Bucket elevator capable of avoiding material residues

A bucket elevator and material technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high cost and hazards of returning bucket elevators, and can extend the distance, avoid material scattering, and facilitate cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Various exemplary embodiments of the present invention will now be described in detail. The detailed description should not be considered as a limitation of the present invention, but rather as a more detailed description of certain aspects, features and embodiments of the present invention.

[0028] It will be apparent to those skilled in the art that various modifications and changes can be made in the specific embodiments of the present invention described herein without departing from the scope or spirit of the present invention. Other embodiments will be apparent to the skilled person from the description of the present invention. The specification and examples in this application are exemplary only.

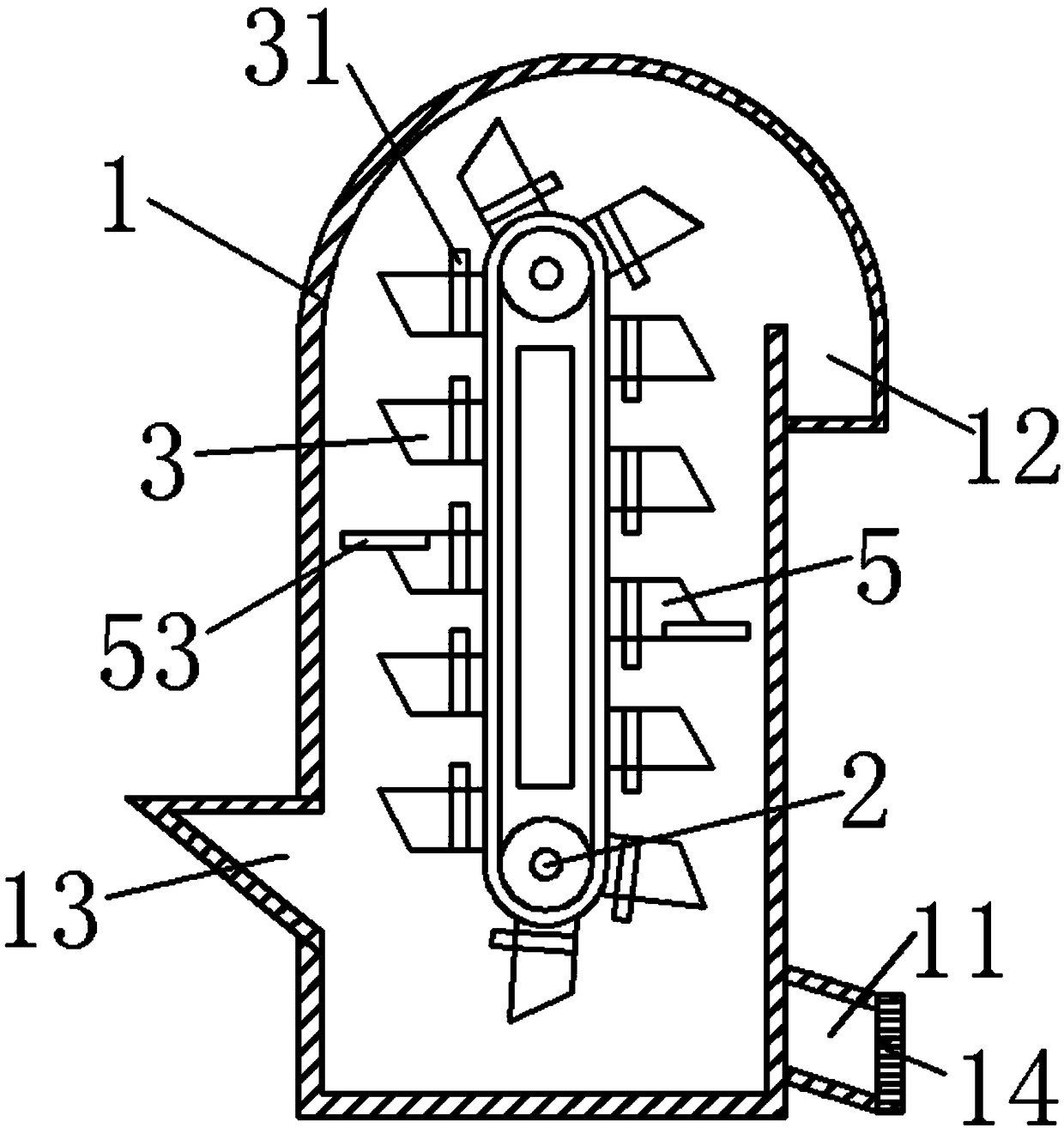

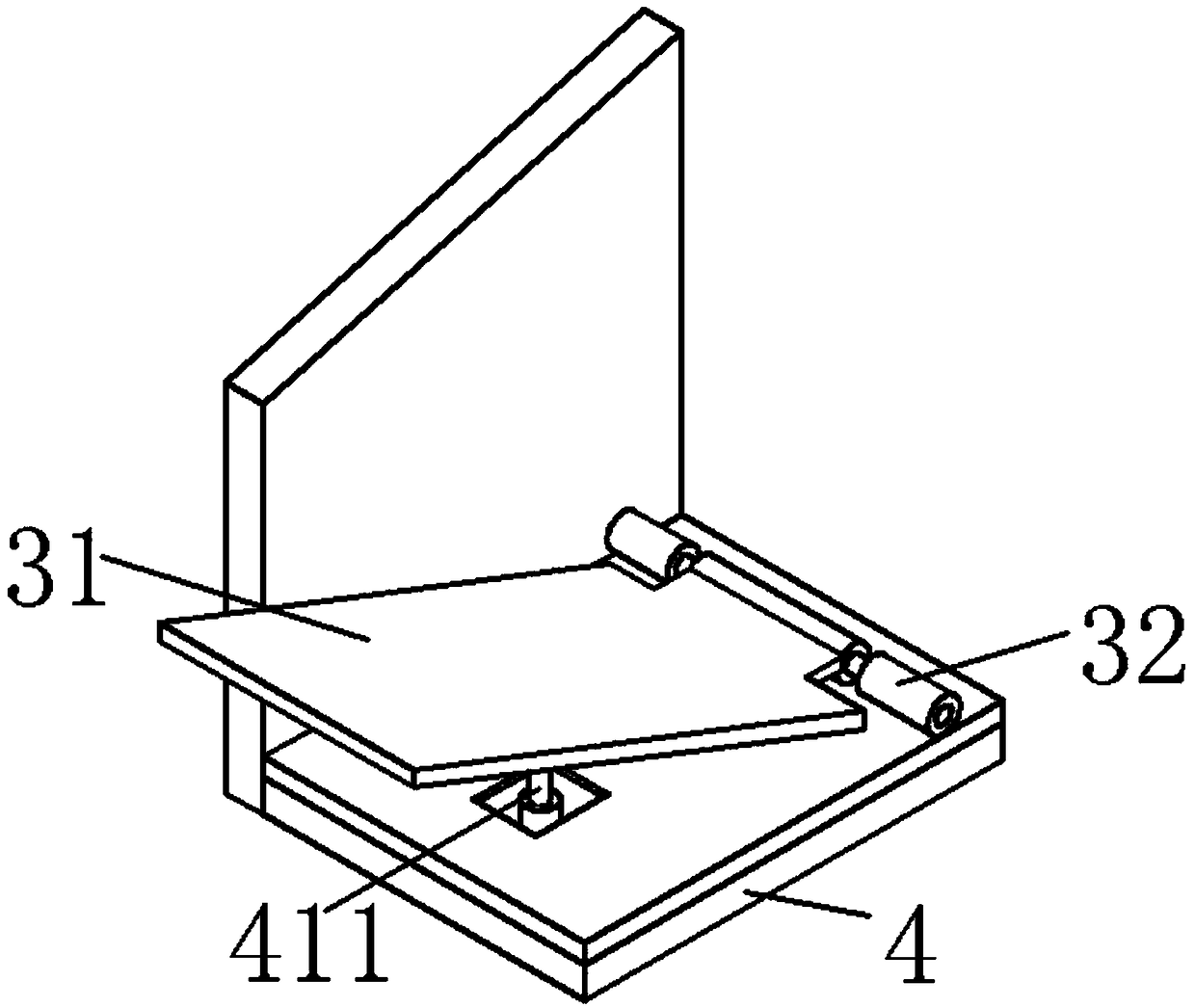

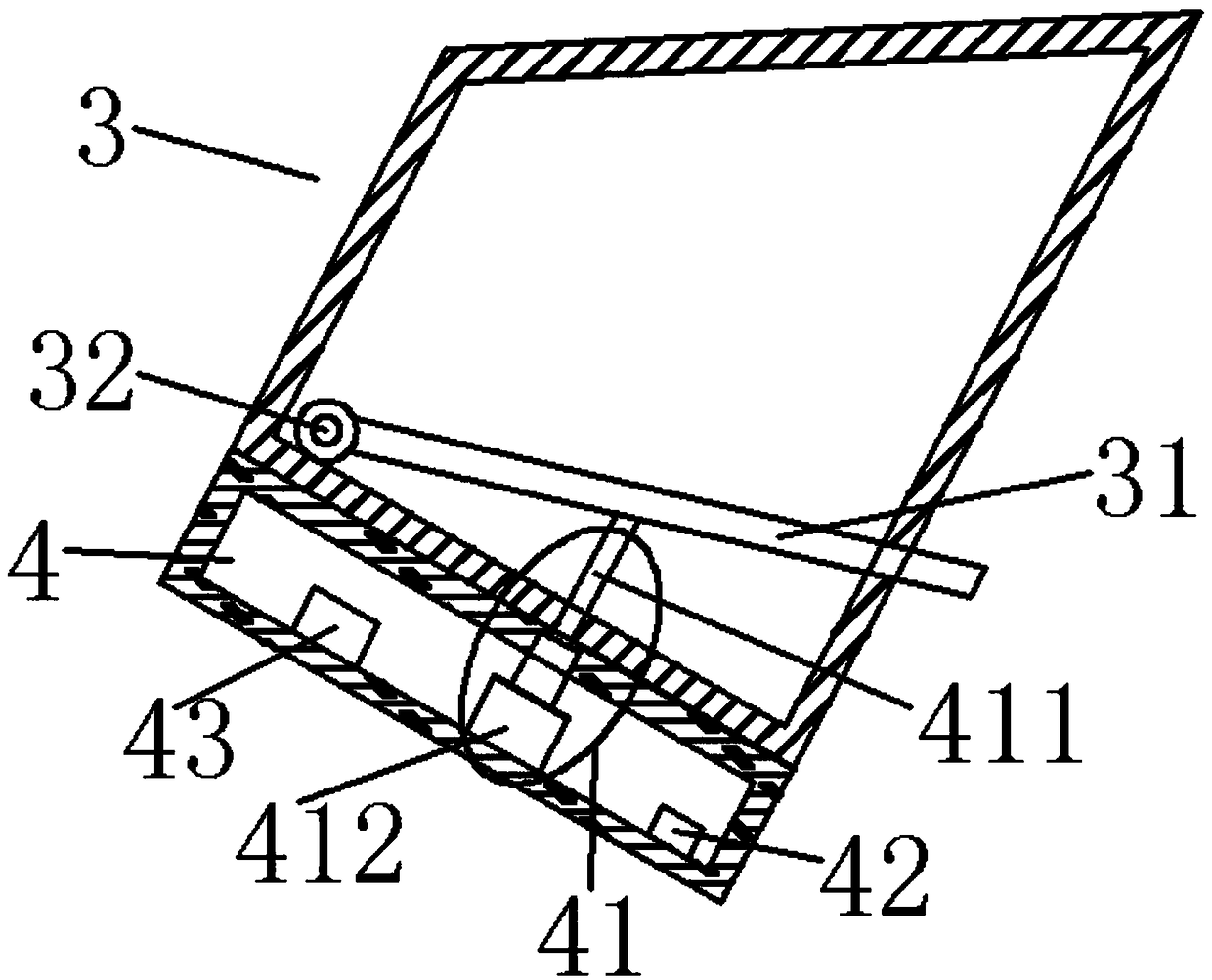

[0029] Examples, please refer to the attached Figure 1-6 , a bucket elevator to avoid material residue, including a casing 1, a traction mechanism 2, and a plurality of feeding hoppers 3 fixed on the traction mechanism 2, one side of the feeding hopper 3 is fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com