Automatic glue brushing and tape adhering device

A technology of automatic brushing and equipment, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of inability to realize fully automatic brushing of equipment, uneven brushing, impact on human health, etc., and achieve a convenient and fast operation mode , technical data and upload, parameter setting humanized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

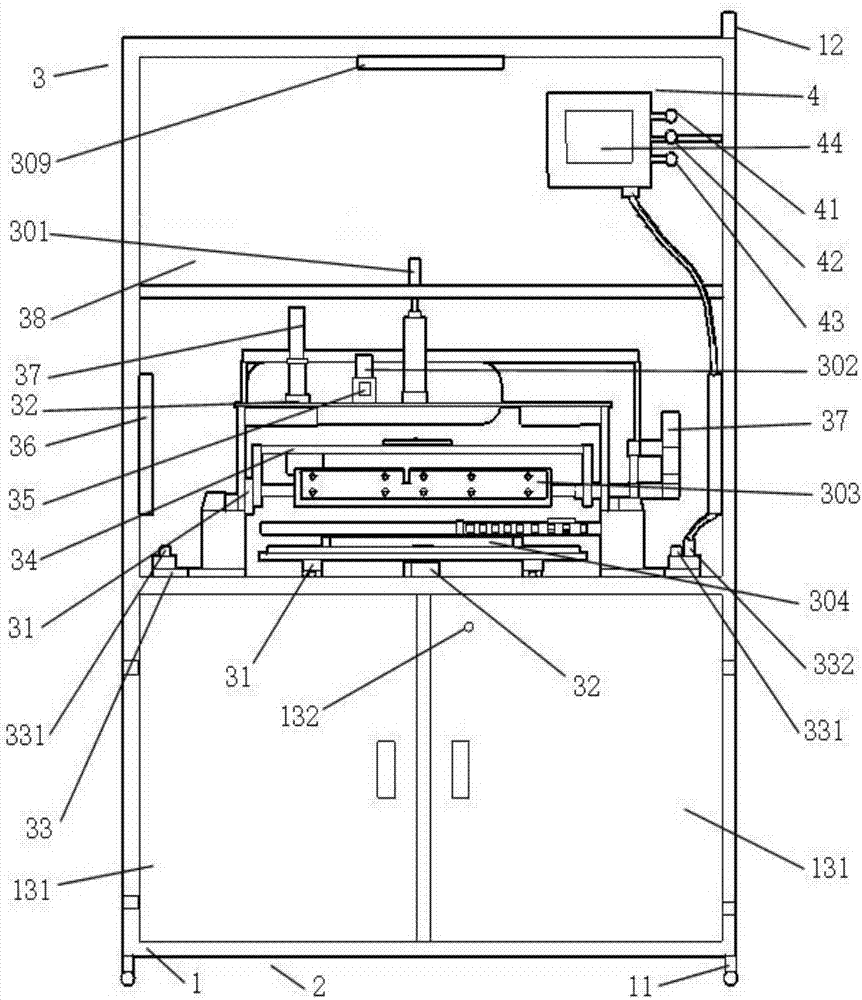

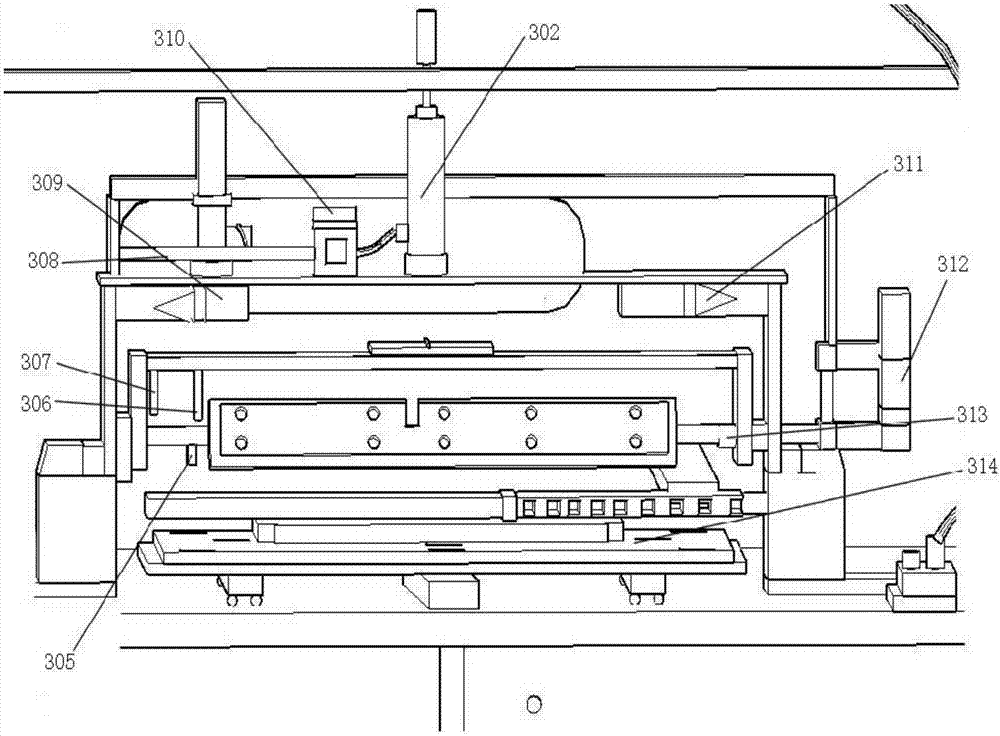

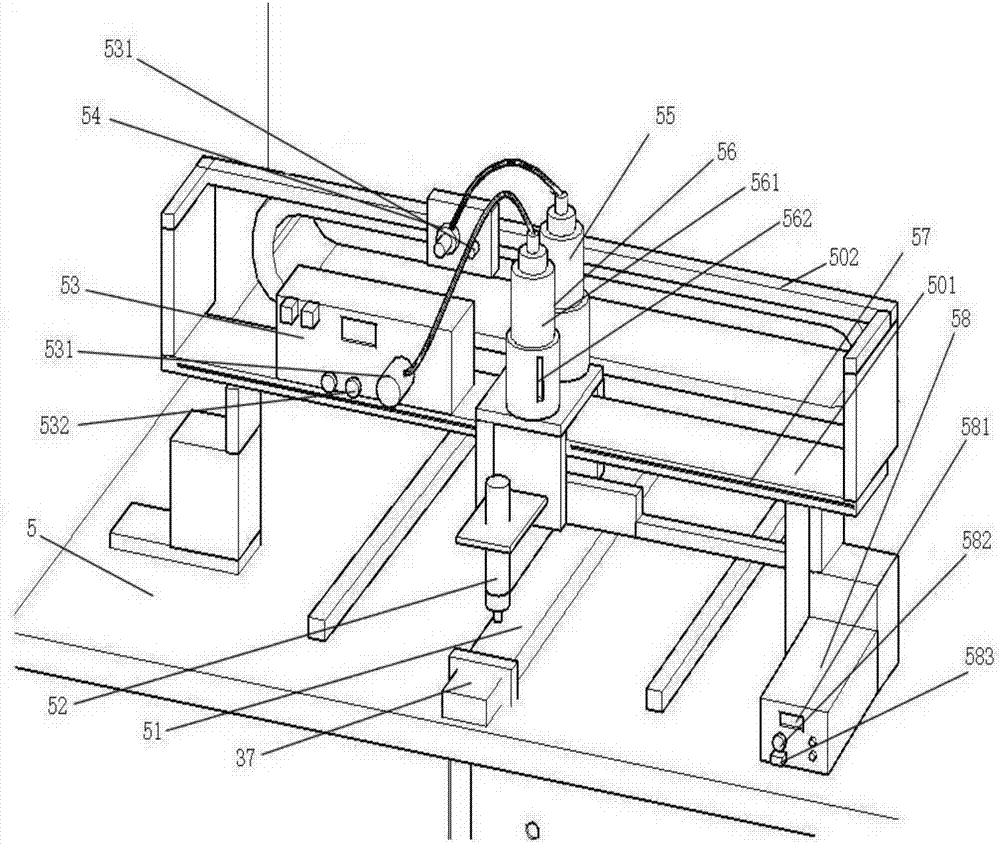

[0126] Please see attached figure 1 , attached figure 2 , attached image 3 , figure 1 It is a three-dimensional structural schematic diagram of an automatic glue brushing and pasting equipment of the present invention. An automatic glue brushing and pasting equipment, the automatic glue brushing and pasting equipment includes a device main frame 1, a lower frame 2, an upper frame 3, a liquid crystal display operation screen 4, and a workbench 5; the device main frame 1 includes Mobile casters 11, warning lights 12; the lower frame 2 includes an electric control box 21; the electric control box 21 is provided with an electric control box door 22 and a door lock 23; the upper frame 3 includes a guide rail slider 31. Transplanting module 32, button box 33, pressing module 34, digital pressure gauge 35, safety grating 36, servo motor 37, protective cover 38, LED lighting 39, pressing stroke adjustment 301, pressing Cylinder 302, rubber strip jig 303, product jig 304; describ...

Embodiment 2

