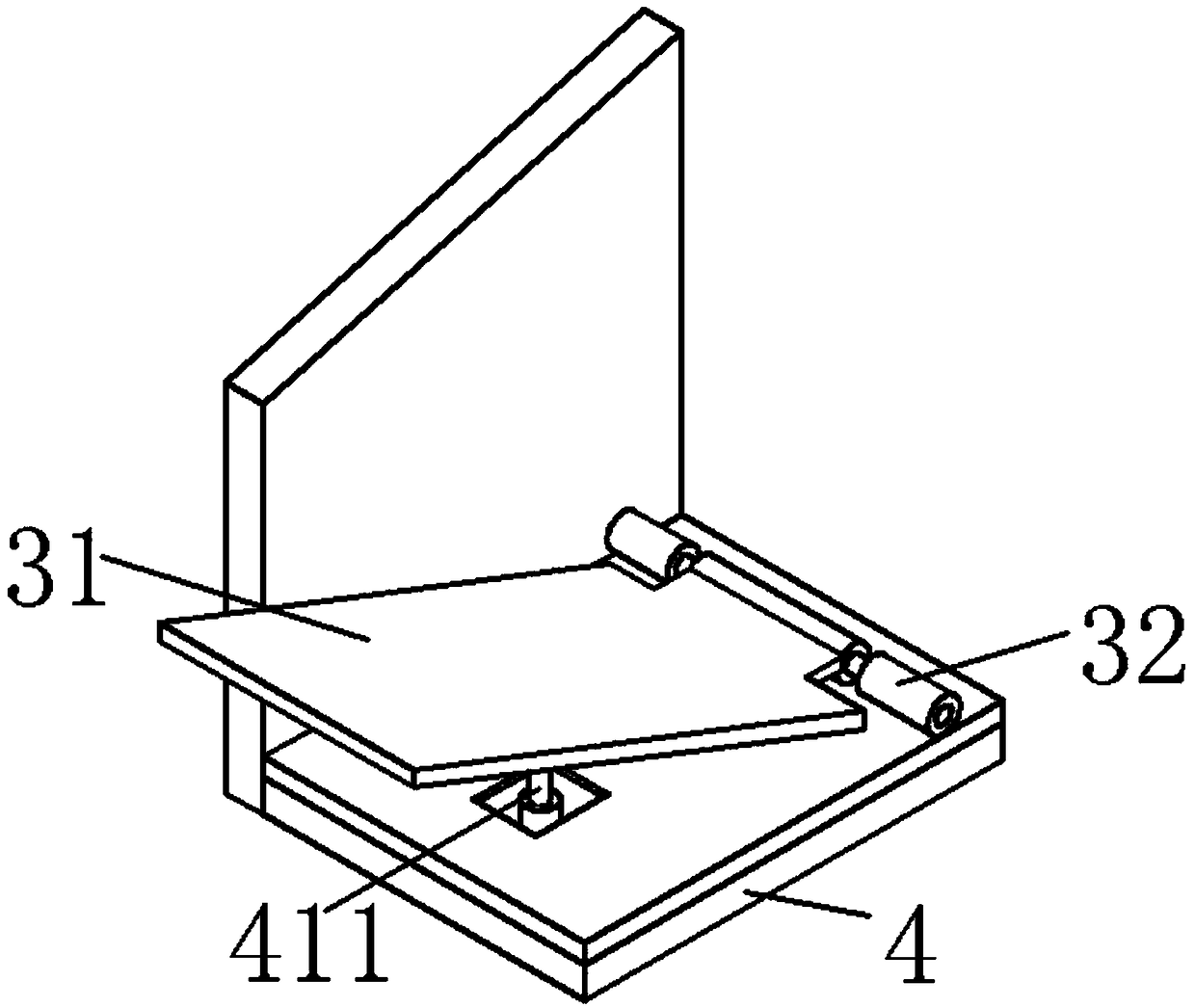

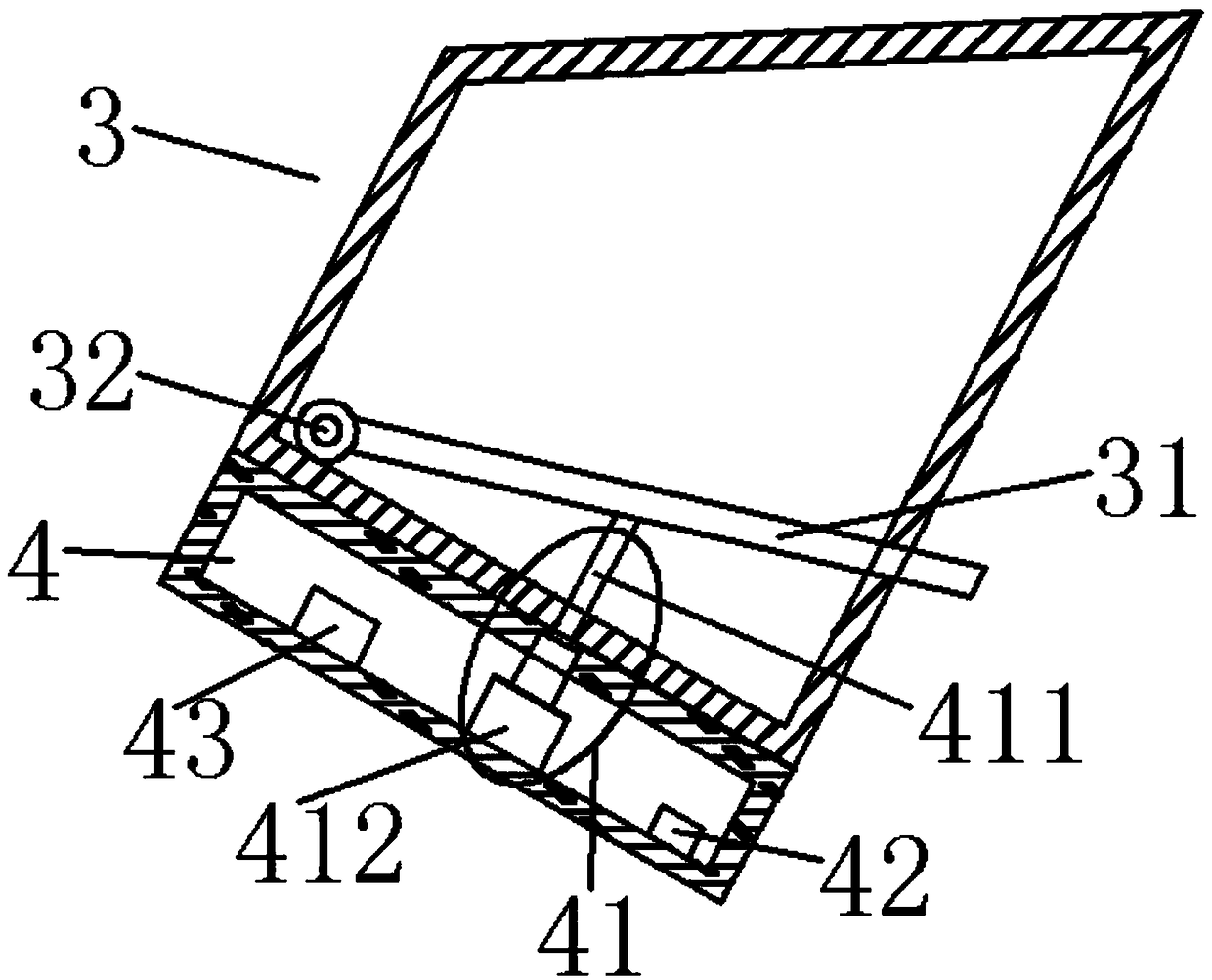

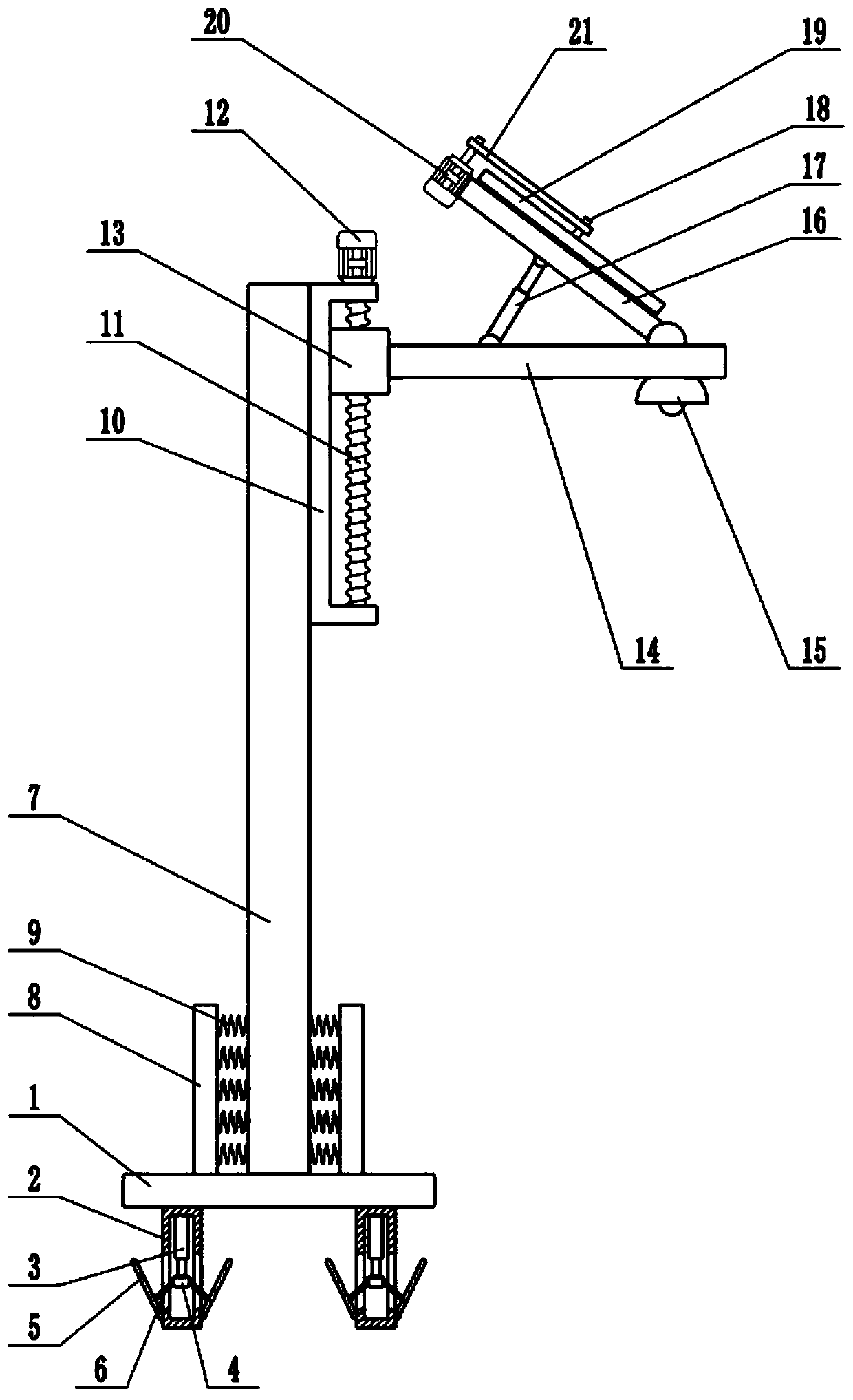

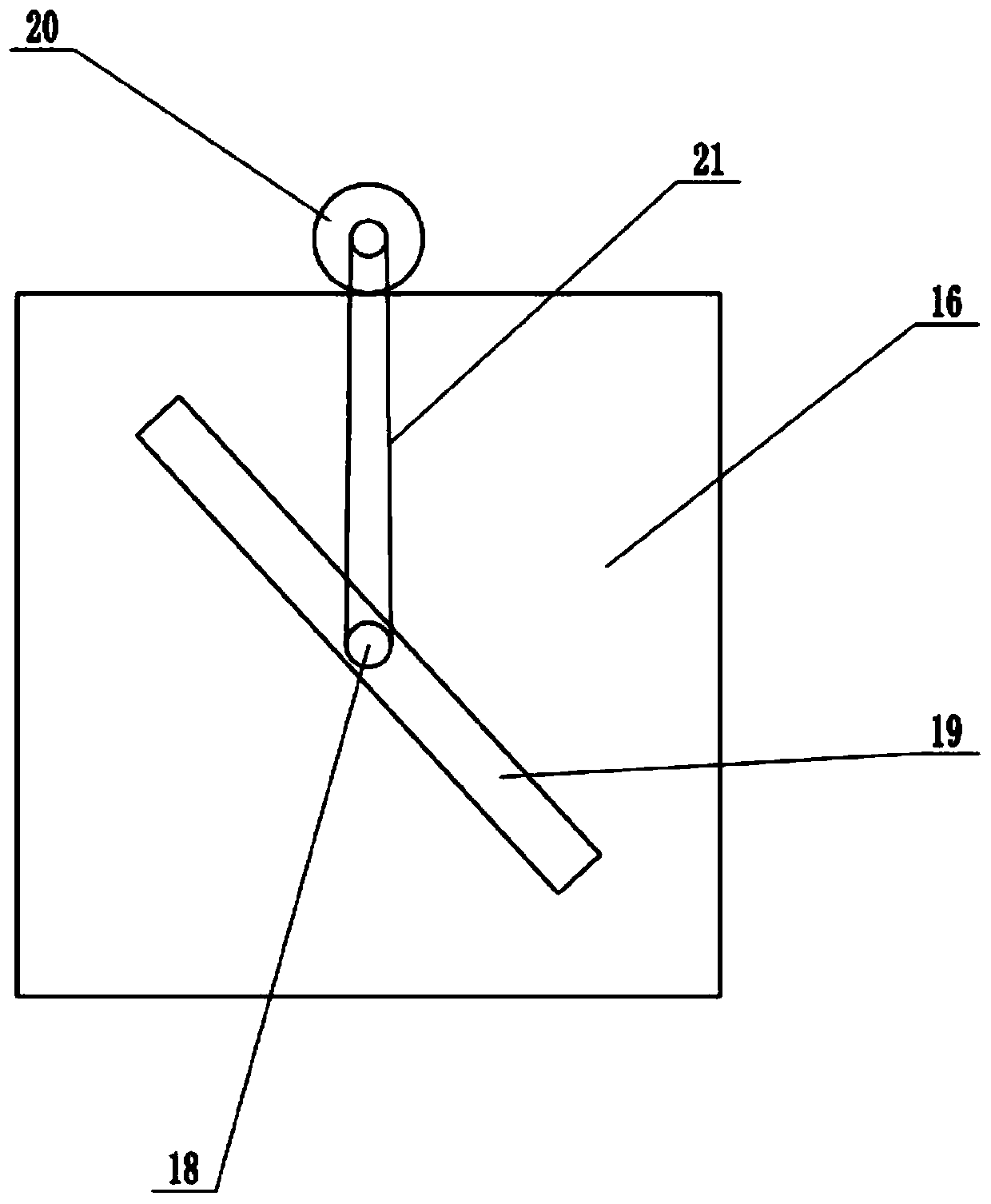

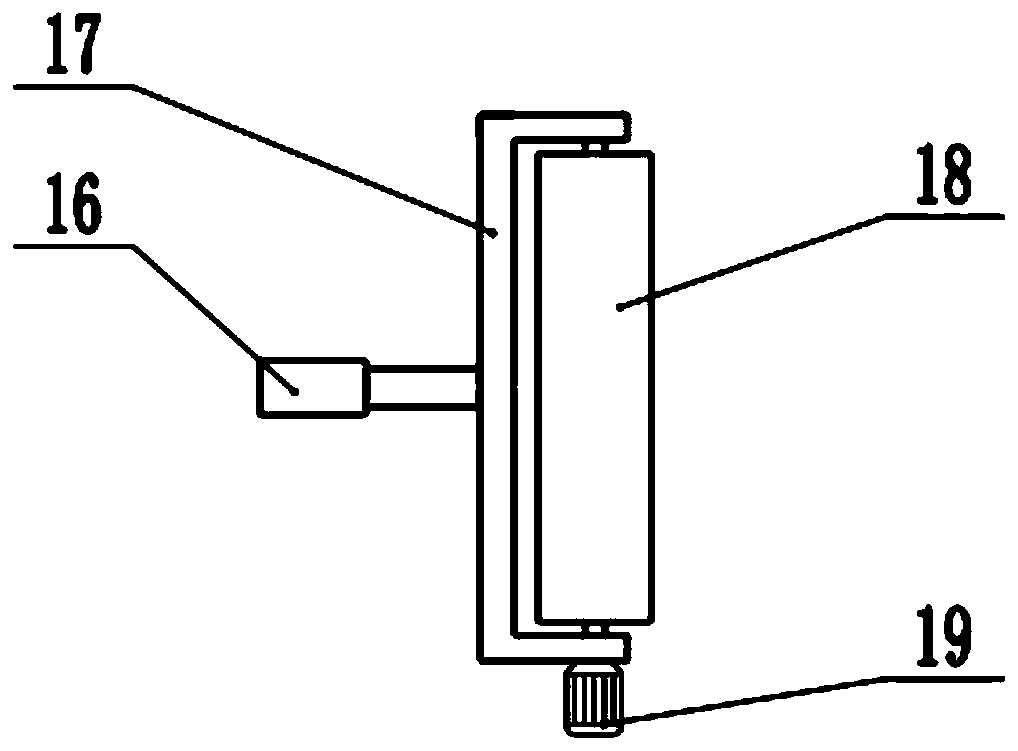

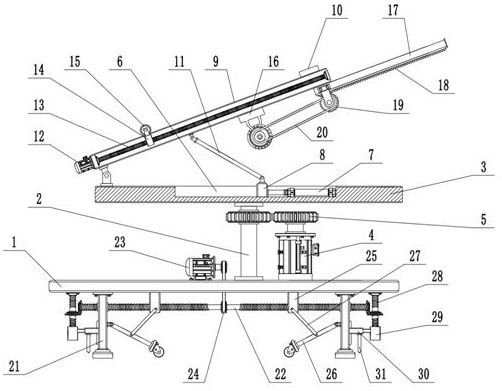

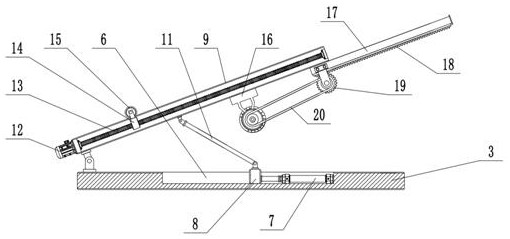

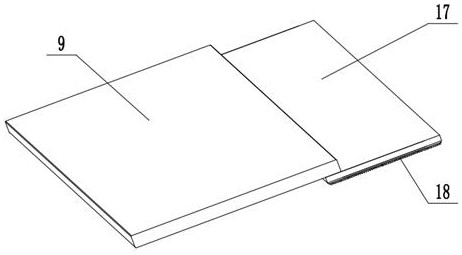

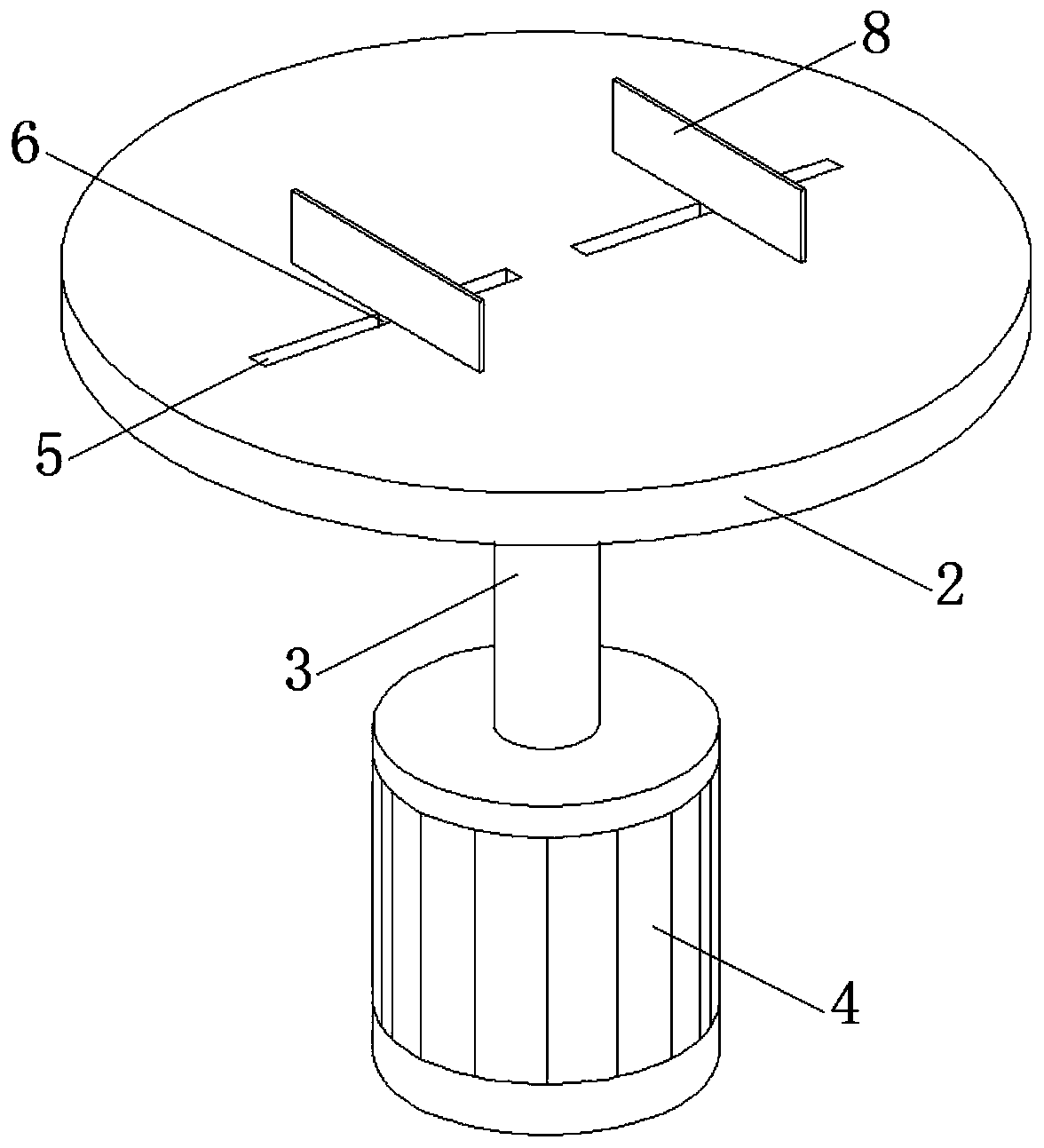

Light following type solar photovoltaic panel and solar power generation equipment

InactiveCN113225007AImprove power generation efficiencyReduce the hassle of manual cleaningPhotovoltaic supportsSolar heating energyEngineeringSolar power

The invention relates to the field of photovoltaic technology, in particular to a light following type solar photovoltaic panel and solar power generation equipment. The light following type solar photovoltaic panel comprises a base, wherein a rotating assembly is mounted above the base, a rotating disc is mounted on the rotating assembly, a main photovoltaic panel is hinged to the rotating disc, an adjusting assembly is mounted on the rotating disc, the adjusting assembly is connected with the main photovoltaic panel and used for adjusting an inclination angle of the main photovoltaic panel, a first lead screw is rotationally installed at the edge of the main photovoltaic panel, a second motor used for driving the first lead screw to rotate is installed on the main photovoltaic panel, a movable block is in threaded connection with the first lead screw, a cleaning roller is installed on the movable block, and bristles are distributed on the surface of the cleaning roller. The illumination angle changes along with the change of the position of the sun, the illumination angle is monitored in real time through using a photosensitive sensor, the rotating assembly and the adjusting assembly are controlled to work, sunlight can perpendicularly irradiate the main photovoltaic panel, and the power generation efficiency is greatly improved.

