A non-burning brick-making equipment for making construction waste into bricks

A construction waste and equipment technology, applied in the field of non-fired brick making equipment, can solve the problems of difficult to control the amount of materials and large deviation of brick density, so as to reduce the trouble of manual cleaning, the quality of finished bricks is good, and the production efficiency of equipment is high Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

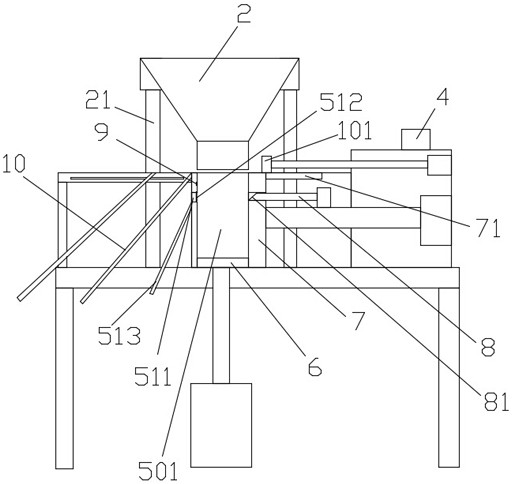

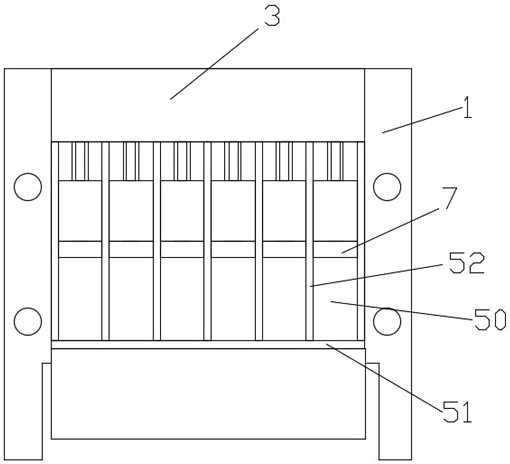

[0033] A non-fired brick-making equipment for making construction waste into bricks, including a machine 1, a silo 2, a cabinet 3 and a control device 4, and the machine is provided with one or more upper and lower sides and one end open The semi-frame-shaped mold cavity road 50, the mold cavity road includes a road end plate 51 and a road wall plate 52, the bottom of the mold cavity road is provided with a bottom pressure plate 6 that can be raised and lowered along the mold cavity road, opposite to the road end plate A movable side pressure plate 7 is inserted into the open end of the open end, and the bottom pressure plate, the side pressure plate and the mold cavity channel cooperate to form a mold cavity 501. On the mold cavity, a through hole is opened on the side pressure plate, and a resisting plate 8 that can extend into the mold cavity is arranged in the through hole.

[0034] Corresponding to the height of the abutment plate, there is a alignment hole 511 on the end...

Embodiment 2

[0038] The difference from the above embodiment is that the outer side of the channel end plate is provided with a sloping material guide plate 513 corresponding to the lower edge of the alignment hole, and a material collecting structure is arranged below the sloping material guide plate at the bottom of the machine table. The collecting structure can be a structure such as a material box or a material conveyor belt.

[0039]The feed bin is set up and down above the machine platform through a lifting mechanism, and the feed bin is set on the machine table through lifting feet 21, and the lifting feet are connected with telescopic cylinders. The lifting equipment of the material bin is convenient for the observation, operation or maintenance of the mold cavity, and at the same time, the bricks can be taken out from the top of the mold cavity. The top of the cavity is removed.

Embodiment 3

[0041] The difference from the above-mentioned embodiment is that a height limit alarm device 9 for controlling the automatic feeding amount of the feeding bin is provided in the area of the cavity channel higher than the abutment plate. When the amount of material is greater than the amount of bricks, it can be controlled by the height limit alarm device, which can be an infrared induction device or a touch switch. Once it reaches this position, it will send a signal to the control device. The silo stops feeding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com