Workshop system and technology for producing aluminum hydroxide from corrosive wash liquid

An aluminum hydroxide and generation system technology, applied in the field of aluminum processing, can solve the problems of waste of resources, environmental hazards, and increased tank voltage, and achieve the effects of reducing labor intensity, restoring production capacity, and reducing cleaning water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

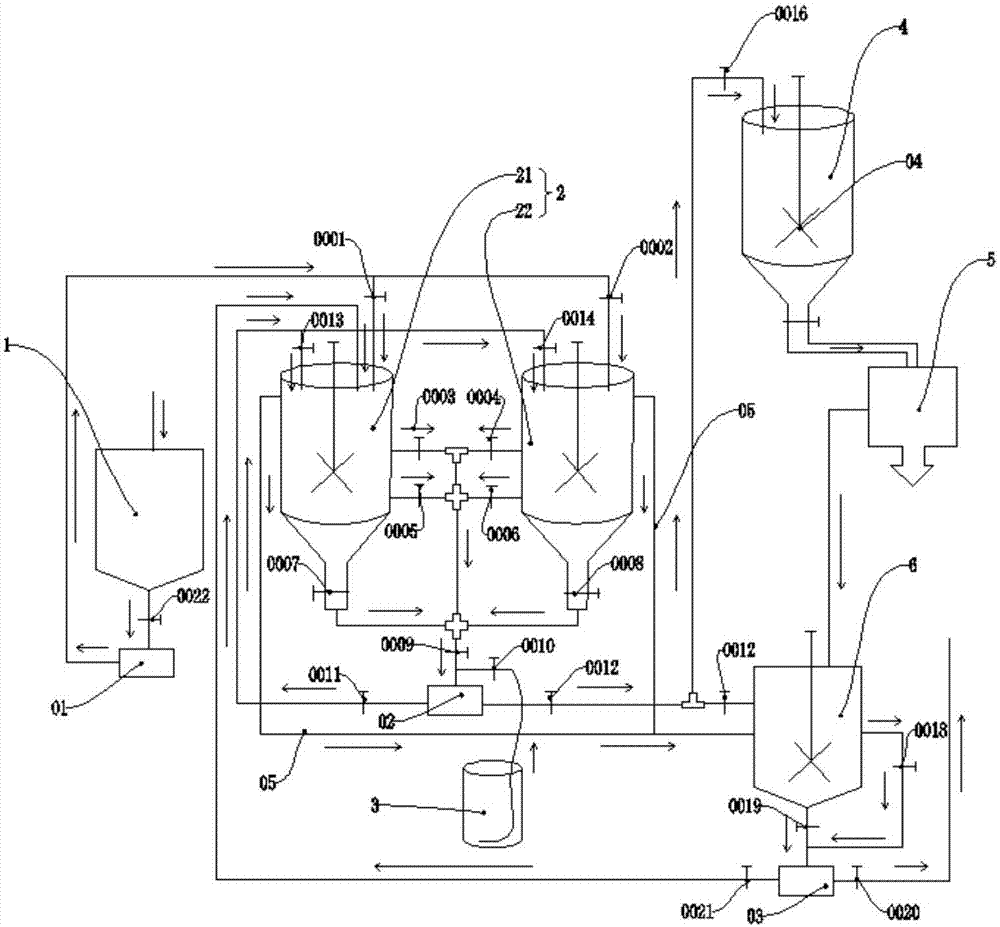

[0096] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0097] Theoretical basis for the recovery of aluminum ions from pot mold waste liquid to produce aluminum hydroxide:

[0098] When the mold is potted, the aluminum material in the abrasive tool undergoes the following chemical reaction in the alkaline etching solution:

[0099] al 2 o 3 +2NaOH=2NaAlO 2 +H 2 O (Natural Oxide Removal) (1)

[0100] 2Al+2NaOH+2H 2 O=2NaAlO 2 +3H 2 ↑(melted aluminum) (2)

[0101] NaAlO 2 +2H 2 O=Al(OH) 3 ↓+NaOH (bath solution decomposition, regenerated lye) (3)

[0102] 2Al(OH) 3 =Al 2 o 3 .3H 2 O (scaling on the tank wall, clogged pipes) (4)

[0103] According to the two formulas (1) and (2), the higher the alkali concentration, the faster the aluminum dissolution rate; according to the two formulas (3) and (4), the potting liquid is unstable, easy to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com