Owner:WEST ANHUI UNIV

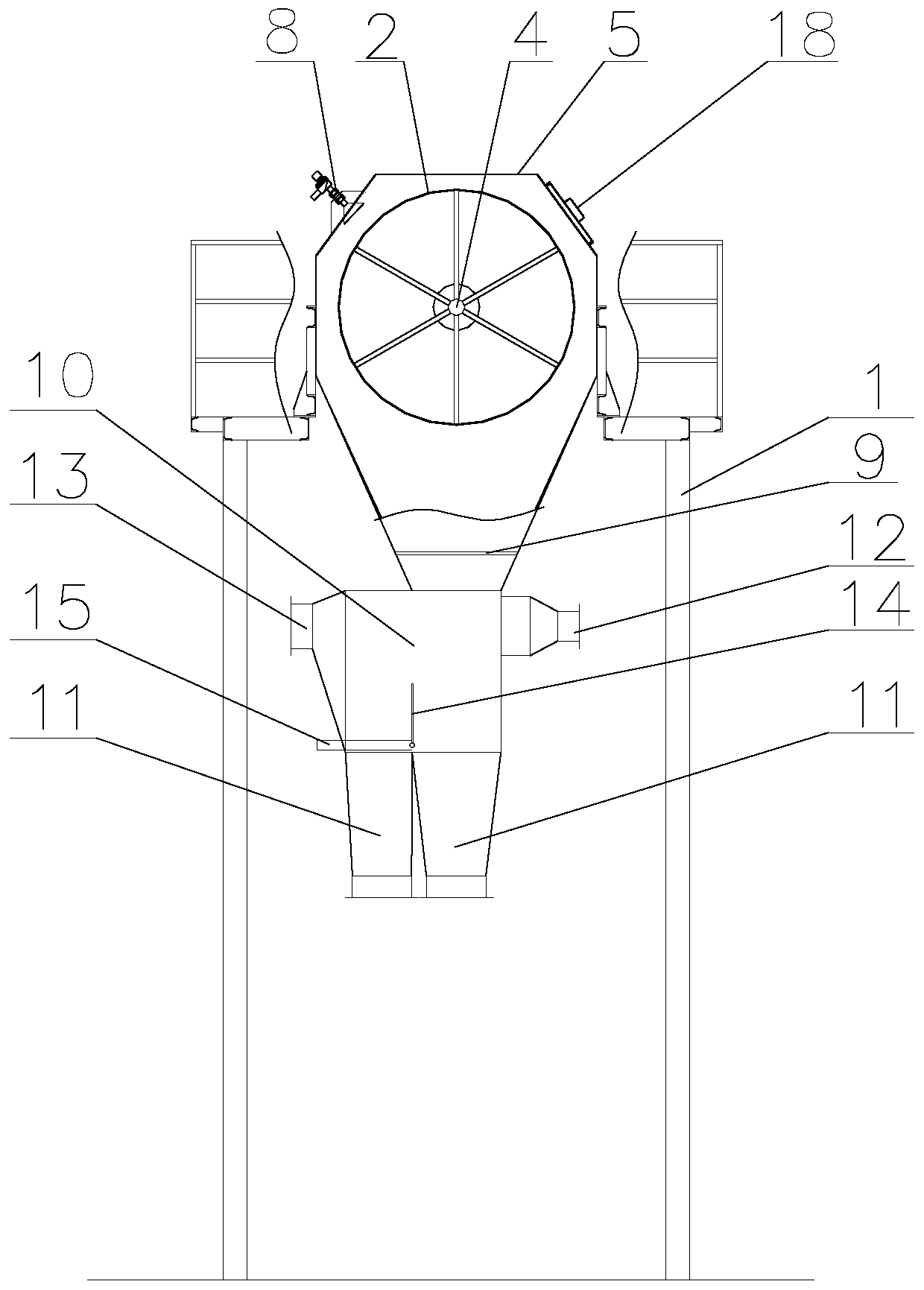

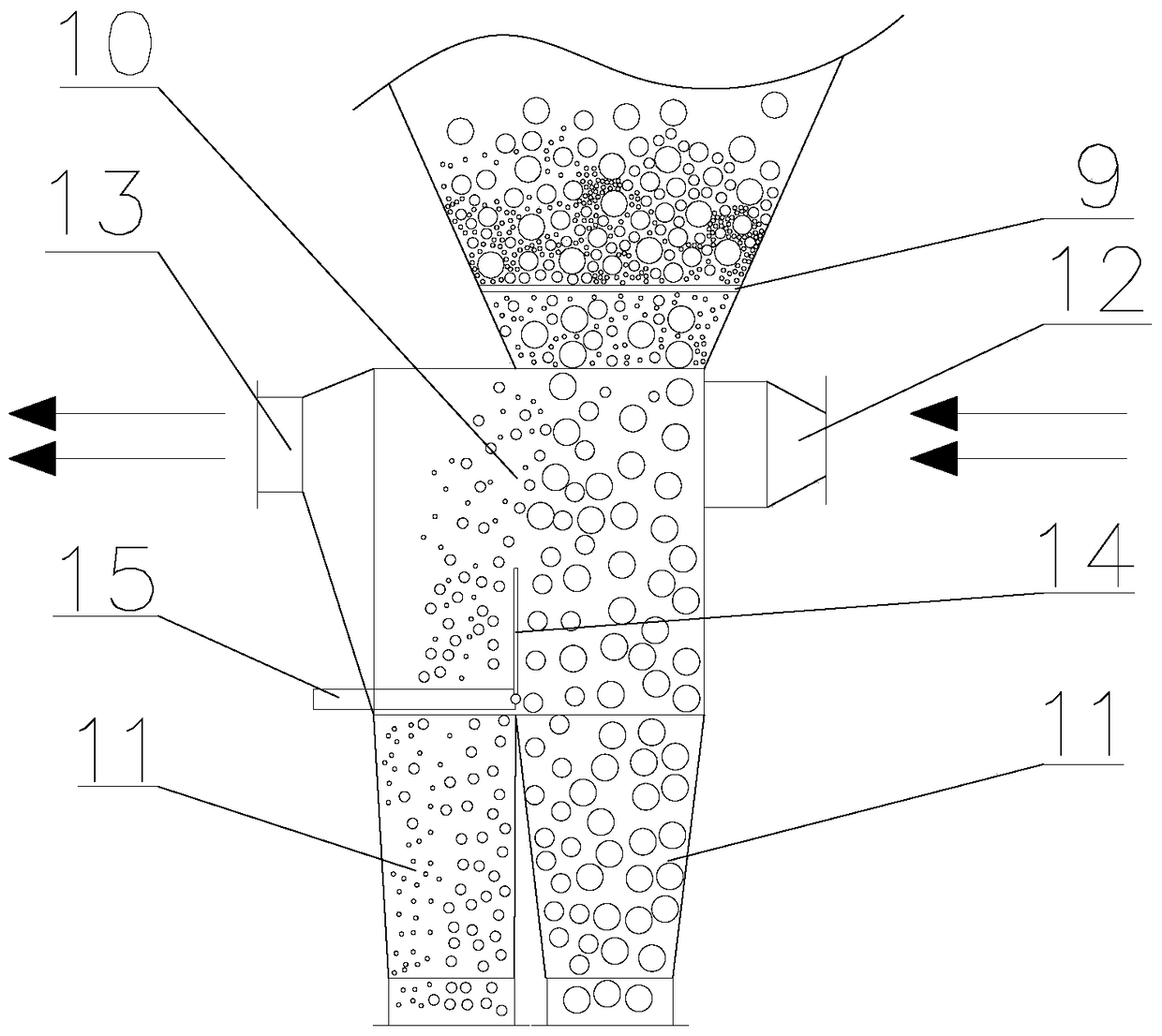

Sorting device with sand and stone sorting function

PendingCN112791866AImprove screening efficiencyImprove sand production efficiencyReversed direction vortexStructural engineeringMechanical engineering

The invention relates to the technical field of building construction, and discloses a sorting device with a sand and stone sorting function. The sorting device comprises a multi-stage sand sorting device, a sand discharging device and a collecting tank, wherein the multi-stage sand sorting device comprises a screening mechanism, a rotational flow sand sorting mechanism and a conveying system; the screening mechanism is used for screening large-particle sand and stone and medium-particle sand and stone, the rotational flow sand sorting mechanism comprises at least one cyclone, the cyclones are used for screening small-particle sand and stone, and the conveying system is used for conveying to-be-screened sand and stone to the screening mechanism and the rotational flow sand sorting mechanism; the sand discharging device comprises a discharging groove and a vibrator; and the collecting tank is arranged below the discharging groove. According to the sorting device with the sand and stone sorting function, the large-particle sand and stone, the medium-particle sand and stone and the small-particle sand and stone can be separated out, the sand and stone of various different sizes can be separated and screened, and the sand and stone screening efficiency is greatly improved.

Owner:深圳市桥梁维修设备科技有限公司

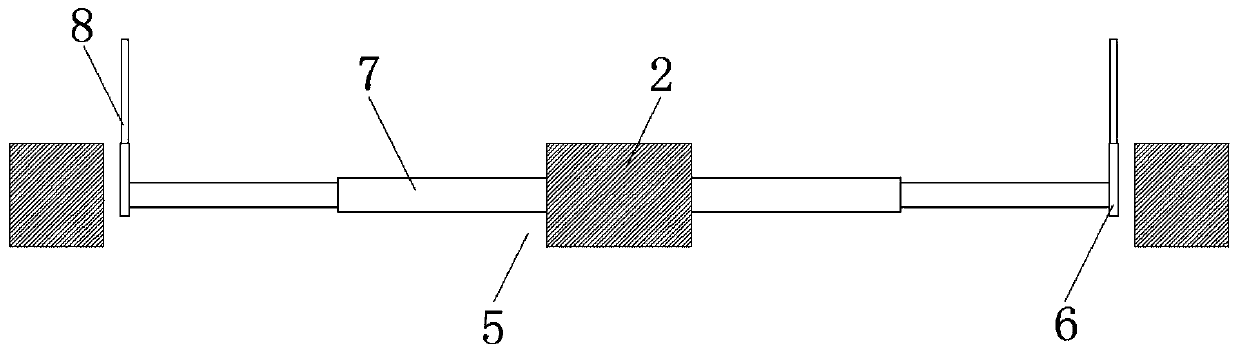

Shrimp screening machine

PendingCN106938249AReasonable designSimple structureSievingScreeningMarine engineeringPower apparatus

The invention discloses a shrimp screening machine. The shrimp screening machine comprises a frame and a mounting frame; a storage device is mounted at the upper part of the frame; a shrimp screening mechanism is arranged on the frame below the storage device; a power device is arranged in the mounting frame, and is in transmission connection with the shrimp screening mechanism; the shrimp screening mechanism includes a shrimp screening tank downwards inclined in the frame; a vibration screening device is arranged in the shrimp screening tank, and is in transmission connection with the power device; multiple shrimp screening plate mechanisms are arranged at the lower part of the vibration screening device; containers are arranged below outlet positions of the shrimp screening plate mechanisms; and the containers are corresponding to the shrimp screening plate mechanisms one to one. The shrimp screening machine is reasonable in design, simple in structure, convenient to maintain, relatively lower in cost, fast in shrimp screening speed and accurate in screening size classification, totally eliminates the shrimp break condition, reduces the manual cleaning trouble, meanwhile, saves the cost, increases the selling price, and is suitable for popularization.

