Aluminum profile cutting equipment

A technology for cutting equipment and aluminum profiles, which is used in metal processing equipment, clamping, and supporting. It can solve the problems of inconvenient cleaning of the surface of profiles and inconvenient clamping, and achieve the effects of fast clamping, reduced vibration and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

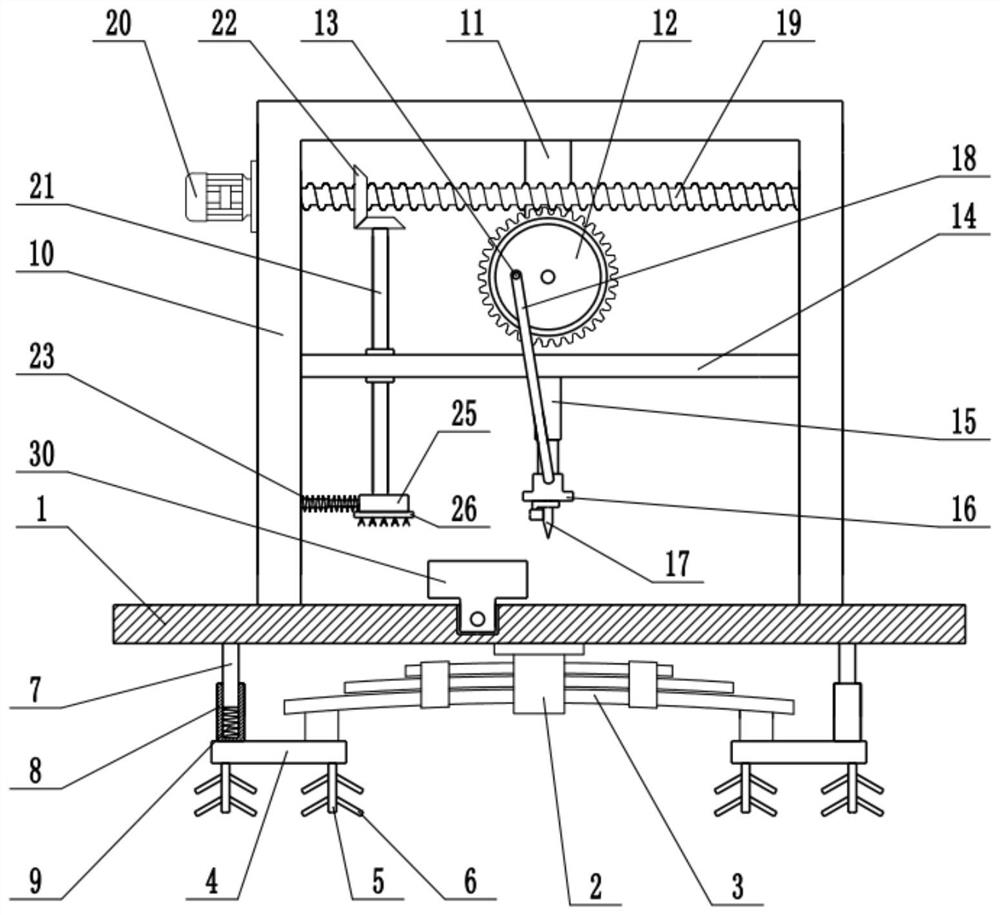

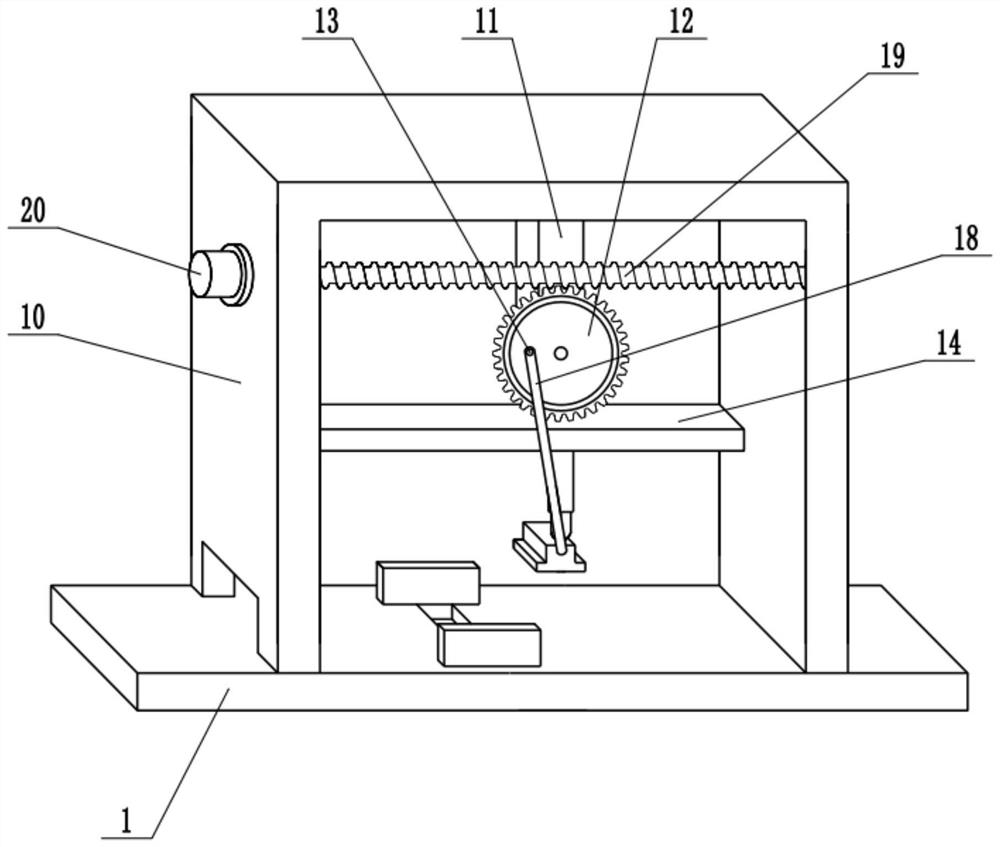

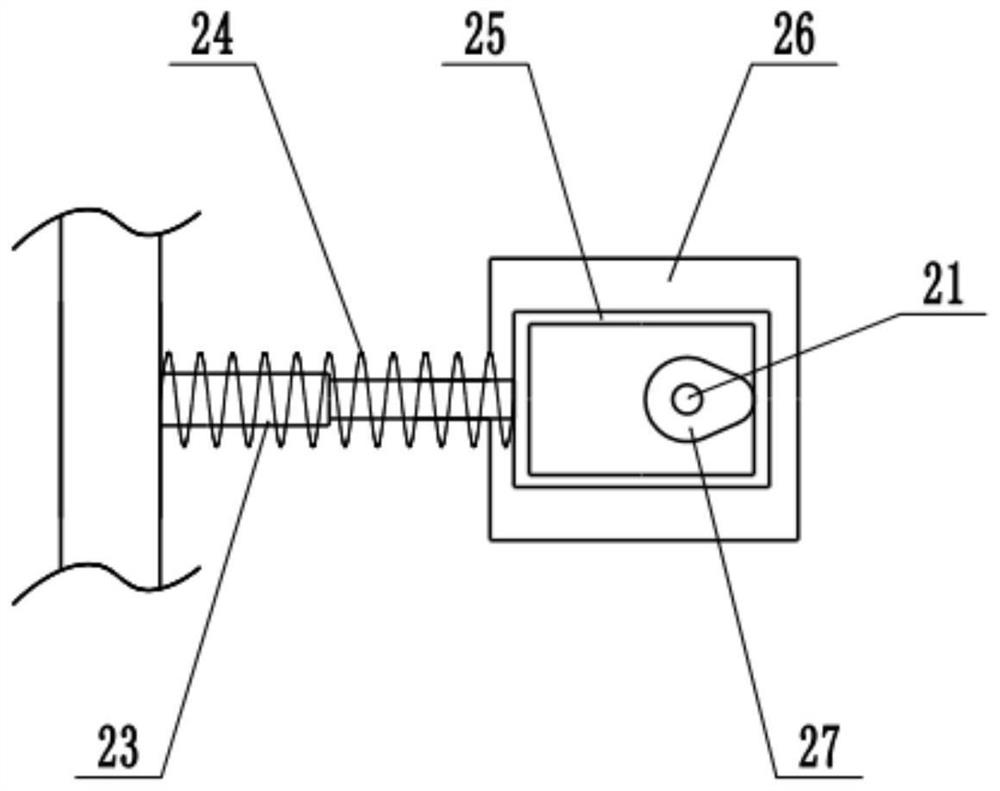

[0023] see Figure 1-4 , in an embodiment of the present invention, an aluminum profile cutting equipment includes a fixed table 1, a fixed frame 10, a mounting plate 14, a lifting seat 16 and a cutting machine 17, the upper surface of the fixed table 1 is fixedly connected with a fixed frame 10, and the fixed frame The top of 10 is fixedly connected with bracket 11, and the lower end of bracket 11 is connected with worm wheel 12 in rotation, and the surface of worm wheel 12 is fixedly connected with fixed rod 13 near the edge, and the bottom of worm wheel 12 is provided with mounting plate 14, and the two ends of mounting plate 14 and The inner wall of the fixed frame 10 is fixedly connected, the lower surface of the mounting plate 14 is fixedly connected with the first telescopic guide rod 15, the lower end of the first telescopic guide rod 15 is fixedly connected with the lifting seat 16, and the lower surface of the lifting seat 16 is equipped with a cutting machine 17 , t...

Embodiment 2

[0025] On the basis of Embodiment 1, a shock absorbing mechanism is installed on the bottom of the fixed table 1, and the shock absorbing mechanism includes a mounting bracket 2, a leaf spring 3, a support plate 4, a support rod 7, a sleeve 8 and a shock absorbing spring 9, and the fixed table The bottom of 1 is fixedly connected with a mounting frame 2, a leaf spring 3 is installed on the mounting frame 2, a supporting plate 4 is installed at the end of the leaf spring 3, the supporting plate 4 is connected to the ground, and the lower surface of the supporting plate 4 is fixedly connected with Fixed pile 5, fixed rod 6 is distributed on the fixed pile 5, fixed pile 5, fixed rod 6 are embedded in the ground, utilize fixed pile 5, fixed rod 6 to improve the stability of this device, utilize plate spring 3 to play the function of shock absorption Function, the lower surface of the fixed table 1 is fixedly connected with a support rod 7, the lower end of the support rod 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com