[0132] Please see attached Figure 4 , Figure 4 It is a three-dimensional structural schematic diagram of another automatic glue brushing and pasting equipment of the present invention. This embodiment is basically the same as Embodiment 1, except that the protective cover 38 in this embodiment includes an outer protective cover 381 and an inner protective cover 382; the protective cover 38 is an inner and outer double-layer structure; The inner protective cover 382 is fixed on the upper frame 3; the outer protective cover 381 is arranged on the upper layer of the inner protective cover 382, and can be fixed and moved up and down. On the one hand, the inner protective cover 382 can be used to protect the LED lighting. On the other hand, when the equipment is glued and pasted, glue splashes will inevitably occur, and the outer protective cover 381 can be pulled down to prevent glue from splashing out of the equipment to the greatest extent, which is conducive to environment...

Embodiment 3

[0142] Please refer to Figure 12 , Figure 12 It is a flow chart of a method for automatic gluing and pasting of the present invention. Described method comprises the following steps:

[0143] Step 1. Manually put the product on the designated position;

[0144] Step 2. Press the start button with both hands, and the device starts the automatic operation program;

[0145] Step 3. Manually paste the strands into the jig and leave the equipment with both hands;

[0146] Step 4. The equipment automatically runs the program and sends the product to the cleaning station;

[0147] Step 5, the product reaches the cleaning station, and the equipment starts the cleaning function to remove the product dirt;

[0148] Step 6. After the cleaning is completed, the equipment automatically brushes the glue function to perform glue brushing;

[0149] Step 7. After the glue brushing is completed, the equipment will automatically send the product to the baking station;

[0150] Step 8, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com