Owner:周红

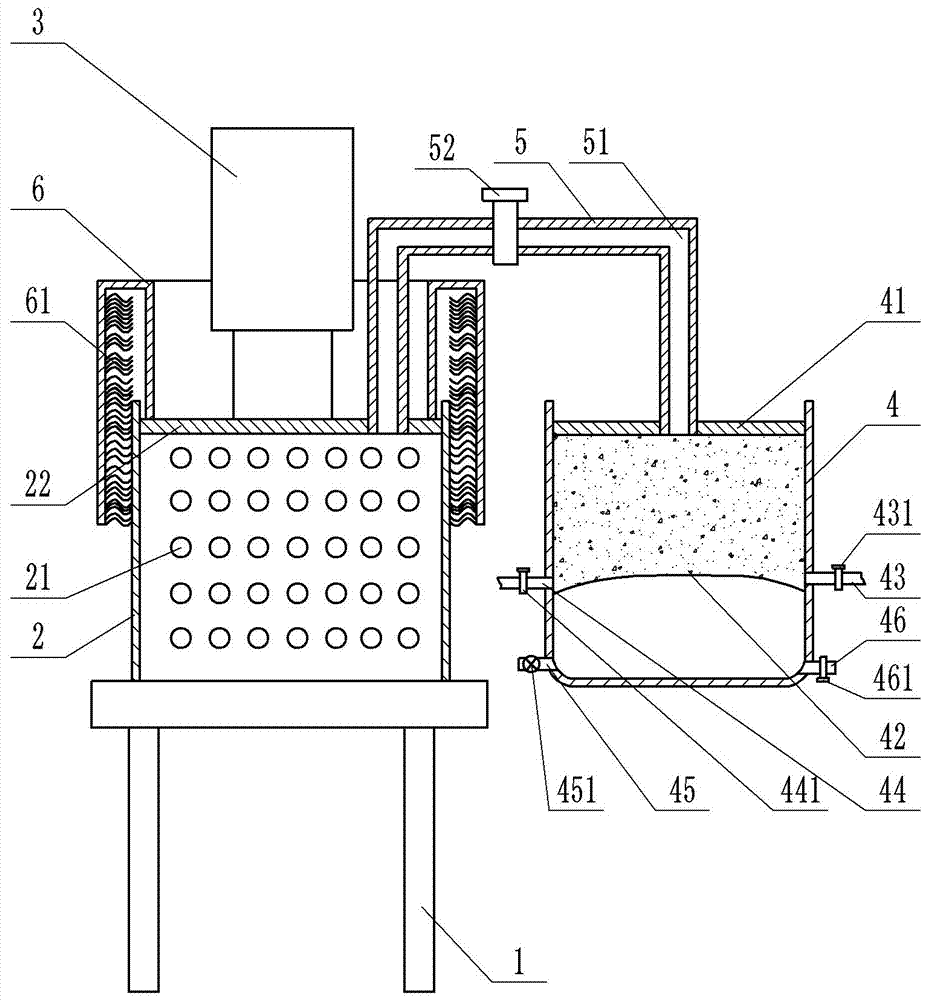

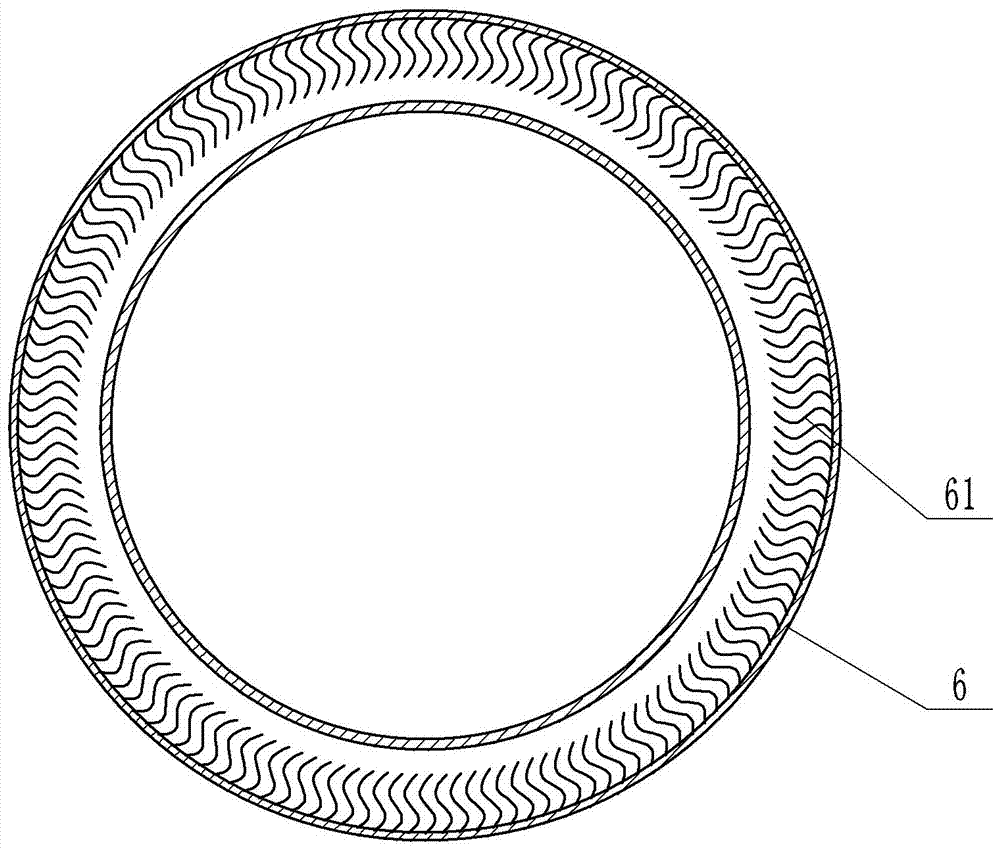

Medicinal liquid extraction device

InactiveCN108786239AAccelerateImprove the effectStationary filtering element filtersEngineeringUtilization rate

The invention discloses a medicinal liquid extraction device which comprises a tank body, wherein a feeding hole is formed at the top of the tank body; a taking hole is formed in the side wall of thetank body; the tank body is internally provided with a separation mechanism and a dreg discharge mechanism which is arranged above the separation mechanism; the separation mechanism is matched with the dreg discharge mechanism. Due to adoption of the separation mechanism, medicine dregs generated after steaming and boiling can be recycled for medicinal liquid extraction, the consequence that a medicinal liquid in the medicine dregs cannot be sufficiently utilized and waste of the medicinal liquid in the medicine dregs is caused can be avoided, the utilization rate of medicinal liquid extraction is increased, and the medicinal liquid extraction efficiency is improved; due to adoption of the dreg discharge mechanism, the medicine dregs after medicinal liquid extraction can be automatically taken out by using a mechanical device, the time and the labor for manually discharging the medicine dregs can be saved, and the medicine dreg cleaning efficiency can be improved; due to cooperation ofthe mechanisms, efficient medicinal liquid extraction on residual medicine dregs after steaming and boiling can be implemented, the medicine dregs can be directly cleaned out after extraction is completed and are later manually cleaned, and thus the medicinal liquid extraction efficiency can be greatly improved.

Owner:徐春英

Aluminum profile cutting equipment

InactiveCN111730139AFast clamping speedImprove efficiencyFeeding apparatusPositioning apparatusClassical mechanicsEngineering

The invention relates to the field of machining equipment, in particular to aluminum profile cutting equipment. The aluminum profile cutting equipment comprises a fixing table, a fixing frame, a mounting plate, a lifting seat and a cutting machine, the fixing frame is fixedly connected to the upper surface of the fixing table, a support is fixedly connected to the top of the fixing frame, a worm gear is rotationally connected to the lower end of the support, the mounting plate is arranged below the worm gear, a first telescopic guide rod is fixedly connected to the lower surface of the mounting plate, a lifting seat is fixedly connected to the lower end of the first telescopic guide rod, a worm is arranged above the worm gear, a second telescopic guide rod is fixedly connected to the innerside wall of the fixing frame, a movable frame is fixedly connected to the end of the second telescopic guide rod, and a brush plate is mounted on the lower surface of the movable frame. A bidirectional lead screw is used for driving a clamping plate to clamp the aluminum profile, so that the aluminum profile is kept stable, the clamping speed is high, the efficiency is high, the brush plate is driven to move left and right while cutting operation is carried out, the brush plate is used for cleaning the surface of the aluminum profile, and impurities on the surface are removed.

Owner:李超

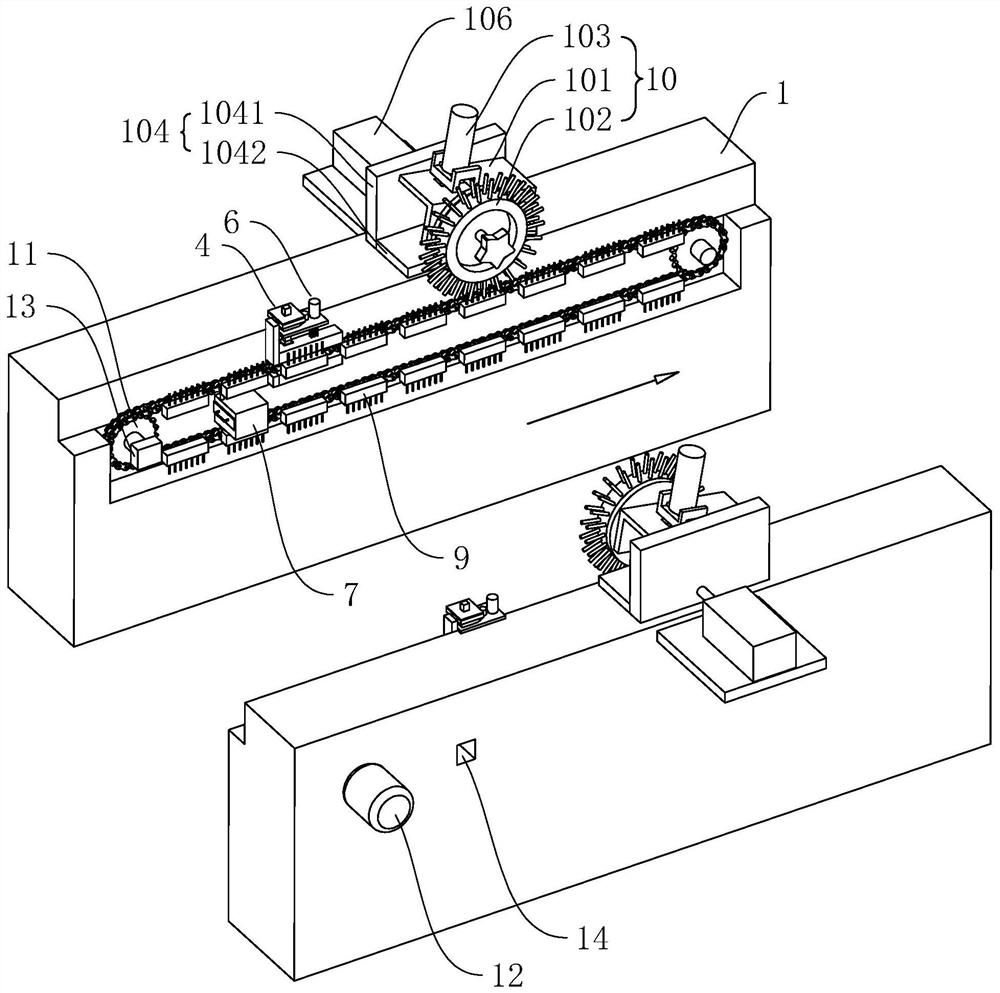

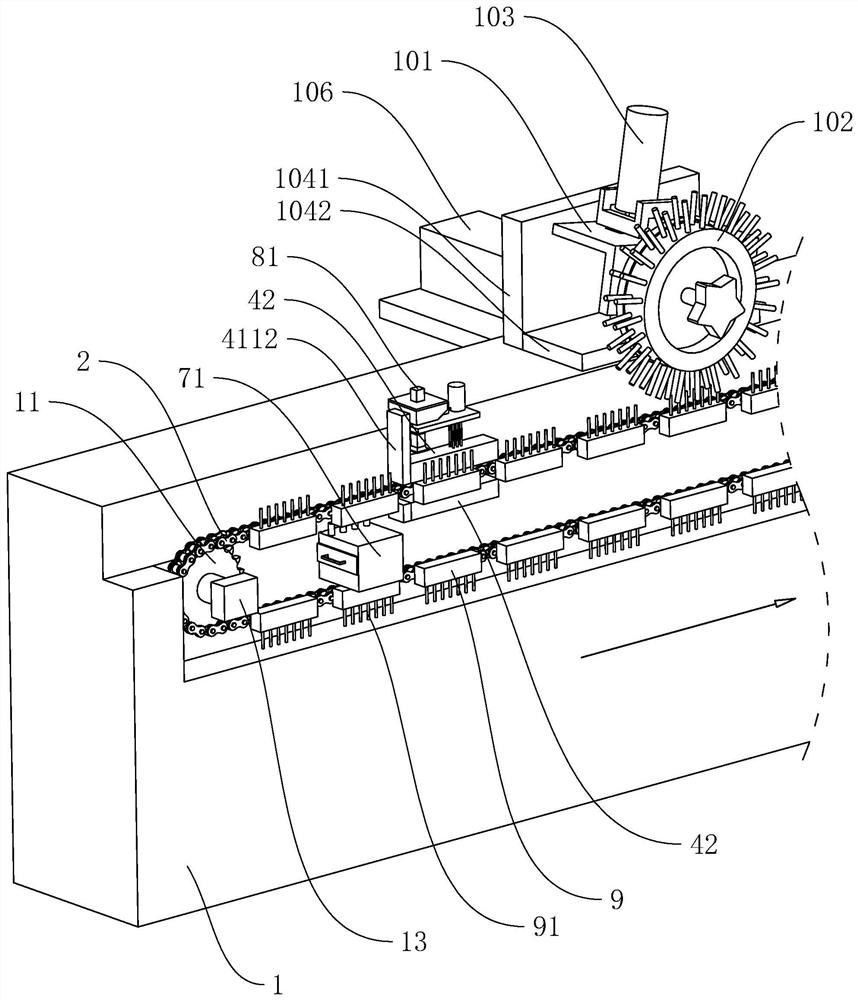

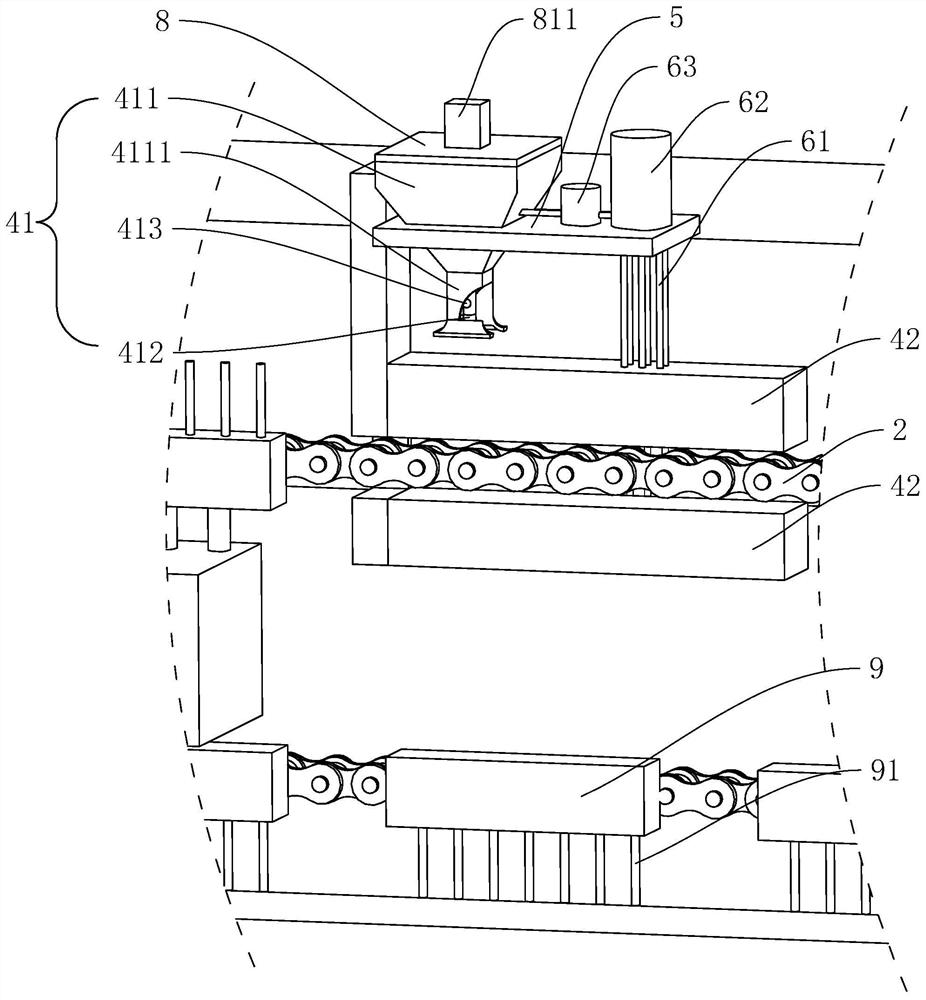

Setting machine and cloth production process using setting machine

InactiveCN112161029AReduce decreaseReduce drippingGearingGear lubrication/coolingControl systemControl engineering

