Setting machine and cloth production process using setting machine

A sizing machine and fabric technology, applied in the field of sizing machines, can solve problems such as polluting the working environment, dripping lubricating oil, uneven refueling, etc., and achieve the effect of convenient operation, simple connection, and less trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

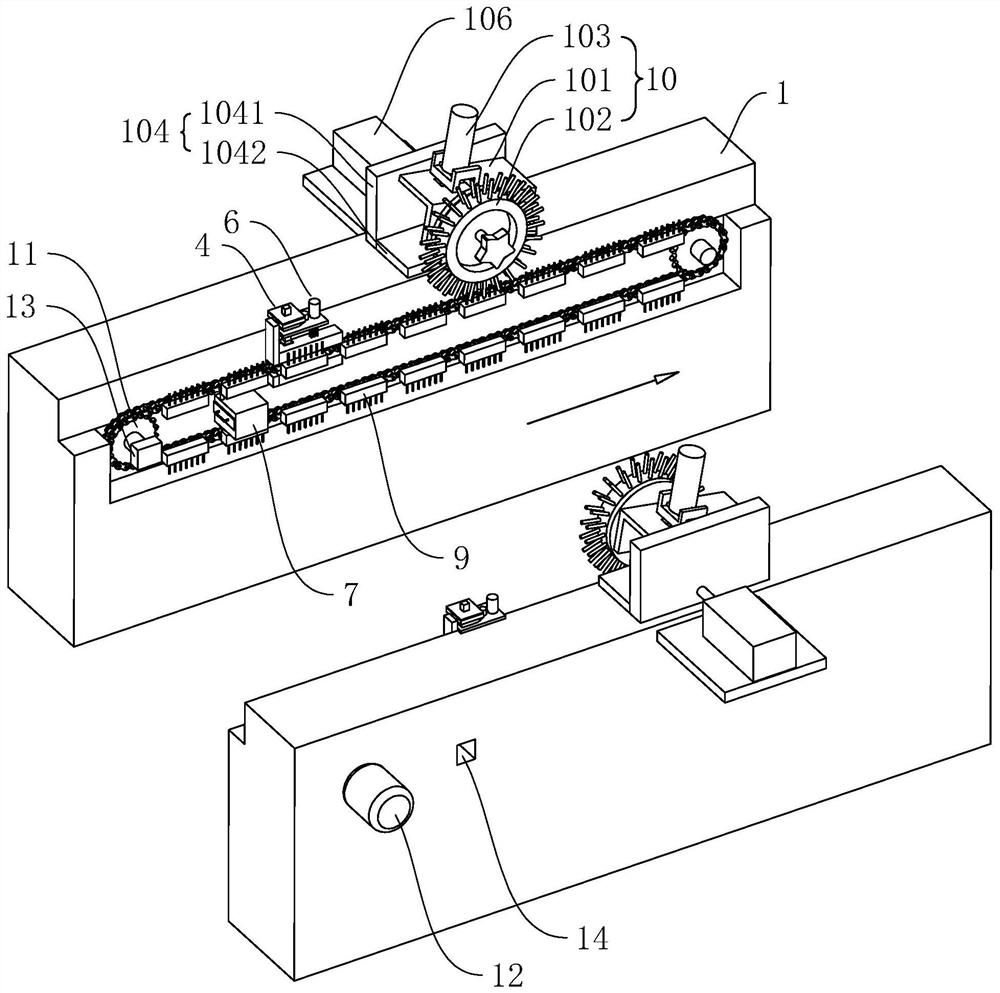

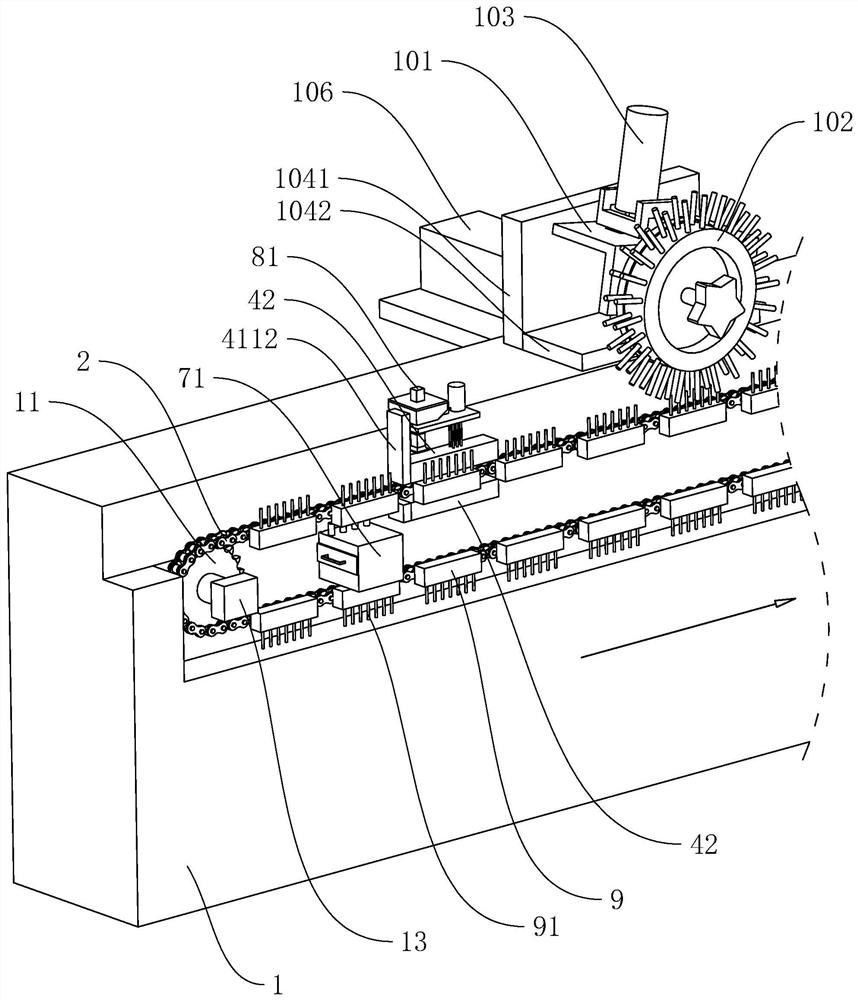

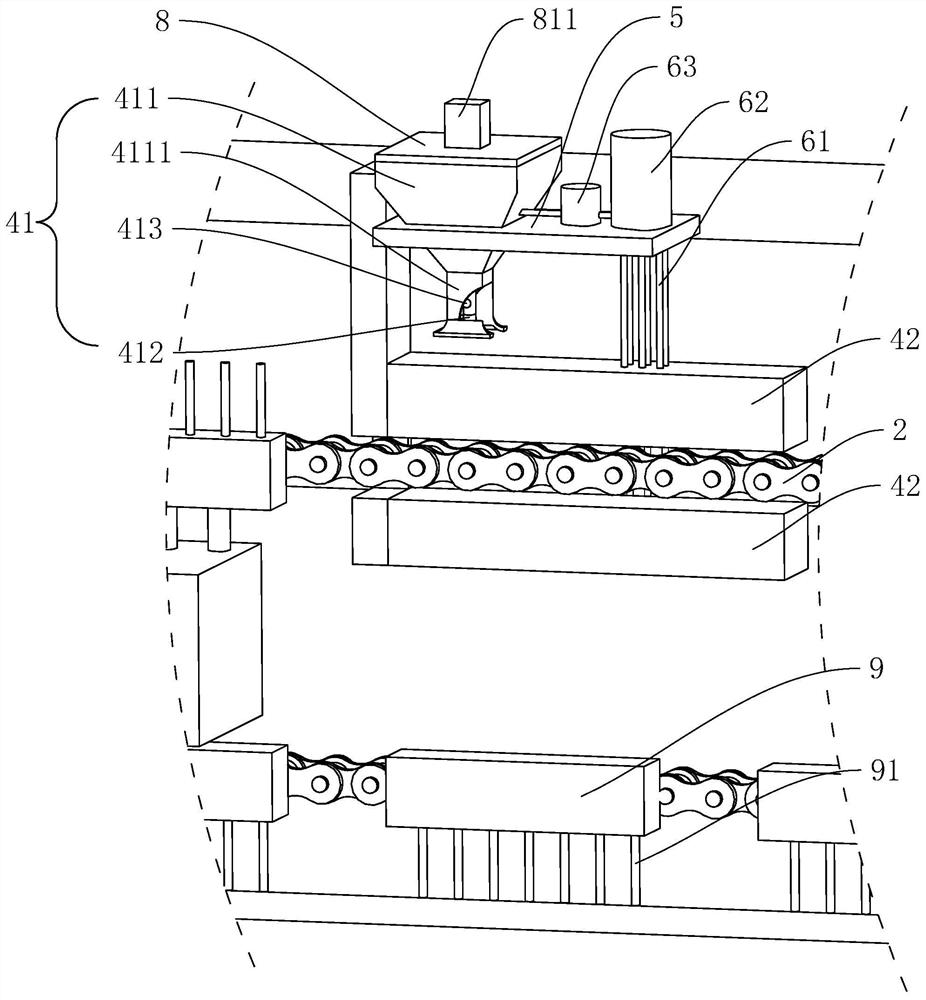

[0066] The following is attached Figure 1-6 The application is described in further detail.

[0067] The embodiment of this application discloses a setting machine, wherein the control system is a PLC control cabinet, the speed sensor is a BH60 series RS485 encoder 13, and the flow meter is an LDG-SIN electromagnetic flowmeter 413.

[0068] refer to figure 1 and figure 2 , including a frame 1 and a chain 2, and a sprocket 11 is installed on the two ends of the length direction of the frame 1 for rotation respectively. The chain 2 is disposed between the two sprockets 11 and the chain 2 is engaged with both sprockets 11 . One of the sprocket wheels 11 is driven to rotate by a drive motor 12, and the sprocket wheel 11 is connected to the drive motor 12 through a belt transmission. The driving motor 12 is fixed on the frame 1 , and the output shaft of the driving motor 12 is keyed to the rotating shaft of the sprocket 11 . During work, the chain 2 moves toward the oven of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com