The invention relates to a setting machine and a cloth production process using the setting machine. The setting machine comprises a frame and a chain, wherein the chain is driven to rotate through two chain wheels; a rotation speed sensor is arranged on the frame; an oil brushing device is arranged on the frame and comprises an oil supply mechanism and sponges; the rotation speed sensor is used for transmitting rotation speed signals to a control system; at least two sponges are arranged; one sponge is located above the chain and abuts against the upper surface of the chain; and the other sponge is located below the chain and abuts against the lower surface of the chain. According to the setting machine, the rotation speed signals of the chain wheels are transmitted to the control signalby the rotation speed sensor; rotation speed values in the rotation speed signals are compared with a preset rotation speed range value in the control system; when the rotation speed values in the rotation speed signals are lower than the rotation speed range value, the control system can control the oil supply mechanism to supply oil; lubrication oil drips on the sponges, so that the lubricationoil can be coated on the chain by the sponges; and the chain continuously moves, so that the upper surface and the lower surface of the chain are in contact with the two sponges continuously so as tofinally enable the lubrication oil on the chain to trend to be uniform.

Owner:诸暨市华都联和印花有限公司

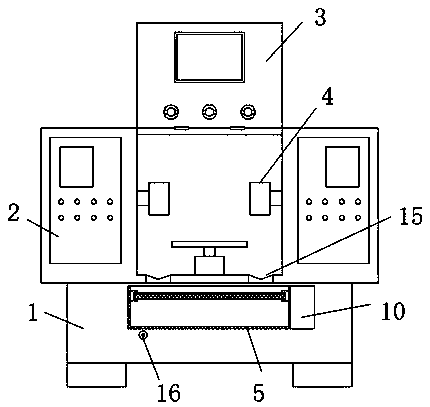

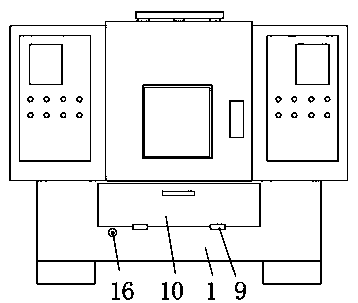

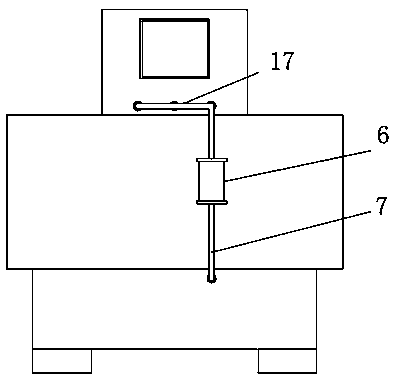

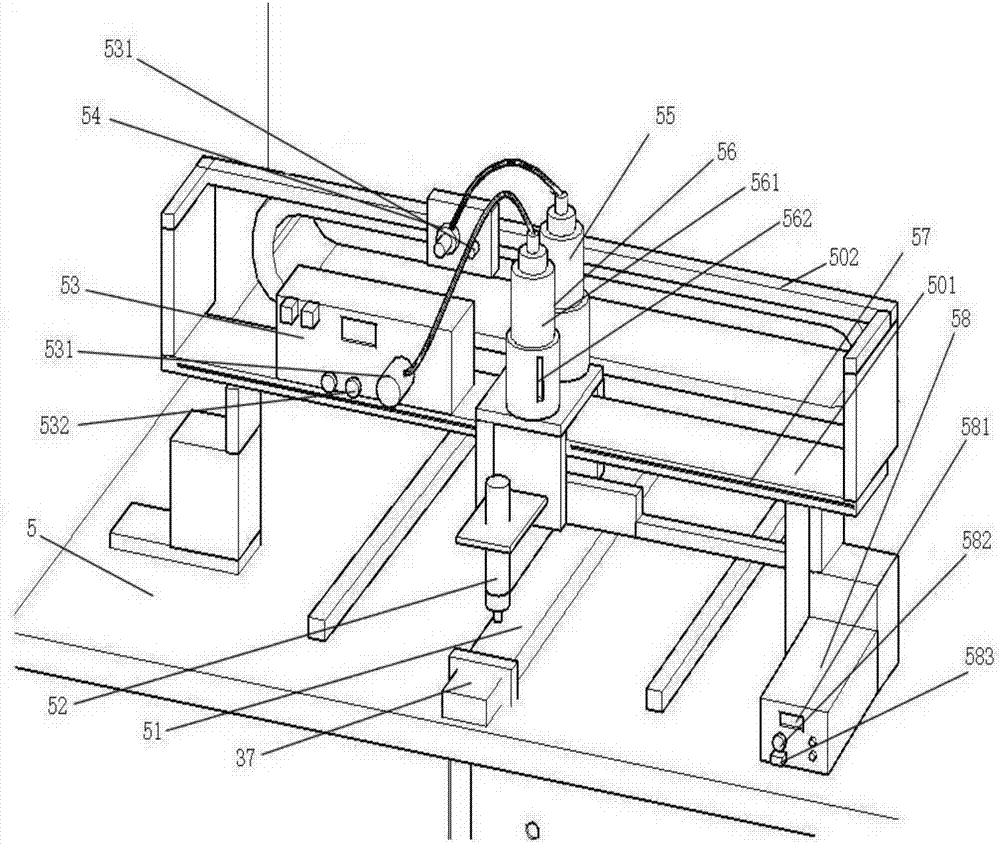

Numerically-controlled machine tool with automatic cleaning function

PendingCN110270541AReduce the hassle of manual cleaningRealize automatic controlCleaning using liquidsMaintainance and safety accessoriesNumerical controlMachine tool

The invention discloses a numerically-controlled machine tool with an automatic cleaning function in the technical field of numerically-controlled machine tools. The numerically-controlled machine tool with the automatic cleaning function comprises a numerically-controlled machine tool body and an automatic cleaning device used for cleaning the interior of the numerically-controlled machine tool body; the numerically-controlled machine tool body comprises a machine base, control boxes, a machine door and internal machining assemblies; and the automatic cleaning device comprises a water tank, a water pump, a water pipe and sprayer heads, the water pipe is sequentially connected with the water tank, the water pump and the sprayer heads, the water pump is used for pressing water in the water tank into the sprayer heads through the water pipe to clean the inner wall of the numerically-controlled machine tool body and the machining assemblies, and the water pump is electrically connected with the control boxes. The automatic cleaning device is additionally arranged in the numerically-controlled machine tool, therefore, the interior of the numerically-controlled machine tool can be quickly cleaned when machining is finished, next-time use is convenient, the trouble that the numerically-controlled machine tool needs to be manually cleaned by operating personnel is reduced, time and labor are saved, and the service life is prolonged.

Owner:三星智能科技盐城有限公司

Pickled vegetable pressing and desalting device

InactiveCN106962852AReduce labor intensityIncrease productivityFood scienceHydraulic cylinderBristle

The invention belongs to the technical field of pickled food or food materials, and particularly discloses a pickled vegetable pressing and desalting device. The pickled vegetable pressing and desalting device comprises a worktable, a pressing block, a pressing barrel, a hydraulic cylinder, a water inlet tube, a water outlet tube and a water storage tank, wherein the pressing barrel is fixed on the worktable; the pressing block is slidably connected to the inside of the pressing barrel; the water inlet tube and the water outlet tube respectively communicate with the water storage tank; a one-way valve which only can be opened towards one side of the water storage tank is arranged on the water inlet tube; a first valve is arranged on the water outlet tube; the inside of the water storage tank is slidably connected with a piston; the piston is provided with a linkage rod which is connected with the pressing block; a channel which communicates with the water storage tank and the pressing barrel is formed in the linkage rod; a second valve is arranged on the linkage rod; an annular brushing barrel is arranged on the upper surface of the pressing block; and bristles which are extruded by the outer wall of the pressing barrel are arranged on the inner wall of the brushing barrel. Pickled vegetables are pressed and desalted by the device, a water outlet hole can be prevented from being blocked, the trouble of cleaning is avoided, the pickled vegetables can be cleaned in a pressing process, and therefore, salinity of the pickled vegetables is reduced effectively.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Planing machine body of gantry planing machine

InactiveCN104354011AReduce work intensityImprove work efficiencyCleaning using toolsLarge fixed membersReciprocating motionPulp and paper industry

The invention relates to a planing machine body of a gantry planing machine. The planing machine body comprises a base, wherein horizontal guide rails are arranged on the planing machine body, a worktable is arranged on the guide rails and does reciprocating movement along the guide rails, horizontal through grooves are formed in the worktable and are used for fixing a workpiece, the bottom part of each through groove is provided with an inclined surface, and a chip receiving groove is formed in one end of the worktable, is positioned at the bottom end of each inclined surface, and is detachably connected with the worktable. The planing machine body has the beneficial effects that the worktable can do reciprocating movement, the certain vibration will be generated, and planing chips in each through groove will fall onto the bottom end of the corresponding inclined surface, and then fall into the corresponding chip receiving groove; the planing chips in the through grooves are automatically discharged into the chip receiving grooves.

Owner:CHONGQING XIHUA BELT PULLEY MACHINERY MFG CO LTD

Automatic vacuum garden dead leaf recovering machine

InactiveCN108672018AImprove practicalityPrevent fallingRoad cleaningGrain treatmentsDrive motorEngineering

The invention discloses an automatic vacuum garden dead leaf recovering machine which comprises a recovering opening. A draw-off pump is installed at the top end of the recovering opening, a tree branch filtering net is fixed above the draw-off pump, limiting rods are inlaid at the two ends of the draw-off pump, the top end of the draw-off pump is connected with a draw-off pipe, a smashing chamberis installed at the tail end of the draw-off pipe, a driving motor is arranged at the top end of the smashing chamber, the bottom end of the driving motor is connected with a scrapping rod, a dead leaf smashing rod is installed below the scrapping rod, a bottom sinking rod is arranged on the bottom side of the dead leaf smashing rod, a screening net is installed at the bottom end of the bottom sinking rod, an extrusion chamber is fixed below the screening net, and a conveying device is installed on the bottom side of the extrusion chamber. In the using process of the automatic vacuum garden dead leaf recovering machine, the groove-shaped recovering opening quickly sucks dead leaves to the inner side of the draw-off pipe, and the design of the tree branch filtering net can avoid tree branches from being brought into the inner side of the draw-off pipe.

Owner:叶群

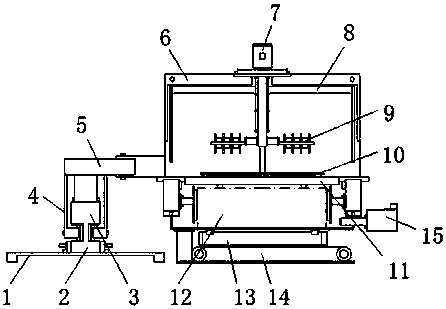

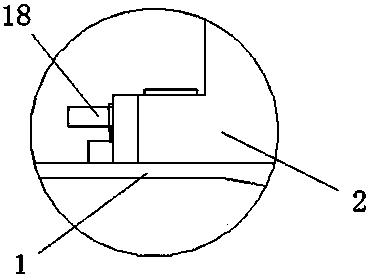

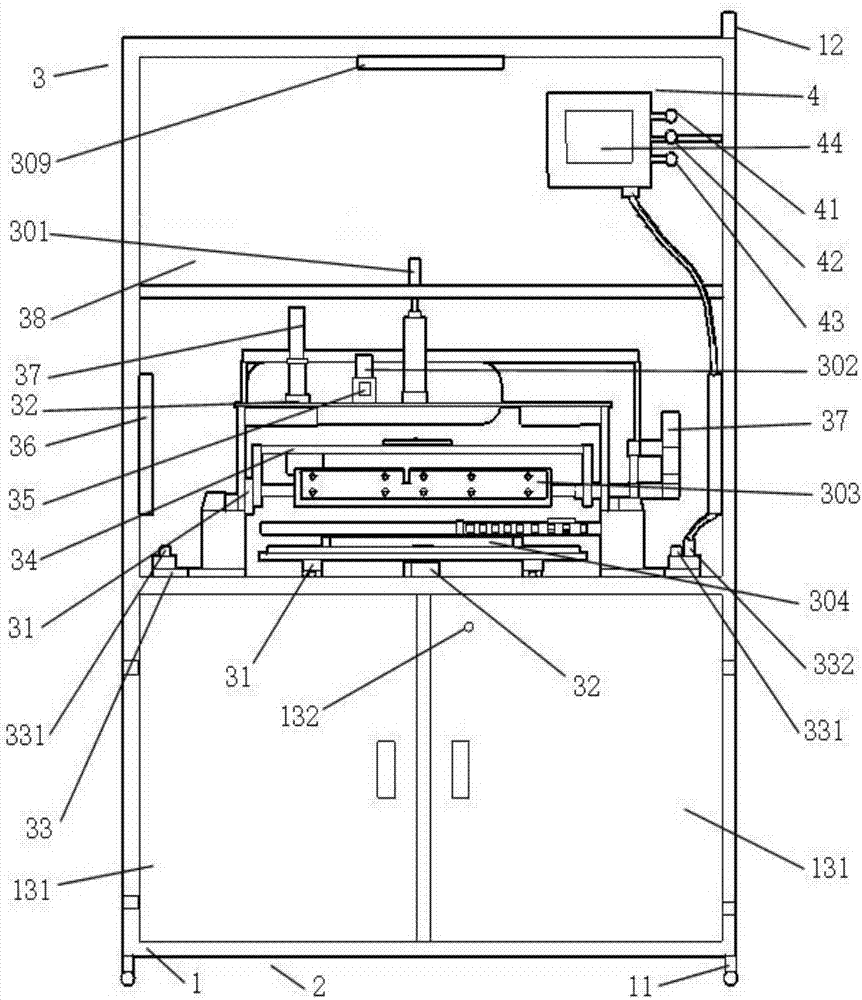

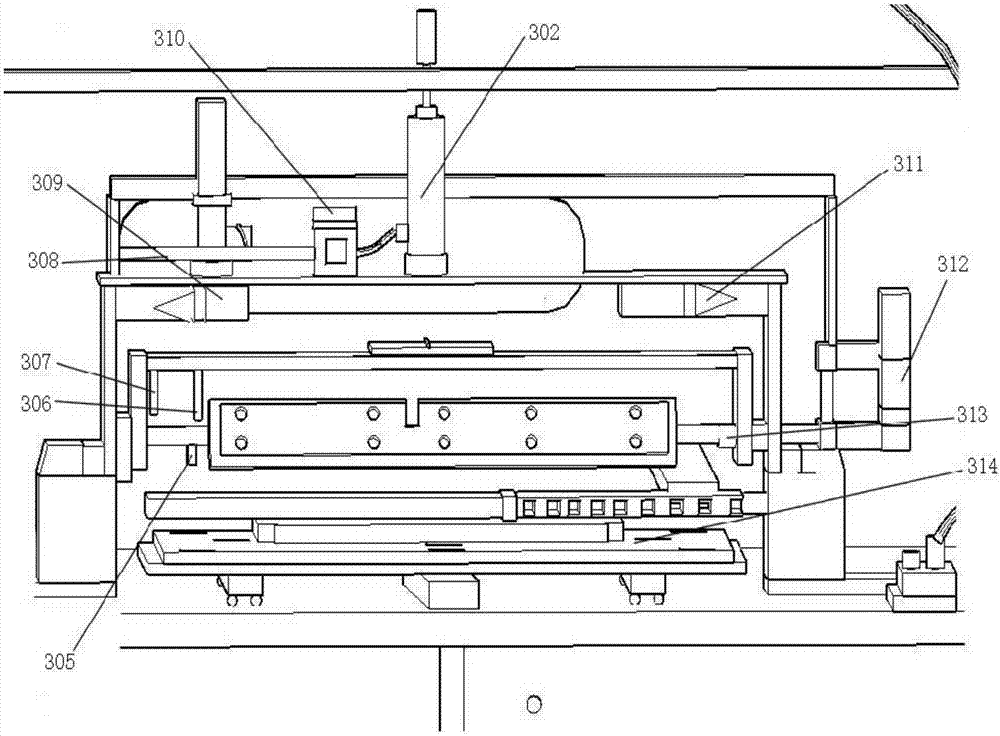

Automatic glue brushing and tape adhering device

InactiveCN107214050AEasy to placeEasy accessLiquid surface applicatorsCoatingsGratingLiquid-crystal display

The invention relates to an automatic glue brushing and tape adhering device. The device comprises a main frame, a lower frame, an upper frame, a liquid crystal display operation screen and a worktable, wherein the upper frame comprises a guide rail slide block, a moving and inserting die set, a button box, a press fitting die set, a digital-display pressure gauge, a safety optical grating, a servo motor, a protecting cover, an LED lighting lamp, a press fitting stroke adjustor, a press fitting cylinder, a tape jig, a product jig, a pre-pressing die set, a glue brushing gun, a washing gun, a vacuum absorbing jig, a supporting portal frame, a pressure regulating valve, a press fitting cylinder, a safety label, a rotating servo, a rotating die set and a material picking and positioning plate. The device has the advantages that the instability caused by manual washing, manual tape brushing and manual tape adhering can be avoided, and the working efficiency is increased; meanwhile, the product stability can be ensured through an automatic pressure controller; the automatic absorbing function is provided, so that the absorbing treatment can be carried out after washing and glue brushing, and as a result, the environmental protection is achieved.

Owner:SHANGHAI RONGNAN TECH CO LTD +2

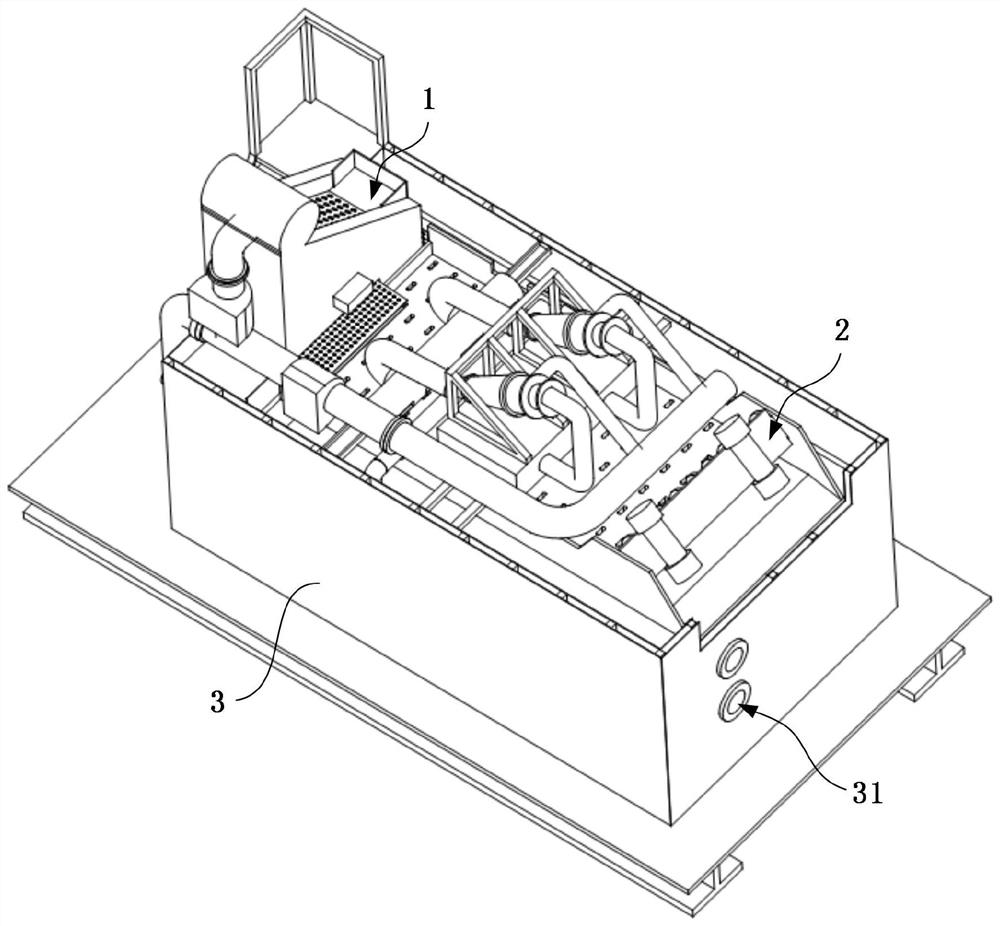

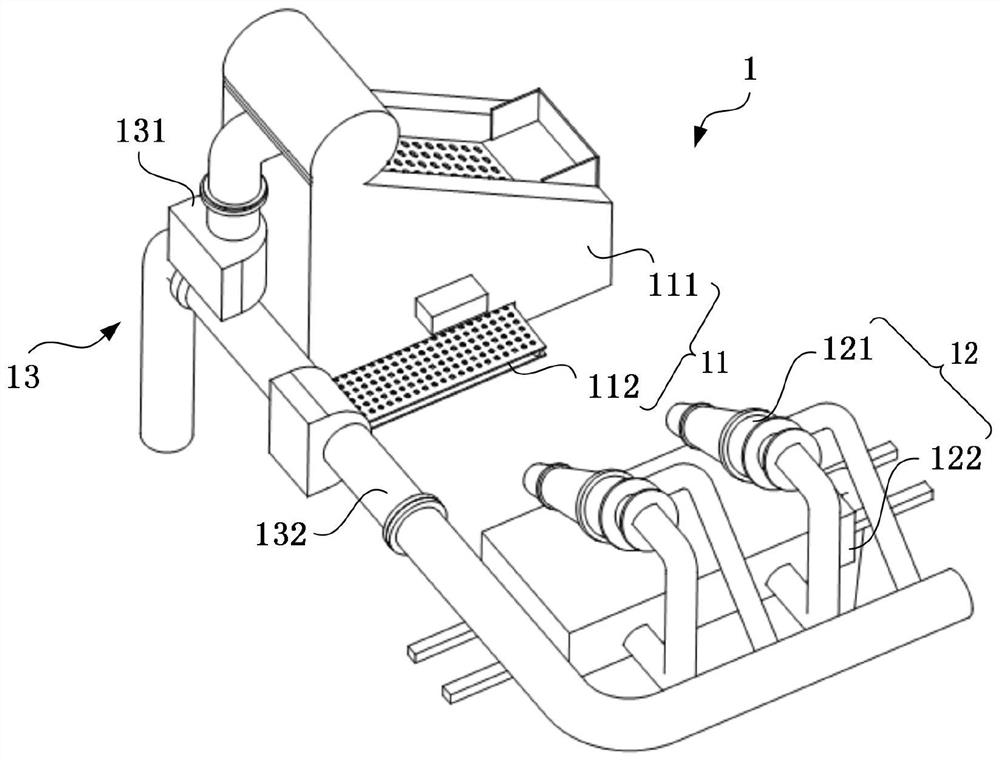

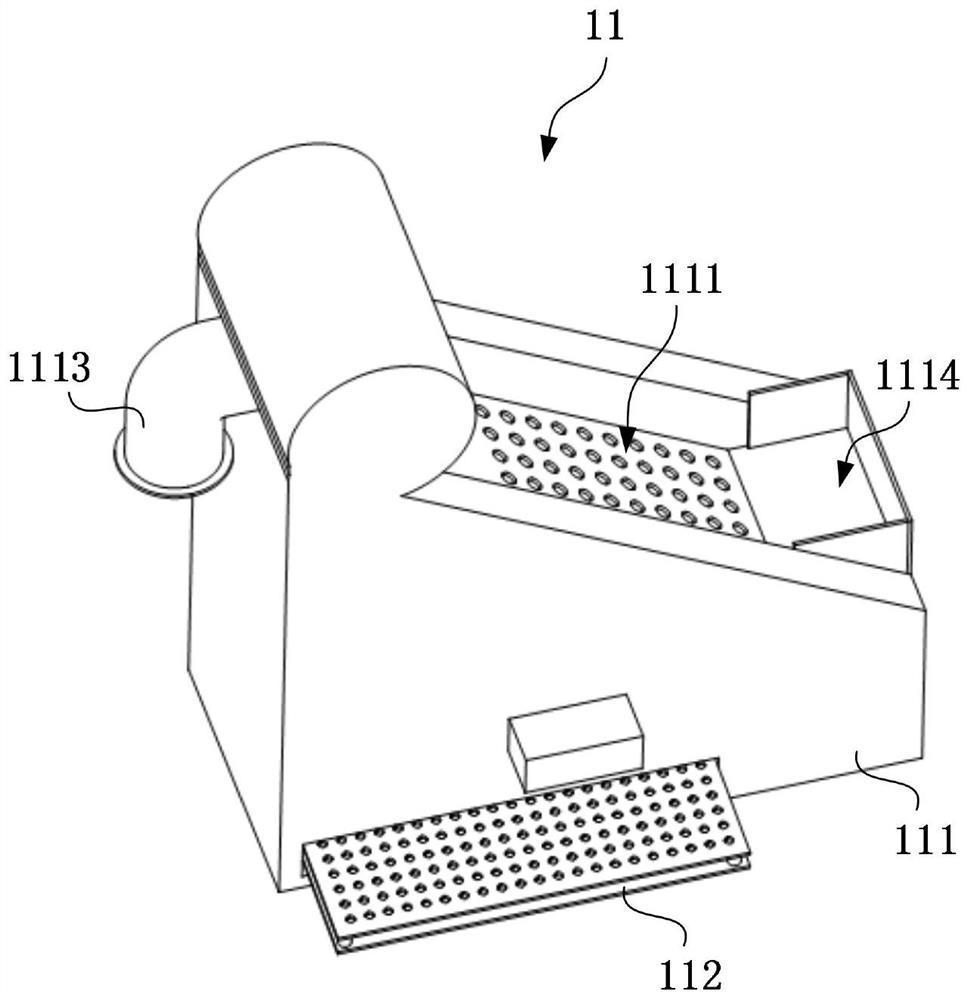

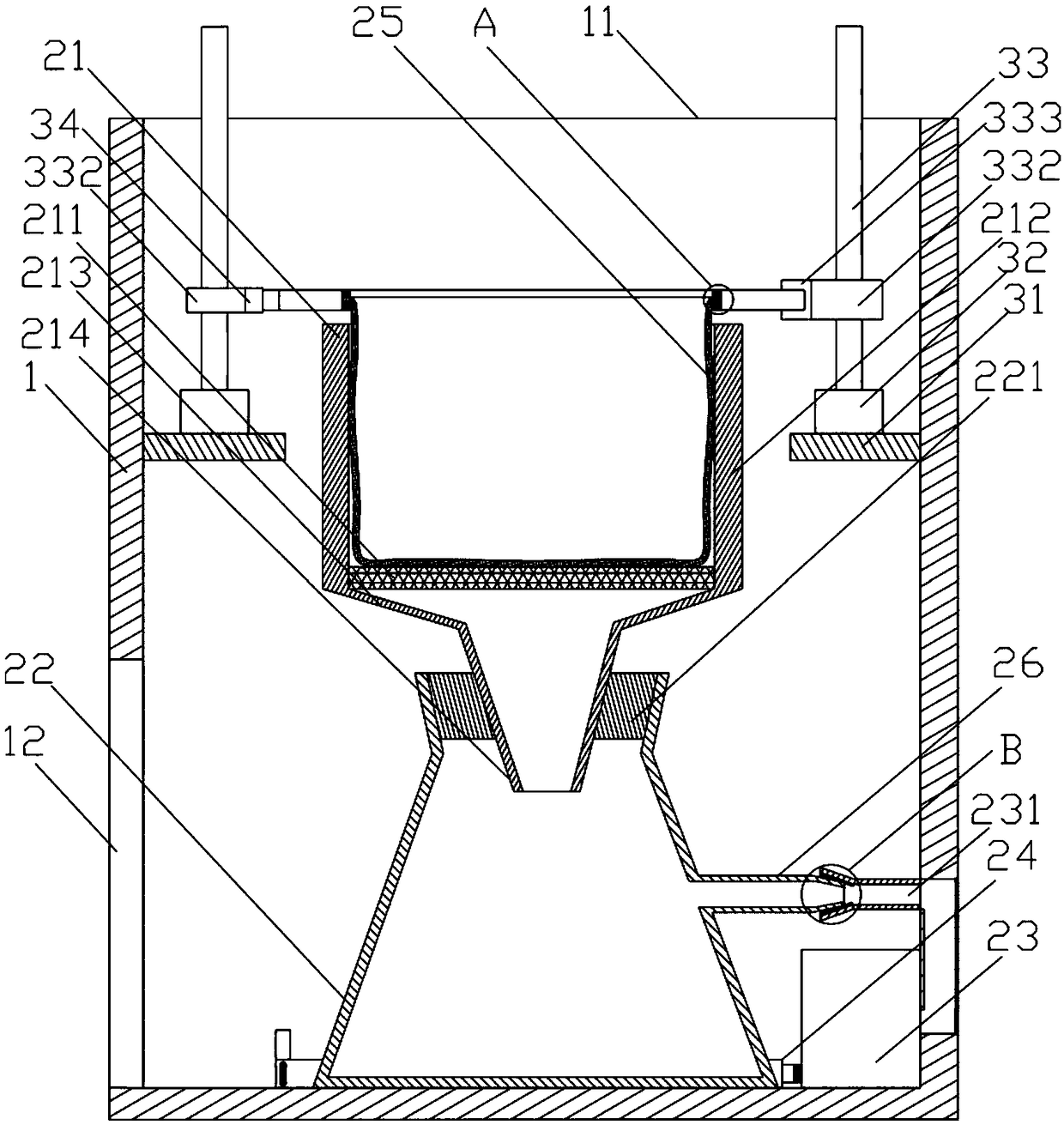

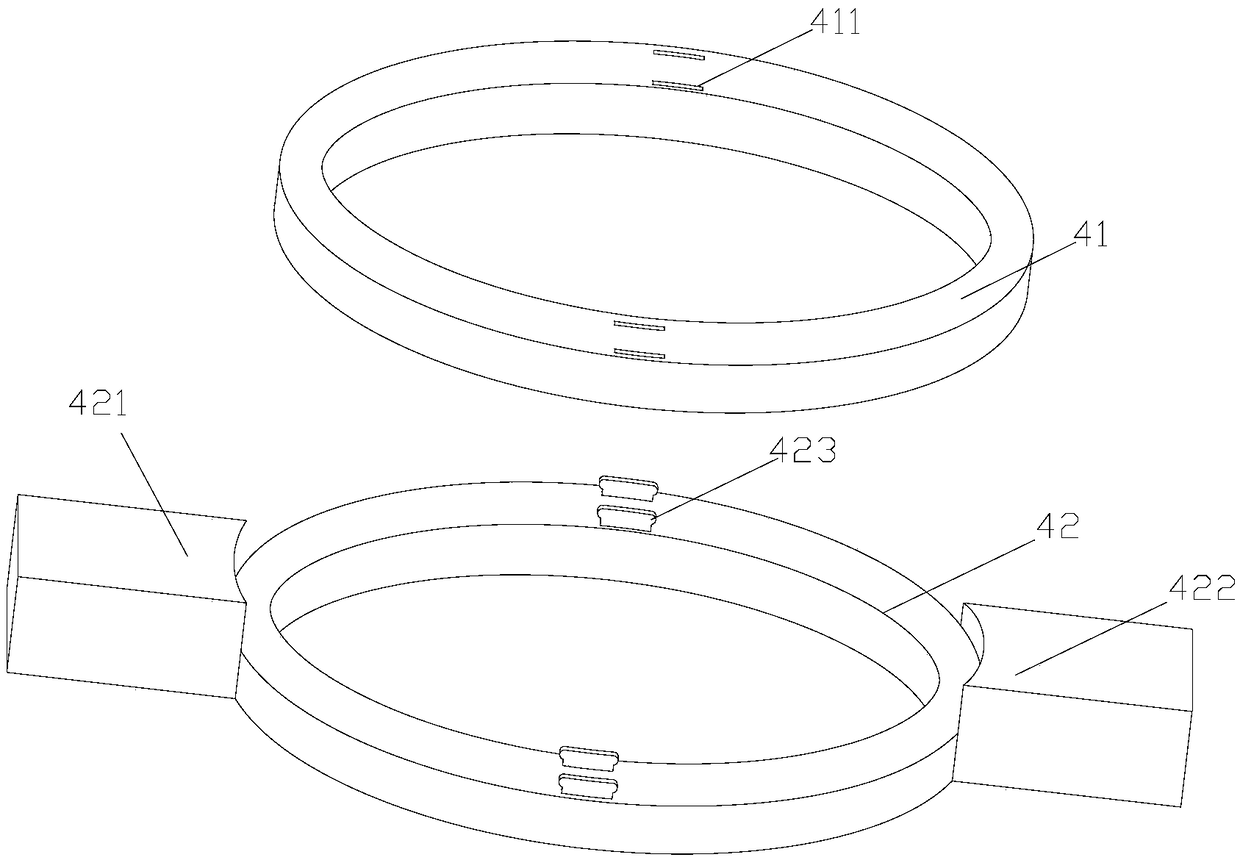

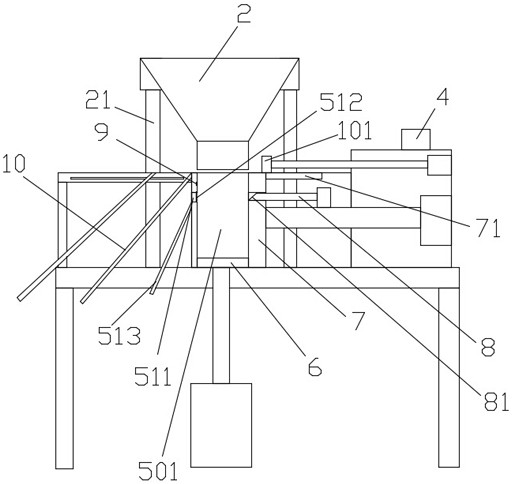

A casting mold separating device for pump casing casting

The invention discloses a casting mold separating device for casting and processing a pump casing, which relates to the technical field of auxiliary casting equipment. It consists of left and right longitudinal support plates and two transverse support connecting rods welded at intervals between the rear end sections of the two longitudinal support plates. The top half of the left and right longitudinal support plates are symmetrically welded with There are four vertical support rods, and two reciprocating screw rods are installed through the front half of the left and right longitudinal support plates, and the two reciprocating screw rods are rotated and located in the middle of the left and right vertical support rods; The top end of the vertical support rod is welded and fixed with a connecting frame in the shape of a bar. The two top blocks of the present invention can be rotated and pushed to drive the two L-shaped force-bearing members and the two mold frames to intermittently reciprocate up and down. The sticky foundry sand on the inner wall of the mold frame is thoroughly removed by vibration to solve the problem of a large amount of residual foundry sand.

Owner:诺沃机械南通有限公司

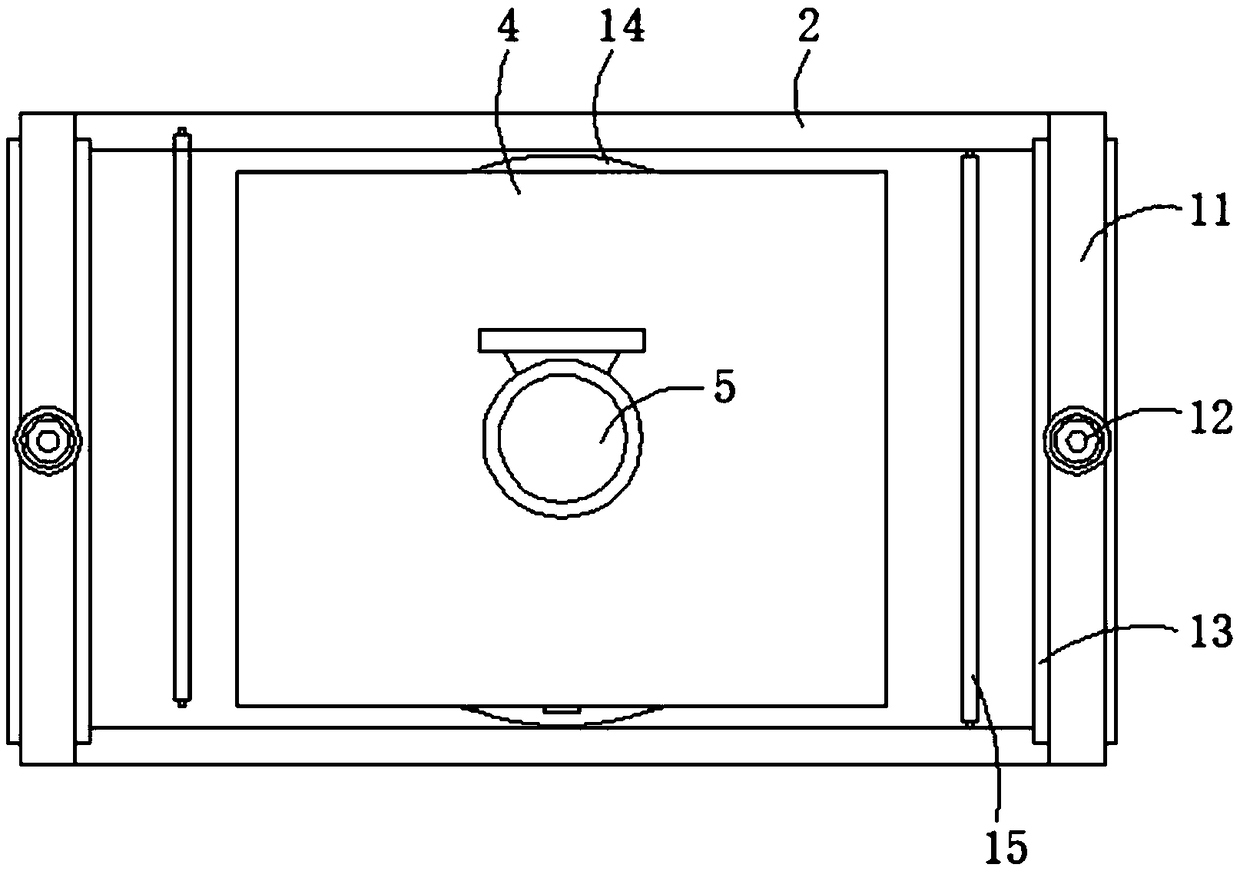

Optical parts adjusting device

The invention discloses an optical parts adjusting device. The device comprises a worktable and an adjusting plate; the adjusting pate is arranged in an inner cavity of the worktable, a motor is fixedly welded at a bottom wall of the worktable, a driving shaft is arranged between a motor and the adjusting plate; two groups of mutually parallel moving slots are formed on a top wall of the adjustingplate, an adjusting block and a first telescopic rod are arranged in the inner cavity of each group of moving slots; two mutually parallel clamping plates are arranged on the adjusting plate; a sliding chute is formed at one side of the top wall of the worktable, and a stretching rod and a sliding block are arranged in the inner cavity of the sliding chute. By arranging the sliding chute, the stretching rod, the sliding block, an upright, a transverse plate, a direction-adjusting shaft, and a blower, a fan and the stretching rod in the blower can work simultaneously to drive the blower to blow the air to various locations on the surface of the adjusting plate, thereby conveniently feeding the scraps produced by machining the parts into the inner cavity of a machining table in a unified manner, and the scraps can be discharged subsequently in the unified manner.

Owner:扬州辰亚光学科技有限公司

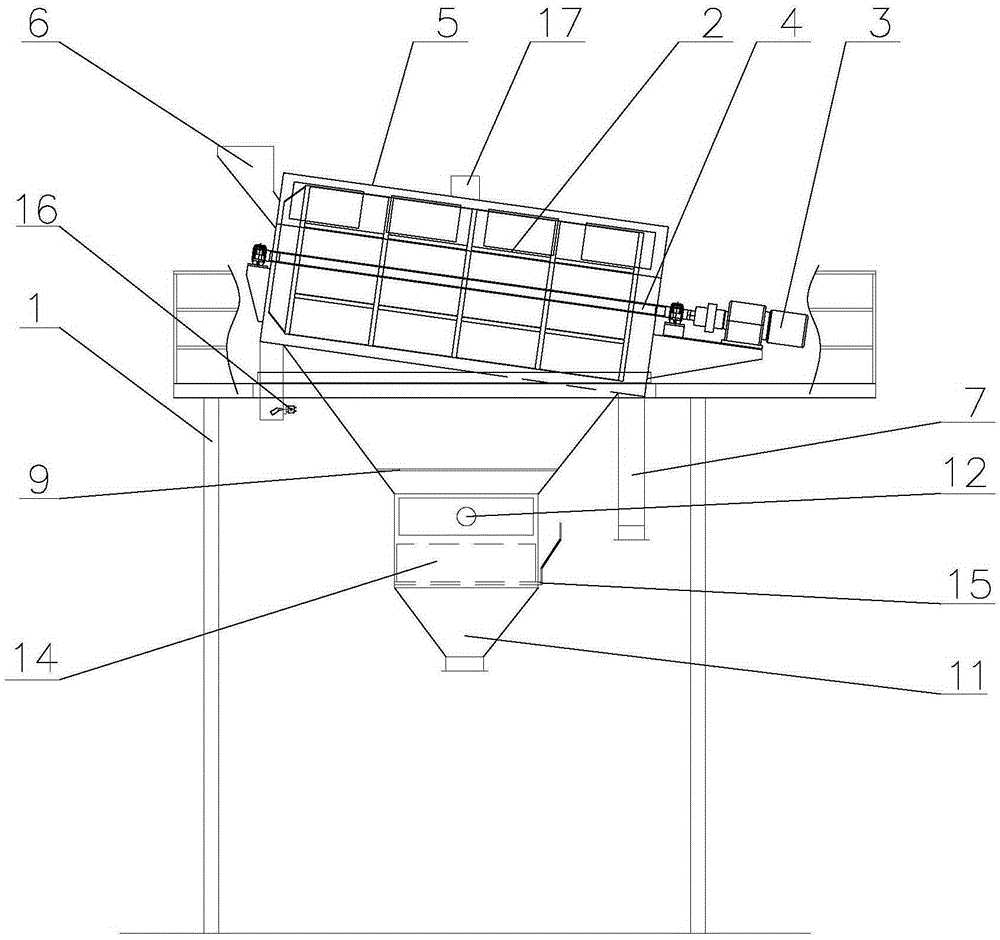

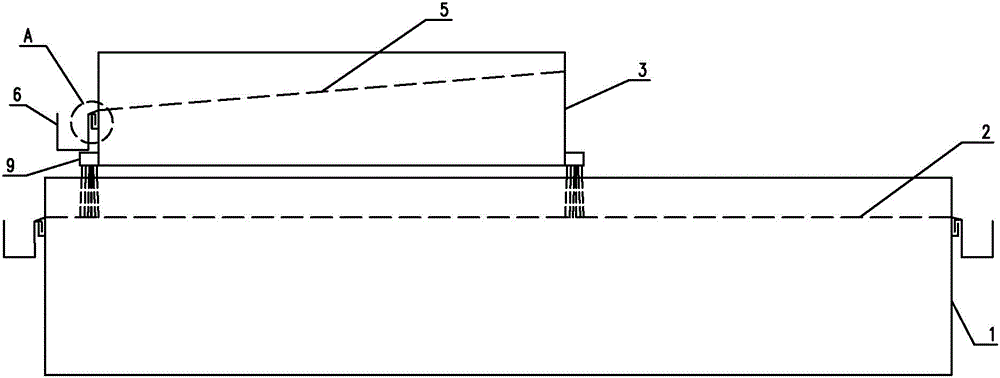

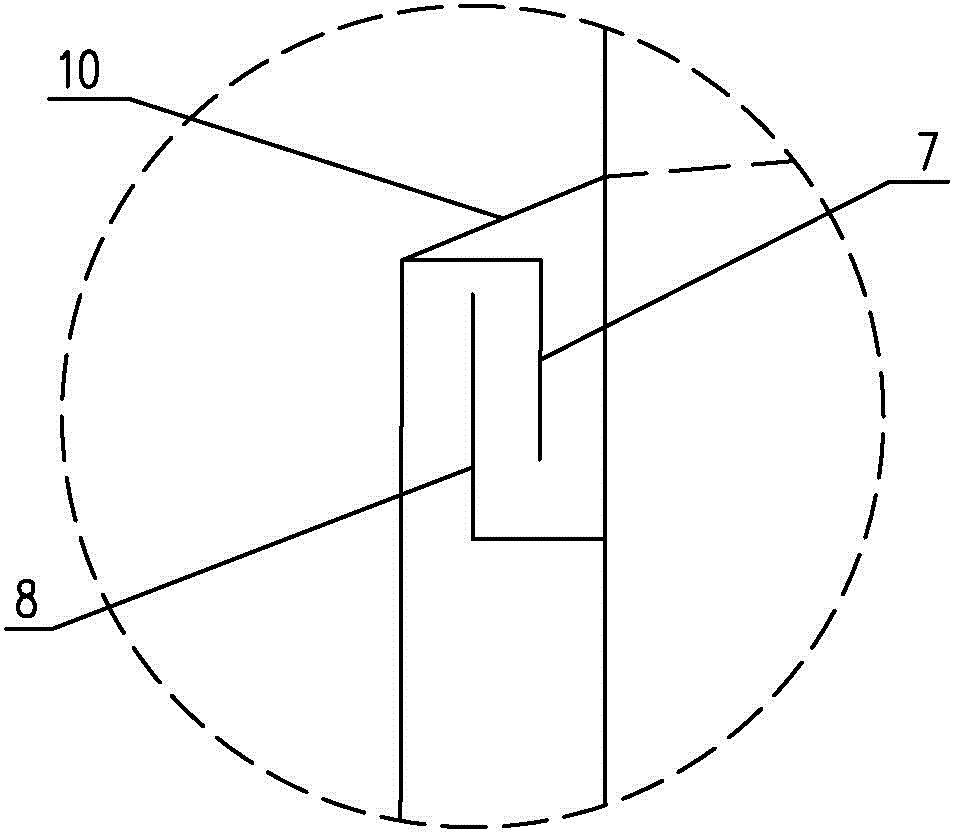

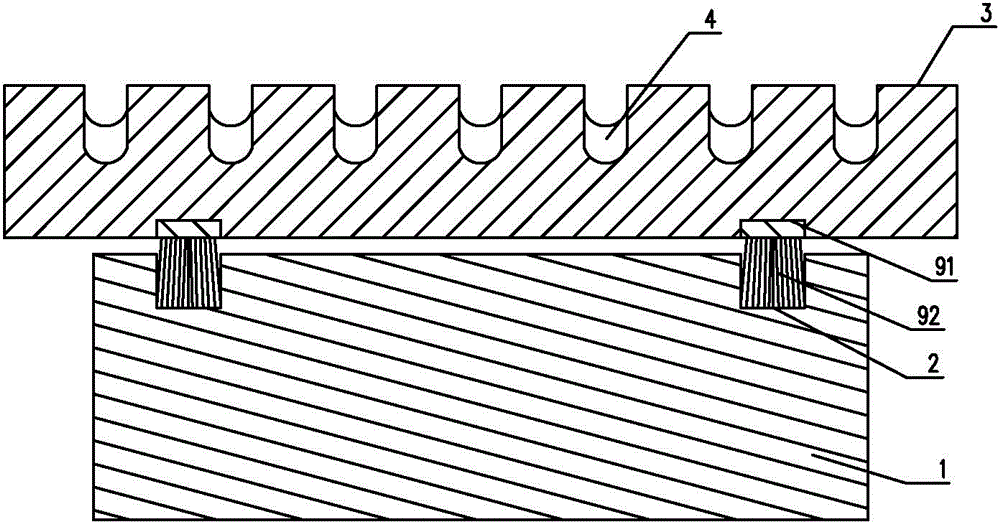

A non-burning brick-making equipment for making construction waste into bricks

ActiveCN110253719BStrong controllability of materialsImprove qualityFeeding arrangmentsShaping press ramBrickArchitectural engineering

The invention belongs to the field of brick making, and in particular relates to a burn-free brick making equipment for making construction waste into bricks. Including machine table, silo, cabinet and control device, the machine table is equipped with one or more semi-frame-shaped mold cavity channels with upper and lower sides and one end open. The cavity channel includes channel end plates and channel wall plates, and the bottom of the cavity channel There is a bottom pressing plate that can be raised and lowered along the mold cavity road, and a movable side pressing plate is inserted into the open end opposite to the end plate of the road. The opening, at least the feeding opening, is liftable against the mold cavity, and a through hole is opened on the side pressing plate, and a supporting plate that can extend into the mold cavity is provided in the through hole. This application has completely changed the traditional way of making bricks from construction waste. The vertical top is sealed with a top plate, and the bottom bottom plate pushes materials to make bricks, and the discharge port of the silo can not only reach the mold cavity. The frame of the present application is neat and tidy, and the material loss is less, and a small amount of surplus material pushed out by the abutting plate also leaks through the through hole for centralized recovery.

Owner:杭州钱江新城市政园林建设有限公司 +1

Anti-clogging trommel screen with secondary screening device

ActiveCN105344601BImprove utilization efficiencyReduce the hassle of manual cleaningSievingGas current separationPulp and paper industryUltimate tensile strength

The invention relates to the technical field of screening equipment, in particular to an anti-blocking type drum screen with a secondary screening device. The anti-blocking type drum screen mainly consists of a rack, a drum screen body, a rotary motor, a rotary shaft, an outer cover, a charge hole formed in one end of the outer cover, a waste discharge hole formed in the other end of the outer cover, anti-blocking devices and the secondary screening device positioned at the lower end of the outer cover; the drum screen body and the horizontal plane are arranged on the rack at an angle of 5-10 degrees; the rotary shaft is inserted into the drum screen body; one end of the rotary shaft passes through the drum screen body and is connected with the rotary motor; the outer cover covers the outer side of the drum screen body; and the plurality of anti-blocking devices are uniformly arranged on the outer surface of the outer cover. After adopting the structure, the screen can be cleared at fixed time by virtue of a pulse type air cannon, so that manual clearing trouble is avoided in case of not affecting using efficiency of the drum screen body, and therefore, labor intensity is reduced; and the secondary screening device can be utilized to further screen materials, and materials in precise proportion are obtained by virtue of a collecting and mixing regulating plate, so that the utilization efficiency of the drum screen body is improved.

Owner:JIANGSU WOLVES MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com